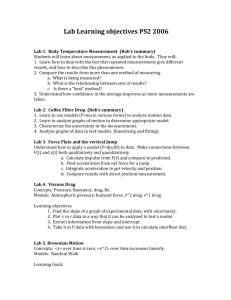

Experimental methods

advertisement

The 8TH International Symposium on Fluid Control, Measurement and Visualization, 2005 Effects of hydrophobic surface with microstructures on turbulent boundary layer flow Xu Zheng and Zhanhua Silber-Li* LNM, Institute of Mechanics, Chinese Academy of Sciences, 15, Bei Si Huan Xi Lu, Beijing 100080, China. lili@imech.ac.cn Corresponding author Zhanhua Silber-Li Abstract Introduction Drag reduction is an interesting subject, which has not been resolved well. Different methods have been tried to achieve drag reduction. Recently, hydrophobic surface attracts researchers attentions. Watanabe et al. [1] [2] first studied drag reduction by water-repellent wall. Balasubramanian et al. [3], Yu and Wei [4] and Min and Kim [5] have devoted their studies on understanding the physical mechanism of drag reduction on hydrophobic surfaces. Barthlott and Neinhuis [6] showed that lotus leaves are a kind of super hydrophobic surface, and the contact angle (CA) is about 160°(Fig.1). From SEM pictures, the micro-structures and nano-structures on lotus leaves surface can be observed (Fig.2). With poly-dimethylsiloxane (PDMS), we replicate the micro-structures on lotus leaves surface, whose CA is up to 146°(Fig.3) [7]. This surface may be used as hydrophobic material in the experiments of drag reduction. This paper focuses on measuring the velocity profiles of turbulent boundary layer near a plate in a water tunnel with three different surfaces: a smooth plate made of polymethyl methacrylate; a smooth plate covered by a layer of flat PDMS, and a smooth plate covered by a layer of PDMS with micro-structures, which is processed by MEMS methods. From the comparison profiles, we will study the effect of hydrophobic surface on drag reduction. Fig.1. CA on lotus leaves surface. Fig.2. Micro/Nano-structures on Fig.3. Surface of PDMS replica lotus leaves surface [7]. [7]. Experimental methods The experiments are carried out in the water tunnel of State Key Laboratory of Nonlinear Mechanics, Institute of Mechanics. It is an over-flowing gravity water tunnel. The test section is approximately 3m long, 0.2m0.2m. The free-stream velocity in the water tunnel is from 0.05m/s to 1m/s, and the turbulence intensity is less than 0.3%. The experimental setup is shown in Fig.4. The length of the plate is 80cm and thickness is 1.2cm. A cylindrical stick installed at the plate introduces the turbulent boundary layer. The hot-wire anemometer (Dantec models 90N10) with a 55R15 boundary layer probe is used to measure velocity profiles. The measurement position is at about X=50cm. The distance approaching to the plate of the probe can be reached to 0.2mm. n-1 Fig. 4. Schematic side elevation of the test section. Experimental results The experiments include three parts. At this moment, we have finished first part: a smooth plate made of polymethyl methacrylate. The velocity profile of the smooth plate (Fig.5) agrees with the formula as u 2.44 ln u* y B (1) ū is time average of velocity fluctuation in the u* measurement position, u* friction velocity, y is the wall-normal coordinate, y+ normalized y by inner variables y+=u*y/, is fluid kinematic viscosity, B is constant un-determined. The velocities on the smooth plate covered by a layer of PDMS (CA 103 °) and covered by PDMS layer with micro-structures (CA 145 °) are on measurement. followed: Fig. 5a-b. Measured dimensionless velocity profile of turbulent boundary layer in a smooth plate (U=0.1m/s, x=0.49m, U=0.15m/s, x=0.59m) Keyword: Microstructure, Hydrophobic, PDMS, Drag reduction, Turbulent boundary layer References [1] Watanabe K., Ohkido K. and Mizunuma H., “Drag reduction in flow through square and rectangular ducts with highly water repellent walls”, ASME, Fluids Engineering Division FED Proceedings of the 1996 ASME Fluids Engineering Division Summer Meeting, San Diego, CA, USA, Vol. 237, n2, (1996), pp 115-119. [2] Watanabe K., Yaguar, Ydagawa H., “Drag reduction of Newtonian fluid in a circular pipe with a highly water-repellent wall”, Journal of Fluid Mechanics, Vol. 381, (1999), pp 225. [3] Balasubramanian AK., Miller AC. and Rediniotis OK. “Microstructured hydrophobic skin for hydrodynamic drag reduction”, AIAA Journal, Vol. 42, No. 2, (2004), pp 411. [4] Yu Yongsheng and Wei Qingding “Experimental study on the characteristic of drag reduction of water-repellent materials”, Proceedings of the 6th China national conference on experimental fluid mechanics, Tai Yuan, China, Vol. 1, (2004), pp 55-59. [5] Min T. and Kim J. “Effects of hydrophobic surface on skin-friction drag”, Physics of Fluids, Vol. 16, No. 7, (2004), pp L55. [6] Barthlott W. and Neinhuis C., “Purity of the sacred lotus, or escape from contamination in biological surfaces”, Planta, Vol. 208, (1997), pp 1-8. [7] Zheng X. & Silber-Li Z.H., “The hydrophobicity of micro-structures of lotus leaves with PDMS replication” ,2005, submitted to Langmuir. 8th International Symposium on Fluid Control, Measurement and Visualization, China, 2005