3. Deterioration models and gamma process

advertisement

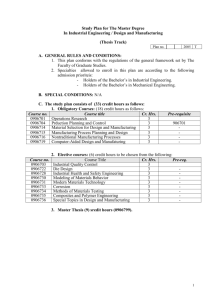

Document

Confidential

Probabilistic Framework of

Shell Non-Intrusive

Inspection Methodology

Probabilistic Framework of

Shell Non-Intrusive Inspection

Methodology

Master of Science Thesis

by Sebastian Kuniewski

Shell Global Solutions

Shell Global Solutions is a trading style used by a network of technology companies of the Royal Dutch/Shell Group.

1

Acknowledgments

The author would like to express sincere appreciation to the Delft University of Technology, where

he has had the opportunity to study for last two years. He likes to extend his sincere gratitude to the staff

member of the Risk and Environmental Modelling department (Applied Mathematics TUDelft), especially to

Prof. dr Roger M. Cooke for His support in study and life.

The author would like to acknowledge his supervisors: Dr. Svetlana Borovkova (TUDelft), Ir. Sieger

Terpstra and Kees den Hejier (Shell Global Solution) for their support, guidance and advice.

The author would also like to acknowledge Maarten-Jan Kallen, Prof. Jan M. van Noortwijk, Dr

Hance van der Weide for their help, Daniel Lewandowski and Oswaldo Morales Napoles for being good

friends and their supports.

2

Summary

Non-Intrusive inspection is often times applied during component operation processes. This

automatically reduces costs related to shutdown that occurs when internal visual inspection is necessary.

However there is inherent uncertainty related to the performance of applied inspection techniques and the

so called probability of detection has to be associated with these techniques. The use of mathematical

models is desirable for adjusting our belief about the condition of a component and/or optimization

procedures for setting inspection scheduling optimally with respect to safety and economical constrains.

The thesis reviews the literature available on reliability modelling and update of the defect size distribution

given non-intrusive inspection results. It also presents a mathematical tool for modeling deterioration of a

component, namely a gamma process. The mathematical model for wall thickness loss caused by

corrosion is proposed. The model uses a gamma process for the deterioration process and an inverted

gamma distribution for the uncertain corrosion rate. The confidence about the condition of a component is

related to the estimated maximum defect size distribution and the corrosion rate distribution. The model

enables to update the confidence about the condition of a component given non intrusive inspection results.

With new information the next inspection time is calculated. This calculation, however, is determined

considering the safety constraint only.

3

Conclusions

Throughout the report we have seen the importance of accounting for uncertainties in the process

of inspections. For instance, calculation of time inspection intervals should be based on the model which

incorporates uncertain range of the corrosion rate and the uncertainty within the corrosion development

process.

Discussion in Chapter 1 points out the importance of NDT examination. It is desirable to have a

good knowledge about detection skills of employed detection technique. The confidence that the inspection

requirements, such as expected defects are detectable, are fulfilled, is directly connected with the detection

knowledge.

Measurement errors, as is shown in the example in Chapter 1, play a significant role in assessing

safety of operating component. Under the assumption that safety is lost when the deterioration reaches the

maximum allowable value (the defect depth become unacceptable), the critical measurement needs to be

calculated. This measurement determines the upper value for inspection response data. If this value is

reached, then there is unacceptably high probability that the real defect size exceeds the maximum

allowable size. The model in Section 4.2, however, does not take measurement errors into account.

Instead, the measurement is treated as the actual defect size.

Chapter 3 points out the disadvantage of modelling degradation with a random variable model

which is currently associated with the S-NII model. The main criticism of this model is that it does not

capture variability associated with the defect development. It means that the degradation represented by a

straight line is fixed during the entire life of a component, while the degradation represented by a gamma

process is nowhere free from uncertainty. The paths of a gamma process are nowhere continuous. It

means that when we look at the value of a gamma path at time t and the value of this path at the time just

after time t, t + dt, we observe a jump. This jump is observed for every positive value of dt and its size is

random.

The model proposed for S-NII methodology presented in Section 4.2 offers properties that fit well

with the physical properties of corrosion, especially because a gamma stochastic process represents wall

degradation process due to corrosion. Additionally, the model includes uncertain range of the corrosion rate

for linear expected degradation.

Setting the parameters for the model is made similarly to the S-NII model. The parameters are

linked to the S-RBI assessments, so that the required input is entirely taken from S-RBI. The proposed

coefficient of variation c of the gamma deterioration process (this parameter corresponds to the variability of

deterioration process) is such that the process offers minimum uncertainty, which corresponds to the S-RBI

very high (VH) confidence factor. It should be noted that if the inherent uncertainty related with the

deterioration process (not the one assign for the corrosion rate distribution) is higher than S-RBI VH

confidence factor then the value of c can be chosen differently. Table 3 from Section 4.1 presents the links

between c and the S-RBI confidence factors.

For the case of components that undergo maintenance every time when a defect is detected, the

model with uncertain defect initiation can be employed. The example of such model used for maintenance

actions scheduling of the Eastern-Scheldt barrier block mats is shown in Chapter 3, Example 3.3.2.

4

Recommendations

This project had intention to design a mathematical model that integrates the uncertainties among

various branches of the S-NII methodology. Many of the important parts of the real inspection process have

not been presented in this report. One of these is for instance the so-called sampling inspection approach.

This approach amounts to choosing certain areas of a vessel or pipe that are then inspected. The inference

about degradation in the vessel is made based on investigation of the inspection results from the sampled

areas. The mathematical model that would incorporate possibility of sampling approach is desirable.

Such a model should first test the hypothesis that the chosen areas are representative for the

whole stratum of inspected item. This depends on the results found among sampled areas (spatial

distribution of defects) and the percentage of the inspected areas. If the sample area is 100% then the test

of alternative hypothesis (the chosen areas are not representative) should be rejected with probability 1.

We can also think of certain specification of defects spatial distribution. Given this distribution, the sampling

approach can be applied and the resulting data compared to the pre-specified spatial defect distribution.

Next step would be to combine the sampling approach with the model of defect development so

that the inference about the corrosion rate is made, and the confidence about presence of unacceptable

defects is achieved.

Before these steps in the model development are made, the model given in Section 4.2 needs to be

improved. As suggested in Chapter 3 (Example 3.3.1) the uncertain corrosion rate from the gamma

deterioration model can be updated given imperfect measurements. We have already seen the relevance of

measurement errors in the estimation of a component safety (Chapter 1).

The last suggestion is to employ economical constraints for the maintenance and inspection

planning. This extension is studied in Ref [3], [7], [8], [13].

5

Table of Contents

LIST OF TABLES

6

LIST OF FIGURES

7

LIST OF DEFINITIONS

9

INTRODUCTION

10

1.

12

12

16

18

18

20

20

24

24

25

27

28

NDT NON-DESTRUCTIVE TECHNIQUES

PERFORMANCE OF NDT: POD CURVE

POD ESTIMATION

2.

SHELL NON-INTRUSIVE INSPECTION AND SHELL RISK BASED INSPECTION

2.1

SHELL RISK BASED INSPECTION

2.2

SHELL NON-INTRUSIVE INSPECTION

2.2.1

S-NII Model

3.

DETERIORATION MODELS AND GAMMA PROCESS

3.1

RELIABILITY ASSESSMENT AND MODELLING DETERIORATING STRUCTURES

3.2

GAMMA PROCESS

3.2.1

Example of a discreet gamma deterioration process

3.2.2

Statistical estimation for parameters of a gamma process

1.1

1.2

3.2.2.1

3.2.2.2

Method of Maximum Likelihood

Method of Moments

28

29

3.3

APPLICATIONS OF A GAMMA PROCESS

3.3.1

Example 1

3.3.2

Example 2

4.

