Secondary Containment

advertisement

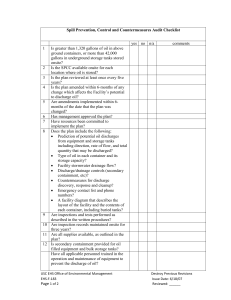

Secondary Containment Program Template Secondary Containment Program Table of Contents I. II. III. OBJECTIVE AND SCOPE DEFINITIONS RESPONSIBILITIES A. Secondary Containment Program Manager B. Supervisors C. Employees D. Management E. Third Party Contractors IV. PROCEDURE A. Secondary Containment Applicability B. Design and Construction of Secondary Containment C. Containment Drainage D. Long Term Maintenance E. Protection and Security F. Ventilation and Lighting G. Loading and Unloading H. Cleaning up a Release V. TRAINING A. Employee Training B. Training Records VI. REFERENCES A. Business Unit Policy References B. Site Policy References C. Regulatory and Standard Industry References VII. APPENDICES Appendix A - Sample Calculation of Secondary Containment Capacity Appendix B - Secondary Containment Water Drainage Log Appendix C - Spill Control System Inspection Checklist VIII. DOCUMENT CONTROL Secondary Containment Program for [Company Name/Location] I. OBJECTIVE AND SCOPE The purpose of the [Company Name/Location] Secondary Containment Program (SCP) is to contain chemical releases and protect the facility, public health and the environment by preventing chemicals from entering the soil, surface water and groundwater. Secondary containments control or minimize chemical releases from leaving the facility boundaries and provide additional time to properly clean up the releases. Benefits of secondary containment also include reduced costs of cleaning up releases, potential for environmental damage or injury to health and safety of personnel, and liabilities in the event of a chemical release. Secondary containment may be required by multiple governmental regulations depending on the type and quantity of hazardous substances stored or handled. It may also be a requirement under local regulations, which are usually incorporated into zoning, building, fire protection, or other regulations. The procedures described in this Program are intended to facilitate compliance with applicable governmental regulations. If there is a conflict between this program and a governmental regulation, the governmental regulation will apply and this Program will be modified. However, all other requirements in this Program will apply even if they are more stringent than governmental regulations. II. DEFINITIONS Container - Any portable device in which a material is stored, transported, treated, disposed of, or otherwise handled. Primary Containment - The first level of containment, consisting of the inside portion of that container which comes into immediate contact on its inner surface with the material being contained. Secondary containment - A means of surrounding one or more primary storage containers or articles to collect any hazardous material release in the event of loss of integrity or failure of the primary container. Tank - A stationary device, designed to contain a regulated material, which is constructed primarily of non-earthen materials (e.g., wood, concrete, steel, plastic which provide structural integrity and support). Date: May 18, 2009 Version: Final Version 1.0 Next Review: May 18, 2010 Authorized by: Regulatory Affairs Counsel Uncontrolled when printed 1 Tank system - A regulated material storage or treatment tank and its associated ancillary equipment and containment system. Ancillary equipment - Any device including, but not limited to, such devices as piping, fittings, flanges valves, and pumps, that is used to distribute, meter or control the flow of regulated material from its point of generation to a storage tank(s), between tanks to a point of use on-site, or to a point of shipment for use off-site. III. RESPONSIBILITIES A. Secondary Containment Program Manager [Responsible Person] shall manage the SCP for [Company Name/Location.] The Program Manager is responsible for implementing all aspects of the program and shall: 1. Identify areas in the facility required to have secondary containment. 2. Determine secondary containment requirements under applicable governmental regulations including local fire and building codes. 3. Identify local jurisdictions responsible for oversight of secondary containment requirements. 4. Ensure proper maintenance of secondary containment monitoring and drainage systems. 5. Ensure appropriate employees are trained in their responsibilities under SCP. 6. Maintain records of all documents related to SCP requirements. B. Supervisors Supervisors shall work with the Program Manager to ensure that: 1. The requirements of this program are implemented in their respective departments. 2. Secondary containment areas are inspected and maintained. 3. Releases are cleaned up immediately and corrective actions are taken to prevent such occurrences, in accordance with the facility Spill Response Plan. C. Employees Employees in each department will be responsible for complying with these SCP requirements. Date: May 18, 2009 Version: Final Version 1.0 Next Review: May 18, 2010 Authorized by: Regulatory Affairs Counsel Uncontrolled when printed 2 D. Management [Company Name/Location] will provide all necessary resources and training to comply with this SCP. Facility Manager will ensure proper adherence to this Program through regular review. E. Third Party Contractors Third Party Contractors are responsible for complying with this Program, and shall insure that their employees have the necessary training to comply with this Program. IV. PROCEDURE A. Secondary Containment Applicability [Company Name/Location] will provide secondary containment in areas of the facility where regulated materials are handled or stored in containers including tanks, totes, drums, or small pails including: 1. 2. 3. 4. 