Earthworks for Roads Design Standard

advertisement

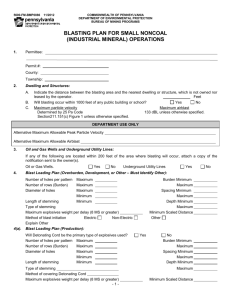

Transport Services Division EARTHWORKS Standards & Guidelines DPTI DESIGN STANDARD: EW 100: EARTHWORKS FOR ROADS CONTENTS 1. 2. 3. 4. 4.1. 4.2. 4.3. 4.4. 5. 6. 6.1. 6.2. 6.3. 6.4. 7. 8. 9. 10. 11. GENERAL ........................................................................................................................................................................ 2 REFERENCES ................................................................................................................................................................. 2 DESIGN REPORT............................................................................................................................................................ 2 DESIGN REQUIREMENTS.............................................................................................................................................. 3 Design Life .................................................................................................................................................................. 3 Design Objectives ....................................................................................................................................................... 3 Design Criteria ............................................................................................................................................................. 3 Verification of Material Design Parameters ................................................................................................................. 4 WATER TABLE ................................................................................................................................................................ 4 VOLUMETRIC CHANGE ................................................................................................................................................. 4 General ........................................................................................................................................................................ 4 Calculations ................................................................................................................................................................. 5 Seasonal Moisture Changes ....................................................................................................................................... 5 Performance Criteria for Volumetric Change .............................................................................................................. 6 SLOPE STABILITY .......................................................................................................................................................... 6 PARAMETERS FOR USE IN PAVEMENT DESIGN ....................................................................................................... 7 DESIGN OF CUTTINGS IN ROCK .................................................................................................................................. 7 DESIGN OF CONTROLLED BLASTING .................................................................................................................... 8 RECORDS ................................................................................................................................................................ 10 EW 100 Version Register Date-Version Details of Revision Authorised By 7 Nov 2014 – Ver 0 Knet Doc:9068195 Version No: 0 Issue Date: 7 Nov 2014 Doc. Owner: Manager Traffic Operations UNCONTROLLED COPY WHEN PRINTED Page 1 of 10 DPTI Design Standard: Earthworks for Roads: EW100 1. GENERAL This Design Standard specifies the requirements for the design of earthworks for roads, including material selection, construction methodology, geometric design, water /moisture control measures and surface treatment. It excludes the design of backfill for Reinforced Soil Structures (refer to DPTI Design Standard:”Reinforced Soil Structures”). 2. REFERENCES Unless specified otherwise, all design must be undertaken in accordance with the following: 1) AS 2187.2 Explosives – Storage, Transport and Use – Use of Explosives1 2) AS 2870 Residential Slabs and Footings2 3) AS 3798 Guidelines on Earthworks for Commercial and Residential Developments. Notes: 1: for calculating seasonal moisture changes only. 2: where applicable. Unless specified otherwise, the definitions in the following documents shall apply to the terms used the design of earthworks: (a) Austroads Publication No. AP-C87-14 “Glossary of Terms” (available from: https://www.onlinepublications.austroads.com.au/items/AP-C87-14). (b) Civil Contractors Federation publication “Earthmover & Civil Contractor - Plant Specs” (available from: http://www.earthmover.com.au/plantspecs). (for construction plant classifications); and (c) 3. Part 210 “Earthworks” of the DPTI Master Specification for Transport Infrastructure. DESIGN REPORT The earthworks design must be documented in a Design Report which includes: (a) a “Design Basis Report” containing: i) any interpretations, clarifications or assumptions made; ii) all technical