potential environmental impact during the construction

advertisement

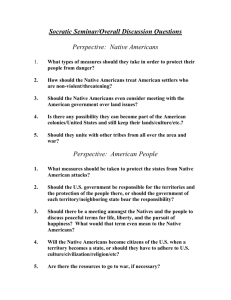

ORDER: Contract No. 2008-G/8-36 CLIENT: Latvenergo AS Pulkveža Brieža iela 12, Riga, LV-1230 CONTRACTOR: Firma L4 SIA Jelgavas iela 90, Riga, LV–1004 ENVIRONMENTAL IMPACT ASSESSMENT FOR THE 2ND STAGE OF THE RECONSTRUCTION OF RIGA TEC-2 – INSTALLATION OF A NEW (SECOND) POWER GENERATING UNIT Work Report Summary Riga, 2008 2nd Stage Reconstruction of the Riga TES TEC–2 Plant: Installation of a New Power Generating Unit – Environmental Impact Assessment. Work Report Summary. INTRODUCTION Riga TEC-2, whose reconstruction is ongoing and whose existing generating capacity is being replaced, is located at p/n Acone, LV–2119 in the Salaspils Region of Riga District. The core facilities at Riga TEC-2 entered service during the period from 1973 to 1979. Throughout its operating history, it has been and continues to be the City of Riga’s principal source of heating, as well as its most important source of base-load electrical power. The location of the combined heat and power plant (CHPP) is very convenient for the City of Riga, because the heating and electricity generating units are close to the city’s main consumer base. The territory of the CHPP is served by a broad communications-engineering infrastructure. And therefore, it is desirable that additional generating units should be deployed within this very same territorial area. In accordance with the provisions regulating the City of Riga’s heating supply, the total heating capacity installed at Riga TEC-2 after the first stage of its reconstruction is due to reach 1148 MW th, including around 270 MW th for the new steam – gas cycle installation’s power generating unit. In turn, the total electrical power installed is due to reach 800 MW el, including around 400 MW el for the new 2nd stage power generating unit. If the second stage of the reconstruction project is realised, a second generating unit will be built next to the first generating unit with analogous parameters whilst the operation of the existing power-generating boilers and turbines will cease. The main task of the TEC-2 plant is the production of electricity and production of heating energy in the requisite amount during the heating period. The goals of the reconstruction of TEC-2 are as follows: a reduction in Latvia’s dependency on imported electricity and the increased safety of its electricity supply; increased competitiveness – by raising electrical efficiency in condensation mode from 33% (existing installations) to 56 – 57%; an increase in the total efficiency of TEC-2 from the current figure of 82% to 87%; an increase in the production of specific electricity per heating energy unit from 0.53 to 1.3; fulfilment of the requirements of EU Directive 2001/80/EC “on the limitation of emissions of certain pollutants into the air from large combustion plants’’. These requirements prescribe that maximum emissions of NOX for existing combustion plants shall not exceed 200 mg/nm3 when burning gas and 400 mg/nm3 when burning liquid fuel. Depending on their set capacity, the prescribed limits for new installations are: 100-150 mg/nm3 for gas and 200-400 mg/nm3 for liquid fuel respectively. The aforementioned requirements also prescribe the replacement of some existing installations that do not meet the requirements of LCP Directive 2001/80/EC with new installations that comply with international standards; a reduction in repair costs which rise as existing installations get older. Page 2 of 22 2nd Stage Reconstruction of the Riga TES TEC–2 Plant: Installation of a New Power Generating Unit – Environmental Impact Assessment. Work Report Summary. The reconstruction and operation of TEC-2 are conducted in accordance with the legislation of the Republic of Latvia. The heating energy industry’s best available techniques will be deployed in the reconstruction of the CHPP. CURRENT SITUATION OVERVIEW The location and ensuring the functionality of the new power generating unit Riga TEC-2 plant is located at Acone in Riga District, in the north-western section of Salaspils Region’s administrative territory on the boundary of Stopiņi Parish (see Figure 1). The boundary of the City of Riga is 2km to the west. The distance to the centre of Riga is approximately 8 km, whilst the city of Salaspils is 7.5 km away. The territory of TEC-2 plant occupies an area of 67.1 ha. The establishment of the 2nd power generating unit is planned in the western section of the existing TEC-2 territory between the 1st power generating unit and the cooling towers, one of which is due to be demolished. At present, the density of installations and structures provided for ensuring the various functions of TEC-2 is at its lowest in that territorial area where the construction of the power generating unit is planned. This territory is crossed by an underground drainage collector. Currently, the territory in question is occupied by construction equipment, building materials and temporary buildings utilised for the construction of the 1st power generating unit. The structures located here include a chlorine treatment facility, fire fighting depot and cooling towers. Construction of the second power generating unit is due to be carried out on the parcel of land with Cadastral Number: 8031 001 0258 (this parcel of land covers an area of 41.24 ha) which has been transferred into the administration of the Ministry of Economics in accordance with Cabinet Decree No.295 of 6 April 2006 and will slightly infringe upon another parcel of land with Cadastral Number: 8031 001 0068 (this parcel of land covers an area of 4.72 ha) which belongs to Latvenergo AS in accordance with a purchase contract dated 3 September 2001. The TEC-2 plant is located between the Riga – Ērgļi railway line to the north (Acone railway station is located about 0.3 km to the east of CHPP) and Granīta iela to the south. A small allotment cooperative, Enerģētiķis-2, is located alongside the western boundary of TEC-2 and some of its houses are comparable to private houses, because they are occupied throughout the year. One five-storey and four nine-storey buildings are located opposite the access road to TEC-2 which were originally built to provide accommodation for the TEC-2 workforce. Several low-rise residential buildings are located to the north, a small distance away from the territory of TEC-2 (the nearest is located about 75 m away), which are separated from the territory of the CHPP by the railway line. A manufacturing area is located to the east of TEC-2. Likewise, major industrial and technical building areas are located in the direction of the City of Riga to the south-west and west of the TEC-2 plant. Two cemeteries are located within a 3 km radius of TEC-2. The nearest is located about 1.5 km to the west of the plant’s territory. In turn, public buildings in the form of two schools are located just over 2 km away from the plant. The company’s territory borders natural habitats of various types including fields, shrubbery and forests. Most of the company’s territory and the surrounding area are enclosed by woodland which has been significantly transformed and fragmented due to commercial activity and Page 3 of 22 2nd Stage Reconstruction of the Riga TES TEC–2 