GAMMA DETERIORATION MODEL FOR S-NII MODEL

4.1

GAMMA DETERIORATION MODEL (CASE 1)

4.2

GAMMA DETERIORATION MODEL WITH UNCERTAIN CORROSION RATE (CASE 2)

4.2.1

Updating the model parameters

REFERENCES

30

31

34

37

37

44

49

52

APPENDIX A:

53

APPENDIX B:

55

APPENDIX C: SOFTWARE MANUAL 1

58

APPENDIX D: SOFTWARE MANUAL 2

62

DISTRIBUTION

63

6

List of tables

Table 1.

Links between S-RBI and S-NII confidence parameters......................................

22

Table 2.

Links between S-RBI consequences of failure and S-NII minimum integrity

levels....................................................................................................................

23

Links between S-RBI confidence factors and parameters of the gamma

deterioration process............................................................................................

39

Links between S-RBI consequences of failure and S-NII minimum integrity

levels. The case of the gamma deterioration model............................................

43

S-RBI confidence factors and the gamma deterioration model with uncertain

corrosion rate.......................................................................................................

48

Table 3.

Table 4.

Table 5.

7

List of figures

Figure 1.

Probability of detection curve............................................................................

13

Figure 2.

Example of data received from NDT under examination. The dashed lines

indicate the statistical estimates for confidence bounds...................................

13

Figure 3.

Illustration of the critical measurement of a defect size....................................

15

Figure 4.

S-RBI Determination of inspection frequency...................................................

19

Figure 5.

S-NII model for wall thickness loss over time caused by degradation

mechanisms......................................................................................................

21

Figure 6.

S-NII integrity curve..........................................................................................

23

Figure 7.

Figure shows linear mean function (dashed read line), 97.5% quantile of a

gamma process with µ = 1 and medium confidence factor (blue full line), and

2µt (blue dashed line).......................................................................................

39

Illustration of the five defect depth densities. Each represents different

confidence class. The maximum allowable defect depth is 10.........................

41

Illustration of a linear wall deterioration model. The model with a gamma

deterioration process........................................................................................

41

The lifetime cumulative distribution functions for all confidence factors. The

Remnant life is equal to 10. The vertical line crosses each distribution at the

value equal to the exceedance probability........................................................

42

The tails of a lifetime distributions in log10 scale. The Integrity curves,

y = 10................................................................................................................

43

Illustration of linear wall deterioration, were the deterioration process is a

gamma deterioration process and uncertain corrosion rate is represented by

a distribution function........................................................................................

45

Gamma density with the mean 10 and c=0.2305 (H) together with the

average deterioration densities with c=0.2305 (H) and v1= 3.0042, v2=

0.3984, v3= 0.0938. The mean of each distribution is equal to 10...................

47

Defect depth distribution is located according to the confidence classes. The

estimated defects grow is 1, and the corrosion allowance level is

10......................................................................................................................

49

Update of the expected defect depth distribution. The case when: no defects

detected and the expected defect depth distribution’s 90% quantile is bigger

then q0.9 of POD................................................................................................

50

The expectations of corrosion rates (dashed lines) after and prior to

update...............................................................................................................

51

The input date that includes the specification of the corrosion rate estimate,

the maximum corrosion allowance level, the minimum integrity level, the

maximum time t for the calculation, POD and inspection

results...............................................................................................................

59

Figure 8.

Figure 9.

Figure 10.

Figure 11.

Figure 12.

Figure 13.

Figure 14.

Figure 15.

Figure 16.

Figure 17.

8

Figure 18

For a given specification of the uncertain maximum defect depth range (total

factor) and the mean Mu·t (left-upper corner), the program calculates the

deterioration model input parameters v and c...................................................

62

9

List of Definitions

Def 1.

A gamma random variable...................................................................................

25

Def 2.

An inverted gamma random variable...................................................................

26

Def 3.

A stochastic process............................................................................................

26

Def 4.

A gamma process................................................................................................

26

10

Introduction

In the oil industry a lot of attention is given to inspection of steel components, such as vessels,

pipes and so on. The major cause of deterioration of steel components is corrosion. Corrosion can be

defined as the reaction of a material to its environment. A material can interact chemically,

electrochemically and sometimes mechanically with the environment in which it is placed. Therefore,

corrosion must be considered at the design stage, during operation and throughout the maintenance of

plant and equipment. Control of corrosion is an issue that must be addressed, as failure to do so results in

corrosion damage and failure of plant and equipment.

Methodologies that have been developed for planning inspections (where and when to inspect)

require certain knowledge about corrosion. In general, the process of corrosion (degradation of material) is

uncertain. This uncertainty significantly affects the inspection planning, especially when assessing the

corrosion mechanisms and setting the inspection times. The methodologies are designed to be of the form

of recursive routines. This means that inspection results influence further inspection planning. At this stage

we see that, if the inspection results are imperfect (uncertain), then the new planning should take into

account this uncertainty. In general, the inspection planning should be based on the knowledge about

component’s degradation mechanisms, and, if the resources of this knowledge are limited (not enough

data), the planning should take into account expert’s assessments about the distribution of the degradation

process.

Over the last decades, there has been an increased interest in the so called non-intrusive

inspections. Methodologies for inspection planning that employ non-intrusive techniques for degradation

detection need special attention regarding uncertainty. Within Shell the so-called Shell Non-Intrusive

Inspection (S-NII) methodology has been developed. This method provides guidelines for inspection

planning design. These guidelines consider the specification of an inspection target, the detection

technique that has to be employed and the scheduling of the inspections. The aspect of uncertainty within

this methodology needs to be captured with a mathematical model. The model should be able to account

for all uncertainties from the various branches of the inspection process.

The intension of this project is to design such a mathematical model for integrating some possible

uncertainties within the S-NII methodology. The model of interest should provide measures for the following

issues:

How the inspection results contribute to updating the corrosion rate estimate?

How the inspection results contribute to updating the confidence regarding corrosion rate

estimate?

What is the effect of measurement errors on the maximum defect size estimate and how it

contributes to the confidence regarding safety?

What is the effect of the detection technique accuracy on the confidence regarding

presence of defects?

In order to fulfil this task an introduction into relevant issues regarding S-NII methodology is given.

First, in Chapter 1 the reader gets acquainted with the basic knowledge about non-intrusive techniques.

After that, the main uncertainties that are related to the performance of these techniques are introduced.

Chapter 2 provides the description of the mathematical model used by S-NII methodology. This

methodology was designed for the inspection of a particular component in a plant. Assessment of the

parameters in the model is linked to a more general inspection planning methodology, called Shell Risk

Based Inspection (S-RBI). Chapter 2 introduces these two methods and points out the links between S-RBI

assessments and S-NII model parameters.

General mathematical models for components reliability are discussed in Chapter 3. Knowledge

about the reliability of a component is crucial for planning inspections. For that reason the component

reliability is modelled with mathematical tools, and given the inspection result, this reliability is updated. The

discussion about disadvantages of the mathematical model currently used by S-NII is given, and as an

alternative for deterioration modelling, the gamma stochastic process is proposed.

11

Chapter 4 introduces the gamma deterioration process as the main tool for the S-NII model. We

can observe in this chapter that setting the model parameters is done in a similar fashion as in the model

presented in Chapter 2. Inspection measurements of the actual degradation are used, so that the

knowledge about the degradation phenomenon (corrosion rate) behaviour is incorporated within the model.