standards, references, material properties, durability, performance requirements, design loadings and design lives used for the design; and iii) a description of the design methodology / rationale and design software. (b) all relevant analysis and calculations for the design, including calculations to demonstrate that volumetric change, settlement/creep and slope stability comply with the specified design criteria at the end of construction and during the design life of the earthworks (c) description of the proposed construction methodologies and permissible Optimum Moisture Content (to be incorporated into the Earthworks /Construction Management Plan); (d) details of all assumed and specified material properties (with reference to Part 210 “Earthworks”) and the testing regime to verify these properties are achieved; (e) complete details of any techniques to improve material properties, such as preloading or vertical drainage systems; (f) details of any associated structures or measures such as rock bolting, rock netting, soil nails, geotextiles, subsoil drains and surface treatments (e.g. hydroseeding, matting and mulching); and (g) any proposed instrumentation and the proposed inspection and monitoring regime. Knet Doc:9068195 Version No: 0 Issue Date: 7 Nov 2014 Doc. Owner: Manager Traffic Operations UNCONTROLLED COPY WHEN PRINTED Page 2 of 10 DPTI Design Standard: Earthworks for Roads: EW100 The calculations must address: (a) the nature, strength, compressibility and variability of existing fill and natural soils; (b) ground improvement of foundation soils prior to embankment construction; (c) the nature, strength, compressibility and variability of proposed earth fills; (d) moisture conditioning and compaction of earth fill; (e) rate of embankment construction and any staging of embankment construction; (f) any surcharging of completed embankment; (g) effects of variations in soil moisture content arising from seasonal effects or during long term moisture changes to the equilibrium moisture condition; and (h) the effect of proposed drainage and landscaping including proposed vegetation and any measures taken to reduce the effect of the vegetation on soil moisture content. 4. DESIGN REQUIREMENTS 4.1. Design Life Earthworks must be design for the following minimum design life: ELEMENT DESIGN LIFE (YEARS) Embankments, including reinforced embankments 100 Cut batters, including batter treatments 100 4.2. Design Objectives To the extent practicable, the design must achieve the following: (a) providing a safe run off area for errant vehicles; (b) providing a natural fit into the surrounding terrain; (c) minimising ongoing maintenance costs; (d) providing a safe work environment for personnel undertaking maintenance; (e) minimise adverse environmental effects, including maximising the reuse of excavated materials and minimising the impact on vegetation; (f) minimising the length of traffic barriers consistent with safety requirements; (g) limiting level changes and undulations in the finished pavement surface; and (h) limiting seasonal or permanent changes in the subsurface moisture regime. 4.3. Design Criteria Earthworks must be designed to meet the specified performance criteria for: (a) Volumetric Change: i) settlement due to consolidation / creep in embankments and material under embankments or subgrade in cut; and ii) non load dependent soil volumetric changes, including reactive soil movements (b) Slope Stability: iv) batters are stable and will not display any detectable instability or evidence of impending loss of stability during the Design Life; Knet Doc:9068195 Version No: 0 Issue Date: 7 Nov 2014 Doc. Owner: Manager Traffic Operations UNCONTROLLED COPY WHEN PRINTED Page 3 of 10 DPTI Design Standard: Earthworks for Roads: EW100 v) overhanging, loose or unstable material in cuts is prevented for slipping or failing; and vi) in cuts, any material which becomes detached is prevented from reaching the road shoulder; (c) Durability and Maintainability: i) detrimental effects from water (e.g. concentrated flows, erosion, ponding of water) are kept to the minimum practicable; ii) the surface is highly resistant to surface scour and erosion and will not suffer detrimental effects from a in 10 year Average Recurrence Interval storm event; iii) there is no undermining or destabilisation of any existing batter slopes or structures; iv) maintenance that would normally be required of the road and environs can be readily and economically undertaken; and v) Plant and equipment access must be available to the final batter slope to allow ready installation of any treatment measures which may become necessary and to facilitate inspection and maintenance of the face of the batter. Performance criteria may be specified in contract documentation (such as a Specification, Statement of Requirements or Contract Scope and Technical Requirements). If no performance criteria are specified, the values in this Design Standard shall apply. 4.4. Verification of Material Design Parameters The design must include a testing regime to verify that the design parameters for the volumetric change (e.g. Shrink / Swell and the coefficient of volume change) and strength (e.g. c’, φ’, c u’) have been achieved during construction for each and all fill materials. 