Plant: Installation of a New Power Generating Unit – Environmental Impact Assessment. Work Report Summary. infrastructural development. The largest single parcels of woodland are located to the south of the TEC-2 plant in the direction of the Getliņi Household Waste Dump which is about 3 km away from TEC-2. The relatively small distance to Riga is attributable to the intensive development and changing forms of land use affecting the area around the territory of TEC-2. The development of the area is largely typified by the emergence of new low-rise residential housing estates. However, industrial and technical building areas are also planned and in some cases are already under development in a number of small territories within individual locations. Page 4 of 22 2nd Stage Reconstruction of the Riga TES TEC–2 Plant: Installation of a New Power Generating Unit – Environmental Impact Assessment. Work Report Summary. Page 5 of 22 2nd Stage Reconstruction of the Riga TES TEC–2 Plant: Installation of a New Power Generating Unit – Environmental Impact Assessment. Work Report Summary. Figure 1: the territorial location of TEC-2 and specially protected nature territories in its vicinity. Environmental conditions The territory of TEC-2 is located in the costal lowland climatic zone. The closest water courses are the Dauguļupīte, Piķurga, Dreiliņupīte and Daugava. The territory of TEC–2 is crossed by two drainage ditches which are also infiltrated by TEC–2’s surface and drainage waters that do not end up in the artificially established TEC-2 rainwater drainage system. The territorial drainage ditches at TEC-2 have been partly rebuilt into collectors with a diameter of 1.5 m to ensure that pollution does not end up in surface waters in the event of a fuel oil leak emanating from the fuel oil management territory. Excessive moisture has not been ascertained within the territory of TEC-2 and therefore there is no need to further modify the existing territory. The territorial ditches, collectors and through flows at TEC-2 must be monitored and if necessary cleaned on a regular basis to avert potential problems. Likewise, care must be taken to ensure that beavers do not start living in the existing drainage ditches which is a possibility given that the territory adjoining the TEC-2 plant is forested and not densely inhabited by humans. The territory overall is characterised by a relatively level relief. The absolute height of the surface of the area of land allocated for construction ranges from 8.4 m to 9.0 m above sea level (a.s.l.) and the deviations in height are less than 0.6 m. The upper part of the geological cross-section in the eastern part of the territory is formed by a layer of Quaternary sediment that covers sediment from the Upper Devonian Salaspils D3slp suite to a depth of 5 – 7 m which is mainly characterised by an intermingling of layers of clay and gypsum. In turn, a layer of Quaternary sediment that is approximately 17 m thick lies on top of dolomites and marlstone from the Upper Devonian Pļaviņu D3pl suite in the central and western parts of the territory. The upper part of the Quaternary sediment in the territory on which TEC-2’s second generating unit is due to be built is comprised of a layer of technogenous sediment whose composition varies. Research drilling has revealed that its density is 0.3 m. Sand with a varying granulometric composition characterised by a mixture of fine gravel and pebbles that was first formed in Baltic ice lake conditions is embedded under the technogenous sediment to a depth of approximately 13 m. Geological engineering conditions in the territory allocated for construction can be characterised as being complex, because the thickness of layers varies when divided in terms of gravel density. However, drilling and probes carried out in the territory provided for construction have uncovered gravel amenable to construction, that is, sand that is dense and moderately dense with a varying granulometric composition. No specific gravel was observed with the exception of the aforementioned amenable gravel and no processes were revealed that could be deemed to be unfavourable for construction. Dolomite chips have been applied at the second research point, whilst in the remaining territory allocated for construction gravel has been redug to a depth of 0.4 m. Intensive geodynamic processes have not been observed in the territory provided for construction. Page 6 of 22 2nd Stage Reconstruction of the Riga TES TEC–2 Plant: Installation of a New Power Generating Unit – Environmental Impact Assessment. Work Report Summary. An analysis of heavy metals in gravel quality indicators prompts one to conclude that the concentration of heavy metals in the gravel samples does not exceed the safe limit value (B), that is, the level of pollution, which could have a potentially harmful impact on human health or the environment when exceeded. One exception is a heightened concentration of copper (Cu) in one gravel sample that is, most plausibly, linked to the denudation of copper ions from technogenous gravel. In recent years, no heightened concentration of oil products in groundwater has been observed in the study territory with the exception of slightly increased quantities of oil products which were discovered in two drilling samples in 2006. As a result of laboratory analyses, it was ascertained that, overall, pollution of groundwater in the territory of the planned power generating unit does not exceed the safe limit value (B). In accordance with the requirements of regulatory enactments, a study of the polluted area and gravel quality monitoring do not need to be carried out provided that concentrations of polluting substances do not exceed safe limit values (B). Emissions from sources of industrial pollution in the immediate vicinity of the TEC-2 power plant were assessed in order to diagnose current air quality. Research indicates that the biggest polluters in the area are: the Knauf SIA drywall panel, metal profile and finishing plaster production plant and the boiler houses managed by SAKRET SIA and Stopiņi Parish’s Municipal Agency, Saimnieks. Emissions from the other companies in the surrounding area are smaller. The TEC-2 plant generates emissions of harmful substances from its chimney, reservoirs and railway fuel oil run-off trestle. No specially protected nature territories (including those that are part of the Pan-European Natura 2000 network of nature protection areas) are located in the immediate vicinity of the territory which has been allocated for the construction of the TEC-2 power generating unit. The closest specially protected nature territory is the Doles sala Nature Park (included in the Natura 2000 list of nature protection areas) which is located 8km to the south / south-west of TEC-2. Given the location of specially protected nature territories in relation to TEC-2, their location behind significant natural barriers (the River Daugava and Lake Ķīšezers) and the direction of the prevailing winds, one may conclude that the reconstruction of TEC-2 (that is, the establishment of the 2nd power generating unit) will not have a major impact on the quality of the environment. At present, several industrial and management building complexes are situated within the 67.1 ha