The new development of austempered ductile iron (ADI) in China

advertisement

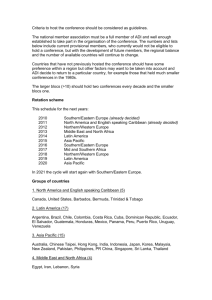

The new development of austempered ductile iron (ADI) in China Yicheng Zeng, Kerui Li, Xianlong Wu, Zhongchou Zhang 1. Survey of the development of ADI ADI (Austempered Ductile Iron) has been systematically researched and developed for about 40 years in the world. Its development goes through a process from experimental study, application development, to industrial manufacturing. Because of its advantages of high strength (maximum Rm>1600MPa), good ductility (maximum A%>11%), high dynamic performance (bending fatigue strength can reach 420~500MPa, contact fatigue strength is up to 1600~2100MPa), good abrasive resistance and shock absorption performance, ADI has been developing rapidly and its application scope has been enlarged gradually. The production volume of ADI keeps rising and has almost reached 300,000 tons in 2007. In which the American ADI production is about 200,000 tons, Europe 25,000 tons, and China about 60,000 to 80,000 tons. The ADI market share is listed in Table 1. Table 1 The ADI market share in North American and European professions Industry Medium and heavy Light Building Agricultural General duty truck vehicle &Mining machinery machinery 26 25 8 14 11 16 25 20 11 17 15 12 34 14 22 4 5 3 2007 ADI ratio of the total production North year America 2010 year volume (%) Europe (2007) Railway Energy &source 18 We can see that in Table 1 the automobile industry takes the main share of about 45% of the ADI market, especially the chassis parts of the heavy trucks. It is introduced that there are at least 500 kg ADI parts in one heavy truck in America. Extensive production experience and data have been gained through tens of years of manufacturing and application. ADI used to be substitute goods, but now it can be designed by modern design technology such as FEA according to its characteristic features and service conditions to reduce wall thickness, weight, and save energy and materials. 2 Progress of China ADI manufacturing technology and industrialization in recent years. 2.1 Establishment and publishing of national standard on “Austempered ductile iron castings” The National Casting Standardization Committee held the conference of review on national standard “Austempered ductile iron castings” on Dec 27th, 2008. And the national standard GB/T 24733—2009 was issued on Dec 30th, 2009. 2.2 Quality of ADI rough castings have been improved greatly, setting the stage for ADI volume production 1)High quality charge for ADI iron has been realized High quality original iron melt is required for ADI castings, which calls for high quality foundry iron and steel scraps. Previously Q10 and Q12 were used as pig iron for ductile cast iron production in China, as we do not have high purity pig iron like Sorel metal abroad. The contents of P and Ti in Q10 and Q12 are high, and the impurity elements were not strictly limited as abroad (see Table 2). Table 2 The maximum allowance of Trace elements Trace elements Maximum content (%) Cr V Mo Sn Sb Pb Bi Te As B Al 0.05 0.03 0.01 0.02 0.002 0.002 0.001 0.003 0.02 0.002 0.02 Note: The sum of ten trace elements contents plus Ti content <0.1%. As the development of pig iron smelting technology, in recent years, several enterprises have succeeded in smelting high purity pig iron and set up their enterprise standards. These enterprises and the chemical constitution of their high purity pig irons are listed in Table 3. Plants that can produce pig iron with P<0.04%, Ti<0.05% and Mn<0.3% are listed in Table 4. Table 3 The chemical constitutions of high purity pig iron in China Chemical constitutions (%) Producer Chengde Baotong Profiled Cast Iron Bar Corperation Jinan Gengchen Iron and Steel Materials Co., Ltd Hebei Longfengshan Foundry Co., Ltd P S Mn <0.022 0.006 <0.021 0.024 ~0.035 ≈0.02 0.01 ~0.035 0.012 ~0.02 Sn Sb Ti Al As <0.00005 <0.0005 0.01 0.00745 0.001 <0.10 0.0011 ~0.0004 0.0002 ~0.0003 0.027 <0.10 <0.005 <0.005 0.012 ~0.02 Bi <0.00005 <0.0005 0.0001 ~0.0011 <0.005 <0.0005 Pb 0.0001 ~0.0002 <0.0005 <0.0005 Table 4 The chemical constitutions of high quality pig iron in China Chemical constitutions (%) Producer Hebei Youli Iron and Steel Materials Co., Ltd P S Mn Sn Sb Ti 0.025 ~0.04 0.02 ~0.03 0.015 ~0.1 <0.0017 < 0.01 0.02 ~0.06 < 0.005 < 0.002 ≤0.038 ≤0.02 ≤0.1 0.0005 ≤0.005 0.02 ~0.06 < 0.005 ≤0.04 0.028 0.2 ~0.3 - 0.001 0.047 0.002 0.0005 <0.001 <0.0005 0.04~ 0.041 0.014~ 0.021 0.08~ 0.092 <0.0005 <0.0005 0.04~ 0.068 - <0.005 - <0.0005 0.026 ~0.038 0.008 ~0.018 0.07 ~0.08 <0.0005 <0.0005 0.030 ~0.043 0.031~ 0.035 0.015~ 0.029 0.09~ 0.13 <0.001 0.043~ 0.047 Henan Linzhou Iron and Steel Materials Co., Al As Bi Pb 0.0012 < 0.001 <0.005 < 0.00005 0.0002 Ltd Shanxi Dongcheng Iron and Steel materials Co., Ltd Henan Linzhou Hexin Co. Fushun Hanwang Direct Reduced Iron 0.0005 <0.0005 <0.001 0.001~ 0.004 Co., Ltd Hebei Spring Breeze Foundry Co. Ltd <0.001 0.002 Recarburizing process treated high grade steel scraps can be used to produce high grade iron melt except for using high grade foundry pig iron or high purity pig iron. In fact, recarburizing process treated high grade steel scraps has been widely used in China. Recently, FAW Foundry Co., Ltd and its business partners obtained original iron liquid for ductile iron by adopting high purity pig iron and recarburizing process to steel scraps when developing ADI crankshaft of supercharger engine of 1.8T Besturn. The chemical constitutions are listed in Table 5. So it is true that these two kinds of metal charging can be used to obtain original iron liquid which meets the requirements. Table 5 Chemical constitutions of the original iron liquid obtained by using high purity pig iron and recarburizing process to steel scraps in FAW Foundry Co., Ltd (%) High purity pig iron C Si Mn P S Cu Mo Cr Ti 3.67 1.84 0.12 0.017 0.008 0.7 0.22 0.051 <0.008 3.9 1.90 0.24 0.021 0.003 0.67 0.18 0.023 Recarburizing process to steel scraps 2) In order to meet the requirements for yield and quality of ductile cast iron in both domestic and international markets, enterprises adopt advanced process and equipment when building new plants, and set up technical reform in old plants. At present, the yield of ductile cast iron in China is over 5000 tons, and there are over 80 companies (cast pipe companies are not included) with advanced equipment and stable product quality. Cupola-electric furnace process or intermediate frequency furnace to smelt raw materials is used, carbon equivalent meter and vacuum direct reading spectrometer are equipped, and more attention to the quality of original iron melt is paid. Some plants employ pneumatic, agitating, desulfuration process to obtain low oxidized original iron melt with high temperature (>1500℃), and low sulphur content (<0.02%). molding is mechanically done, such as static press, high pressure press and extrusion processes with clay bonded sand of high degree of compaction. Permanent mold, shell mold with iron pellets, sand lined-metal mold and resin bonded sand mold are used to ensure the stiffness of mold. The mushy freezing character of ductile cast iron and expansion caused by graphite are exploited to solve the shrinkage problem. Professional factories can offer nodularizers and inoculation agents with different chemical constitutions and grain sizes according to the requirements of ductile iron casting. Except for pouring process, several methods such as covered ladle, turning ladle, wire feeding and jetting, are widely used, as well as other advanced processes like ladle inoculation, stream inoculation, mould inoculation, and so on. So, the basic requirements for stably manufacturing high quality ductile iron casting has satisfied in China. In 2008, the ductile iron yield in China has reached about 8,000,000 tons, which accounts for one third of the world, of which structural components with high quality takes over 900,000 tons. These enterprises are able to produce ADI castings. 2.3 Obvious progress has been made in application of CADI grinding balls and ADI scaleboards ADI has high abrasive resistance and high toughness, and CADI (carbide austempered ductile iron) has high hardness (HRC>56) and wear resistance. So, these two materials have great prospects of being used as wear parts in the machineries for metallurgic mines, coal mine, engineering and agriculture,. Currently, many domestic factories have launched the research work such as coal conveyer scraper, CADI grinding balls, coal pulverizer motherboard, and etc. In European ADI market, mine and engineering machinery take 22%, ranking only second to automobile industry. In UK, ADI has been used to make racks and bevel gears in JCB light excavator. The rack weighs 7 kg, Φ90×275mm, and the bevel gear weighs 8 kg, Φ140×210mm, with trade name of 1200-850-3. Before