5. WATER TABLE The earthworks design must: (a) not permanently affect any existing groundwater table level; and (b) incorporate every reasonable endeavour to avoid temporarily lowering the existing groundwater table by dewatering. If dewatering cannot be avoided, the design must: (a) ensure that the extent and depth of the area to be dewatered is held to a practicable minimum; (b) ensure that the duration of any dewatering is held to a practicable minimum; (c) provide full details of any dewatering system, including the quantity and proposed method of disposal in the Quality Plan; and (d) ensure that dewatering water is disposed of in such a manner that it does not harm the environment and is in accordance with the Environmental Protection Act 993. Full details of any dewatering system, including the quantity and proposed method of disposal, must be included in the Design Report. 6. VOLUMETRIC CHANGE 6.1. General “Volumetric Change” includes changes in levels due to settlement, consolidation, creep and reactive soil movement (both seasonal and long term equilibrium change). Design and construction must be Knet Doc:9068195 Version No: 0 Issue Date: 7 Nov 2014 Doc. Owner: Manager Traffic Operations UNCONTROLLED COPY WHEN PRINTED Page 4 of 10 DPTI Design Standard: Earthworks for Roads: EW100 completed in such a way that Volumetric Change will have no adverse effect on the performance of the pavements and structures. The design must take into account short and long term consolidation, seasonal moisture variations and the change of soil moisture as the material reaches the long term equilibrium condition. 6.2. Calculations Calculations must be provided for Volumetric Change at the completion of construction and 6 years thereafter. Issues to be addressed in the calculations include: (a) effects of the presence of organic soils; (b) areas unsuitable to act as a foundation for structures; (c) the strengths, compressibility and variability of existing soils; (d) the depth of existing topsoil or organic material to be removed; (e) the strengths, compressibility and variability of earth fills; (f) any methods for accelerating or limiting Volumetric Change; (g) level of compactive effort and surcharge during fill construction; (h) any difference between the as constructed moisture content and the equilibrium moisture content; (i) seasonal variations in soil moisture content; and (j) effect of proposed drainage and landscaping including proposed vegetation and any measures taken to reduce the effect of these. 6.3. Seasonal Moisture Changes The calculation of seasonal or long term surface movements must be in accordance with AS 2870 with the following clarifications: (a) for the purpose of the calculation of seasonal surface movements, the active zone for seasonal soil moisture variation shall be 4m from the top of pavement; (b) total soil suction variation at surface level shall be 1.2 pF units, decreasing linearly with depth to 0 pF units 4.0 m below top of pavement surface level; (c) the depth of the crack zone is 3m from the existing ground surface where a site has been cut less than two years prior to earthworks construction and the depth of the cracked zone may be reduced by the depth of the cut; (d) α for cuts and fills must be calculated in accordance with section 2.3.2 of AS 2870 and must not be less than 1.0; (e) for the purpose of calculating movements and volume change, the words “building construction” in AS 2870 means all earthworks, structures, and pavement construction; (f) the effects of new (i.e. included in the landscape design) and existing trees on surface movements must be accounted for in the design; (g) Ys must be calculated as the sum of the changes in layer thickness due to change in total suction; (h) the change in layer thickness is the product of layer thickness by ∆u (in pF) by Ipt, where ∆u equals the average change in total suction of the layer under consideration and Ipt is the instability index of the layer; and (i) the effect of existing and proposed trees, large bushes and dense plantings of shrubs on the design profile of total soil suction change must be estimated in accordance with the “Special Provisions” document of the Footings Group, South Australia. Knet Doc:9068195 Version No: 0 Issue Date: 7 Nov 2014 Doc. Owner: Manager Traffic Operations UNCONTROLLED COPY WHEN PRINTED Page 5 of 10 DPTI Design Standard: Earthworks for Roads: EW100 Moisture barriers in accordance with relevant Australian Standards may be incorporated within the construction of embankments to prevent the effects of moisture ingress of stormwater and/or desiccation from vegetation. Where appropriate, the use of low permeability capping materials adjacent to the edge of pavement, horizontal and vertical separation of drains, sub-soil and sub-pavement drainage and other measures must be considered. The method of verifying the actual Iss (%) values of the construction materials must be addressed. 