5. Flammable and combustible materials Hazardous substances Hazardous waste Materials included on governmental lists of regulated materials Oil and other petroleum-based products or waste Unless otherwise required, containers less than 5-gallon in capacity are not required to have secondary containment. B. Design and Construction of Secondary Containment Secondary containment systems will be designed, installed, and operated to prevent any migration of accumulated liquid out of the secondary containment. It must also be capable of holding liquids until the collected materials are removed. 1. Containment Volume The containment will be constructed such that the containment area is large enough to meet the regulatory volumes specified for the type of material stored. a. The effective capacity of secondary containment for a single container will be a minimum of 110% of the primary container. b. Effective capacity of secondary containment for multiple containers will be a minimum of 110% of the largest container's volume or 10% of the aggregate volumes of all containers, whichever is greater. c. All secondary containment systems exposed to rainfall must be able to hold 4.5 inches of rainfall in addition to the required secondary containment volume. d. All secondary containment systems exposed to fire sprinkler discharge must be able to hold the discharge from all sprinkler heads over the Date: May 18, 2009 Version: Final Version 1.0 Next Review: May 18, 2010 Authorized by: Regulatory Affairs Counsel Uncontrolled when printed 3 secondary containment system for 20 minutes in addition to the required secondary containment volume. Appendix A contains a sample of calculation of secondary containment capacity. 2. Structural Strength - The base and walls of the system will be strong enough to support the weight of all the materials and equipment that will enter it. Materials designed and approved to withstand weathering effects and wear and tear and be able to withstand a full hydrostatic head will be used for construction. 3. Impermeability and Compatibility – The system will be constructed so that it is liquid tight. All joints and cracks will be sealed. The surface of the system must be resistant to penetration by the materials stored there and be compatible with them. The structure must be made of noncombustible materials if flammable or combustible materials are stored in the area. Incompatible materials will be accumulated in separate secondary containment areas. 4. Integrity – The secondary containment system will be designed so that any leaking materials cannot be released into the environment or into sewer systems. Side walls and the base will not be penetrated by drains, piping channels, or openings of any kind where liquids may escape. If drains or openings do exist, any discharges into them will be manually controlled. C. Containment Drainage Uncontrolled drainage from a secondary containment system is prohibited. Accumulated storm water or sprinkler flow water may only be released from a secondary containment system after it has been determined to be uncontaminated following the method below. 1. Drain valves for storage tank secondary containment systems, if provided, must be kept closed and locked at all times, except when draining accumulated storm water. 2. A visual check of accumulated storm water must be performed and documented prior to draining. 3. For tanker unloading areas, available drains for secondary containment must be closed whenever a tanker is present within the containment area. Date: May 18, 2009 Version: Final Version 1.0 Next Review: May 18, 2010 Authorized by: Regulatory Affairs Counsel Uncontrolled when printed 4 Appendix B is a sample Secondary Containment/Water Drainage Log for use during containment drainage. D. Maintenance Inspections of the secondary containment systems shall be conducted monthly and documented. Any necessary repairs will be scheduled and performed and records will be kept. Appendix C is a list of items to check during a secondary containment system inspection. E. Protection and Security Access to the containment system will be restricted to protect against tampering or trespassers. Isolation distance requirements from property lines and streets, alleys, or other public ways and sources of ignition are as follows: [Fill in] All applicable storage requirements for flammable and combustible liquids storage are [attached] hereto and will be met including aisle widths, spacing distances between storage tanks, and stacking limit of the containers. F. Ventilation and Lighting Adequate ventilation to avoid the buildup of explosive or flammable fumes and to protect workers entering the area will be provided. This will be accomplished by natural or mechanical ventilation with discharge or exhaust to a safe location outside the building. Without adequate ventilation, a secondary containment area could become a confined space. Secondary containment areas will be properly lighted for safety and to deter vandalism. G. Loading and Unloading Materials will be handled safely when being transferred in and out of the containment system and in the dock area. These areas must have safe approaches and adequate space for vehicle access and maneuvering room. Avoid excessive sill height which would hinder movement. Any spilled material in a dock area must be prohibited from entering public sewers, drainage systems, or waterways. H. Cleaning up a Release Any releases into the secondary containment will be cleaned up in accordance with the facility Spill Response Plan and the Emergency Action Plan. If the precipitation and/or other materials collected is determined to be a hazardous waste it will be managed according to hazardous waste management requirements. If the fluid is not a hazardous waste, it may be discharged to a municipal wastewater sewer system only if properly authorized by governmental requirements. Date: May 18, 2009 Version: Final Version 1.0 Next Review: May 18, 2010 Authorized by: Regulatory Affairs Counsel Uncontrolled when printed 5 V. TRAINING A. Employee Training All appropriate employees will be trained in the requirements of this SCP. B. Training Records All training pertaining to this program shall be maintained in accordance with the facility Records Retention Plan. VI. REFERENCES A. B. C. VII. Business Unit