Supplementary Material

advertisement

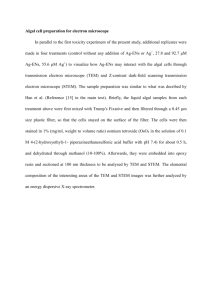

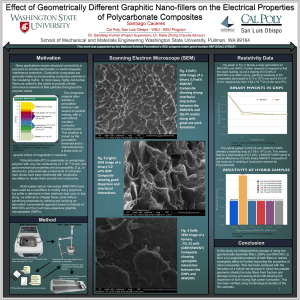

Supplementary Material METHODS SUMMARY Preparation of fullerene and multi-walled carbon nantoubes (MWCNTs): To synthesize fullerenes and MWCNTs in the electric arc-discharge apparatus, an arc was generated between two electrodes in a reactor under helium atmosphere. The cathode (15 mm diameter, 15 mm long) and anode (6 mm diameter, 100 mm long) were pure graphite (purity 99.99%). The arc-discharge was created by a current of 60 A; at a voltage drop of 25 V between the electrodes was maintained by keeping a constant distance of 2 mm between them. Characterization methods: Scanning electron microscopy (SEM) was carried out on a Philips (FEI XL30 LaB6, 30 kV) equipped with energy dispersive X-ray (EDX) detector. Transmission electron microscopy (TEM), fast Fourier transform (FFT) and selected-area electron diffraction measurements were carried out on a Philips Tecnai 20 S-TWIN (200 kV) field emission high resolution TEM equipped with a post specimen aberration corrector. The TEM samples were prepared by drying a droplet of the MWCNTs suspension on a Quantifil® R2/2 (lacey-carbon) grid. (a) (b) 20 m (c) 5 m (d) 20 m 5 m Figure S1. SEM image of MWCNT deposit top surface (a), (b) after the termination of arc discharge and (c), (d) moved away electrodes without termination of arc-discharge. (a) (b) Figure S2. Optical images of (a) a soap bubble. (b) a soap tube. When a strong pressure is applied on the soap film through the ring (by air blowing), small bubbles are formed. When the air is slowly pushed through the soap film, large size and elongated bubbles are formed. Depending upon the applied pressure, the shape of the film can be changed to attained equilibrium. Figure S3. TEM image showing MWCNTs at the nucleation stage. Figure S4. Schematic illustration of branched MWCNT formation from graphene layers