UNIVERSITY OF KENT

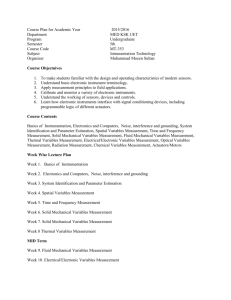

advertisement

UNIVERSITY OF KENT MODULE SPECIFICATION 1. The title of the module EL875: Advanced Instrumentation Systems 2. The Department which will be responsible for management of the module Electronics 3. The start date of the module September, 2009 4. The number of students expected to take the module 20 5. Modules to be withdrawn on the introduction of this proposed module and consultation with other relevant Departments and Faculties regarding the withdrawal N/A 6. The level of the module (eg Certificate [C], Intermediate [I], Honours [H] or Postgraduate [M]) M 7. The number of credits the module represents 15 8. Which term(s) the module is to be taught in (or other teaching pattern) Spring 9. Pre-requisite and co-requisite modules 10. The programme of study to which the module contributes MSc in Embedded Systems and Instrumentation 11. The intended subject specific learning outcomes and, as appropriate, their relationship to programme learning outcomes On successful completion of the module, students will: 1. Have an understanding of the principles of measurement and instrument design; 2. Have an understanding of modern sensors and optical sensing systems; 3. Have an understanding of imaging based instrumentation systems; 4. Have an understanding of intelligent measurement technology; 5. Have the necessary skills to design and implement embedded instrumentation systems; 6. Have the knowledge and skills to design and implement specialised measurement and monitoring systems. These contribute to knowledge and understanding of the principles of advanced sensors and instrumentation systems as specified in the subject specific learning outcomes of the MSc programme in Embedded Systems and Instrumentation (A1, A3, A4, A6, A7, A8, A9). The module will require students to demonstrate the use of mathematical models, scientific principles and computer methods for design and implementation of advanced measurement and instrumentation systems, contributing to the Intellectual Skills in the advanced learning outcomes for the MSc and PDip in Embedded Systems and Instrumentation (B1-B6). Students will need to use advanced techniques to solve hardware/software problems, contributing to programme learning outcomes in the category of Professional Practical Skills (C1, C2, C4, C6). 12. The intended generic learning outcomes and, as appropriate, their relationship to programme learning outcomes Students will need to demonstrate skills in generating, analysing, presenting and interpreting data, will learn to use ICT, and will develop core key skills, such as learning effectively, critical thinking and time management, contributing to the Transferable/Key Skills in the generic learning outcomes for the MSc and PDip programme (D1, D2, D5-D7). 13. A synopsis of the curriculum Lecture Syllabus SENSORS AND SENSING SYSTEMS (6) Measurement terminology: Input and output, range, accuracy, precision, resolution, sensitivity, linearity, repeatability, reproducibility, calibration and traceability; Sensors and transducers: Resistive sensors, capacitive sensors, ultrasonic sensors, electromagnetic sensors, electrostatic sensors, radiological sensors, primary and secondary sensors, integrated and smart sensors, MEMS, and ‘soft’ sensors; Optical sensing techniques: Light detectors, optical fibres and fibre optic components, solid state lasers; IMAGING BASED MEASUREMENT AND MONITORING TECHNIQUES (10) Digital imaging technologies: CCD and CMOS camera architectures, digitisation, characterisation of imaging devices (resolution, modulation transfer function, point spread function, noise, and spectral sensitivity); Image processing techniques: Image enhancement and filtering, histogram modification, edge detection and segmentation, feature extraction, pattern clustering and classification algorithms, Fourier domain representations and filtering, wavelet compression; Imaging systems: CCD/CMOS camera based measurement and detection systems, industrial process tomography (IPT), stereoscopic imaging systems, real-time imaging techniques; INTELLIGENT MEASUREMENT AND MONITORING TECHNIQUES (4) Soft computing techniques for measurement and monitoring. Advanced analysis: combined time and frequency domain methods, wavelet analysis, and Hilbert-Huang transforms. Virtual instruments and systems: hardware and software, fieldbus, internet based systems. INDUSTRIAL CASE STUDIES (4) On-line measurement of difficult flows. On-line fuel tracking. Flame detection and flame imaging. Characterisation of granular materials. Other specialised imaging systems for industrial applications. EXAMPLES CLASS - SENSORS AND SENSING SYSTEMS EXAMPLES CLASS - IMAGING-BASED MEASUREMENT AND MONITORING TECHNIQUES EXAMPLES CLASS – INTELLIGENT MEASUREMENT AND MONITORING SYSTEMS LABORATORY – ADVANCED MEASUREMENT SYSTEMS There are two substantial experiments to be conducted on a half of a day. Students will design, construct and test advanced measurement systems using low-cost optical/imaging sensors and image processing software. Formal reports on the experiment are required. ASSIGNMENT – INDUSTRIAL CASE STUDIES Real-life industrial measurement and monitoring problems are assigned to students for suitable solutions. 14. Indicative Reading List Background Reading Sensors and Systems, Usher M.J. and Keating, D.A., MacMillan Principles of Measurement Systems, Bentley, Longman, 2004, ISBN-10: 0130430285 Measurement and Instrumentation Systems, W. Bolton, Butterworth-Heinemann, 1996, ISBN-10: 0750631147 A collection of focused research papers on relevant topics. 15. Learning and Teaching Methods, including the nature and number of contact hours and the total study hours which will be expected of students, and how these relate to achievement of the intended learning outcomes The module is taught mainly through lectures, examples classes, practical laboratory sessions and directed self-studies. It is estimated that each 1-hour examples class with its associated self-study will require 3 hours of total study, and there are 6 examples classes in total. The material covered in each lecture will need some extra study to be digested, with extra time for revision/examination, giving a required study time of 4 hours for each one of the 24 lectures. There are two 4-hour laboratory classes, which require extra 8 hours (4 hours for a 4-hour laboratory class) for students to review and understand properly the work carried out. Students will also be expected to spend 20 hours to complete the substantial assignment. There total are thus 38 student contact hours, and 150 total study hours for the module. 16. Assessment methods and how these relate to testing achievement of the intended learning outcomes This module is assessed by exam (60%) and coursework (40%). The assessed elements will test the learning outcomes 1-6. 17. Implications for learning resources, including staff, library, IT and space There are two 4-hour laboratory classes to be accommodated in the Project Lab at the Department of Electronics. 18. We confirm that, as far as can be reasonably anticipated, the curriculum, learning and teaching methods and forms of assessment do not present any non-justifiable disadvantage to students with disabilities Statement by the Director of Learning and Teaching: "I confirm I have been consulted on the above module proposal and have given advice on the correct procedures and required content of module proposals" ...................................................................................... ..................................................... Director of Learning/Teaching Date Statement by the Head of Department: "I confirm that the Department has approved the introduction of the module and will be responsible for its resourcing" ...................................................................................... Head of Department ............................. ........................ Date