This in turn will contribute to update of the corrosion rate and the “confidence” regarding this rate. The

model provides the so-called next inspection time interval. This time value indicates the time during which

there is an “acceptable” small probability of observing a defect larger than the critical defect. The detection

accuracy is taken into account by means of the probability of detection curve. This represents the fact that

in the case of no detection, the confidence regarding absence of defects is increased only up to a certain

level.

The summary and conclusions are given at the beginning of the report. Recommendations, which

describe the issues that have not been taken into account in this project, and that could be dealt with in

further research, are also presented at the beginning of the report.

12

1. NDT Non-destructive techniques

Non-destructive techniques are the basic tool for inspecting defects related to internal degradation

of a vessel’s wall thickness. Throughout many years these technique were employed for carrying out nonintrusive inspections. The studies and projects for development of better techniques were conducted and

the use of those techniques is more and more appreciated.

Among many advantages of non-intrusive inspection methods, the two most valuable are that the

inspection can by carried out during the system operation state (what significantly influence the costs of an

inspection) and a component is not exposed to mechanical damages related to its preparation for visual

inspection (a component should be taken out of operation, opened and cleaned). Another issue is that for

some components, non-destructive inspection is the only feasible inspection.

However, none of non-destructive techniques is perfect. Those techniques provide detection of

defects and/or measurements of a wall thickness or defect size that most of the time are uncertain. In order

to measure the extent of uncertainty an investigation of a technique’s performance has to be conducted and

the meaning of response data interpreted. As a result of this investigation, a technique receives probability

of detection (POD) curve, which corresponds to probability of detecting a defect with a given size. For

techniques that provide quantitative respond (measurement â of a real defect size a), the measurement

error may be calculated from the data collected during examinations.

This chapter provides a discussion about the use and importance of POD and measurement errors

in mathematical models for reliability assessment. In Section 1.1 an example of updating the defect size

distribution is shown. The update is based on uncertain information from inspection that uses NDT. The last

paragraph discuses the estimation of POD. The discussion is based on Safizadeh, Forsyth and Fahr [1].

1.1 Performance of NDT: POD curve

The application of a non-destructive technique requires certain specifications of its performance.

Two main uncertainties are related to a given NDT. One uncertainty regards the detection of a defect itself.

This uncertainty should change relatively with the size of a defect (big defects are detectable with higher

probability). The characterization of the detection performance is given by probability of detection curve

(example of a probability of detection curve (POD) is shown in Figure 1). This curve is obtained by

experimentally testing detection skills of a technique (short discussion about POD estimation is presented

in paragraph 1.2 of this Chapter).

The second uncertainty is the measurement error. Because the NDT response data are usually

uncertain, the specification of confidence bounds for this uncertainty is advisable. From tests of NDT

performance conducted on a specimen the response data are collected and statistical inference about

measurement errors is made. Usually the measurement error, denoted by ε, is assumed to be normally

distributed with mean zero and standard deviation . In some cases, when a technique has tendency to

over- or under-estimate the true defect size, the error mean is chosen to capture the badness of estimation.

Let xm be a measurement of the maximum defect depth. The actual maximum defect depth X is

defined as:

X xm ,

where

N (0, ) .

(1.1)

13

Figure 1. Probability of detection curve

Figure 2. Example of data received from NDT under examination. The dashed lines indicate the

statistical estimates for confidence bounds.

Figure 2 presents an illustration of defect size measurements versus the actual defect size. From

these data, statistical estimate of is made.

In order to show the importance of measurement errors and POD curve in modelling a component’s

reliability, we present, as an example, the model proposed in (Zheng, Ellingwood [2]).

Consider an operating component that is subject to degradation. The criterion of its safe operation

is defined by the maximum allowable size of degradation. When the actual size of degradation exceeds

maximum allowable size, then the component is assumed to fail. This event is called failure event. If the

actual defect size (degradation size) is uncertain, then we say that the component is under big or

unacceptable risk of failure if the probability of a failure event is at least equal to the critical predetermined

probability. We have:

14

P( y X 0) pcr ,

(1.2)

where y is the maximum allowable defect size, X is the actual defect size and pcr is the critical probability.

Given that only an uncertain measurement is available, the following questions arise:

What is the actual defect size?

Has the component reached its unacceptable risk of failure?

If the measurement would be perfect then the actual defect size becomes deterministic and at the

time when the measurement is taken we would have that X=xm. It would be easy then to verify whether

y xm 0 or not.

Unfortunately, the measurement includes an error, and given that, the target information might be

to determine the critical measurement. The critical measurement is the largest measurement such that, for

a given error size, the probability that the actual defect size X is less than y, is on the boundary of

acceptability. This situation is presented below.

Continuing as suggested in [2], we assume that the relationship between actual and measured

defect size is given by (1.1). Then we have that:

P( y X 0 | xm ) 1 P( X y | xm ) .

(1.3)

Substituting (1.1) into (1.3) we obtain:

1 P( y xm ) 1 y xm ,

(1.4)

where is the standard normal cumulative distribution function.

Being consequent with the criterion of safety (1.2) we set (1.4) to be the value of the critical

probability pcr:

y xm 1 pcr .

(1.5)

Taking the inverse of the cumulative distribution function (CDF) , we get that the critical

measurement

xcrm is given by:

xcrm y 1 (1 pcr ) .

(1.6)

For example: choosing pcr to be equal to 0.025 we have that the critical measured size is

approximately:

xcrm y 2 .

(1.7)

15

Figure 3. Illustration of the critical measurement of a defect size

Figure 3 presents an illustration of the critical measurement. We can see that the measurement xcrm

is the largest measurement for which the upper confidence bound (on the axis of actual defect depth)

reaches corrosion allowance level y.

As mentioned in the beginning, the application of any NDT technique is imperfect from two points of

view. One is that it provides uncertain measurements, and the other one is that the capability of detection is

poor for smaller defect sizes. The situation when no defect is detected does not necessarily mean that no

defect is present. Continuing with the example of the model presented in [2], the update of actual maximum

defect size distribution given POD curve can be done as follows:

Let

f X ( x) be the prior probability density function (PDF) of defect size. The conditional posterior

CDF of defect size is then:

P( X x | D)

where

P({ X x} D)

,

P( D)

(1.8)

D is an event that no defects has been found.

The numerator of (1.8) is given by:

x

P({ X x} D) 1 POD( s ) f X ( s )ds

0

and the dominator:

(1.9)

16

P( D) 1 POD( s ) f X ( s )ds .

(1.10)

0

Hence, the posterior PDF of defect size, given no detection, is:

f X ( x | D)

1 POD( x) f X ( x)

1 POD(s) f

X

.

(1.11)

( s)ds

0

The proposed method is aimed at updating the knowledge about defect size based on what is

learned during an inspection. However, one might be interested in updating the defect growth as well. In

practice this is difficult [2].

It should be noted that, for the update of the defect growth, the measurements at least at two points

in time have to be taken (required information for updating the growth of a defect is the time of a defect

growth and the defect’s increment). For that reason the stochastic process of the defect size has to be

considered. The model proposed by Kallen and van Nortwijk [3], however, considers the situation when the

update of the defect growth is performed based on imperfect measurements. The short discussion about

this model is given in Chapter 3, where the gamma stochastic process is discussed.

1.2 POD estimation

An important part of the inspection process is the determination of an NDT reliability. We know that

a technique’s performance is summarized within its POD curve and the design of an inspection process 1 as

well as the update of an actual defect size relies on this curve. Therefore it is essential to know how

confident one can be about the validity of a POD curve.

