Ultrapure Water Production

advertisement

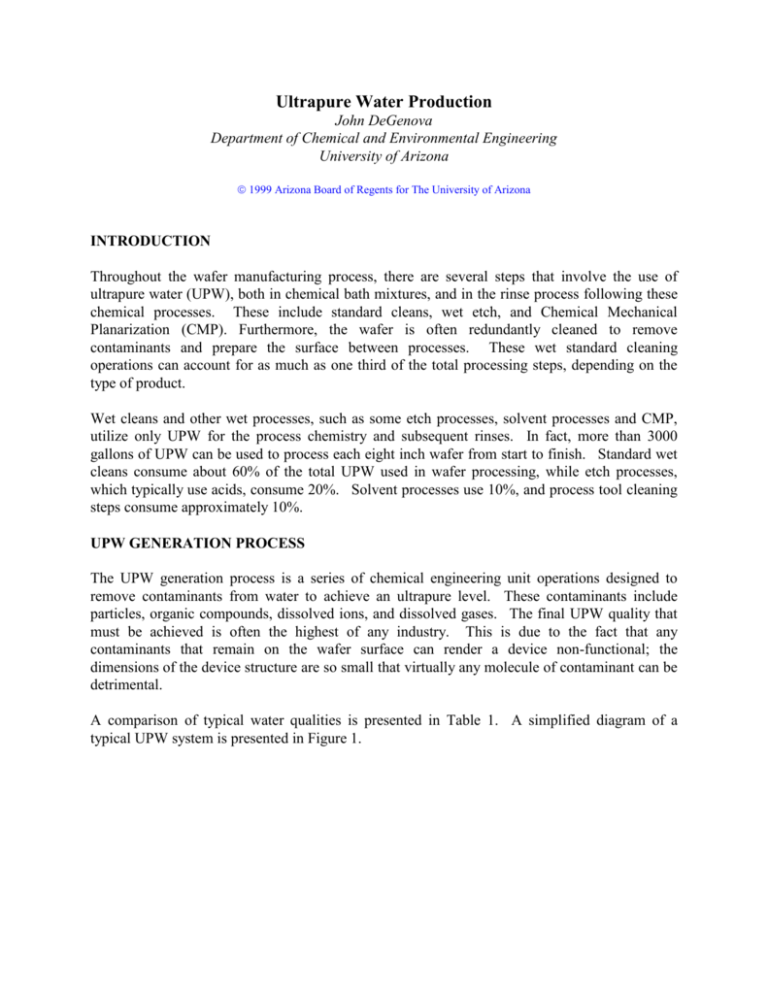

Ultrapure Water Production John DeGenova Department of Chemical and Environmental Engineering University of Arizona 1999 Arizona Board of Regents for The University of Arizona INTRODUCTION Throughout the wafer manufacturing process, there are several steps that involve the use of ultrapure water (UPW), both in chemical bath mixtures, and in the rinse process following these chemical processes. These include standard cleans, wet etch, and Chemical Mechanical Planarization (CMP). Furthermore, the wafer is often redundantly cleaned to remove contaminants and prepare the surface between processes. These wet standard cleaning operations can account for as much as one third of the total processing steps, depending on the type of product. Wet cleans and other wet processes, such as some etch processes, solvent processes and CMP, utilize only UPW for the process chemistry and subsequent rinses. In fact, more than 3000 gallons of UPW can be used to process each eight inch wafer from start to finish. Standard wet cleans consume about 60% of the total UPW used in wafer processing, while etch processes, which typically use acids, consume 20%. Solvent processes use 10%, and process tool cleaning steps consume approximately 10%. UPW GENERATION PROCESS The UPW generation process is a series of chemical engineering unit operations designed to remove contaminants from water to achieve an ultrapure level. These contaminants include particles, organic compounds, dissolved ions, and dissolved gases. The final UPW quality that must be achieved is often the highest of any industry. This is due to the fact that any contaminants that remain on the wafer surface can render a device non-functional; the dimensions of the device structure are so small that virtually any molecule of contaminant can be detrimental. A comparison of typical water qualities is presented in Table 1. A simplified diagram of a typical UPW system is presented in Figure 1. Water Quality Parameter Units Typical Municipal Water Supply Typical Ultrapure Water Product Resistivity pH TOC Ammonium Calcium Magnesium Potassium Silica Sodium Chloride Fluoride Sulfate M Ohms-cm units ppb ppb ppb ppb ppb ppb ppb ppb ppb ppb 0.004 8 3500 300 22000 4000 4500 4780 29000 15000 740 42000 >18 6 <10 <1 <1 <1 <1 <10 <1 <1 <1 <1 Table 1 – Water Quality Comparison Figure 1: Typical UPW Schematic F e e d F lo w (g p m ) 744 120 79 133 Feed Tank 1776 A c t. R e v e rse R e v e rse UV C a rb o n O sm o si s O sm o si s 254 n m 1199 U P W S u p p ly 1000 1776 1332 1199 444 IW W 1079 120 P ri m a ry D EG A S P ri m a ry (R O ) M ix e d UV Tank 1199 254 n m Be d 1199 1199 IX 1199 U P W R e tu rn 500 1079 500 P o l i sh UP W M ix e d UV P o l i sh Tank 1579 185 n m Be d 1579 IX U .F . 1579 1500 79 Makeup Water Feed water to a UPW facility is typically pumped from either a local well or from a municipal water treatment plant (sometimes both) to a raw water storage tank. Pumps from this storage tank re-pressurize the stream and provide a steady pressure flow through the pretreatment process. This pretreatment usually includes filtration steps such as multimedia filters (a combination of gravel, sand and anthracite) and/or activated carbon filtration. In the multi-media filtration process, water flows downward through the layers of media, leaving suspended solids trapped in the interstitial spaces. Multimedia filters require periodic backwashing, which fluidizes the media and releases the trapped particles. In an activated carbon process, water usually flows downward, adsorbing some of the organic compounds and typically all of any oxidizing compounds. Some manufacturers heat the water at this point to ensure better processing downstream. Heating the water improves hydraulic performance of the reverse osmosis (RO) units. It also, however, increases the species flux for most contaminants through the membrane, thus rendering the process less efficient at removing those contaminants. Chemical pretreatment to the RO process typically includes pH adjustment, such as an acid injection, and possibly a chlorine reducing agent, such as sodium bisulfite. If activated carbon filtration is present, addition of a reducing agent is not necessary. In some cases, an antiscalant is also added to help prevent precipitation and fouling on the RO membrane surface. Some UPW makeup systems incorporate water softeners to help remove ionic impurities that might otherwise foul RO membranes. These usually consist of filter housings that contain cartridge filters with a nominal pore rating of 0.5 to 1.0 m located immediately upstream of the RO pumps. These filters serve as a mixing chamber for the pretreatment chemicals as well as a vehicle for removing relatively large particles before the water enters the RO high pressure pumps. Reverse Osmosis The RO process is considered to be the workhorse of the UPW system. This process typically removes >98% of all dissolved solids, TOC, silica and particles from the feedwater stream. Most RO systems are labor intensive. They also consume a significant