Word document - San Diego State University

advertisement

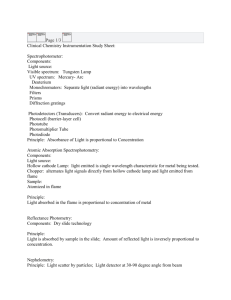

The Third Asia-Pacific Conference on Combustion June 24-27, 2001, Seoul, Korea TIME SCALE ANALYSIS FOR OPPOSED-FLOW FLAME SPREAD - THE FOUNDATIONS Subrata Bhattacharjee Department of Mechanical Engineering San Diego State University San Diego, CA 92182, USA Subrata@voyager5.sdsu.edu ABSTRACT Time scales: Figure 1 depicts a schematic of steady opposed-flow flame spread in the flame fixed coordinates. The opposing flow Opposed-flow flame spread over solid fuels has been extensively studied over the last three decades. These studies have addressed major regimes such as thermal regime with sub-regimes of thick and thin fuels, kinetic regime, downward spread and microgravity regimes among others. A general study, where all these sub-regimes are defined and put into perspective, is still lacking. In this paper, a novel scale analysis is presented which brings together all different regimes and sub-regimes of opposed-flow flame spread. velocity V g , can be due to forced-flow or buoyancy induced flow. With respect to the flame the oxidizer, assumed to be a mixture of oxygen and nitrogen, approaches the flame with a velocity Vr V g V f and the fuel with a velocity Vf . To identify the relevant time and length scales, attention is focussed on the leading edge of the flame where the forward heat transfer, the fundamental mechanism of any flame spread[2], occurs. Two control volumes, one in the gas phase of size The thermal regime, the backbone of this opposed-flow flame spread problem, is first established through a time scale analysis in which competition among different heat transfer mechanisms, gas-phase and solid-phase kinetics are reduced to comparing individual time scales expressed in terms of known parameters of the problem. Various sub-regimes are established by removing thermal-regime assumptions one at a time, and defining the appropriate non-dimensional numbers through ratios of competing times. Results from existing analytical solutions, comprehensive computational model and available experimental data are used to validate some of the conclusions and lay down the foundations of scaling for the opposed flow flame spread phenomena. one in the solid phase of size Lgx xLgy xW and Lsx xLsy xW , are drawn at the W being the fuel-width in the z direction and the length scales, L gx , L gy , L sx and Lsy , unknown at this flame leading edge, point. The essence of flame spread mechanism[2], steady forward heat transfer to the unburned fuel, with respect to these control volumes of Fig. 1(a) can be stated as follows. In the gas-phase control volume the vaporized fuel and oxidizer react to raise the gas temperature from its ambient value flame temperature Keywords: flame spread, scale analysis, microgravity. Tf T to a characteristic . The velocity at which the solid fuel must be fed through the solid-phase control volume in the negative x direction to steadily raise the fuel temperature from its ambient INTRODUCTION value Opposed-flow flame spread over solid fuels has been extensively studied over the last three decades[1]. While most of the work have been concentrated into separate studies of the sub-categories such as the thermal regime, thick fuels, thin fuels, super-thin fuels, downward spread, kinetic regime, radiative regime, and, recently, microgravity regime, efforts to bring them together through a single analysis have been relatively few[2]. Although scaling arguments[2,3] have been used in the past to understand the mechanism of flame spread and the complicated energy balance on the fuel surface, in this work we offer a novel time scale analysis encompassing all sub-regimes for the first time following the scale-analysis conventions established by Bejan[4]. Existing analytical solutions, comprehensive computational model and available experimental data will be used to validate the results and, whenever possible, determine critical values of the non-dimensional numbers arising out of