In this section we discuss the effect of flaw size distribution on the estimate of POD curve. The

discussion is based on Ref. [1].

To examine an NDT performance engineers conduct certain experiments. During those

experiments NDT data are collected and the POD curves are estimated. One can ask the following

question: what are the requirements for the examination process to achieve a sufficiently reliable POD

estimate? This question is rather difficult to answer. There are some techniques for which it is very hard to

judge whether the POD estimate is sufficiently rich for indication of detection performance.

This section, however, does not intend to answer the question of sufficiency of estimated POD. The

intension is rather to stress the fact that the whole inspection process with employed NDT is surrounded by

uncertainty and even the POD estimation from NDT examination may be not free from uncertainty.

Ref. [1] discuses the effects of flaw size distribution on the estimate of POD curve. The NDT

performance is examined using engineered specimen. Notice that in the case of complex geometries,

specimen manufacturing may be a significant portion of the cost of entire POD experiment, and it is

therefore desirable to choose the optimal set of flaw sizes to be produced to achieve the best estimate of

POD.

Because it is not possible to know the transition region of the POD prior to experiment, it may be

reasonable to uniformly distribute flaw sizes between the minimum and maximum of the size of potential

1

The following question has to be answered in the design of non intrusive inspection process: Does the performance

of a technique fit with the required detection skill?

17

interest. However, the knowledge about the distribution of a number of defects may influence significantly

the POD estimation. This is the main result of Ref. [1] and its summary is given below.

First, the ‘true’ or ‘underlying’ POD curve is chosen. The authors explain that this is done by

following the convention proposed by The United States Air Force MIL-HDBK-1823. This convention says

that for the system that provides quantitative response, measurement â of a flaw size a, the specimen for

testing the NDT performance that contain at least 40 flawed sites is recommended. The system that

provides only hit/miss (detect/no detect) data needs at least 60 flawed sites distributed among the

specimen. It also suggests that the flaw sizes should be uniformly distributed on a scale covering the

expected range of the region of the POD function.

MIL-HDBK-1823 also notes that very large flaws and very small flaws provide very little information

about POD. Therefore, it is important to maximise the number of flaws in the transition region 2 of POD.

An inspection was simulated; testing the specimen of 50 uniformly distributed flaw sites. From the

collected data the ‘underlying’ POD function was established by estimating two parameters form the

cumulative lognormal curve. Next, the estimation of PODs for different distributions of flaw size and

different number of flaws was made.

The uniform, lognormal and Rayleigh3 flaw sizes distribution are considered, with the 20, 15 and 10

number of flaws. For estimation of PODs the tests were performed 100 times. During each test the error

between ‘underlying’ POD and estimated POD was calculated as the area between those curves, and the

mean error form 100 trials computed.

The conclusion of Ref. [1] is that the Rayleigh distribution of flaw sizes provided the most accurate

estimate of POD for fixed number of flaws. The result with less accuracy was found for the lognormal

distribution, and the worst result for the uniform flaw size distribution (the biggest error).

The authors do not say that the number of flaws used (20 and less) is sufficient for determination of

NDT reliability. However, they say, in many practical situations decisions must be made based on limited

resources.

The article [1] shows that for a different distribution of flaw sizes the different estimation of POD can

be achieved. This indicates that the attention should be focused on the NDT examination in designing and

performing the tests.

The result of examination of NDT performance is relevant in the inspection planning design

process. An NDT is applied to detect certain defects. Engineers decide what techniques have to be

employed based on expectation of defects and the techniques performance. If the technique performance

is under-estimated then there may be misleading in the confidence about a condition of inspected

component.

2

3

The transition region of a POD curve is a region where the POD values change form near zero to near one.

x2

The Rayleigh probability density function given parameter b is defined as: f ( x | b) x e 2b2 .

b2

18

2. Shell Non-Intrusive inspection and Shell Risk Based

Inspection

During 1990’s, the Shell Risk Based Inspection (S-RBI) methodology was developed. This

methodology is aimed at planning inspections that are applicable to all vessels. The methodology is fully

presented and described in the S-RBI manual [4]. Additionally, an approach to apply non-intrusive

inspection (NII) techniques was developed, called Shell Non-Intrusive Inspection (S-NII) methodology. S-NII

training manual [5] provides the entire inspection planning process for all components, for which nonintrusive techniques are feasible or not feasible.

The S-RBI determines which particular plant item should be inspected and how often, while S-NII

addresses how a particular plant item should be inspected in terms of invasive or non-invasive inspection,

what inspection method should be applied (e.g. visual, ultrasonic, radiographic etc) and which areas of the

vessel should be inspected.

This chapter provides a short overview of the methodologies previously mentioned and points the

links between S-RBI and S-NII. The discussion on the links between S-RBI and S-NII is given in (MCConnell

[6]).

2.1 Shell Risk Based Inspection

An RBI program suggests that the inspection effort should focus on those pieces of plant where the

risk of failure is greater, or where inspection will lead to the maximum practicable risk reduction. The basic

aspects of inspection planning are established within the S-RBI process. This section presents the basics of

the S-RBI process: the main focus is made on the elements that overlap the S-NII method.

In the first place, when starting the design of an inspection process, the plant engineers make an

assessment about the parts of the plant, equipment, or a vessel 4, which are subjects to certain degradation

mechanisms. This assessment is called corrosion loop assessment. The next step is to determine the

factors that contribute to the calculation of inspection frequency (Inspection Interval Factor (see Figure 4)).

The Inspection Interval Factor is calculated for the parts of a plant that belong to one corrosion loop. For

this, the assessments of Susceptibility to failure, Consequences of failure and Confidence Rating are made.

The first two define the Criticality Matrix (Figure 4).

4

A vessel is divided into several chambers. Each chamber usually contains different toxins, which cause different

degradations. Therefore a vessel can be a part of more then one corrosion loop.

19

Figure 4. S-RBI Determination of inspection frequency

The susceptibility to failure is assessed by a qualified expert team that classifies this variable within

four classes: ‘Negligible’, ’Low’, ’Medium’ and ’High’. The chosen class represents the component’s

sensitivity to degradation, and consequently its chance of failure.

The assessment of the consequence of failure considers aspects such as safety and health,

possible environmental damages and economics losses.

Those two parameters define the so called Criticality Matrix. This is a 4x4 matrix with cells ranging

form ‘Negligible’ to ‘Extreme’ criticality or risk of failure.

The Confidence Rating reflects the confidence in the degradation mechanisms that are under

prediction. This has been classified within three categories5: ‘Low’, ‘Medium’, ‘High’, and directly depends

on the available information about the degradation of the same or similar vessels in the same or similar

service.

The last parameter that is required for calculating the maximum inspection interval is the actual

corrosion rate (CRa). CRa is the parameter which indicates the ‘fastest’ rate of wall thickness degradation

(the coefficient in the linear function on Remnant Life Plot, Figure 4) and consequently this rate influences

the determination of the inspection frequency. CRa is given by an assessment. The assessment is based

on the literature or the corrosion monitoring data form similar plants (where available).

Given CRa, the nominal wall thickness and minimum wall thickness6 (nomWT and minWT

respectively on Remnant Life Plot, Figure 4) one can calculate TRemnant Life (Remnant Life Time), by the

formula:

TRemnant Life (nomWT - minWT)

CRa

.

(2.1)

The classes given by criticality matrix together with confidence ratings provide an inspection

interval factor matrix. The cells of this matrix multiplied by the Remnant Life Time generate the maximum

5

The three classes given above are the main classes of confidence. It is also the case that the confidence rating is

extended to five classes ranging form ‘Very High’ to ‘Very Low’.

