行政院國家科學委員會專題研究計畫成果報告

advertisement

Stress Effect on the Reaction Kinetics of Metal/Silicon

systems

計畫編號:甲-91-E-FA04-1-4

執行期限:94 年 4 月 1 日至 95 年 3 月 31 日

主持人:C.J. Tsai

計畫參與人員:Y.C. Chu, and L.H. Wu

Department of Materials Science and Engineering, National Tsing Hua University,

Hsinchu, Taiwan, ROC

Ⅰ. Abstract

stability of phase3,4, the nucleation site of

epitaxial growth5,6, and even the property of

The stress-field distribution of the

periodic nano-scale-pattern NiSi2 templates,

fabricated using polystyrene nanosphere

lithography, has been simulated using finite

element method in our previous experiments.

From the results of simulation, controllable

nano-scale stress field is formed clearly on

the surface of Si substrate. In this experiment,

we show that this stress which induced by the

lattice mismatch between NiSi2 and Si

device7. In our previous experiments, we

have observed that a tensile stress obviously

enhances the mobility of Si during the

annealing process in the TiN/Ti/Si system.

Here, another effect of stress: stress-induced

shape transition of epitaxial NiSi2 clusters on

Si substrate, is shown and explained by the

results of strain energy simulated by finite

element method.

NiSi2 is easy to form epitaxial structures

substrate will influence the shape of NiSi2

clusters as the clusters grow. By calculating

the total strain energy of different aspect ratio

of NiSi2 clusters, long thin structure is found

to allow better stress relaxation but has larger

NiSi2 surface and NiSi2/Si interface. Because

the volume-to-area ratio increase as the

volume of NiSi2 clusters increase, NiSi2

clusters form a special stable shape on the

balance between strain energy and interface

with Si because the lattice mismatch between

one another is only 0.46 % (at room

energy for different volume. For this reason,

NiSi2 cluster will grow in a square shape at

first and transform to a shape with high

aspect ratios at larger sizes.

polystyrene nanosphere lithography in our

pervious experiments. The stress field of

these structures has also been simulated using

finite element method. From the results of

simulation, the NiSi2 can induce a stress

distribution in the Si substrate due to the

lattice mismatch between the NiSi2 and Si

substrate. These structures with periodic

stress distribution on substrate surface are

temperature). The normal shapes of NiSi2

epitaxial cluster are facet bar structures with

{111}-oriented interfaces with Si and

<110>-oriented edges on the surface of Si

substrate. Large-area periodic nano–scale

-pattern NiSi2 templates have been

successfully fabricated using a convenient

and simple nano-lithography method:

Ⅱ. Introduction

Stress is found to influence the rate of

chemical reaction1,2, the formation and

1

useful for experiment studies or device

on Si substrate. During the simulation

applications.

Tersoff and Tromp have use a simple

geometry to derive an approximation for the

strain energy of a dislocation-free islands and

proposed that a strain-induce shape transition

may occur from square to rectangular as the

islands grow8. Brongersma etc. have also

seen this phenomenon in the growth of CoSi2

clusters on Si substrate9. In opposition to the

approximation calculation Tersoff and

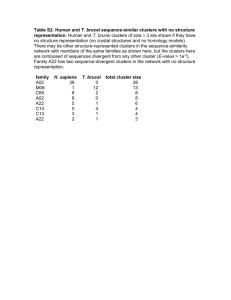

Fig. 1. The 3-D structures used to simulate the strain

energy of the NiSi2 cluster.

Tromp use, more accurate solutions to the

strain energy in the epitaxial structures are

simulated using finite element method with a

3-D structure. The more exactly relation

process, the cubic symmetry of mechanical

property for Si substrate and NiSi2 are taken

into account. The volumes of the Si

substrates in all cases are fixed and large

enough to stabilize the solutions of

simulation.

In order to fix the volume of NiSi2

clusters, a cluster with unit length in all (110)

edges is selected as the reference structure.

between stable shape, strain energy, surface

energy, and interface energy of the epitaxial

structures is obtain in this experiment.