territory occupied by the TEC-2 plant which overall creates an industrial landscape with individual elements characteristic of a manufacturing type landscape. The most discernible features of the landscape are the cooling towers, a 180 m tall chimney, the existing power generating unit and fuel oil reservoirs. The structure of the landscape in the more distant northern and eastern areas that surround the TEC-2 territory is mainly comprised of woodland and various areas occupied by an assortment of buildings. Accordingly, both the immediate and more remote landscape environment in the vicinity of the intended work site has been degraded. There are no valuable territorial landscapes in the immediate vicinity of the proposed work site and therefore these areas do not have any quality recreation and tourism potential. The closest valuable individual nature and landscape elements and areas suitable for recreation are located 2 – 3 km away from the TEC-2 territory. Page 7 of 22 2nd Stage Reconstruction of the Riga TES TEC–2 Plant: Installation of a New Power Generating Unit – Environmental Impact Assessment. Work Report Summary. There are no State-protected cultural monuments within the territory of the TEC-2 plant and its immediate vicinity or within a 3 km zone around the power station. Communications-engineering, overview infrastructure and commercial activity site The territory of TEC-2 around the main complex is comparatively densely occupied by underground communications (Figure 2). The needs of the CHPP are satisfied by the communications-engineering network which includes the following elements: water supply and drainage systems, including three artesian wells; electricity transmission lines; a heating grid; a gas pipeline. The most important highway in the immediate vicinity of TEC-2 providing vehicles with access to the site during working hours is the Grade 2 V35 Highway on the Šķirotava – Saurieši route which continues as Granīta iela within the boundaries of the City of Riga. The structure of approach roads to TEC-2 is made up of four road branches from Granīta iela, as well as several locally significant streets and roads. A railway line that is part of the Riga – Ērgļi route adjoins the territory of TEC-2 to the north for a distance of 1.6 km with a branch line to the TEC-2 territory. More than 100 companies representing various sectors are located in the vicinity of the TEC-2 plant (within a radius of approximately 3 km) including educational, medical and cultural institutions, as well as several domestic service providers (post offices, bank branches etc.) that are mostly situated in the municipal centres of Stopiņi Parish, Ulbroka and Dreiliņi. PROPOSED OPERATION OVERVIEW A description of the new power generating unit and the grounds for its selection Electricity produced at the TEC-2 plant is supplied via the Latvenergo AS electricity grid along high voltage electricity transmission lines. The designated electrical power for the new power generating unit is 400 MW el, but the CHPP’s total electrical power after the 2nd stage of reconstruction will be approximately 800 MW el. The necessity for the second stage of construction is primarily determined by the shortage of electric power which will be created by several significant factors within the electricity market such as: the closure of Ignalina AES at the end of 2009 and the delay in the preparatory work for the construction of the new AES; the undertaking of Estonia’s power stations to reduce SO2 emissions by 2016 and a delay in the implementation of this obligation; the physical and moral depreciation of Russia’s power stations and a delay in the establishment of new capacities; Page 8 of 22 2nd Stage Reconstruction of the Riga TES TEC–2 Plant: Installation of a New Power Generating Unit – Environmental Impact Assessment. Work Report Summary. a significant increase in annual electricity demand in all Baltic and Russian markets; insufficient development of connections compared to electricity markets in other EU states. The essential purpose of the reconstruction of the TEC-2 plant is modernisation of its technology to the point where it is transformed into a modern technological base which in turn will facilitate an increase in technical-economic performance indicators, an increase in the power plant’s electrical capacity and a reduction in its harmful impact on the environment. The latest techniques deployed within the global power sector which have been tried and tested at functioning sites currently in service were analysed in order to select the optimal technical solution for the power station. From all the modern technological solutions considered, a new power installation was chosen which conforms to the best available techniques (BAT) and the tasks specified for the projected site to ensure the requisite electrical and heating capacities (400 MW el and 270 MW th respectively). In the global power sector, steam-gas cycle technology is widely utilised. This is a cogeneration technique: a combined cycle gas turbine with heating regeneration. Installation of gas turbines significantly increases the station’s electrical capacity, but the combination of two cycles (steam and gas) makes it possible to increase the efficiency of fuel utilisation. Given the relationship between electrical and heating capacities, the steam and gas turbine installation with a binary cycle scheme is the most effective of all. In addition to the techniques proposed for the project, other types of plants could also be utilised and therefore the following alternatives are being analysed in regard to the construction of the new power plant: a coal-fired power plant; an oil shale power plant; a nuclear power plant; steam cycle gas power plant (the current technology utilised at TEC-2); gas cycle power plant; hydropower plant(s); a wind power plant(s); a regenerative resource power plant(s). Analysis of alternative techniques is being carried out utilising 25 criteria (industry and environmental indicators). To solve problems related to the forecast deficit of electricity production in Latvia by building a power plant in Latvia, there are two practically feasible alternatives that are economically viable and environmentally friendly: 1st alternative: a combined cycle steam-gas power plant; 2nd alternative: a coal-fired power plant. Page 9 of 22 2nd Stage Reconstruction of the Riga TES TEC–2 Plant: Installation of a New Power Generating Unit – Environmental Impact Assessment. Work Report Summary. Comparing both alternatives, it was ascertained that the technique selected in accordance with technical-economic indicators and environmental aspects: the combined cycle steam–gas power plant is more environmentally friendly and economically viable than a coal power plant. Moreover, the technological solution selected for the reconstruction of TEC-2, the combined steam–gas cycle installation complies with the best available techniques for large combustion plants. Resources necessary to ensure the operation of the power station The fuel utilised for the new steam–gas cycle installation’s power generating unit (2nd power generating unit) will be natural gas. And it is planned to utilise diesel fuel with a sulphur content below 0.3% as an emergency fuel. Natural gas will also