6.4. Performance Criteria for Volumetric Change The design of the Works must achieve the following: Element Pavements Property Differential movement between any two points on the pavement surface up to 10 metres apart Performance Criteria Maximum change in level of the pavement surface of : Expressways (including ramps) - 20 mm. Arterial Roads – 25 mm Other Roads – 30mm Structures Pavement Interface Differential movement 5 mm max where no bridge approach slab is provided. 10mm max where a bridge. approach slab of minimum 3 m length is provided and for transitions from rigid to flexible pavements Culverts and Retaining Walls 7. Any movement Culverts and Retaining Walls are undamaged, do not pond water and performance is not diminished in any way. SLOPE STABILITY Slope stability analysis must be undertaken for both long and short term slope geometries and soil conditions. The minimum Factors of Safety (FoS) must comply with the following: Embankment Design Criteria Minimum Factor of Safety Application During construction Post Construction Low risk Post Construction High risk Surcharge 1.3 10 kPa 1.4 10 kPa for local roads 1.5 20 kPa for arterial roads, expressways (including ramps) Soil Shear Strength Parameter Values Lower quartile Where these minimum values for the FoS cannot be achieved, suitable earth retaining structures must be provided. Knet Doc:9068195 Version No: 0 Issue Date: 7 Nov 2014 Doc. Owner: Manager Traffic Operations UNCONTROLLED COPY WHEN PRINTED Page 6 of 10 DPTI Design Standard: Earthworks for Roads: EW100 The risk category for a particular slope must be assessed in terms of the potential for loss of life or injury to persons and the potential for economic and environmental impacts should the slope fail. Examples of high risk slopes are slopes adjacent to pedestrian areas or main roads. An example of a low risk slope is one that only impacts open areas such as landscaped zones. Slopes behind or above earth retaining structures or below bridge abutments are considered high risk slopes. The impact of any proposed excavations or changes in soil moisture regime on embankment or cutting stability must be assessed. A rigorous limit equilibrium method of soil stability analysis must be undertaken (such as Spencer or Morgenstern and Price). The analysis must cover non-circular slope failure geometries where appropriate. 8. PARAMETERS FOR USE IN PAVEMENT DESIGN The design parameters used in the pavement design for standard fill materials must not exceed the following values unless documented evidence that higher values are appropriate can be provided. The maximum allowable design modulus for fill materials is 100 MPa. Material (Refer to Part 210 for definitions) Design Parameter Type A Fill E 70MPa, = 0.45 Type B Fill E 50MPa, = 0.45 Type C Fill E 50MPa, = 0.45 E = Vertical Resilient Modulus, = Poisson Ratio of all sub-layers. 9. DESIGN OF CUTTINGS IN ROCK Where batter slopes will be constructed in rock, the design must comply with this Clause and be undertaken by a Geotechnical Engineer or Geologist with relevant experience rock cuttings. A geotechnical model must be developed of the rock cuttings to facilitate the following strategies for batter designs and treatments: (a) engineer the batters to the appropriate angle, not the steepest angle to reduce earthworks volumes; (b) consider defect related mechanisms as well as global stability; (c) consider long term performance and maintenance requirements; and (d) install treatments during construction. Kinematic analysis of rock cuttings must include consideration of toppling, wedge, ravelling, rotational shear and planar failures. A risk management strategy for the slopes, including probability analysis, must be provided. Working faces must be limited to safe heights and slopes, and the surface must be drained to avoid ponding and erosion. The design must take into account the affect of water and where appropriate, include cut off drains at the top of all rock cuttings. Any drainage structures located on the rock cuttings must be concrete lined. The designer must include recommendations for monitoring and maintenance of the rock cuttings for their design life. Knet Doc:9068195 Version No: 0 Issue Date: 7 Nov 2014 Doc. Owner: Manager Traffic Operations UNCONTROLLED COPY WHEN PRINTED Page 7 of 10 DPTI Design Standard: Earthworks for Roads: EW100 10. DESIGN OF CONTROLLED BLASTING Where blasting is proposed to be used in the construction of earthworks, the design of the blasting process must comply with this clause. Australian Standard 2187.2-2006 ‘Explosives – Storage, Transport and Use – Use of Explosives’ contains guidelines for ground vibration levels for human comfort and control of damage to structures. The values for human comfort have been chosen by regulatory authorities as used in overseas standards and guidelines. The design of the blasting must take into account Utility Services and liaise with the relevant authority for any special requirements. The blasting works must be designed for a 5 mm/s Peak Particle Velocity (PPV) for 95% of blasts with 10 mm/s maximum at all sensitive structures as the governing ground vibration limit for the blasting works (more than 20 blasts, Table J4.5 (B) AS 2187.2-2006). These PPV limits must be based on the surrounding houses and at the Project Property Boundary. Blasting works will target a PPV of less than 5 mm/s at all times at Project Property Boundary. The design must identify the