Belshaw Donut Robot® Mark 6 Doughnut System

advertisement

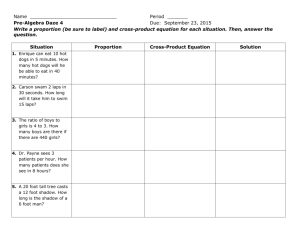

Zhiyin Qin WRIT-340 Improvement in the Making of the All-Time American Treat: Deep-fried Doughnut Abstract Have you ever wondered where did doughnuts come from and how did it come about? Most importantly, how do you make doughnuts? What does it take and what’s the process of producing such a delicious sweet treat? Doughnuts have had a long history so let me tell you all about the making of doughnuts. In addition, the engineering behind developments and improvements of doughnut making are also a focus of discussion. Keywords Snacks, doughnuts, deep-frying, food engineering, processing Introduction Think about some of the most popular sweet treats, pies, danishes, croissants, cakes, cookies, and brownies. Seems like something is missing from the list, come on, Think harder. Yes, you got it. It is the all-time famous sweet treat, the Big-O-Ring, doughnuts. Have you ever wondered where did doughnuts come from and how did it come about? Most importantly, how do you make doughnuts? What does it take to produce it and what’s the process of producing such a delicious sweet treat? Lastly, how have doughnut making changed or could be changed technologically to keep doughnuts remain popular on the market? History The exact beginning of doughnut is unclear but existences of food that resemble doughnuts did appear very early in history. Ancient Egyptians were believed to have eaten fried cakes [1]. Doughnut-like fossil remains have been discovered by archaeologists in prehistoric Native American settlements [2]. It was around the 15th century that the Portuguese adopted the Hawaiian malassada, which is fried dessert dough, and spread it around the globe during colonization [1]. These food items all Zhiyin Qin WRIT-340 familiarly resemble doughnuts because they were also fried dough. They could possibly be the early origin of doughnuts indicating primitive existence of doughnuts. The historical evidences and development of doughnuts have also been recorded. The term doughnut first came from Washington Irving in 1809 when he wrote about Dutch settlers boasting about dishes of balls of sweetened dough in the “History of New York” [1]. Thus, doughnuts were believed to be derived from the Dutch olykoeks meaning oily cakes. The origin of the hole in the doughnut was believed to have originated from a New England ship captain named Hanson Gregory [2]. The captain’s mother made deep-fried dough for the captain so he can bring it along with him on his voyage [2]. The captain claimed he gave the doughnut its hole in the middle when he cut the hole using the top of a round tin pepper box [2]. This gave doughnuts their common ring shape. In 1872, John F. Blondel patented the doughnut cutter but the first doughnut machine did not come until around 1920 in New York City [1]. Since then, the inventor of the doughnut machine, Adolph Levitt, had made a fortune from selling fried doughnuts [2]. Doughnuts became a popular sensational food in the 1930s and continued to flourish since then. The first Krispy Kreme opened in 1937 [1]. Thereafter, numerous Krispy Kreme stores continuously opened and the first Dunkin’ Donuts opened in 1950 [2]. Engineering Influences in Doughnut Making The growth of the doughnut industry was largely enabled due to the engineering innovations and development of the doughnut machine. When Adolph Levitt sold fried doughnuts from his bakery, the tasty treat brought in numerous customers and that induced Levitt to invent the first doughnut machine [2]. The doughnut machine allowed faster production of doughnuts to satisfy high customer demand. As a result, greater Zhiyin Qin WRIT-340 consumption of doughnuts spurred the growth of the doughnut industry. This trend continued when the Ring King Junior came to existence in the early 1950s [2]. The Ring King Junior was an advanced automatic doughnut maker that produced 60 dozen doughnuts per hour [3]. With the Ring King Jr., Krispy Kreme quickly expanded into a chain of 29 store-factories in 12 states by late 1950s [2]. As the Ring Kind Jr. was replaced by newer and more elaborate equipments, doughnut making and doughnut production were furthermore influenced. A modern Belshaw doughnut making Century system can make 90 to 720 dozen doughnuts per hour [4]. Whereas the Belshaw HV Industrial Systems can make 1000 to 3000 + dozen doughnuts per hour [4]. Besides faster doughnut production of uniform quality, there are other improvements in doughnut making such as shape and flavors to ensure doughnuts remain popular on the market. The technological creation of doughnut cutters was key to the development of greater variety in doughnut shapes. Doughnut cutters can cut the dough into different shapes before frying giving a variety of after-frying doughnut shapes. As shown in figure 1, besides the typical ring-shaped doughnut, doughnuts can come in spheres, twists, and more. Nicole Saidi Figure 1. A selection of sweets from Sublime Doughnuts in Atlanta, Georgia. Zhiyin Qin WRIT-340 As for development of flavors, some of the engineering innovations include doughnut glazer, tumbler, filler machine and more. A doughnut glazer can produce glazed doughnuts with chocolate or icing surface layer. A tumbler is a revolving drum into which doughnuts can be sent for sugar coating. Jelly filled doughnuts can be produced with a filler machine where filling is injected into the doughnuts. All of these different