be utilised for the first new power generating unit and water heating boilers which ensure that maximum heating capacities are attained. However, fuel oil is due to be utilised as the emergency fuel for water heating boilers. The stock of fuel oil provided as an emergency fuel (for 10 days) will amount to 10,830 tonnes (at -20 0C) and will be fully provided by one of the four reservoirs with a capacity of 20,000 m3 that will remain in service. The emergency reserve stocks of diesel fuel for 10 days will amount to about 18,700 m3 which will be provided by making one of the existing fuel oil reservoirs operational for work with diesel fuel. Utilisation of water resources Water from the Riga HES reservoir and subterranean water from three local artesian wells that are located outside the territory of TEC-2 will be utilised to provide water to the TEC-2 plant. Reservoir water is utilised for TEC-2 production purposes, while artesian water is utilised for drinking water purposes. The total maximum surface water consumption from the Riga HES reservoir after the 1st stage of the reconstruction of the TEC-2 plant was forecast at 11,160,000 m3 annually. After the 2nd stage of the TEC-2 reconstruction, it is likely that there will be a slight reduction in the consumption of surface water from the Riga HES reservoir. With the installation operating at full capacity, TEC-2’s planned water consumption after the 2nd stage of reconstruction will be approximately 10,500,000 m3. The new power generating unit’s water consumption for domestic drinking water supply purposes will be approximately 16,800 m3 annually. Total domestic drinking water consumption following the reconstruction of the CHPP will amount to approximately 120,000 m3. Wastewater overview The following categories of wastewaters are generated by the operating processes at the TEC-2 plant: domestic wastewater; Page 10 of 22 2nd Stage Reconstruction of the Riga TES TEC–2 Plant: Installation of a New Power Generating Unit – Environmental Impact Assessment. Work Report Summary. rain wastewater; wastewater (rain and production) polluted with oil products; chemical water treated (CWT) wastewater; cooling system wastewater; continual pressurised boiler operation. The wastewaters generated by the TEC-2 plant have two outflow points: Outflow No.1 – wastewater from production processes, cooling and rain wastewater is channelled into the City of Riga’s rainwater drainage system; Outflow No.2 – domestic wastewater is channelled into the drainage collector of Rigas ūdens SIA. In order to control the quality of groundwater, nine monitoring boreholes for the performance of groundwater monitoring have been installed within the territory of the CHPP and in its immediate vicinity. As a result of the operation of the TEC-2 plant, after the 2nd stage of its reconstruction the plant’s water supply sources, its main water chemical treatment processes (for supplying heating networks) and treatment procedures for wastewater containing oil products etc. will be maintained. The existing wastewater channelling system is also due to be retained. The quantity of rainwater polluted with oil products will already be reduced after the 1st stage of reconstruction, because the existing fuel oil depot is located in the 1st power generating unit’s construction zone and a section of it has been dismantled. Thus, a potential source of pollution has been reduced. The quantity of wastewater from technological processes will also be reduced after the reconstruction of the CHPP, because there will be a notable decline in the production of condensation polluted with fuel oil due to the discontinuation of the utilisation of fuel oil as the main fuel and the transition to the combustion of natural gas. Types of waste and their management At present, the following types of waste are generated during the TEC-2 production process and the construction of the 1st power generating unit (classified in accordance with Annex 2 to Cabinet Regulation No.985 of 30 November 2004): 1. waste containing heavy metals (from the washing of regenerative air heaters); 2. sediment containing boiler cleaning water; 3. waste from the preparation of water to be utilised industrially; 4. installation operational and technical maintenance dregs and waste that contain oil products (including used active charcoal); 5. batteries and accumulators; 6. waste from technological process of utilising paints and varnishes; 7. waste containing mercury; Page 11 of 22 2nd Stage Reconstruction of the Riga TES TEC–2 Plant: Installation of a New Power Generating Unit – Environmental Impact Assessment. Work Report Summary. 8. luminescent lamps; 9. paper waste collected separately; 10. plastic waste collected separately; 11. electric and electronic installation waste; 12. unsorted domestic waste; 13. construction and building demolition waste – mixed; 14. construction and building demolition waste – metals (cast iron and steel); 15. construction and building demolition waste – metals (aluminium). Waste comparable to domestic waste in the form of scrap metal and construction debris will arise as a result of the construction of the second power generating unit at TEC-2. In turn, just like at present, both domestic and hazardous waste will be generated by the TEC-2 production process after reconstruction. Management of domestic and hazardous waste that is generated during reconstruction will be carried out with the assistance of a contractual organisation partner in conformity with the provisions of the relevant contract and the environmental requirements prescribed in regulatory enactments. The capacities of existing waste reservoirs are sufficient for the storage of waste generated at the new power generating unit until it is transferred into the care of a licensed company which will manage its subsequent use. Preparation of the territory for the construction of the new power generating unit and the sequence of construction work Currently, a tip containing the materials of the general contractor of the 1st power generating unit is located on the 2nd power generating unit’s construction site. In the place where the 2nd power generating unit will be situated, gravel has been replaced during the 1st stage of reconstruction. In addition, sites should be prepared for a few 2nd stage reconstruction buildings and a waste materials tip. The main jobs that are to be carried out during the territorial preparation work are demolition of one of the cooling towers, the chlorine treatment facility and fire fighting depot, removal of peat and moulding of sand around the areas where the demolished buildings formerly stood, gravel compression, establishment of a construction site fence and the establishment of the necessary communications for the requirements of the construction site. No significant impact on the environment is expected during construction work and any impact that does occur will be short-term. During the course of construction, there may be an increase in the level of noise in the vicinity of the construction site, as well as in dust resulting from gravel digging work and vehicle transport. Construction of the power generating unit’s buildings and structures, installation assembly and entry into service is due to be carried out in a certain order