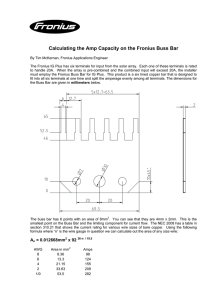

Grounding Explained by Greg KB4VVE

advertisement

GROUNDING In Florida, it is claimed that the average lightning strike is 70,000 Amps. 40,000 amps is the US average. It usually hits a high point – antenna – and comes down the transmission line to find ground. It does so generally as a ‘Common Mode’ event, as opposed to a “Normal Mode’ event. IE, whole cable conducts strike, not just the center conductor. A good ground is 5 ohms. This results in a voltage spike of 350,000 volts. If the strike finds ground by going thru the radio, it becomes a fuse, blows up, and your warranty is void. The key to minimizing lightning damage is to prevent the surge current from entering the shack and flowing through the equipment by giving it a shorter, lower impedance, path to ground. HOW: A good, low resistance and low reactance (inductance), single point ground system. All shack inputs and outputs (AC power, all RF, telephone, internet, and cable TV) equipped with TVSS (surge protectors) located close to and bonded to the single point ground buss. Good coupling to ground system with multiple ground wires or flat copper strap. Do not use stranded or braided wire outside due to corrosion and IM generation (salts get into the wire – mini diodes). Route with minimum bends and current ‘flow’ in mind. Do not ever disconnect or cut an existing ground wire. Bond using an approved clamp such as a ‘split bolt’. Soldering is allowed, but only in addition to a proper mechanical connection. A good low impedance ground rod system for the shack consists of multiple rods 8 – 16 feet apart, connected together, bonded externally to electrical entrance ground, any copper plumbing, and telephone and cable grounds. Use 8’copper clad steel ground rods and bronze ‘acorn’ type clamps (or Cad Weld). If you have a tower, a ground system for it should be installed around the base. Verify or install surge protection at the building electrical power entrance panel suitable for rated service ( normaly 200 Amps). Install wiring on load side of larger breakers (AC, water heater, range, dryer). Best done by an electrician for code compliance and safety. Many codes require TVSS device be installed inside panel for explosion protection. This will depend on the device type(s). Have the electrician verify a good, tight ground connection at this time. Ground outer conductor (shield) of all coaxial cables as they leave tower/mast, install with ‘minimum radius bend’. Rotor and other control wires should be coiled at this point. Route all cables to their protectors at the single point ground buss. Now you can ground your equipment to the ground buss, but do it directly – but don’t ‘Daisy Chain’. Here you can use stranded or braid wire. #12 is fine. Most of this is ‘shunt’ protection, giving the lightning surge current a shorter path to ground. An additional aid is to provide series protection, a longer path for the surge through the equipment. This is done by forming coils in the cables to act as chokes and/or to add ferrite chokes. The goal is to lower the impedance to ground and to raise it to the equipment. A buried ground ring around the building is excellent, but can be very difficult on existing structures. 8’ copper clad steel ground rods every 8-15 feet and at the corners, #4 or better solid copper wire buried 6” or more (never use stranded or braided wire outside). Use quality clamps – no Zinc, steel, or ‘pot metal’ items. Avoid dissimilar metals outside. Avoid any vertical ground loops exterior to the single point ground buss. These can act as a transformer, often conducting the surge into the shack. This usually occurs when tower and building grounds are bonded together. Most industry sources have NOT recommended that the tower and building ground systems be bonded together, as the ground resistance dissipates energy. This view may now be changing, Motorola R56 does bond them together. Each installation will require its own design. Existing buildings may require compromise. The station ground buss should be solid copper for the best service. Buy a large enough buss so it’s not outgrown. The Harger brand works well and is affordable. (HRO, Georgia Copper) Two #4 solid copper wires or strap equivalent should be run from the ground buss to the outside ground ring. This tends to cancel inductance. Electro-Static Discharge dissipaters are not recommended. Multiple plug-in MOV type AC surge protectors are recommended, minimum of one per branch circuit, all around the house. These are inexpensive and fail in the ‘shorted’ state, indicating the failure (breaker trips and won’t reset). An appropriate AC surge protector for the station feed should be mounted in the shack, close to the station ground buss along with the station disconnect. Do not buy expensive surge protectors – more of the inexpensive units spread around differ circuits will perform better. (Home Depot or Lowes) RF surge protection will be based on the frequency bands and power levels used. For the VHF/UHF there are a number of manufacturers such as Polyphaser and Cellwave but for HF, the Alpha Delta series seem to work better. Also MFJ units work well. Ground connections must be short for low inductance. (HRO, AES, MFJ) Rotor and other control lines can be protected with 12V MOVs or commercial control protectors, again close to ground buss. (Digikey – maybe a club order?) There is a 90% rule to lightning protection – each point in the process will divert 90% of the strike current. Three steps will get it down to 70 amps and that is sustainable. Spend time planning and not on fancy protection equipment. As each station will be different, feel free to consult with your club technical committee, Ernie AJ4BP, Jody W4SLC electrical, Greg KB4VVE lightning prevention. gtb/s 4/15 Desired grounding logic Entrance and ground buss solution – all in one box for Amateur station. Guy wire grounding No braid outside! Outside buss. Typically optimum grounding connections Small indoor ground buss (Harger type). Place on backboard for mounting RF, AC power, telco/internet and control surge protectors. Proper connection to ground rod with ‘Acorn’ clamp. Solid wire only outdoor.