the application of ADI, quenched and tempered forging steel were used. The hardness of these materials is about 55~60HRC after heat treatment and then shot peening follows. Using the ADI, the parts were machined already before heat treatment. After heat treatment, the maximum tolerance can reach 0.05mm, and recently about 0.02mm. Using the net-shape castings machining allowance can be reduced, and quenching, tempering and shot peening processes can be omitted, which notably reduce cost. Moreover, the service life is prolonged and maintenance cost is reduced compared with forging steel. Hebei Qianxi Aodiai Mechanical Casting Co., Ltd developed a kind of CADI grinding balls (φ40mm~φ150mm) containing 10% carbides used in mine ball mills. Obvious progress was made after over two years’ service test. The service life has been prolonged for 1~3 times of the former materials (low chromium), electric consumption decreases about 10%~20%, production efficiency increases by 10%~20%, noise reduces by 10~12 dB, and no out-of-circularity and break happened. One plant in Hebei Chengde produces tens of thousand tons of CADI grinding balls with same progress by using hard spots of carbide and nitride of vanadium and titanium. Qianxi Aodiai Mechanical Casting Co., Ltd took high trade name (over 1400) ADI instead of high manganese steel to produce globe mill scaleboards, and received good results. Beijing Feimeite Machinery Co., Ltd took 1600-1 ADI instead of QT800-2 to produce biofuel baling press mold which was heat treated in Suzhou A.P Company. The mechanical performance can be stable at 1600-3, even 1700-2, and small volume production has been launched. 2.4 Improve the design according to the ADI performance to make full use of ADI It is introduced that there are over 500kg ADI parts in one 20t heavy truck in USA, but in China ADI parts are not that much used. In 2008, the production volume of heavy truck in China is over 600,000 units, so the prospect of ADI is brilliant. In recent years, testing has made great progress. For example, Dongfeng Motor Co., Ltd use ADI instead of traditional cast steel for making 5t high mobility cross-country vehicle. They use CAE technology to design parts, reduce the weight of the key parts while the parts are strengthened, and optimize the structure according to the good casting and mechanical properties of ductile iron. To be exact, compared with traditional material, the total weight of 14 ADI parts was reduced by 249.96kg, from 630.62kg to 380.66kg, with the weight-reduction ratio 39.6%. Later, there are more ADI parts, and the total weight of all ADI parts reaches 550.4kg. Another example, FAW Technology Center is actively doing research on ADI for backing plates of heavy mine-used vehicles. They are doing tests on forward shaft, slewing journal, rear axle, and wheel boss. Their aim is weight reduction and cost saving, the same as that of Europe. 2.5 Preliminary results have been achieved about establishment of professional heat-treatment centers and special manufacturing factories of ADI Zhejiang Jiashan Sanyong Electrical Furnace Industry Co., Ltd firstly built and successfully set up a controlled atmosphere seal box type special furnace production line in Jan., 2006. Suzhou Aipu Component Manufacturing Co., Ltd (A.P. Suzhou) imported a controlled atmosphere multipurpose furnace production line from American AFC and debugged successfully in the first half of 2007 after installation. Since then, professional heat treatment centers appear in China. In recent years, A.P. Suzhou has played a very important role in the development of ADI products in China by actively helping Chinese companies in ADI production developments and testing. Hebei Qianxi Aodiai mechanical Casting Co., Ltd bought two controlled atmosphere seal box type furnace austempering production lines made by American AFC from Shanghai Powermax Furnace Co., Ltd in 2007, and the production lines were put into operation in June, 2010 to achieve the aim of establishing an austempering heat treatment center in North China. Holding the belief that there will be a wide ADI application in China, Aipu Company established its branch Jilin Aipu Company in Changchun. Two production lines were installed, the size of one hearth is about 2000 × 2000 × 1500mm, and 4.5 tons of casting can be heat treated at one time. The production lines have been put into operation in August, 2011, and Jilin Aipu Company