and in accordance with the requirements of the standards currently in force. Page 12 of 22 2nd Stage Reconstruction of the Riga TES TEC–2 Plant: Installation of a New Power Generating Unit – Environmental Impact Assessment. Work Report Summary. Construction of the power generating unit’s buildings and structures, installation assembly and entry into service is due to be carried out in the following order: Reconstruction of the existing communications-engineering and infrastructure or construction of new structures After the 2nd stage of reconstruction, the four existing steam boilers and three turbine sets (one boiler and one turbine set right after the 1st stage of reconstruction) which have currently expended more than 50% of their resources will be taken out of service. Four water heating boilers will remain in service along with the emergency reserve fuel depot, the chemical plant, other auxiliary installations and the existing communications-engineering and networks that ensure the stable and safe operation of the installations and water heating boilers due to be utilised. The new steam–gas cycle installation 2nd stage power generating unit (hereinafter referred to in the text as: SGI) will be situated to the west of the main complex in what is practically a vacant territory between the existing water cooling towers and the 1st stage power generating unit that is under construction. Heating supply from the SGI power generating unit will be carried out within the heating grids of Rigas Siltums AS by building pipelines and connecting them to the existing CHPP network before the 2nd level network water pumping station. The following new water supply and drainage structures are due to be provided in order to ensure the necessary engineering support for the SGI buildings and structures: water supply, drainage and fire extinguishing external and internal networks and an installation for the treatment of wastewater polluted with oil products. The diesel fuel pipeline will pass from the diesel fuel reservoir in the existing fuel oil depot area along the existing fuel oil and steam pipeline trestle in the northern part of the territory and further south to the 2nd stage power generating unit where the diesel fuel pressure will be raised to the pressure level required by the gas turbine. Equivalent systems and installations are provided for within the new power generating unit for the safe and accident-free service of the power station in conformity with the regulatory documents that are currently in force. Fire fighting measures for SGI buildings and structures are being implemented in accordance with regulatory documents. The following systems are due to be installed at the new power generating unit: a fire detection and alarm system; an emergency warning system. Both of the aforementioned systems will be fitted with an automatic operational control function. Its solutions will conform to the standards in force in the Republic of Latvia. Furthermore, in places where gas leaks are possible, gas detectors will be installed that will generate alarm signals and will activate the appropriate technological protection devices. A new fire fighting pumping station with reservoirs (water collected from the technical water supply system) is provided for internal, external and automatic fire extinguishing. Page 13 of 22 2nd Stage Reconstruction of the Riga TES TEC–2 Plant: Installation of a New Power Generating Unit – Environmental Impact Assessment. Work Report Summary. A separate automatic fire extinguishing system is utilised to extinguish the gas turbine with the assistance of carbon dioxide. A flame and heat detector is due to be installed next to the turbine to detect any fires. The turbine’s gas fire extinguishing system is supplied together with the turbine. Potential restrictive factors Several objects are located within the study area for which protective boundaries have been prescribed in accordance with the Protective Zone Law that are also considered to be the most significant restrictive factors for the proposed activity. The area where the power generating unit is due to be built is adjoined by the railway protective zone which has been determined 200 m from the railway. Any construction work or gravel creation and transportation within the railway’s protective zone are prohibited without clearance from the administrator of the railway infrastructure which in this case is Latvijas Dzelzceļš VAS. A local railway line to the TEC-2 territory branches off from the main railway line which ensures the supply of emergency fuel in the form of fuel oil to meet the requirements of TEC-2. Protective zones are not prescribed for local railway branches. The territory of Riga TEC–2 is crossed by two drainage ditches whose total confluence basin at the point where they come together or flow out of the territory of Riga TEC–2 is 8.25 km2. The confluence basin of these ditches up to or flowing into the territory of Riga TEC–2 is 6.60 km2. Prior to the construction of the 1st power generating unit, the ditch in the TEC-2 territory was embedded within the underground drainage system. Protective zones around drainage structures and installations are only prescribed for woodland and land utilised in agriculture. Four fuel oil tanks each of which has a capacity of 20,000 m3 of fuel oil are situated in the southwestern part of the TEC-2 territory along with fuel oil pumping stations, a fuel oil run-off trestle and fuel oil pipelines. A protective safety zone has been prescribed around the reservoir parks, filling and outpouring trestles which is 100 m away from the territorial fence surrounding these objects or restrictive structures. Protective zones have been prescribed around the fuel oil pipelines with a width of 25 m running in both directions from the pipeline. Gravel that is favourable for construction, that is, sand that is dense and moderately dense with a varying granulometric composition has been discovered in the territory provided for construction which is not a limiting factor. The transformation of hot, run-off, watercourse shores or other unfavourable processes have not been observed in the territory allocated for construction. The territory of the TEC-2 plant borders the territory of multi-storey residential houses. The nearest individual residential house is located about 75 m away to the north of the CHPP. No such restrictions, obstacles or restrictive factors exist in the territory allocated for construction that could seriously encumber the construction of the power generating unit in the chosen territory. Page 14 of 22 2nd Stage Reconstruction of the Riga TES TEC–2 Plant: Installation of a New Power Generating Unit – Environmental Impact Assessment. Work Report Summary. POTENTIAL ENVIRONMENTAL IMPACT DURING THE CONSTRUCTION AND OPERATION OF THE POWER GENERATING UNIT Management of waste generated during the construction process Waste such as construction debris and scrap metal will be generated during the construction of the 2nd power generating unit at TEC-2. Waste generated during the construction process will be managed by the relevant construction company. After the completion of construction work the territory of the TEC-2 plant will be completely cleaned up and all waste generated during the