6

Usually the minimum wall thickness is provided by the manufacturer of a component.

20

inspection interval. Those intervals are considered as the upper boundary for timing the inspection

frequency.

2.2 Shell Non-Intrusive Inspection

A NII program is primarily based on defining the particulars of the inspection. This ranges from the

definition of inspection to detailed specification about the inspection itself. The inspection planning process

among other things includes the definition of the inspection purpose, assessments of corrosion and other

mechanisms governing degradation, inspection design (e.g. inspection intervals), implementation, analysis

of non-destructive techniques employed (Chapter 1) and overall confidence evaluation.

The use of mathematical models is particularly appreciated in the overall confidence evaluation, in

the calculation and updating of the corrosion parameters, and calculation of time inspection intervals.

In this section the current S-NII model is presented and the links between S-RBI corrosion

parameters and S-NII model input parameters are explained.

2.2.1 S-NII Model

The S-NII model makes use of a normal probability density function to account for uncertainty

associated with the real degradation (maximum defect depth at time t) and the assessment (prediction) of

the ‘worst case’ degradation (CRa given by S-RBI).

The model assumes a linear defect growth in the depth dimension (loss of a wall thickness) over

time and also that defects start to grow form day one (time t = 0). This situation is shown in Figure 5, where

a picture of the wall thickness with its nominal value and minimal acceptable value (nom and min

respectively on the vertical line at the bottom picture, Figure 5) is presented. The degradation scenario is

indicated by the two lines: dashed line is the actual wall loss given by S-RBI (CRa) and full red line is the

average wall loss (CRo in the S-NII model).

The degradation process Xt is represented as a linear function in time. The process is defined as

follows:

X t WTnom CR t ,

where CR is normally distributed corrosion rate,

(2.2)

WTnom is a nominal wall thickness and t is the time. The

expectation and variance of the Xt can be found in Appendix B.1.

21

Figure 5. S-NII model for wall thickness loss over time caused by degradation mechanisms

The model parameters are established by relating the actual corrosion rate (CRa) from S-RBI with

the S-NII average corrosion rate (CRo) and confidence ratings (S-RBI) with the width of the corrosion rate

density. This is done in the following way:

The confidence rating is associated with the range of the corrosion rate density and with the socalled exceedance probability. The meaning of exceedance probability is given below as well as its relation

to the parameters of the corrosion rate density.

The range of the corrosion rate density, for each confidence factor, is presented in the third column

in Table 1 and is determined relatively to the mean (CRo) of the density. The standard deviation of this

density ‘ ’ is fixed relatively to the mean by the use of the coefficient of variation p. The coefficient p is

named by the predictability factor:

CRo

p

(2.3)

The values of the predictability factor p are shown in Table 1 (second column) and are determined

in the following way (we present an example for calculating p for the medium confidence rating):

Let CR denote the corrosion rate ( CR ~ N CRo,

CRo

). Then for the medium confidence factor

p

(after standardizing our normal random variable) we have that:

2 CRo CRo

P CR 2 CRo P N

P N p 0.975 ,

CRo

p

and consequently

(2.4)

p q0.975 2 , where q0.975 is 97,5 % quantile of the standard normal distribution.

22

Table 1. S-RBI and S-NII confidence parameters.

S-RBI

Confidence factor

S-NII

Predictability factor p

The range of a

distribution

Exceedance probability

Very High

10

P{X<1.2·CRo}=0.975

0.1

High

4

P{X<1.5·CRo}=0.975

0.2

Medium

2

P{X<2·CRo}=0.975

0.3

Low

1

P{X<3·CRo}=0.975

0.4

Very Low

0.4

P{X<6·CRo}=0.975

0.5

The exceedance probability is the probability of a proportion of defects that would exceed the

minimum wall thickness at the remnant life time. For each confidence factor this probability is fixed and the

values are shown in Table 1. The exceedance probability and the actual corrosion rate CRa (S-RBI) are

used for determining the average corrosion rate CRo. We have that:

P{CR TRemnant Life WT min} P{CR TRemnant Life CRa TRemnant Life }

P{CR CRa} Exceedance probability .

(2.5)

Standardizing normally distributed CR in (2.5) gives:

CRa CRo

P N

Exceedance probability ,

CRo

p

(2.6)

and finally:

CRa CRo

q1-Exceedance probability .

CRo

p

(2.7)

The parameters CRo and p of the corrosion rate density are determined by (2.4) and (2.7), where

the required inputs are the actual corrosion rate (CRa) and the confidence factor (S-RBI).

Next, the concept of the integrity curve is introduced. The integrity curve is a function of time. At

every time t the integrity represents the probability of observing an unacceptable defect. The integrity at

time t is defined by the following probability:

P CR t WT min .

(2.8)

Notice that the probability (2.8) at the remnant life time is equal to exceedance probability given in

Table 1.

The integrity is plotted in the log10 scale against time and the resulting function (integrity curve) is

shown on the bottom picture in Figure 6.

23

Figure 6. S-NII integrity curve

As we have in the S-RBI method, the determination of inspection frequency depends, among

others, on the consequences of failure. This factor also appears in the S-NII model and is represented by

so-called the minimum integrity level. The links between S-RBI consequence class and S-NII minimum

integrity level are shown in Table 2.

Table 2. Links between S-RBI consequences of failure and S-NII minimum integrity levels.

RBI

Consequence class:

Minimum

Integrity Level:

Negligible

10-1

Low

10-2

Medium

10-3

High

10-4

The minimum integrity level determines the maximum allowable probability of having an

unacceptable defect. With this criterion the inspection time interval can be calculated. The maximum time

value for the inspection time interval is calculated by solving the equation (2.9) with respect to time t:

P CR t WT min MIL ,

(2.9)

where MIL is the minimum integrity level.

The S-NII model takes as input the parameters that are associated with the S-RBI method. The SNII methodology is design such that the knowledge gained with the inspection results is used as a feedback

to update the corrosion parameters. Planning of next inspection time is directly related with the corrosion

rate parameters. Therefore, it is desirable to extend the S-NII model so that it is be able to update corrosion

parameters, especially the corrosion rate and the confidence factor.

The next chapter proposes to use a gamma deterioration process. The gamma model and the

procedure of updating the corrosion rate density is presented and discussed.

24

3. Deterioration models and gamma process

Section 3.1 gives reference to articles with an overview on the deterioration and maintenance

modelling. The discussion about inadequate tools that are used for modelling deterioration, such as

Brownian motion, is also given and the disadvantages of the currently employed by S-NII methodology

mathematical model are highlighted.

Then we give an introduction to gamma processes and their properties, which justify the application

of such processes for deterioration models. Additionally, the two methods for statistical estimation of the

gamma process parameters are presented in section 3.2.2.

The chapter concludes with two examples of gamma deterioration models. Example 1 shows a

gamma deterioration process with uncertain input parameter, which represents corrosion rate. The

uncertain corrosion rate updating procedure, which is based on imperfect inspections, is also shown.

Example 2 shows the model for calculating reliability of the Eastern-Scheldt barrier block mats. The model

combines the processes of a defect development and random initiation of defects.

3.1 Reliability assessment and modelling deteriorating structures

References (van Noortwijk [7], Frangopol, Kallen, van Noortwijk [8]) provide an overview on

deterioration and maintenance modelling. In both papers authors discuss a general way of modelling the

system reliability. The reliability usually is assessed with the help of deterioration and decision models. The

deterioration model is used to approximate and predict the actual process of aging. The decision model

uses the deterioration to determine the optimal inspection times. In many cases a cost-optimal inspection

frequency is additionally determined. In the content of references [7] and [8] reader can find an introduction

to gamma stochastic processes for modelling deterioration, and economical and safety constraints for

decision models.