flavors are pictured in figure 1. Study had shown that business in the U.S. doughnut market alone valued 3 to 4 billion dollars annually [5]. This showed that doughnuts remain a popular sweet treat today. Since we have come to discuss the shapes and flavors of doughnuts today, before discussing further engineering influences in doughnut making, let’s do an overview of the modern doughnut making process to give you a little more background. Process The two common types of doughnuts are yeast-raised doughnuts and cake doughnuts. The process in making one type of doughnut is different from the other type. From figure 2, you can see a flowchart of the doughnut making process for both types of doughnuts. Zhiyin Qin WRIT-340 Figure 2. Donut Flowchart The first step in making doughnuts is mixing all the ingredients from a formulated doughnut recipe. Uniform mixing is very important. Hydrating the ingredients will cause leavening effects in the dough [6]. Cake doughnuts undergo an alkali and acid reaction to produce carbon dioxide but yeast doughnuts undergo fermentation where yeast consumes sugar in the flour to release carbon dioxide. Thereafter, the carbon dioxide causes the dough to expand and rise up. Although it takes longer, yeast provides better inflation in the dough and so yeast doughnuts have a lighter and fluffier texture than cake doughnuts. Cake doughnuts are cake-like and denser than yeast doughnuts. Referring to figure 3, Zhiyin Qin WRIT-340 when the dough is ready, it will be extruded out of the mixer through the doughnut cutter. For cake doughnuts, the batter extruded out of the cutter is directly transferred to the fryer. However, for yeast doughnuts, cut doughnut batter must undergo the proofing stage where the cut doughnuts are conditioned for transfer to the fryer. Look at figure 4 for a visual. During the frying stage, the dough loses moisture and fry oil would be absorbed. After frying, the doughnuts are to be cooled to an internal temperature of 32-35 degrees Celsius [7]. The last stage would usually be some type of coating or glazing to add sweetness to the doughnuts and for aesthetic appeal reasons. That is how ring-shaped doughnuts are generally made. The following media links can provide more detailed description and visualization of the doughnut making process and equipments. Belshaw Donut Robot® Mark 6 Doughnut System producing yeast-raised doughnuts: http://www.youtube.com/watch?v=_D2Q99X3Db8 Belshaw Donut Robot® equipment use in cake doughnuts making process: http://www.belshaw.com/donutrobot/video madehow.com Figure 3. Doughnut making: mixing and extruding Zhiyin Qin WRIT-340 madehow.com Figure 4. Doughnut making: proofing, frying and glazing Engineering Influences in Doughnut Making Continued Although the improvements in shape and flavors in addition to its delicious taste have kept doughnuts remain popular on the consumers market today, these developments might not be enough to keep it a popular consumer treat in the future. Consumers today are driven to demand food products that are lower in oil or fat content because of health concerns. Although deep-fried doughnuts are delicious sweet treats, discussion centered on their potential health hazards repeatedly catch people’s attention. As a result, new food engineering technologies that comply with both health concerns and consumer preferences are developing. Some of such technologies are vacuum frying and edible coatings or bio-films in food engineering. These developing engineering technologies might be key to keeping doughnuts popular on the consumer market when consumers are so driven for healthier food products today. Vacuum Frying Vacuum frying can possibly be an alternative to traditional frying in providing food products with reduced oil content that still retain the desired flavor and texture of Zhiyin Qin WRIT-340 traditionally fried foods. During vacuum frying, food product is heated at a pressure well below atmospheric pressure so the boiling points of oil and water in food product are decreased [8]. There are five main advantages in the vacuum frying process. They include reducing oil content in the fried food, preserve natural color and flavors of the food due to low temperature and oxygen control during the process, giving less negative effects on oil quality, decreasing acrylamide content during frying and preserving nutrients in the food [8]. Referring to figure 5, during the process, the food product will be placed in the fryer in the vacuum chamber. Then the transport belt will carry the finished product out of the fryer and into a container. Food Engineering Reviews Figure 5. Schematic diagram of semi-continuous vacuum fryer designed by Pe´rez-Tinoco et al. Unfortunately, the vacuum frying method seemed to be unrefined and imperfect for doughnuts. As study shown, the oil content of cake donuts was lower with vacuum frying than with atmospheric frying [9]. However, the oil content of yeast-raised donuts was lower with atmospheric frying in comparison to vacuum frying [9]. The doughnuts deepfried under atmospheric conditions at 140°C for 5 minutes had higher sensory scores than any of the other processing conditions for both cake and yeast-raised doughnuts. This indicated that although vacuum frying has shown to work for fruits, vegetables and other Zhiyin Qin WRIT-340 food products in providing its five given advantages compared to atmospheric frying, further research for vacuum frying doughnuts still need to be done to