construction process will be deposited in the places provided for it or delivered into the care of appropriate waste management organisations. Air quality changes Analysing the result of calculations performed regarding the spread of nitric oxide from the (new) power generating unit due to be built during the 2nd stage of reconstruction, one must conclude that there are no instances in which the forecast concentrations of polluting substances exceed the air quality limit value for the protection of human health or ecosystems. Comparing the situation after the 2nd stage of the reconstruction of the CHPP with the existing situation, there have been no instances in which the prescribed limit values have been exceeded. However, compared with the existing situation, overall there will be an increase in concentrations of polluting substances. After the 2nd stage of the reconstruction of TEC-2, fuel oil and perhaps diesel fuel too are only due to be utilised as emergency fuels (reservoirs are scheduled to be refilled once every few years). Regular reloading of oil products will not take place at TEC-2 and emissions of malodrants will be insignificant. Assessing the results of calculations made regarding the spread of pollution during the construction process, one must conclude that the air pollution caused by digging work will be significant, but excess air-ground concentrations of polluting substances will only affect the company’s territory and residential housing areas will not be affected by this. Noise distribution assessment After the 2nd stage of reconstruction, the level of noise in individual surrounding areas will increase and overall there will be an increase in noise distribution. However, thanks to the location of the 2nd power generating unit’s buildings and structures which in this instance act as anti-noise barriers, the distribution of noise will be restricted. Additionally taking the increased intensity of vehicle traffic into consideration following the construction of the 2nd stage, the impact of noise caused by vehicle traffic will increase in the vicinity of those roads and residential areas that are located in the area surrounding the site, particularly during evening and night hours. Assessing the results of the calculations made regarding the level of noise caused by all sources, one may conclude that the noise level in the low-rise residential housing areas to the north of the thermal power station and in business areas to the west of Riga TEC-2 will increase by an average of approximately 3 dB(A) during all periods both during the day and at night. The Page 15 of 22 2nd Stage Reconstruction of the Riga TES TEC–2 Plant: Installation of a New Power Generating Unit – Environmental Impact Assessment. Work Report Summary. most significant impact from the 2nd stage of construction will be observed in the multi-storey residential housing area where the noise level in the central part of the area will increase by 3-8 dB(A) and in individual territorial areas, especially those located to the north-west, by as much as 15 dB(A). Irrespective of the noise pollution caused by highways in the vicinity of Riga TEC2, the most significant source of noise that will cause discomfort for this multi-storey residential housing area is the heat-electric generating station. However, it should be noted that the calculations were made on the assumption that all sources will operate concurrently during the long-term. The impact of air pollution caused by transport Analysing the results attained, one may conclude that currently a significant proportion of pollution is directly caused by the flow of vehicle transport. By just comparing the results of the spread of pollution caused by vehicle transport with the total pollution caused by TEC-2 and flows of vehicle transport, it is evident that the maximum concentrations ascertained from calculations of the spread of pollution do not significantly differ, because air pollution caused by vehicle transport is dominant. The results of calculations for the year 2010 regarding the spread of pollution caused by all TEC-2 and transport NOx emission sources indicate that the most significant amount of pollution that will cause the highest hourly concentrations within the air-ground layer will be emitted from vehicles. Calculating the total air pollution from the 2nd power generating unit and from installations already installed, it was ascertained that maximum concentrations of nitric oxide will be observed for approximately 500 m to the south-west of TEC-2 and these will reach 62-67% of air quality limit values currently in force (taking existing air pollution into consideration). Potential pollution of gravel and groundwater Groundwater within the territory of TEC-2 is not protected from surface pollution, because it is not covered by weak water permeable sediment and because the aeration zone is thin and does not ensure the self-purification of pollution. Gravel with good filtration properties is characteristic of the research territory. In the event of pollution, these properties could give rise to the distribution of pollution across a wide areal zone. Therefore, all the requirements prescribed in regulatory enactments that apply to the protection of groundwater must be observed to prevent its pollution during the course of reconstruction and operation of TEC-2. Particular attention must be paid to the fuel oil depot. Prior to the construction of the 1st power generating unit, four fuel oil reservoirs were dismantled which has resulted in a reduction in the quantity of emergency fuel. Since diesel fuel could be utilised as the emergency fuel following the 2nd stage of reconstruction, the possibility of utilising one of the reservoirs for storing diesel fuel and leaving fuel oil in the remaining three is being considered. These four reservoirs share a gravel rampart that is 1.5m high. In turn, each tank is separated by a 1.3 m high reinforced concrete rampart. In emergencies, this will prevent possible leaks of diesel fuel and fuel oil into the surrounding area. One positive factor that should be noted is that the underground water here can be counted as pressurised water, thus it is very difficult for it to be infiltrated by pollution. Page 16 of 22 2nd Stage Reconstruction of the Riga TES TEC–2 Plant: Installation of a New Power Generating Unit – Environmental Impact Assessment. Work Report Summary. The concentration of oil products in the groundwater is comparatively negligible with the maximum natural concentration in borehole No. 2a. As monitoring data confirm, every year the concentration of oil products in groundwater is falling due to the effects of ongoing oil product decomposition processes. There is little possibility of the pollution of gravel and groundwater during the course of reconstruction and operation of TEC-2 due to observance of the requirements of regulatory enactments and implementation of the relevant safety measures that apply to the protection of gravel and groundwater. Forecast on changes to the hydrological and hydrogeological regime No changes to the hydrological regime within the TEC-2 territory are expected either during or after the 2nd stage of the reconstruction of the CHPP. Theoretically, possible changes to the hydrological regime could