lab jobs assignment

advertisement

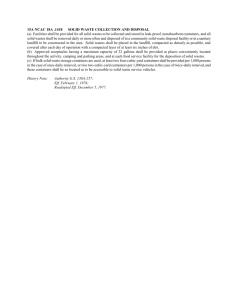

Dalton Group monthly lab job schedule Jul - Dec 2008 Month Responsibility Jul Ilya Aug Josh Sep Scott Oct Stephanie Nov Meghana Dec David Purchase solvents Call for waste pick-up Common lab areas cleanliness and orderliness Follow-up check for weekends and holidays Comments by supervisor Checklist for monthly lab jobs The following are detailed instructions for lab jobs. 1. Check the solvent cabinet in Lab 152. Make sure there is adequate solvent in each 20 L/4 L container (methanol, acetone, hexanes, ethyl acetate, dichloromethane, chloroform). Ether, Toluene, Ethanol, Acetonitrile and solvents like these that are used only in small quantities, can be purchased in 4 L or appropriate size containers. 2. Check the status of spare solvents. At all times, there should be spare 20 L/4 L containers of hexanes and ethyl acetate (1 each), which should be stored in the flammable cabinet. 3. Check the corrosive chemicals cabinets under the fume hoods/sinks and inorganic shelves. Make sure there is adequate amount of commonly used acids (HCl, HNO3, H2SO4, CH3COOH), bases (NaOH, KOH, K2CO3, NaHCO3) and drying reagents (Na2SO4, MgSO4). 4. When liquid and/or solid waste containers are full, label them properly and call for pickup. 5. Check that communal areas of the lab are clean and in good order, such as the balance area, the rotary evaporator tables. 6. By 4:00 pm Friday each week the solvents should be fully stocked, all full liquid and solid waste containers called in, and all empty solvent and chemical containers disposed of. For the people not on duty Please be considerate. If you are not on duty this does not preclude you from the responsibility to keep the labs functional. Keep common work place clean and tidy. Don’t leave things lying around in communal areas; keep the balance area clean; keep the common office areas clean and tidy; do not leave print-out lying on the printer; do not leave gloves and safety glasses on the common desks. Do not leave 4L solvent bottles on the benches longer than required. Any closed 4L bottle on the bench is violation of UW regulations. Please return to the yellow flammables’ cabinet as soon as done. Empty 4 L containers should be placed inverted in a safe place to drain off residual solvents and leave them in the pickup place without the caps on. Keep the caps in carton boxes for use with disposal of special waste. These should be removed from the inventory, if possible and the name of the solvent/chemical and the barcode should be crossed through with a Marker pen. If you use the last of a common chemical available from the shelves (ammonium chloride, magnesium sulfate, sodium carbonate, sodium hydroxide), either replace it from the stockroom or write in the ‘Requests’ box on the duties sheet. Label containers with the date when first opened. If possible use an already opened container in preference to a new one. Before ordering any chemical please double check the inventory database and make sure we do not have it. If you found we have it and not in usable condition, quench/dispose it off appropriately before placing order for new one. General responsibilities Samy: General safety captain; authorized signatory; managing meeting schedules, chemical inventory; synthetic labs supervision. Phil: General safety captain; authorized signatory; characterization lab supervision. Scott: Group safety officer - will make sure all members follow safety regulations, prepare UW laboratory safety survey checklist when required, test peroxide in peroxide forming solvents periodically and take appropriate actions in handling them, procure hazardous waste labels when needed, etc. Specific responsibilities Denise Todd Josh Stephanie : : : : Scott Guian, Meghana : : Patrick, Ilya Jocelyn, Ben O Ben O : : : Photostability equipment, UV-vis spectrophotometer Printer papers, cartridges, chemicals refrigerators Dry solvent system, Common Office cleanliness and UV, Fl spectrophotometers (to get help from Denise, Scott or Samy/Brenden) NMR Lab coordinator (to get help from Scott when needed) Common group computers maintenance; lab safety officer (see above) IR, CV, common vacuum pump in 152B, and vacuum oven in 152B and all air ovens, chemicals refrigerators TGA, DSC (to get help from Phil or Scott), Flash Master, Office refrigerators Spin-coater facility Characterization facility Individual member responsibilities: Your hoods Your bench Your pump - Keep it clean and clear (uncluttered). Maintain it clean, clear. Change oil once every three months or sooner. Freeze vacuum trap before turning on the pump and remember to discharge the trap after use. Rotavapor and chiller (these are common but they lye on your bench) – keep clean, and functional at all times. Label all containers with tags at the minimum (vials, flasks, etc.). Label reactions as to what is going on there (an arrowed reaction scheme with all major ingredients and possible hazards).