There are two parts in the analysis of the

relation between strain energy and aspect

ratios of NiSi2 clusters. First, we fix the

volume and simulate the strain energy of

different aspect ratios NiSi2 clusters. The

surface and interface areas of different aspect

ratios NiSi2 clusters are calculated to

compare with the strain energy. A most

stable shape will be obtained if the surface

and interface energy of the NiSi2 are known

in this volume. Second, we calculate the

evolution of total energy change for different

aspect ratios of NiSi2 clusters as the volume

We change the length of short edges in Fig. 1

from nine-tenth to two-tenth of the unit

length and use the volume of reference

structure to calculate the lengths the long

edges need to have. NiSi2 clusters with nine

different aspect ratios range from 1 for the

reference structure to about 84 for the

structure with two-tenth short edge length are

obtained.

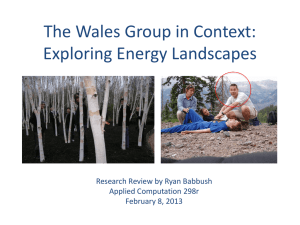

Fig. 2 (a) shows the relation between the

of the clusters grow. A shape transition can

be observed clearly in this process.

strain energy and the aspect ratios of the

NiSi2 clusters. It can see clearly that the

relaxation of the lattice-mismatch-induce

stress is strongly dependent on the geometry

of the NiSi2. As the aspect ratio of NiSi2

cluster increase form 1 to about 10, the strain

energy decrease rapidly. As the aspect rations

increase more, the strain energy decrease

Ⅲ. Results and Discussion

An example of the 3-D structures we

used to simulate the strain energy in this

experiment is shown in Fig. 1. These

structures mimic the real NiSi2 clusters grow

more slowly. Fig 2 (b) is the evolution of the

2

and interface energy as the aspect ratios of

NiSi2/Si Interface Area / Volume of NiSi 2

NiSi2 surface and the NiSi2/Si interface areas

Strain Energy

1.0

0.9

0.8

0.7

0.6

0

(a)

20

40

60

Aspect Ratio

80

100

10

structure with 3/10 short edge length

structure with 5/10 short edge length

structure with 7/10 short edge length

structure with 9/10 short edge length

9

8

7

6

5

4

3

2

1

0

20

40

(a)

60

80

100

Volume of NiSi2

120

140

7

6

NiSi2/Si interface

NiSi2 surface

6

5

2.4

4

3

2

2.2

2.0

3

2

1.8

1.6

1.4

1.2

1

1

(b)

4

Aspect Ratio

Aspect Ratio

Area

5

1.0

0.8

0

20

40

60

Aspect Ratio

80

100

0

(b)

Fig. 2 (a) The relation between the strain energy and

0

100

0

200

2

4

300

Volume

6

8

10

Volume

400

12

500

14

600

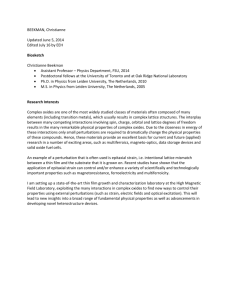

Fig. 3 (a) The evolution of volume-to–area ratios as

the aspect ratios of the NiSi2 clusters. All of the strain

the volume of NiSi2 growth for different aspect ratios

energy are normalized to the strain energy of reference

structures. (b) The stable shapes for different volume

structure. (b) The relation between the area of NiSi2/Si

of epitaxial structure. The inset shows the evolution of

interface, NiSi2 surface, and the aspect ratios of the

shape when the volume of cluster is small.

NiSi2 clusters. All of these areas are normalized to the

NiSi2 surface area of the reference structure.

structures change, we can speculate that

when an epitaxial system with small strain

energy or larger interfacial energy, it will

tend to form lower aspect ratios structures to

reduce the total energy. Oppositely, a higher

as the aspect ratios of NiSi2 clusters increase.

A continuously increase of the NiSi2 surface

and the NiSi2/Si interface areas is shown

even the aspect ratios of NiSi2 clusters are

large than 80. The stable shape of NiSi2

cluster at this volume is the structure with the

lowest total energy: strain energy adds the

surface and interface energy. If the surface

and interface energy of NiSi2 are known and

take into account, the stable shape will be

obtained.

