Adapting a genetic algorithm to schedule variants of the

advertisement

Adapting a genetic algorithm to schedule variants of the

manufacturing shop.

P. R. Drake* and I. A. Choudhry

Intelligent Systems Laboratory,

Systems Division, School of Engineering, University of Wales Cardiff,

Queen's Buildings, Cardiff, CF2 3TE.

Abstract

Whilst it is well documented how genetic algorithms (GA's) can be applied to

scheduling jobs for simple manufacturing shop models, this paper shows how they can

be used to schedule jobs for some of the more complex standard models. The simplicity

of the methods presented, and the use of proprietary spreadsheet software and GA 'addin' to implement them, support the conjecture that GA's can provide a highly flexible

and user-friendly solution to the general shop scheduling problem.

1

Introduction

Since the late 1980s there has been a growing interest in genetic algorithms (GA's) optimisation algorithms based on the principles of natural (Darwinian) evolution. As

they are based on evolutionary learning they come under the heading of Artificial

Intelligence. They have been used widely for parameter optimisation, classification and

learning in a wide range of applications. More recently, production scheduling has

emerged as an application. In particular, such applications have started to appear in this

journal (Jain and Elmaraghy 1997) (Lee, Piramuthu and Tsai 1997). Whilst it is well

documented how GA's can be applied to simple job sequencing problems, this paper

shows how they can be implemented to sequence jobs/operations for manufacturing

shops with precedence constraints among manufacturing tasks, alternative routeings

(machines), sequence dependent set-up times and scheduled machine downtime. The

methods presented are very simple and easy to implement and therefore support the

conjecture that GA's can provide a highly flexible and user-friendly solution to the

general shop scheduling problem.

The work presented here is carried out using standard spreadsheet software and an 'addin' to provide the basic GA. The use of this proprietary software demonstrates how

simple it is to implement the GA approach to schedule optimisation - very little software

skill is required. Spreadsheets are used widely in manufacturing industry and they are

particularly suitable for production scheduling because they store and manipulate data in

tables.

2

2

The Sequence Optimisation GA

Detailed introductions to GA's are given by Goldberg (1989) and Davis (1991). The

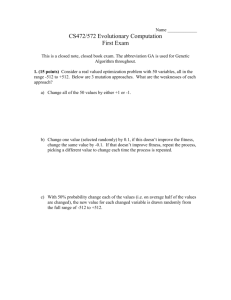

flowchart for the particular GA used here is given in Figure 1. First, an initial population

of randomly generated sequences of the tasks in the schedule is created. These

individual schedules form 'chromosomes' which are to be subjected to a form of

Darwinian evolution. The size of the population is user-defined and the fitness of each

individual schedule in the population is calculated according to a user-defined fitness

function such as: total makespan; mean tardiness; maximum tardiness; number of tardy

jobs. The schedules are then ranked according to the value of their fitness function.

Once an initial population has been formed, 'selection', 'crossover' and 'mutation'

operations are repeatedly performed until the fittest member of the evolving population

converges to an optimal fitness value. Alternatively, the GA may run for a user defined

number of iterations.

The 'selection' process consists of selecting a pair of parents from the current population

using a rank-based mechanism to control the probability of selection. These parents then

mate to produce a child by applying (in this particular implementation) the 'uniform

order-based' crossover operator (Davis 1991). This is based on using a randomly

generated bit string (zero-one) template to determine for each parent which genes are

carried forward into their child. The operator is explained by the example in Figure 2.

Here, the bit string template contains a one at positions {2, 3, 5, 6}. The genes (jobs) in

these positions in parent-1 are carried straight across into the child. The template

contains zeros at positions {1, 4, 7, 8}. In these positions parent-1 has genes {1, 4, 7, 8}.

These genes are copied into the child in the same order as they appear in parent-2 {8, 4,

3

7, 1}. The proportion of the jobs in the child coming from the first parent is defined by

the crossover rate which has a value between 0 and 1.

Following crossover, the resultant child may be mutated. The particular mutation

operation used here is 'order-based' mutation. In this operation two jobs change

positions in the chromosome. The probability that a job is mutated is defined by the user

defined mutation rate which lies in the range 0 to 1. The purpose of mutation is to

ensure that diversity is maintained within the population. It gives random movement

about the search space thus preventing the GA becoming trapped in 'blind corners' or

'local optima'. Finally, the new 'child' schedule replaces the weakest (least fit) schedule

in the current pool or 'population' of schedules.

A population size of 50, a crossover rate of 0.65 and a mutation rate of 0.006 are used in

the experiments presented here.

3

Why use GA's for Shop Scheduling ?

It is a characteristic of the schedule optimisation process that once fairly good solutions

have been formed their features will be carried forward into better solutions, and lead

ultimately to optimal solutions. It is in the nature of the GA that new solutions are

formed from the features of known good solutions. Therefore, it follows that GA's are

particularly attractive for scheduling.