scaling arguments that delineate the sub-regimes of opposed-flow flame spread. TF , to a characteristic vaporization temperature Tv is the desired spread rate V f . At any other velocity of the fuel the location of the pyrolysis front, and hence the flame leading edge, will not remain stationary rendering the problem unsteady. For the flame to be established at the end of the gas-phase control volume, combustion reaction must be complete within the available residence time t res, g ~ Lgx . In terms of the Vr characteristic time for combustion t comb , this implies that t res , g must be greater than the other hand, t res , g t comb for kinetics to be considered fast. On must be small compared to t ger (see discussions below and Fig. 1b) for radiative losses from the gas 1 phase to have no effect on Tf Solid-Forward conduction as the only surviving driving forces. It has been experimentally and computationally verified that, of the two Gas-to-Surface conduction is the dominant one in the thermal . Therefore, finite-rate kinetics and gas-phase radiative losses can be considered marginal allowing the use of adiabatic flame temperature T f ,ad for T f if regime, i.e. t comb t res, g t ger . Within the available residence time t res, s ~ t sh t vap ~ t sh , t res,s L ~ sx Vf t sh ~ min( t gsc , t sfc , t gsr , t esr ) ~ t gsc , in the solid TF , t res , s ~ t gsc therefore, phase control volume, the fuel must be preheated and part of it vaporized. That is: where Combining these assumptions, Eq. (1) can be simplified as follows. Under this simplifying scenario the gas phase allows the flame to spread as fast as it can meet the requirement of the solid phase. t res,s ~ t sh tvap , t sfc t gsc . (3) What remains is to be done is to express these time scales in terms of known parameters of the problem before Eq. (3) can be solved to obtain the flame spread rate under the restricting constraints of the thermal regime. (1) Length Scales: In the gas-phase, a balance between the conduction and convection in the x-direction at the leading edge t sh is the time for sensible heating of the solid phase from to Tv and t vap is the characteristic time for the pyrolysis yields the familiar5 expression for Vr T f T of fuel. The characteristic time for a given heat transfer mechanism is defined as the time required by that mechanism, acting alone, to supply the necessary heat to perform the most basic task, that is to preheat the solid-phase control volume. The fastest pathway, i.e. the mechanism with the smallest time scale, is, clearly, the dominant driving force behind the spread. Figure 1(c) depicts the competing heat transfer mechanisms during the solid-phase Lgx or, Lgx ~ ~ L gx . g T f T L2gx g (4). Vr residence time. Conduction from Gas-to-Solid ( t gsc ), The transverse length scale Solid-Forward conduction ( t sfc ), radiation feedback from Delichatsios[3] as the diffusion length in the y-direction within the available residence time. Gas-to-Solid ( t gsr ), and Environment-to-Solid radiation, possibly t res, g ~ from an external source or a large downstream plume, if any, ( t esr ) act in parallel to supply the sensible and latent heat to the virgin fuel. The radiation loss from the Solid to-Environment ( t ser ), on Vr g or, Vr V g The pyrolysis chemistry is considered fast, i.e. g Vr Lgx , (5) The gas-phase conduction being the driving force, on the solid phase making Lsx ~ Lg . Lg is imposed The transverse length L sy , derived in a manner similar to L gy , however, cannot be greater than the half-thickness of the fuel. Therefore, t comb t res, g t ger V g V f , Vr2 Lg Lgx Lgy t res, s . Thermal Regime: The thermal regime of flame spread is defined with the following simplifying assumptions. In the gas phase, radiation loss in the gas-phase is assumed negligible, while combustion kinetics is considered fast. Moreover, the opposing flow velocity is considered much greater than the spread rate. while, can be obtained following Lgy ~ g t res, g the other hand, is an interfering mechanism, just as the