According to evolution of strain, surface,

aspect ratio structure will form in an epitaxial

system with larger strain energy or lower

interfacial energy. Besides, epitaxial clusters

with aspect ration lager than 100 are difficult

to obtain because the strain energy decrease

little but the surface and interface areas still

increase when the aspect ratios of structures

are large.

During the growth of NiSi2 clusters, the

3

volume and area of them will growth with

different rates. Fig. 3 (a) is the evolution of

volume-to–area ratios as the volume of NiSi2

growth for different aspect ratios NiSi2

clusters (surface areas have the same

tendency as interface area and are not shown

in the figure). The higher aspect ratios

structures have larger areas at the same

volume, but no matter what structures the

NiSi2 clusters are, the volume-to-area ratios

are lower when the sizes of clusters are

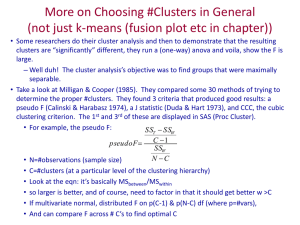

Fig. 4 The SEM image of the NiSi2 clusters growth on

Si (001) substrate.

smaller and increase as the clusters growth. It

implies that the stable structures of epitaxial

clusters will change during the growth

process. Here we arbitrarily give a value to

volume of NiSi2 clusters have been seen in

experiments and are shown in Fig. 4. Squarer

shapes for smaller NiSi2 clusters and long

thin structures for larger clusters are shown

in the SEM image and this result is in

coincidence with our speculation.

the interface and surface energy of NiSi2

clusters and investigate the evolution of

shape transition of NiSi2. The results are

shown in Fig. 3 (b). We can see clearly that

the stable shapes of epitaxial structures are

squarer in the beginning and then elongate as

Ⅳ. Conclusions

the clusters grow. The reason for the shape

transition is because a squarer shape will

reduce the interface energy more than the

increase of strain energy increase as the

volume-to-area ratio is small at the beginning.

After the clusters become larger, high aspect

ratios structures can relax more strain energy

expense a lesser increase in the surface and

interface energy due to the larger

volume-to-area ratios. The aspect rations of

We calculate the strain energy for

different aspect ratios NiSi2 epitaxial

structures using finite element method with a

3-D structure in this experiment. A

stress-induced shape transition in the growth

of NiSi2 clusters is anticipated and evidenced.

The understanding of the factors which

influence the stable shapes of epitaxial

clusters is useful to control the geometries of

nano-structures.

structures do not increase without limit as

show in Fig. 3. As the volume of the NiSi2

clusters increase to a critic size, the aspect

rations of structure are difficult to increase

more. It is because the further elongation of

shape does not efficiently relax the strain

energy but raises the surface and interface

energy as shown in Fig. 2.

The different aspect ratios for different

Ⅴ. Reference

[1] J. Tersoff, Yuhai Tu, and G. Grinstein,

Appl. Phys. Lett, 73, 2328 (1998).

[2] K. S. Kim, J. A. Hurtado, and H. Tan,

Phys. Rev. Lett, 83, 3872 (1999).

[3] E. M. Schaller, B. I. Boyanov, S. English,

and R. J. Nemanich, J. Appl. Phys. 85,

3614 (1999).

4

[4] S. L. Cheng, H. M. Lo, L. W. Cheng, and

L.J. Chen, Thin Solid Films, 424, 33

(2003).

[5] S. Y. Shiryaev, F. Jensen, J. L. Hansen,1

J. W. Petersen, and A. N. Larsen, Phys.

Rev. Lett, 78, 503 (1997).

[6] G. Jin, J. L. Liu, S. G. Thomas, Y. H. Luo,

and K. L. Wang. Appl. Phys. Lett. 75,

2752 (1999).

[7] A. K. Fung, L. Cong, J. D. Albrecht, M. I.

Nathan, P. P. Ruden, and H. Shtrikman, J.

Appl. Phys. 81, 502 (1997).

[8] J. Tersoff and R. M. Tromp, Phys. Rev.

Lett, 70, 2782 (1993).

[9] S. H. Brongersma, M. R. Castell, D. D.

Perovic, and M. Zinke-Allmang, Phys.

Rev. Lett, 80, 3795 (1998).

5