Compared with other optimisation methods, GA's are suitable for traversing large search

spaces since they can do this relatively rapidly and because the mutation operator diverts

the method away from local minima, which will tend to become more common as the

search space increases in size. Being suitable for large search spaces is a useful

4

advantage when dealing with schedules of increasing size since the solution space will

grow very rapidly, especially when this is compounded by such features as alternative

machines/routes. It is important that these large search spaces are traversed as rapidly as

possible to enable the practical and useful implementation of automated schedule

optimisation. If the optimisation is done quickly then production managers can try out

'what-if' scenarios and detailed sensitivity analysis as well as being able to react to

'crises' as soon as possible.

For a simple n jobs and m machines schedule the upper bound on the number of

solutions is (n!)m. Without n and m being very large this value soon becomes massive,

e.g. for 20 jobs and 5 machines the value is 8.52x1091. Traditional approaches to

schedule optimisation such as mathematical programming and 'branch and bound' are

computationally very slow in such a massive search space.

4

Example 1: A Flow Shop

Table 1 gives the job data for this example and the objective is to minimise the

makespan for the schedule. When the GA is applied to this example the best sequence is

3-6-4-7-2-8-1-5 which yields a makespan of 584 units of time. The result of applying

the 'network scheduling technique' to this example was recently reported and the best

sequence found was 3-6-4-7-8-2-1-5 which produces a makespan of 595 units of time

(Akpan 1996). This was also the best result reported when using a heuristic method

(Campbell, Smith and Dudek 1970).

5

Precedence Constraints

5

The normal sequence optimising GA will rearrange freely the jobs in a schedule.

However, in most production scheduling situations there will be precedence constraints

on the order of operations within a particular job. For example, holes must be drilled

before they are tapped. To implement such constraints, a precedence table is introduced

as in Table 2 for the example considered in the next section. This table shows that, for

example, task 5 must be done before tasks 6 and 7. When the GA creates a child the

precedence table is checked. If any precedence constraints are broken then tasks which

must be performed earlier in the sequence are moved up the schedule.

6

Example 2: Alternative Machines

There may be a choice of machines that can be used for a particular operation as

illustrated in Table 3. In this example operation 2 for job A can be performed on

machine 1 or 3, operation 2 for job B on machine 1 or 2, and so on. Table 4 presents the

same information in the form of a 20 job-operation sequence. Note, five of these

operations {tasks 3,7,13,15,19} will not in fact be performed. They are present in the

table solely for the purpose of making the alternatives available to future generations.

The first occurrence of a duplicated operation is taken to be an 'actual' occurrence that

must be included in the calculation of the fitness function while subsequent occurrences

are ignored. However, all occurrences are included in the crossover and mutation

operations.

Using integer programming, Jiang and Hsiao (1994) produce two optimised schedules

for this example - one to minimise the total absolute deviation from the due dates and

one to minimise the total finishing times of the individual jobs. They show that the

minimum total absolute deviation is four time units and the minimum total finishing

time is ten time units. The GA produced the same results. Figures 3 and 4 show the

6

schedules generated to optimise the two fitness functions. Table 5 illustrates how the

GA presents the optimal solution for the minimum total finishing times schedule. As

explained before, this is a sequence of 20 operations including 5 duplicated operations

that are to be ignored.

7. Example 3: Sequence Dependent Set-up Times

Inter-operation set-up times may depend on the type of operation that has just been

completed, as well as on the type of operation to be performed. In such situations it is

not valid to absorb the set-up time for a job into its processing time. To accommodate

sequence dependent set-up times, look-up tables containing the times are introduced.

Then, fitness functions such as total makespan (lead-time) can be calculated for a

schedule by combining process times with the appropriate set-up times in the look-up

table.

Table 6 presents an example schedule with the corresponding sequence dependent setup times being given in Tables 7 to 9. The smallest total makespan found by the GA is

45 time units with the task sequence {1,7,8,9,4,5,10,11,12,2,3,6}. Again, it is a

relatively simple matter to implement the fitness function required to enable the GA to

optimise this schedule.

8. Example 4: Scheduled Machine Downtime

Scheduled machine downtime may be requested for preventive or reactive maintenance.

In the model considered here, the downtime must be inserted into the production

schedule according to the following two rules.

7

i. If there is no production scheduled for a machine at the start of a requested

downtime, then the downtime is allocated as requested. Any production

scheduled to start during the downtime is moved to the end of the downtime.

ii. If production is already scheduled at the start time of the requested downtime,

then the downtime is moved to the end of this operation.

Other rules may be used as desired. The important principle being demonstrated here is

how these rules are applied with the GA.

Consider, the 3-job, 4-machine job shop example in Table 10 taken from Pinedo (1995).