only be forecast in the event of a change in the type of utilisation of the confluence basin land. Currently, the confluence basin territory is a waterlogged and forested area, but, if it were transformed, for example, into a residential area, faster changes in the throughflow of the surface run-off would be likely. Potential changes to the hydrological regime ought to be assessed in greater detail during the preparation of the technical reconstruction project, because, if any of the issues are not successfully resolved, problems could arise channelling surface waters from TEC-2 and its adjoining territories. Accordingly, the technical project ought to contain a section in which issues related to possible changes to the hydrological regime are considered and resolved. No changes in the hydrological regime, including changes in the hydro-dynamic regime of artesian subterranean waters, are expected to arise from the operation of the reconstructed TEC-2 plant. The prognosis regarding the potential impact on biological diversity NOx compounds will be released into the atmosphere as a result of the operations at TEC-2. Nitrous acid will be formed as a result of the atmospheric chemical reactions induced by emissions of NOx. This nitrous acid will partially return to the Earth’s surface in the form of acid rain. The possible enrichment of the soil with nitrogen due to the operations at TEC-2 has also been considered. When analysing the volume of nitrogen sediment from emissions generated by TEC-2 and assessing the impact of TEC-2 in regard to the formation of acid rain, one should note that the total volume of emissions amounts to about 2128 tonnes of nitric oxide annually. However, the spread of pollution is extensive. This means that a significant increase in the amount of acid rain is not expected and therefore after the 2nd stage of its reconstruction, emissions from TEC-2 will not significantly affect the balance of the formation of acid rain or the natural ecosystem in the eutrophication region. Taking the aforementioned factors into account, one may conclude that there will be no increase in the acidity of the soil on the mother rock of the dominant sand soil. Likewise, air pollution caused by TEC-2 will not have a significant impact on the habitat within surrounding forest ecosystems. The territory provided for the reconstruction of TEC-2 has long been fenced off. During reconstruction, the TEC-2 territory will not be expanded and no new roads will be built in the Page 17 of 22 2nd Stage Reconstruction of the Riga TES TEC–2 Plant: Installation of a New Power Generating Unit – Environmental Impact Assessment. Work Report Summary. immediate vicinity of the area. Therefore, no impact on the migration of wild animals or their habitat is predicted during the reconstruction of the site. The impact on the landscape and cultural history of the surrounding area Construction of the new power generating unit at the TEC–2 plant is likely to have minimum impact on the surrounding landscape. The planned activity will be implemented within the existing territory of the TEC-2 company on which the new power generating unit’s building and chimney are due to be built. Since a similar type of construction to that planned is already under way within that section of territory and its surrounding area where the relevant activity is planned, then no significant consequences will arise from either the visual or ecological aspects of the landscape. The area where the activity is planned also has no potential quality in regard to recreation or tourism. Even though, there are objects of cultural-historic and recreation significance 2 - 3 km away at Ulbroka and in its immediate vicinity, these are not threatened by the planned reconstruction work. Impact related to the rebuilding or building of infrastructure The construction and assembly of the new power generating unit will have a certain impact on the environment. This impact could manifest itself throughout the implementation of the project, starting from the preparation of the territory, during the ensuing construction-assembly work, assembly and testing of installations and also after the power generating unit has entered service. The principal potential factors that could have a negative impact on the environment are as follows: harmful emissions into the atmosphere (NOx, CO, HC) from transport and special technology engines; harmful emissions into the air through the performance of metal welding and cutting – welding aerosols (manganese and its oxides, chrome oxides, silicon compounds), as well as nitric oxide and carbon monoxide; emissions of dust into the air through the performance of land work and the transportation and storage and loose construction materials; petrol leaks onto the ground when filling up with vehicles with petrol; an increased level of noise and vibration that is caused by special construction materials and increased flow of vehicles to the construction for the supply of materials, constructions and installations, as well as for the removal of construction waste and unsuitable gravel from the construction site; solid waste, construction debris, as well as harmful waste (asbestos) that will be generated by the dismantling of the water cooling tower. Overall, one may conclude that bearing in mind the location of residential housing, its distance from the construction site and the relatively short period of construction, as well as observing all Page 18 of 22 2nd Stage Reconstruction of the Riga TES TEC–2 Plant: Installation of a New Power Generating Unit – Environmental Impact Assessment. Work Report Summary. measures for the prevention and reduction of environmental impact, no significant impact on the environment is expected during the rebuilding of the infrastructure and construction of the new (second) power generating unit. Materials necessary for construction and useful fossils The modernisation of TEC-2 provides for the establishment of new buildings and structures in vacant territories, as well as in the territories where demolition work on the old buildings will be carried out. Summarising the types of construction materials necessary for the planned structures, it is evident that the following will be necessary: various types of metal construction; reinforced concrete; various types of heating insulation materials; ceramsite blocks; polyester and steel roof coverings; sand; gravel; as well as various less significant and sizable construction materials required during the construction process. Taking the construction of the 1st power generating unit into account, the raw materials were mainly supplied by Latvian manufacturers. Just as was the case with the 1st power generating unit, in the case of the 2nd power generating unit, sand of varying granulometric composition, angular rocks and bituminous concrete will be required for the construction of roads and mouldings of varying significance. Useful fossil deposits are available within a 30 km radius around TEC-2 that are already being serviced, as well as some that have not been exploited as of yet. Public opinion During the course of the relevant surveys, respondents answered a number of questions about the reconstruction of TEC-2 and the installation of the second new power generating unit. Question as to what should be done with the existing TEC-2 plant, the vast majority (77%) of respondents replied that it should be modernised, while 17% of those who participated in the survey had no specific opinion on this matter. 