The literature on mathematical models for time-dependent reliability of a structure proposes various

approaches to modelling deterioration. For example, (Ebrahimi [9]) uses Brownian motion (Wiener

process). The deterioration process in [9] is defined by a stochastic differential equation, for which the

solution is a geometric Brownian motion.

Although the geometric Brownian motion is positive (what seems reasonable for representing the

deterioration process), its paths are not monotonic. For this reason, the geometric Brownian motion or

Brownian motion with drift is inadequate for modelling deterioration which is monotone. The more

appropriate use of Brownian motion is to model exchange values of shares (Black-Scholes model) or

movements of particles in fluids or air.

The next approach for deterioration models is the so called random variable deterioration model

(van Noortwijk, Pandey [10]). In this approach we have typically that a degradation model is included in the

resistance of a component, such as:

Rt R0 A t ,

where

(3.1)

R0 is the initial resistance, A is the random rate of degradation and t is the age of the

component. Next, the state function g is defined as the difference between the structure or component’s

resistance Rt and the applied load or stress S:

gt Rt S .

(3.2)

25

The component or structure is considered to operate safely as long as

gt 0 and unsafe

otherwise. The time t when gt = 0 is called the lifetime of a component, and the value of the g function at this

time is called the failure-limit state of the g function.

The distribution of a lifetime can be obtained from the relation:

t

R0 S

,

A

(3.3)

and it can be derived analytically or numerically depending on the probability distribution of R0, S

and A.

The degradation model presented in (1.1) can be technically considered as a stochastic process.

However, its sample paths are fixed (e.g. linear) over the entire component’s lifetime. The model is free of

temporal variability associated with evolution of the degradation process. In fact, as is explained in [10], the

future sample path in the linear degradation model becomes completely deterministic after a single

inspection that provides the measurement of the degradation. Moreover, under the assumption that the

degradation starts at fixed time, the single inspection can determine the remaining lifetime of the

component without any uncertainty.

The random variable model is currently used by the S-NII method, where the deterioration process

(defined in (2.2)) resembles (3.1) above. This counts as a disadvantage of the current S-NII model, since

the uncertainty associated with the degradation evolution over time is an important consideration for the

determination of inspection time intervals and also for updating the deterioration behaviour.

3.2 Gamma process

This section introduces a gamma stochastic process. Before its definition is given, we proceed with

related topics, such as definition of a gamma random variable and a stochastic process. In this section the

concept of an inverted gamma random variable is introduced. The distribution of this random quantity is

used in two examples presented in the next section (3.3) and also in the model for wall thickness in Chapter

4. After that we show a number of reasons why a gamma process is suitable for modelling deterioration. An

example of the cumulative damage that may occur only on fixed units of time illustrates this suitability. The

last section presents two statistical methods of parameter estimation for a gamma process. This section is

based on (van Noortwijk, Pandey [10]).

To formally define a gamma process we first need to define a gamma distributed random variable:

Definition 1.

We say that a random variable X is gamma distributed with shape parameter 0 and scale

parameter 0 (and denote X ~ ga ( x | , ) ) if its probability density function is given by:

ga( x | , )

1 x

x e I{ x 0} ( x) ,

( )

where the gamma function ( ) is defined as

( ) x 1e x dx ,

0

26

and

I A ( x ) is the indicator function, which takes value one if x A and zero otherwise.

The derivation of the moments of a gamma random variable can be found in Appendix A.1.

Next definition introduces an inverted gamma distribution. This distribution is used across the thesis

in presented models.

Definition 2.

We say that a random variable X is inverted gamma distributed with shape parameter 0 and

scale parameter 0 (and denote X ~ Iga ( x | , ) ) if its probability density function is given by:

1

1

Iga ( x | , )

( ) x

e x I{ x 0} ( x) ,

where ( ) is a gamma function and I{ x 0} ( x ) is an indicator function, as in definition 1.

The derivation of the moments of an inverted gamma random variable can be found in Appendix

A.2.

The inverted gamma distribution is obtained by the inverse transformation of the argument of a

1

gamma distribution. I.e.: a random variable X is inverted gamma distributed if X is gamma distributed.

The next definition introduces a stochastic process. The definition is taken from the reference (Z.

Brzezniak, T. Zastawiak [11]).

Definition 3.

A stochastic process is a family of random variables ( X t ) parameterized by

When T is an interval (typically T [0, ) ), we say that

process. When T

t T , where T

.

X t is a continuous-time stochastic

1, 2,... , we say that X t is a discrete stochastic process (i.e. a sequence of

random variables).

Having defined a gamma distributed random variable and a stochastic process we can define a

gamma stochastic process:

Definition 4.

(t )

t 0 and (0) 0 .

A gamma process X t ; t 0 with shape function (t ) 0 and scale parameter 0 is a

Let

be non-decreasing, left continuous, real-valued function for

continuous-time stochastic process with the following properties:

(ii)

X 0 0 with probability one,

X X t ~ ga( x | ( ) (t ), ) for t ,

(iii)

X t has independent increments.

(i)

Notice that the second condition in the above definition guarantees that the increments of a gamma

process are always positive. This is because the gamma distributed random variable is positive. From

practical point of view it means that the degradation process, which is monotone (the amount of

degradation always accumulates), can be represented by a gamma process, which is monotone too.

27

The third condition in Definition 4 corresponds to the Markov process property. Markov process,

roughly speaking, is a stochastic process with the property that, given the value of Xt, the values of Xτ,

where t , are independent of the values of Xu, u t . That is the conditional distribution of the future Xτ,

given the present Xt and the past Xu, u t , is independent of the past. Deterioration is usually assumed to

be a Markov process.

3.2.1 Example of a discreet gamma deterioration process

To familiarize ourselves with gamma process and it’s suitability for modelling deterioration, we

illustrate it on an example of the degradation that occurs only at fixed points in time (t = 1, 2, 3,…).

Let us assume that

( X i ; i ) is an infinite sequent of independent exponentially distributed

random variables:

X i ~ exp( ) .

(3.4)

These random variables represent the increase in degradation per unit of time. Every increase in

degradation is independent of other ones. The total degradation at time n is defined as a sum of n

exponential random variable (a sum of n increments of degradation):

n

Sn X i .

(3.5)

i 1

It can be proven that the probability distribution function of the total degradation at time n, Sn, is

gamma with parameters n and λ:

f Sn (s) ga(s | n, )

n

(n 1)!

s n1e s .

(3.6)

The readers interested in the proof of this fact are referred to (T Bedford, R M Cooke [12]. Page 61,

theorem 3.6), where the convolution (the sum) of two independent gamma distributed random variables, is

proven to be again gamma random variable.

Clearly in the example above we have that Sn is the sum of n exponentials, which in fact, is the sum

of n gammas with parameters 1 and λ. Given this, we assume that the sum of n-1 gammas is again

gamma, and by theorem 3.6 (Ref. [12]) the sum of n-1 gammas and gamma is again gamma. This and the

mathematical induction imply that for every natural n the sum of n gamma random variable is again gamma

random variable.

The above example shows that the cumulative effect of deterioration at certain time, where the total

deterioration is caused by the independent exponentially distributed deterioration increments, can be model

with a gamma distribution (discrete gamma process).