The precedence constraints for this example are defined in Table 11. The best makespan

found by Pinedo for this example is 28. He uses disjunctive graphs and proves that this

solution is optimal. The GA finds the same solution but with a different sequence of

operations. The Gantt charts for the two solutions are given in Figure 5.

Now consider that before the execution of the schedule the maintenance department

request machines 1, 2 and 4 for the times given in Table 12. This machine downtime is

inserted into the schedule according to the above two rules to give the schedule in

Figure 6. This increases the makespan to 55 time units. Rerunning the GA to optimise

this schedule, the makespan is reduced to 51 as shown in Figure 7.

9

Conclusion

8

The adaptation of a GA to schedule jobs in manufacturing shops with precedence

constraints among tasks, alternative routeings, sequence dependent set-up times and

scheduled machine downtime has been demonstrated. The simplicity of the methods

used supports the conjecture that GA's can provide a highly flexible and user-friendly

solution to the general shop scheduling problem. The use of proprietary spreadsheet

software and a proprietary 'add-in' to implement the GA has shown how simple it is to

implement this approach to scheduling.

References

AKPAN, E. O. P., 1996, Job-shop sequencing problems via network scheduling

technique, International Journal of Operations and Production Management, 16, 76-86.

CAMPBELL, H. G., SMITH, M. L., DUDEK, R. A., 1970, A heuristic algorithm for the

N jobs, machine sequencing problem, Management Science, 16, B630-B637.

DAVIS L, 1991, Handbook of Genetic Algorithms, New York: Van Nostrand Reinhold.

GOLDBERG, D. E., 1989, Genetic Algorithms in Search, Optimisation and Machine

Learning, Reading, MA: Addison-Wesley.

JAIN A. K., ELMARAGHY H.A., 1997, Production scheduling/rescheduling in flexible

manufacturing, International Journal of Production Research, 35, 281-309.

JIANG J. and HSIAO W., 1994, Mathematical Programming for the Scheduling

Problem with Alternative Process Plans in FMS, Computers & Industrial. Engineering,

27, 15-18.

9

LEE C.-Y., PIRAMUTHU S. and TSAI Y. -K., 1997, Job shop scheduling with a

genetic algorithm and machine learning, International Journal of Production Research,

35, 1171-1191.

PINEDO, M., 1995, Scheduling: Theory, Algorithms and Systems, Prentice Hall, New

Jersey.

Acknowledgements

The authors would like to thank the Pakistan Government for their assistance in this

research.

10

Define population size,

crossover rate and mutation rate.

Generate random initial population

Calculate fitness function values.

Rank population by fitness.

Select two parents

Crossover

Mutate

Check precedence

Calculate fitness of child

Add child to population

Delete least fit member of population

Convergence

No

condition

satisfied ?

Yes

Output best solution

Figure 1: The Genetic Algorithm (GA) for Schedule Optimisation

11

Position in Chromosome

1 2 3 4 5 6 7 8

Parent-1

1 2 3 4 5 6 7 8

Binary Template

0 1 1 0 1 1 0 0

Parent-2

8 6 4 2 7 5 3 1

Child

8 2 3 4 5 6 7 1

Figure 2: Schedule Chromosomes and the Crossover Operator

Machine 1

A-1

Machine 2

E-1

Machine 3

D-1

B-2

B-1

B-3 A-2 C-3

D-2

C-1

Machine 4

E-3

E-2

1

2

D-3

C-2

3

4

A-3

5

6

7

8

9

10

Time

Figure 3 : Schedule to minimise absolute

deviation from due dates.

Machine 1

A-1

Machine 2

E-1

Machine 3

D-1 D-2

Machine 4

E-2

1

A-2 B-2 B-3

C-3

B-1 D-3

2

E-3

C-1

A-3

3

4

C-2

5

6

7

8

9

10

Time

Figure 4 : Schedule to minimise total finishing times.

12

Machine 1

1

Machine 2

3

2

2

1

3

Machine 3

1

Machine 4

2

2

0

5

10

15

3

20

25

30

Time

30

Time

(a) Machine Gantt Chart for Pinedo's Solution

Machine 1

1

Machine 2

2

3

2

1

3

Machine 3

2

Machine 4

2

0

5

10

15

20

25

(b) Machine Gantt Chart for GA Solution

1

3

Figure 5 : Gantt Chart for Pinedo’s Solution and the GA Solution

13

Machine 1

1

Machine 2

2

2

3

1

3

Machine 3

2

Machine 4

2

0

5

1

3

10 15 20 25 30 35 40 45 50 55

Time

Legend:

1

Operation

Machine Unavailability

Figure 6 : Modified schedule with machine downtime inserted

Machine 1

1

Machine 2

2

3

2

1

Machine 3

3

1

Machine 4

2

2

0

5

3

10 15 20 25 30 35 40 45 50 55

Legend:

1

Operation

Machine Unavailability

Figure 7 : Modified schedule after rerunning the GA

14

Time

Table 1: Job Data for 8-job, 7-machine flow line example.