ensure it is indeed a better alternative method to traditional frying in terms of less oil uptake and equal or better sensory taste. Edible Coating Edible coating is another method used in food engineering processing of various food products for lower oil content. Edible coatings are directly applied to the surface of food products before frying. Edible coatings have various uses like protecting perishable food products from deterioration by retarding dehydration, suppressing respiration, improving textural quality, helping to retain volatile flavor compounds and reducing microbial growth [10]. Methylcellulose(MC) and Hydroxypropyl Methylcellulose (HPMC) are hydrocolloid coatings discussed specifically for doughnuts [10]. Another coating discussed for deep-frying doughnuts is gum tragacanth(GT) [5]. The application of these edible coatings is that they act as barrier to lipid absorption by food during deep fat frying [10]. “Cellulose derivatives like methyl cellulose exert thermogelation when heated, and on cooling, it reverts back to the solid state [5]. As a result, these coatings prevent oil absorption during deep-drying and sometimes even help doughnuts retain more moisture content because of the coatings’ hydrophilic character [5]. The “effect of coatings in preventing oil absorption is determined by its mechanical and barrier properties, which depend on its composition and microstructure, and on the characteristics of the substrate being applied to [7]”. MC coating was highly selected for doughnuts because it showed the minimal oil absorption compared to HPMC coatings. “MC coatings also have better moisture barrier Zhiyin Qin WRIT-340 performance than HPMC coatings due to the lower hydrophilic character of MC [7]”. Both MC and GT coatings are effective in reducing lipid absorption during the deepfrying of doughnuts. However, it was shown that GT coating is more effective than MC coating in preventing oil absorption during deep-frying of doughnuts [5]. Sensory evaluation results indicated that edible coatings had no significant effect on quality attributes (texture, flavor, color) of the doughnuts. Fermented doughnut with GT coating had the highest quality score in terms of taste, appearance, aroma and more [5]. Thus, it can be strongly concluded that the application of certain coatings like GT could be an alternative solution to traditional frying in order to comply with both health concerns and consumer preferences. Conclusion As shown, the technological development of the doughnut making process and equipments greatly influenced doughnut making and doughnut production. However, fried foods have been highly related to obesity and other health problems. Thus, reducing the fat content of fried foods is at focus. Improvements in reducing fat absorption during deep-frying of doughnuts have continuously been developing. Vacuum frying can potentially be used in place of traditional frying when the method is more refined and improved for doughnuts. The application of coatings is believed to be an alternative solution to traditional frying that complies with both health concerns and consumer preferences. The reason is because edible coatings appear to be an effective method for reducing oil uptake as demonstrated on studies carried out on traditional frying. Although not all of these techniques have been 100 percent refined and put to use, it is in hope that as food engineering technology advances, more and more improvements will hopefully Zhiyin Qin WRIT-340 continue to happen. For example, improvement in vacuum frying for doughnuts could possibly be achieved by combining both vacuum frying and edible coatings, resulting in doughnuts with much lower fat content but with equal or better taste than traditionally deep-fried doughnuts. Unfortunately, journals articles on the application of coating combined with vacuum frying have not been found [8]. However, further research could easily be done in the future to make doughnuts more consumer-friendly by lowering health hazards but at the same time maintain the quality and sensory tastes of doughnuts. Consequently, the public can benefit from the improvements in food engineering while doughnuts can remain a competitively popular sweet treat on the market even though consumers demand healthier food products. Zhiyin Qin WRIT-340 Reference: [1] Wayne Creekmore. "Fried Dough History." OSO-ONO. 2003. [2] David A. Taylor. "The History of the Doughnut." Smithsonian. 03 1998:1-3. [3] “Krispy Automatic Ring-King Junior Doughnut Machine.” National Museum of American History. 1997. [4] “Commissary and Industrial Donut Systems.” Belshaw. 2011. [5] Z.S. Zolfaghari, M. Mohebbi, and M.H.H. Khodaparast. (2013). Quality Changes of Donuts as Influenced by Leavening Agent and Hydrocolloid Coatings. Journal of Food Processing and Preservation, 37(1), 34-45. [6] "Cake Doughnuts." Bake Info. Baking Industry Research Trust, 2011. [7] "Yeast Raised Doughnuts." Bake Info. Baking Industry Research Trust, 2011. [8] A. Andres-Bello, P. Garcia-Segovia, and J. Martinez-Monzo. (2011). Vacuum Frying: An Alternative to Obtain High-Quality Dried Products. Food Engineering Reviews, 3(2), 63-78. [9] Hwang, J., Sung, W., & Shyu, Y. (2009). Effects of Atmospheric and Vacuum Frying on the Quality of Donuts. Taiwanese Journal of Agricultural Chemistry and Food Science, 47(5), 238-249. [10] M. Garcia, V. Bifani, C. Campos, and M.N. Martino, et al. Food Engineering:Integrated Approaches. New York: Springer, 2008. 225-41.