28

3.2.2 Statistical estimation for parameters of a gamma process

The last part in this section presents the two most common methods of parameter estimation for a

gamma process, namely Maximum Likelihood and Method of Moments. First, a gamma process with shape

function (t ) ct and scale parameter is considered. We assume that the value of b is known (b = 1

represents the linear deterioration), but c and u are unknown. In order to apply the gamma process to a

practical example, the estimation of parameters is made on data that consists of inspection times ti, i = 1,…,

n, where 0 = t0 < t1 < … < tn, and corresponding observations of the cumulative deteriorations xi, i = 1 ,…, n,

where 0 = x0 ≤ x1 ≤ … ≤ xn. The derivation of presented formulas can be found in (van Noortwijk, Pandey

[10]).

b

3.2.2.1 Method of Maximum Likelihood

The likelihood function of the observed deterioration increments i

product of independent gamma

xi xi 1 , i = 1,…, n, is a

densities7:

n

l (1 ,..., n | c, ) ga( i | c(tib tib1 ), )

i 1

n

i 1

c ( tib tib1 )

(c(t t ))

b

i

b

i 1

ic (t

b b

i ti 1 ) 1

exp{ i } .

The maximum-likelihood estimator of

(3.7)

can be obtained by maximising the logarithm of the

of the log-likelihood function,

setting the obtained expression to zero, and solving with respect to , we get that the estimator of is:

likelihood function given in (3.7). By taking the derivative with respect to

b

ct

ˆ n .

xn

(3.8)

Substituting (3.8) into (3.7), and solving the following formula:

log l (1 ,..., n | c) 0

c

with respect to c, we get that the maximum-likelihood estimators ˆ and

the following set of equations:

ˆ nb

ˆ ct

xn

.

n

b

ˆ

ct

[t b t b ] (cˆ[t b t b ]) log t b log n

i

i 1

i

i 1

i

n

xn

i 1

7

(3.9)

ĉ can be obtain by solving

(3.10)

Third condition in the definition of a gamma process states that this process has independent increments. The

likelihood function is then a product of independent gamma distributed increments.

29

The function ( a ) above is called the digamma function. It is defined as the derivative of the

gamma function logarithm:

(a) log (a)

, a > 0,

( a )

a

(a)

(3.11)

and, as is recommended by [10], it can be accurately computed using the algorithm developed by Bernardo

(1976).

3.2.2.2 Method of Moments

The Method of Moments estimates the parameters c and from the set of two equations. The first

equation is the relationship between the average rate of degradation and the parameters. To be more

precise: let us consider the data as given above. We have that i xi xi 1 , is the i-th observed

degradation increment, where i = 1,…, n. The duration of i-th increase in degradation is defined as:

wi tib tib1 , i = 1,…, n.

(3.12)

Notice that according to calendar time the duration of i-th increase in degradation is the time

between (i-1)-th and i-th inspection (e.g. ti ti 1 ).

Now we define a random variable Di as the i-th deterioration increment:

Di X i X i 1 .

(3.13)

It follows that the deterioration increment Di is gamma distributed with shape parameter

scale parameter

for all i = 1,…, n. The random increments

corresponding observation of Di is

cwi and

D1 ,..., Dn are independent. The

i .

We introduce the following average degradation rate per unit of tb time:

n

D

D

i 1

n

i

.

w

i 1

(3.14)

i

It follows that the expectation of

n

n

E ( D)

E ( Di )

i 1

n

w

i 1

i

i 1

n

cwi

w

i 1

D is:

c

.

(3.15)

i

The first equation for the estimates

ĉ and ˆ is:

30

n

cˆ

ˆ

i 1

n

i

w

i 1

,

(3.16)

i

and, since the degradation is cumulating, (3.16) simplifies to:

n

cˆ

ˆ

i

i 1

n

n

x x

i 1

n

w t

i 1

i

i 1

i 1

i

b

i

t

b

i 1

xn

.

tnb

(3.17)

Observe that (3.17) is the same as the first equation in the maximum-likelihood method (3.10).

The second equation needed for the parameter estimation comes from the relationship between the

parameters and the deviation of the degradation increments from the average degradation rate

follows that:

n

wi2

n

n

c

.

E ( Di Dwi ) 2 2 wi i n1

i 1

i 1

wi

i 1

D . It

(3.18)

The second equation is:

n

wi2 n

n

cˆ

w i n1

( i wi ) 2 .

2 i

ˆ

i 1

wi i 1

i 1

n

where

i

i 1

(3.19)

n

w .

i 1

i

The solution of equations (3.17) and (3.19) provides the estimates for

ĉ and ˆ .

3.3 Applications of a gamma process

Among applications of a gamma process are models for gradual damage monotonically

accumulating over time, such as wear, fatigue, corrosion, crack growth, erosion, consumption, creep, swell,

degrading health index.

In this section we present two examples of gamma model. Example 1 is based on article (Kallen,

van Noortwijk [3]). This article shows the possibility of modelling the corrosion (degradation in general) with

gamma process. Additionally an uncertain input parameter for corrosion rate (average rate of degradation)

is given by the prior distribution. Using Bayes’ theorem, the distribution of corrosion rate is updated with the

likelihood of observed degradation, so that the posterior distribution of corrosion rate is available. The

31

article presents two updating processes. One, when perfect inspections are considered (the measurement

error is not taken into account), and the other one with imperfect inspections.

The second example (Example 2 based on article (van Noortwijk, Klatter [13])), shows the

application of a gamma process to the model of scour-holes development in concrete-blocks that form the

Eastern-Scheldt barrier. The blocks are inspected for detection of such scour-holes, and as soon as a hole

is detected, the maintenance action is performed by repairing the defect.

In the model presented in [13] the initiation of a scour-hole and the development of a scour-hole are

considered as stochastic processes. The first process is represented by exponentially distributed interoccurrence times, while the development of a hole (given that a hole is present) is represented by a gamma

process. The probability of an event “in a time interval (0.k] at least one hole occurs which is deeper than y”

is derived, where y is a maximum acceptable depth of the hole.

3.3.1 Example 1

In this example the gamma deterioration process

X t , which represents the cumulative amount of a

wall thickness lost due to corrosion up to time t, is considered.

The degradation rate is assumed to be linear.

We have that:

X t ~ ga ( x | t , ) .

(3.20)

The expectation and variance of

E( X t )

t

,

and

X t are given by (Appendix A.1):

Var ( X t )

t

2

.

In order to give meaning to the parameters

E ( X t ) t ,

and

(3.21)

and

Var ( X t ) 2t ,

, the following is assumed:

(3.22)

where the uncertain parameters and are the rate of the linearly varying mean and the square-root of

the rate of the linearly varying variance respectively.

Combining (3.21) with (3.22) gives us that the parameters of gamma process ( , ) are related

with the uncertain rates as follows:

2

2

,

and

2

.

(3.23)

In [3] authors suggests that in order to keep the model practical and easy to use, the standard

deviation can be fixed in terms of the mean . With the use of the coefficient of variation v, the

standard deviation is given by:

v .

The gamma deterioration process is now given by:

(3.24)

32

t 1

X t ~ ga x | 2 , 2 .

v v

(3.25)

This approach can be observed in many of today’s models. The variance of the uncertain

deterioration process is assessed by expert judgment and subsequently the coefficient of variation v is fixed

in the model. The only uncertain parameter that is left to specify is the rate µ (corrosion rate) of the process

mean. It is desirable to assign a prior distribution to this parameter instead of assessing any singular value.

This distribution should be chosen such that it corresponds to the expert’s belief about all possible

corrosion rates. During the lifetime of a component the corrosion rate distribution is updated with the

likelihood of the inspection measurement. This action makes the prediction about the lifetime of the

component, which is related to the corrosion rate distribution, more accurate and more likely.