PPV values likely to be sustained by structures within the Project Property Boundary. PPV is estimated using the following equation: R PPV K g 1 Q 2 B Where PPV is in mm/s, Kg is the site constant for PPV, R is the distance from the charge to the measured point in m, Q is the maximum instantaneous charge (mass charge per delay) in kg and B is the site exponent for PPV. The design must identify the site constant Kg. AS2187.2 also recommends air blast overpressure limits for human comfort and damage control. For this parameter, a sensitive site rating of 115 dBL for 95% of blasts with no blast exceeding 120 dBL must be adopted as the safe limit for the blasting works along the Southern Expressway (greater than 20 blasts, Table J5.5(A) AS2187.2-2006). Air blast overpressure is estimated using the following equation: R P Ka 1 Q 3 a Where P is the pressure in kPa, Ka is the site constant for air blast overpressure, R is the distance from the charge to the measured point in m, Q is the maximum instantaneous charge (mass charge per delay) in kg and B is the site exponent for air blast overpressure. Pressure is converted to decibels using the following equation: P SPL 10 log 10 P0 2 Where SPL is the sound pressure level in dBL and P0 is the reference pressure of 20 mPa. Refer to Part 110 for details on property condition surveys and Part 155 for environmental considerations. Blast design strategies to minimise damage to structures/stakeholders and ensure safe blasting are outlined in Table 7. Knet Doc:9068195 Version No: 0 Issue Date: 7 Nov 2014 Doc. Owner: Manager Traffic Operations UNCONTROLLED COPY WHEN PRINTED Page 8 of 10 DPTI Design Standard: Earthworks for Roads: EW100 Table 7 - Blast design strategies Blast design strategy Issue Detailed mapping of rock face and rock mass prior to blasting Identify any areas of clays, jointing, fracturing that will propagate ground vibrations towards nearby residents. Provide detailed rock mass characteristics for blast design Optimise face design to reduce blasting requirements Blast plans submitted and approved prior to initiation All blast plans reviewed by Owners Engineers /Client /Designers who have experience in blasting. Timing of blasts To occur at regular time(s) during the day, not at night, high wind period, low cloud cover or electrical storms – reduce air blast impacts Non-electric detonation No premature initiations by stray currents Maximum of 2 holes initiated at one time Reduces ground vibrations Pre-split used Reduce backbreak of rock face as well as ground vibrations travelling to nearby residents Stemming cover a minimum of 1.6m Increase stemming cover to eliminate fly rock by ensuring blast energy is directed into rock mass. Blast mats or extra soil Reduce the fly rock from blasts if insufficient depth Remove loose surface material Reduces fly rock and fugitive dust from blasting Reduce powder ratios (charge mass per hole) Lower powder ratios will limit the escape of blast material, use blast to break and not throw rock mass. Large excavators needed due to tight digging and less fragmentation (larger rock size) Use of ANFO where possible Lower velocity of detonation reduces ground vibration and evenly spreads explosive energy in blast hole Use of Emulsion May be used where water is encountered or if the surface of the blast is flooded to reduce dust emissions Detailed recording of drilling and loading of all blast holes Identify bad drilling, water or fractured zones which may change powder ratio for that hole. Determine exact volume of explosives placed. First blasts in deepest and furthest cut areas away from residents Blast design monitored in these less critical blasts and modified for proceeding blasts as progress towards nearby residents Blast procedures Blast guards at all access points Dilapidation survey Provide evidence of any damage from blasting program, area of potential vibration to be determined Notify nearby stakeholders Neighbours notified prior to each blast Monitoring equipment set up at selected locations Elimination of ‘startled’ and negative responses Site security during blasting operations Restrict access to site, no explosives stored onsite All blasts monitored by video and sound/vibration monitoring equipment Video provides visual feedback on blast design, such as fly rock, detonation sequence etc. Blast monitoring at all sensitive sites ensures compliance to blasting limits. Knet Doc:9068195 Version No: 0 Issue Date: 7 Nov 2014 Doc. Owner: Manager Traffic Operations UNCONTROLLED COPY WHEN PRINTED Page 9 of 10 DPTI Design Standard: Earthworks for Roads: EW100 The design must consider appropriate techniques e.g. (Pre-splitting) to used on rock cuttings and exposed rock surfaces to obtain smooth, uniformly trimmed surfaces and to ensure protection of the batters. The spacing of pre-split drill holes must not exceed 1000mm centre to centre. 11. RECORDS The following records must be provided to DPTI: Drawings Construction drawings. Relevant standard drawings from the DPTI: Road Design Standards and Guidelines. Reports Design Report (refer Clause 3). _________ Knet Doc:9068195 Version No: 0 Issue Date: 7 Nov 2014 Doc. Owner: Manager Traffic Operations UNCONTROLLED COPY WHEN PRINTED Page 10 of 10