Policy references Site Policy references Regulatory and Standard Industry references 1. Uniform Fire Code 2. OSHA (General Industry) where spill containment is specified 1910.10, Flammable and Combustible Liquids 1910.106(d)(6)(iii), 1910.106(e)(2)(iii), 1910.106(f)(7) APPENDICES Appendix A Appendix B Appendix C Sample Calculation of Secondary Containment Capacity Secondary Containment Water Drainage Log Spill Control System Inspection Checklist VIII. DOCUMENT CONTROL This SCP shall be reviewed annually, or as needed if changes to the facility operations, processes, or personnel are made, by [Responsible Person]. Following each change, [Responsible Person] shall document the change and inform all affected by the changes. Document History: Procedure version Date Approved Approved by Date: May 18, 2009 Version: Final Version 1.0 Next Review: May 18, 2010 Reason for Change Authorized by: Regulatory Affairs Counsel Uncontrolled when printed 6 APPENDIX A SAMPLE CALCULATION OF SECONDARY CONTAINMENT CAPACITY The maximum 24-hour rainfall recorded in the last 25 years at this location is 4.5 inches. Bulk Storage Dike Capacity of Tanks within the diked area: Tank 1 = 20,000 gallons (saddle-mounted tank, no significant displacement) Tank 2 = 20,000 gallons (saddle-mounted tank, no significant displacement) Tank 3 = 20,000 gallons (need to account for tank displacement) Tank 7 = 10,000 gallons (on legs, no significant displacement) Dike Dimensions: Dike footprint = 50 feet x 60 feet Dike height = 18 inches = 1.5 feet Dike volume = 50' x 60' x 1.5' = 4,500 ft3 x 7.48 gal/ft3 = 33,660 gallons Displacement Volume of Tank 3: Tank diameter = 10 feet 3.1415 * (10 ft)2 / 4 * 1.5' = 117.8 ft3 x 7.48 gal/ft3 = 882 gallons Available Freeboard for Precipitation: 33,660 gallons - (20,000 gallons + 882 gallons) = 12,778 gallons 12,778 gallons / 7.48 gallons/ft3 / (50 ft x 60 ft) = 0.57 ft = 6.83 inches The dike therefore provides sufficient storage capacity for the largest bulk storage container within the diked area, tank displacement, and precipitation. The containment capacity is equivalent to 164% of the capacity of the largest container (33,660 gallons - 882 gallons)/20,000 gallons). APPENDIX B SECONDARY CONTAINMENT/WATER DRAINAGE LOG This log is to be completed whenever water is discharged from a containment area. Only clean water may be discharged from the containment area. The manual valve must remain closed except when draining water from the containment area. The valve must be closed promptly after the containment area is drained. Containment Area # Date Visible Oil Sheen?* Yes/No Time Valve Opened Time Valve Closed Signature *Note: Water which has a sheen must not be discharged from the containment area. Contaminated water must be treated so that it does not have a sheen prior to being discharged from the containment area, or transported off site by a licensed hazardous waste or waste oil contractor for disposal. APPENDIX C SPILL CONTROL SYSTEM INSPECTION CHECKLIST SPILL CONTROL SYSTEM Inspection checklist This program deals with chemical and waste container and tank storage areas. The questions in this program element pertain to the responsibility and management practices for the prevention, detection, and containment of spills or leakage from tanks and containers. 1 2 3 4 5 6 7 Are outdoor spill control structures sized for the larger of the following: 1.5X the volume of the largest individual container or tank, or For hazardous waste, 1.0X the largest single container or tank plus (+) the amount predicted for 24 hours of rainfall from the site's "25-year storm", or 2% of the volume of all containers served by the structure? (For this program, a "tank" is defined as a container of greater than 55 gallons (208 liters). Double-walled, self-contained storage tanks do not require additional spill control protection, provided transfer operations use dripless connectors, valving and/or pricing which can preclude spillage.) Are indoor spill control structures sized for the larger of the following: 1.0X the volume of the largest individual tank, or 10% of the combined volume of all tanks served by the structure, or 2% of the combined volume of all containers served by the structure? (Indoor spill control structures are those protected from direct rainfall or run-on flow.) 8 Are all spill control structures free of cracks, unsealed joints or otherwise impermeable to leakage or migration to spills to the ground or underlying foundation? 9 For spill control structures which may be shared (via piping) by tanks or containers holding incompatible material, are there written procedures to ensure those materials are never commingled within the structure? 10 Do all tanks have readily accessible means for determining liquid level? 11 Do hazardous waste tanks, or unattended containers collecting liquid waste, have a means to prevent overfilling? 12 For tanks installed in below-grade, open-top, or enclosed spill controls structures, are leaks easily detected? 13 14 15 16 Are the following labeling requirements met: For hazardous waste tanks, labeled for content and capacity? For any vessel or structure holding hazardous waste, labeled either as "hazardous waste", or with the specific name of the waste substance? Are all labels directly affixed to the container or conveyance which holds or transports the material? Do labels on piping indicate the direction of flow? Are all tanks and spill control facilities inspected for leaks or releases, Yes No NA structural damage and/or deterioration as follows: 17 18 19 Hazardous waste tanks and piping on a daily basis? If not spill controlled, piping on outdoor pipe-racks which do not contain hazardous waste, on a daily basis. Containers of oil, fuel and hazardous materials on a weekly basis. 20 Are spill control structures which collect rainwater emptied within 24 hours (allowing for intermittent rainstorms?) 21 Are records of spill control inspections, integrity testing, rainwater or residue analysis, and maintenance records kept on-site for at least three years?