4% of those surveyed believed that the CHPP ought to be closed, while 7% expressed the opinion that its production capacity ought to be reduced. Almost one third or 30% of respondents stated that they have not been informed about the nature of the reconstruction work and that accordingly it was difficult for them to express any specific opinion. The same number of respondents replied that they were more in favour of reconstruction than opposed to it. 3% of respondents were more opposed to the reconstruction than in favour of it, whilst 6% were not in favour of it. However, the majority of respondents or 31% expressed their support for the reconstruction of TEC-2. Page 19 of 22 2nd Stage Reconstruction of the Riga TES TEC–2 Plant: Installation of a New Power Generating Unit – Environmental Impact Assessment. Work Report Summary. Accordingly 61% of respondents were positively disposed to the project, while 9% were negatively disposed and 30% had no opinion on the subject. Social-economic aspect assessment In the report it was ascertained that the current combined capacity of Latvia’s power stations is insufficient to satisfy the demand for power at any given moment. The nation’s electricity supply basically depends on power plants in Latvia and neighbouring countries operating in base-load mode. There is a marked deficit of base-load capacity within Latvia’s power system. Bearing in mind the development of a 330 kV network in the Riga District, the second stage of the reconstruction of Riga TEC-2 should be implemented with the construction of a second generating unit that would operate in condensation mode and would also be utilised for the regulation of Latvia’s power system and to guarantee reserve capacity throughout the year. This would make it possible to maintain and expand base-load electrical capacity in Latvia. Due to the closure of the Ignalina AES at the end of 2009, problems with the electricity supply generated by Latvia’s power system will grow more acute. A conservative development scenario indicated that with one 400 MW generating unit, Riga TEC-2 has a marked capacity deficit and even the most optimistic scenario indicates that with two 400 MW generating units, Riga TEC-2 does not have sufficient electrical capacity to satisfy the nation’s electricity consumption with the generating capacities at its disposal. Overall, it may be concluded that the installation of a second power generating unit at Riga TEC-2 is a significant project which facilitates the development of Latvia’s power system. Adherence to the Salaspils Region’s territorial plan According to the zonal divisions specified in the Salaspils Region’s Territorial Plan, the TEC-2 territory is located in an industrial area. The proposed operation (installation of the second power generating unit) is due to be carried out within the territorial boundaries of TEC-2 within the existing production areas. Therefore, the planned reconstruction of TEC-2 does not contravene the goals and requirements prescribed in the District of Salaspils’ Territorial Plan. Risk analysis for the operation of the power generating unit There is a risk of an industrial accident at any industrial company, including at Riga TEC-2. Emergencies are accidents that are transport-related or of a differing industrial nature, as a result of which people are subject to an enforced risk with serious consequences. Possible causes of accidents at the new (second) power generating unit could be linked to the operation of the installation and the technical back up for its elements, the fuels utilised (the chemical substances utilised – natural gas and if necessary fuel oil or diesel fuel) and to extraordinary situations caused by natural disasters and factors related to human error and acts of terror. However, the likelihood of an emergency utilising gas technology cannot be considered high, because the site will just have been built and its installations will be brand new. The planned Page 20 of 22 2nd Stage Reconstruction of the Riga TES TEC–2 Plant: Installation of a New Power Generating Unit – Environmental Impact Assessment. Work Report Summary. safety control systems will also ensure effective damage or malfunction detection and will help to prevent major emergencies. MEASURES FOR THE REDUCTION AND CONTROL OF ENVIRONMENTAL IMPACT Technical-engineering and organisational measures for the reduction of environmental impact To reduce the environmental impact of the proposed activity, a range of technical-engineering and organisational measures are due to be carried out both during the construction process and the subsequent service life of the installation. During the construction of the installation, a range of measures have been prepared that will ensure that its harmful impact on the environment is kept to a minimum. This package of measures includes measures that will ensure: 1) Air protection; 2) Gravel and groundwater protection; 3) A reduction in the level of noise and vibrations; 4) Prevention of pollution from waste. To reduce the environmental impact of the operation of the proposed installation during its service life, a range of technical-engineering and organisational measures are due to be carried out that include: 1) Measures aimed at reducing and preventing the installation’s impact on surface water; 2) Measures aimed at reducing and preventing the installation’s impact on groundwater; 3) Measures for operations involving chemical substances and chemical products; 4) Measures aimed at reducing and preventing noise; 5) Measures aimed at reducing the installation’s impact on biological diversity and biotopes; 6) Measures aimed at the prevention of emergency situations. Monitoring The environmental impact of the new power generating unit will be continually checked through the performance of continual and regular observations that are part of an overall monitoring strategy. The monitoring strategy provides for several types of observation: 1) Air pollution monitoring (oxygen, nitric oxide, carbon monoxide, carbon dioxide, sulphur dioxide contents in flue gases). 2) Groundwater monitoring (underground water level and quality measurements in observation boreholes). Page 21 of 22 2nd Stage Reconstruction of the Riga TES TEC–2 Plant: Installation of a New Power Generating Unit – Environmental Impact Assessment. Work Report Summary. 3) Wastewater monitoring (pH, chemical oxygen consumption (COC), biological oxygen consumption (BSP5), total oil products, suspended substances, Nkop and Pkop in wastewater channelled into the City of Riga’s rainwater drainage system). All observations will be carried out in conformity with the requirements of the regulatory enactments that are currently in force. At the point where water from the rainwater and industrial wastewater drainage system flows into the overall system, it will be equipped with pH, temperature, electrical conductivity and flow sensors. In the event of amendments to water chemical treatment technologies, the parameters subject to control may be amended or augmented. Page 22 of 22