Job

List

1

2

3

4

5

6

7

8

Processing Times for Machine

1

13

31

17

19

94

8

10

80

2

79

13

1

28

75

24

57

17

3

23

14

10

3

13

38

4

71

94

23

4

58

32

1

40

5

60

60

36

58

4

92

66

6

27

61

8

73

68

94

75

25

7

2

57

86

40

46

89

29

88

Table 2: Precedence Constraints for Tasks

Task

Number

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Must follow

1

1

2

3

5

5

6

7

9

10

12

12

14

13

13

15

17

17

18

19

15

Table 3: The Alternative Machines Schedule

JobOperation

A-1

A-2

A-3

B-1

B-2

B-3

C-1

C-2

C-3

D-1

D-2

D-3

E-1

E-2

E-3

Processing time

for machine

1

2

3

4

2

1

2

1

1

1

2

1

2

2

1

1

2

2

1

1

1

2

1

2

16

Due

Date

6

3

6

6

6

Table 4: GA Representation of the Example Alternative Machines Schedule

Job

Number

Operation

Machine

Process

Time

Contribution

to Fitness

Function

Task

Number*

A

A

A

A

B

B

B

B

C

C

C

D

D

D

D

D

E

E

E

E

1

2

2

3

1

2

2

1

1

2

3

1

1

2

2

3

1

2

2

3

1

1

3

4

2

1

2

1

3

4

1

3

4

2

3

2

2

2

4

3

2

1

2

1

1

1

2

1

2

2

1

1

2

2

1

1

1

2

1

2

2

1

1

1

1

1

2

2

1

1

2

1

1

2

2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

* This column represents the chromosome used in the crossover and mutation

operations.

17

Table 5: GA Optimised Schedule to Minimise Total Finishing Time

Job

Number

Operation

Machine

Process

Time

Contribution

to Fitness

Function

Task

Number*

D

A

A

D

A

D

E

E

B

B

D

D

E

E

B

A

C

C

B

C

1

1

2

1

2

2

1

2

1

2

2

3

2

3

2

3

1

2

3

3

3

1

1

4

3

3

2

4

2

1

3

2

2

3

2

4

3

4

1

1

1

2

1

2

2

1

1

1

1

1

1

1

2

2

2

1

2

2

1

1

1

2

1

1

1

1

1

1

1

2

1

2

2

1

1

12

1

2

13

3

14

17

19

5

6

14

16

18

20

7

4

9

10

8

11

* This column represents the chromosome used in the crossover and mutation

operations.

18

Table 6: Schedule Data for the Sequence Dependent Set-up Times Example.

Job

Operation

Machine

Part Type

1

1

1

2

2

2

3

3

3

4

4

4

1

2

3

1

2

3

1

2

3

1

2

3

B

A

C

B

C

A

A

B

C

A

C

B

1

1

1

2

2

2

3

3

3

4

4

4

Process

Time

4

7

6

9

5

4

1

2

10

8

4

5

Task

Number*

1

2

3

4

5

6

7

8

9

10

11

12

* This column represents the chromosome used in the crossover and mutation

operations.

19

Table 7: Sequence Dependent Set-up Times for Machine 1

From Part Type

None

1

2

3

4

To Part Type

1

2

3

4

2

3

2

4

0

3

1

5

1

0

3

2

2

4

0

1

2

4

2

0

Table 8: Sequence Dependent Set-up Times for Machine 2

From Part Type

None

1

2

3

4

To Part Type

1

2

3

4

2

1

3

1

0

2

3

5

5

0

1

3

4

2

0

1

3

3

4

0

Table 9: Sequence Dependent Set-up Times for Machine 3

From Part Type

None

1

2

3

4

To Part Type

1

2

3

4

1

3

2

2

0

3

2

5

3

0

4

3

2

2

0

4

2

5

3

0

20

Table 10: Processing times and machine sequences for

3-job, 4-machine example

Job

1

2

3

Operation Processing

Times

1st

2nd 3rd

4th

10

8

4

8

3

5

6

4

7

3

-

Machine Sequence

1st

1

2

1

2nd

2

1

2

3rd

3

4

4

Table 11: Precedence Constraint Table

Job-operation

1-1

1-2

1-3

2-1

2-2

2-3

2-4

3-1

3-2

3-3

Must follow

job-operation

1-1

1-2

2-1

2-2

2-3

3-1

3-2

Table 12 : Requested Machine Downtimes

Machine

1

2

4

Requested Downtimes

Start

Finish

Duration

10

20

10

15

30

15

10

40

30

21

4th

3

-