Discussion about the prior distribution for the uncertain corrosion rate µ in [3] mostly concerns the

case with perfect inspections. Authors suggest an inverted gamma distribution as the chose for the

corrosion rate prior distribution. The reasons are that the inverted gamma density multiplied by gamma

distributed likelihood is again proportional to an inverted gamma density. In fact the inverted gamma

distribution is said to be conjugated with respect to the exponential likelihood function, which means that

the product of the inverted gamma density and any exponential likelihood function is proportional to an

inverted gamma density. For more information about the conjugate family of inverted gamma distributions

we refer to (DeGroot MH [14]) and (Diaconies P, Ylvisaker D [15]).

The conjugated property of an inverted gamma distribution is presented below, where by using the

continuous version of the Bayes’ theorem (Appendix A.3) the prior corrosion rate density is updated with

the likelihood of measurements. Detailed calculations are shown in (Appendix B.2).

Let the corrosion rate prior density

( ) be an inverted gamma density:

( ) Iga( | a, b) .

(3.26)

Given the set of perfect measurements of cumulative wall loss xi, i = 1,…, n , 0 = x0 ≤ x1 ≤ … ≤ xn

and inspection times ti, i = 1,…, n, where 0 = t0 < t1 < … < tn, the posterior corrosion rate density is:

n

i 1

( | x1 ,..., xn ) Iga | a

n

ti ti 1

xi xi 1

,

b

,

2

v

v 2

i 1

(3.27)

which, because of cumulative measurements reduces to8:

( | xn ) Iga | a

tn

x

, b n2 .

2

v

v

(3.28)

The second and more realistic approach is to update knowledge about corrosion rate based on

imperfect inspections. Again we want to assign a distribution function for the corrosion rate parameter (µ)

and update this distribution based on imperfect measurements. First a new process is introduced, which

includes the original process X t together with a normally distributed error :

Yt X t ,

N (0, ) .

(3.29)

The measurement taken during inspection is assumed to be the observation from the process

Yt .

The likelihood of the measurement ŷ given the corrosion rate µ is determined by the convolution:

8

If we consider perfect inspections (perfectly measured wall thickness) then only the last inspection is needed for

calculation the posterior distribution. The last inspection provides the measurement of the total lost of wall thickness.

33

l ( yˆ | ) fYt ( yˆ )

f X t ( yˆ ) f ( )d ,

where f X t ( yˆ ) ga yˆ | t

v

2

, 1

(3.30)

.

v

2

The likelihood extended to the case with multiple inspections is given by:

l ( y1 ,..., yn | )

n

...

f X t X t (di i ) f (1 ,..., n )d1...d n ,

i

i 1

i 1

(3.31)

di yi yi 1 , y0 0 , y1 ,..., yn are the imperfect measurements made at times ti, i = 1,…, n,

0 = t0 < t1 < … < tn, and i i i 1 , 0 0 are respective errors. As previously the integrated densities of

where

the deterioration process are gamma:

t t

f X t X t (di i ) ga di i | i i 1 2 , 1 2 for i = 1,…, n.

i

i 1

v

v

(3.32)

The product of gamma densities in (3.31) is because a gamma process has independent

increments, and consequently the joint density of n gamma increments is the product of n gamma densities.

Here we assume that the errors are independent, that is

i

does not depend on

j

for every

i j . In a more general case the dependence between measurement errors may be introduced by using a

multivariate normal distribution with the covariance matrix with non-zero elements on the non-diagonal

cells. Notice also that the joint density f (1 ,..., n ) in the formula (3.31) cannot be reduced any further

i 1 . M. J. Kallen and J. M. van Noortwijk in [3] suggest that in order to

compute the likelihood given in (3.31) we can simulate the errors i ' s and approximate the solution.

Otherwise we would have to calculate the covariance between the ' s and analytically solve the likelihood

using the joint distribution of the ' s , which would considerably complicate matters.

since every

i

depends on

Next, the likelihood in (3.31) can be formulated as an expectation, which in turn can be

approximated by the average of the product:

n

l ( y1 ,..., yn | ) E f X t X t (di i )

i 1 i i1

n

N

1

f X t X t (di i( j ) ) as N

N j 1 i 1 i i1

where f X t X t

i

i 1

d

i

(3.33)

t t

i( j ) =ga di i( j ) | i i 1 2 , 1 2 .

v

v

Here the law of large numbers is used in order to perform the so called Monte Carlo integration. For

each inspection i we sample

i( j )

for j = 1,…, N, and then we calculate

i( j ) i( j ) i(j1) .

Equation (3.33) can be now substituted in Bayes’ formula (Appendix A.3), which then can be solved

by numerical integration to obtain the posterior distribution for corrosion rate given imperfect

measurements. The authors says that the choice for the use of simulation to determine the likelihood (3.31)

34

greatly reduce the efficiency of the model, but also the choice for the prior distribution is no longer restricted

to the inverted gamma density as in the case of perfect inspections.

3.3.2 Example 2

The purpose of the paper [13] by J. M. van Noortwijk and H. E. Klatter is to present the

mathematical model that provides safe and cost-optimal rates of inspection for the block mats. This

example, however, is restricted only to the case of safety and those interested in the whole model are

referred to [13].

The block mats can be damaged in such a way that sand washes away and scour holes occur. To

detect possible scour, the block mats are inspected by application of acoustic techniques. If acoustic

inspection reveals a scour hole, then a detailed inspection will be carried out, followed by a repair.

Since the completion of the barrier in 1986, no scour holes were detected. This fact makes that the

initiation of holes is treated as the main uncertainty. As suggested by the author the scour-hole interoccurrence times are assumed to be exchangeable and exhibit the “lack of memory” property.

Exchangeability means that the order in which the scour holes occur is irrelevant. The “lack of memory”

property means that the probability distribution of the remaining time until the occurrence of the first scour

hole does not depend on the fact that a scour hole has not yet occurred since the completion of the barrier

in 1986.

The successive times between occurrences of scour holes are denoted by the infinite sequence of

non-negative real-valued random variables T1, T2 ,…

Under the assumption that the infinite sequence T1, T2 ,… is exchangeable and satisfies the “lack of

memory” property for all n , we can write the joint probability density of T1,…, Tn as a mixture of

conditionally independent exponentials9:

n

fT1 ,...,Tn (t1 ,..., tn )

0 i 1

where

n

t

exp i dP ( ) f n ti ,

i 1

1

(3.34)

t1 ,..., tn are non-negative real numbers. The random quantity , with the probability distribution P ,

describes the uncertainty about the parameter

occurrence time of scour holes:

lim n

T

n

i 1 i

, or the uncertainty about the limiting average inter-

n .

(3.35)

The probability distribution for the uncertain expectation of the inter-occurrence times ( ) is

chosen to be an inverted gamma distribution:

~ Iga( | v, )

(3.36)

We skip the explanation of this choice, but the interested readers are referred to [13] and

references sited therein. The main advantage of this distribution is that it is said to be conjugated with

respect to the exponential likelihood function. This means that if one wants to update the prior distribution

It can be verified that if a random variable obey “lack of memory” property then this random variable has

exponential distribution function (T. Bedford, R. M. Cooke [12])

9

35

Iga( | v, ) with actual observations t1 ,..., tn , than, using Bayes’ theorem, the posterior distribution is

Iga( | v n, i 1 ti ) .

n

Further, the stochastic process of scour-hole development is discussed. Given that a scour hole