radiative losses in the gas phase control volume, its importance dependent on how t ser compares with Lgx L gy (2) Lsx ~ Lg t vap ~ 0 , so that g Vr and, s g L Lsy ~ min , s sx min , . V V V f f r the solid-residence time is spent almost entirely on the sensible heating through the fastest heating mechanism. If radiation is entirely neglected, this leaves Gas-to-Surface conduction and 2 (6). Spread Rate Formulas in the Thermal Regime: The amount of heat transfer necessary to preheat the solid-phase control volume from TF , to the vaporization temperature Tv , Qchar ~ s c s Lsy LsxW Tv TF , , represents a s c s Lsy LsxW Tv TF , Qchar ~ T f Tv L gxW q gsc g L gxW L gy F s c s Lsy T f Tv Tv TF , , and F, g F s c s g g cg 2 ~ Vr F , s s c s V f ,thick (11) 1. Di Blasi, C., Prof. Energy and Combust. Sci., Vol. 19, pp. 71-104. (1993) 2. Williams, F.A., Sixteenth Symposium (International) on Combustion, The Combustion Institute, Pittsburgh, PA, p. 1281, (1976). 3. Delichatsios, M.A. Twnety-Sixth Symposium (International) on Combustion, The Combustion Institute, Pittsburgh, PA, p. 1281, (1996).. 4. Bejan, A., Convection Heat Transfer, John Wiley and Sons, (1995) 5. de Ris, J.N., Twelfth Symposium (International) on Combustion, The Combustion Institute, Pittsburgh, PA, p. 241, (1969). 6. Delichatsios, M.A., Combust. Sci. and Tech., Vol. 44, pp. 257-267, (1986). 7. Bhattacharjee, S., King, M., Nagumo, T, Takahashi, S., and Wakai K, Proc. Combust. Inst. 28: in press. .(8) L sy in Eq. (8) produce: V f ,thin ~ , References: where, Lg Lsy ~ min , s g F The thin and thick limits of cr ,thinthick, EST Conclusions: A general opposed-flow flame spread problem is studied here with the help of a novel time-scale analysis. Based on the foundations presented here, the thick and thin-fuel sub-regimes are combined into a single unified formula (Eq. 11). The analysis can be extended to include various other regimes of flame spread, a topic left for a future presentation. (7) Substituting Eq. (7) into Eqs. (3) and (6) results in: Vf ~ Spread rates computed with a comprehensive numerical model have validated this formula, at least for the downward configuration7. Computational results also suggest that the fuel becomes thermally thick for T 2 , an apparently universal conclusion. Lsy s c s 1 Vr g c g F g T 1 min 1, T is, therefore, , alone, to supply Qchar . q gsc is the time taken by t gsc ~ t gsc V f ,thick, EST where, characteristic amount of energy at the heart of the flame spread mechanism. The gas-to-solid conduction time Vf and (9) These expressions are identical (except for a constant / 4 for thin fuel) to the analytical solutions of de Ris[5] and Delichatsios[6] indicating the strength of this simplified scaling approach to this complex problem. ACKNOWLEDGEMENT Thick vs. Thin Fuels: Although the transition between the thin and the thick limits cannot occur abruptly, the critical thickness obtained by equating the spread rate expressions in the two limits [Eq. 9] should provide, within an undetermined constant, the vicinity around which the transition takes place. cr ,thinthick ~ s Lg g F . This work was supported by NASA (Contract NCC3-842) Glenn Research Center with Dr. Sandra Olson serving as the contract monitor. (10) If the fuel half-thickness is non-dimensionalzed with such an expression, the spread rate formulas in the thick and the thin regimes can be combined. 3 y Lgx Vr Vg V f gx Lgy x Lsy Lsx t ser t gsr t ger Environment (e) esr tesr t sfc tcomb t res, g Vf gsr t gsc Lgx Vr t vap t sh tres , s Lsx Vf gsc Gas (g) sfc Solid (s) Fig. 1. (a) Control volumes in the gas and solid phases at the leading edge. (b) Available time which combustion must occur (blue). (c) Available time ser t res, s t res , g (black) in the gas phase in in the solid phase (black) in which sensible heating and vaporization must occur (blue) through competing driving mechanisms (red). The green clocks represent non-essential parallel processes. (d) Close up of the leading edge illustrating the various heat transfer pathways. 1