serves an austempering center in northeastern region. Nanjing Guangying Furnace Co., Ltd produced austempering continuous production lines of ADI components used in railway for relevant factories. Hubei Mechanical and Electrical Research and Design Institute improved its design of austempering equipment through using intelligent mechanical arm to ensure process execution. Hankou Furnace Co., Ltd has been dealing with the development and manufacturing work of austempering heat treatment furnace for a long time and can offer austempering furnaces with all kinds of sizes (hearth size from 600×500×800 to 2000×1200×1200mm), as well as chain-belt continuous austempering furnace. In 2005, the first ADI professional factory in China, Henan ADI Foundry Co., Ltd was established. After several years’ development, now it can manufacture large quantities of important components like chassises of heavy trucks and big buses, as well as air picks, coal mining and engineering machinery. In 2007, its production volume of ADI components was about 2,700 tons, and in 2010, 4,500 tons. It is predicted that the production volume in this year will be 7,000 to 8,000 tons. 2.6 ADI crankshaft and gear In recent years, turbocharging technology has been applied to gasoline engine. FAW Foundry Co., Ltd has started to develop the ADI crankshaft of turbocharging engine in 1.8T and 2.0T Besturn. Performance test and fatigue test have been finished, and bench testing is ongoing. It is expected to be the first formally manufactured set of ADI crankshafts. Jiangsu Wanli Machinery Co., Ltd has been dealing with the test work of ADI crankshaft used in multi-cylinder diesel engine and achieved some good results, but it hasn’t yet been put it into production. Gear is the first ADI industrial product, which is true in America, Finland and China. ADI gears have the advantages of high resistance to bending fatigue and high contact fatigue strength, high resistance to pitting, low noise, 10% lighter than same sized steel gear, small deformation after heat treatment, good machining ability, lower cost and so on. More development and application work have been done in automobile and tractor industries in China, and the ADI material was first used in accessories of rear axle in light and medium sized trucks in a small amount. The first mass production of formal products of ADI material is timing gear in high-power diesel engine. The safety factor of bending fatigue strength, of timing gears in Commins engines produced by Dongfeng Motor Corporation and timing gears of crankshaft in 6DF1 diesel engines produced by FAW Wuxi Diesel Engine Works, can be 3.56. Practice has proved that there is absolutely no problem for ADI gears substituting for nitride steel timing gears and partly carburizing-quenching steel gears. The main reason why ADI timing gears haven’t been massively used is the price. Iron and steel industry grows very fast in China. Huge volume blast furnace and pure oxygen top blow plus continuous rolling process for steel production greatly reduced steel cost. In 1990s, when Dongfeng Motor Corporation took ADI substitute for ANST1022 carburizing steel for gear production, the price of Φ80 section low alloyed steel was 8000 Yuan per ton, while the price of high grade pig iron was 700 Yuan per ton, so the manufacturing cost of per set of (six) ADI gears was 124 Yuan and saving 17% compared with steel gears. At present, the price of steel has decreased to 4000 Yuan or so per ton, but the price of high grade pig iron has increased to 4000 Yuan per ton. So, the key to enlarging the application of ADI gears is cost reduction. Recently, some companies tried to reduce the cost by taking a lot of methods like improving the quality of ductile iron castings to decrease rejection rate, controlling heat treatment, reducing machine tooling cost (like elimination of the expensive gear grinding process) and so on. Some companies have been dealing with testing and manufacturing of ADI spiral bevel gears, but, their production amount is small. SEW Company purchased the Finnish Kymi Kymmene Factory. SEW Company insists in using ADI gears in all kinds of products. Pictures 3 and 4 show its two typical products. Since it established plant in Tianjin, SEW Company has been taking an active part in the development of ADI industry in China. In 2009 its ADI production volume is about 500 ~ 600 tons and it is expected to be 1,000 tons in 2011.