amount of the energy and chemicals required to maintain a dependable UPW system. Because the RO process is a membrane process rather than a simple cutoff filter, separation occurs based on the osmotic pressure difference across the membrane. Small molecular compounds that can pass through the membrane will not permeate if the osmotic pressure difference is favorable. Due to this behavior, many UPW systems contain dual pass RO systems, in which two RO systems are arranged in series. Product water from the first pass is fed into the second. In this way, an even better quality RO permeate can be produced. To maintain flow velocity across the membrane surface as the volume of remaining feed and concentrate is reduced by removal of permeate, all industrial RO systems are arranged in tapered arrays or stages. In each train, the concentrate from the first set of vessels is the feed to the second set of vessels. Typically, 100% of the feedwater fed to the first array is separated into two streams; a 50% permeate solution, and a 50% concentrate solution. The vessel configuration typically uses the concentrate produced from the first array to feed the second array, where this is again split into two streams; a 50% permeate solution, and a 50% concentrate solution. The overall permeate conversion is typically 75%. Different array designs are possible depending on feedwater characteristics and flow requirements. Vacuum Degasification Depending on the amount of chemical pretreatment, RO permeate water usually contains undesirable dissolved gasses such as carbon dioxide and oxygen. Typically, these gases are mostly removed with a vacuum degasifier. This system consists of a degasification tower that is under negative pressure by means of a vacuum pump. Water enters the degasifier at the top of the tower through an inlet header containing spray nozzles. As the sprayed water falls through the packing it is broken into fine droplets to create a larger surface area. Carbon dioxide, oxygen, and other volatile compounds are liberated and removed in the vapor flow. There is no waste stream since all water is recovered for further treatment. Storage Tanks Storage tanks utilized for UPW systems are typically lined with an inert polymer coating such as polyvinylidene fluoride (PVDF). Tanks vary in size but all are designed to store water for use in the high purity water re-circulation loops. High purity water storage tanks also receive return flow from the distribution piping network supplying the fab. These storage tanks are also blanketed with high purity nitrogen to prevent contamination from the air and maintain high levels of purity. When the tanks are full, water from the make-up system is diverted back to the raw water storage tank. This allows the RO plant to run continuously using water already metered, and thus reduce the intake of City Water. Mixed Bed Ion Exchange Ion exchange columns or beds, are a series of rubber-lined steel pressure vessels containing either cation exchange resin, anion exchange resin, or in the case of Mixed Bed Ion Exchange, a mixture of two synthetic ion exchange resins. These are commonly referred to as "mixed beds". The two different resins are utilized to perform specific ion exchange functions. As water passes downward through the mixed bed, the cation resins chemically exchange undesirable aqueous cations (e.g., Na+, Ca2+, Mg2+, etc.) with a hydrogen ion (H+) from the resins functional group. Undesirable aqueous anions (e.g., Cl-, SO42-, etc.) are exchanged with a hydroxyl molecule (OH-) attached to the anion resins. The hydrogen and hydroxyl ions then chemically combine to form H-O-H, or H2O, at the vessel outlet. The chemical reaction is fully reversible so that when the resins are completely loaded with the undesirable ions they become exhausted. At this point, dilute acid and caustic solutions are employed to flush away the "contaminant" ions and replenish the supply of hydrogen and hydroxyl ions. This cleansing step is also known as regeneration. All water is recovered while the mixed bed is in service. Regeneration procedures create various waste streams that are recoverable. Depending on the quality they are typically directed to either a reclaim storage tank for reuse in other facilities systems, diverted back to the regeneration water supply tank, or routed to an industrial wastewater neutralization system. Electrolytic Deionization (EDI) is a rather new technique that essentially regenerates the ion exchange resin continuously using electricity rather than regeneration chemicals. This process requires a membrane to separate channels into a permeate and a reject stream. Ions, once removed from the water onto a resin, are pulled from the resin via a charge across electrodes. These ions are pulled toward the electrode through the membrane and then into the reject stream, where they are washed away. EDI usually requires pretreatment with RO to obtain a pure enough feed stream to prevent fouling from salt formation. This process typically recovers 90 to 95% of the feedwater as permeate water. Ultraviolet Oxidizers/Sterilizers Ultraviolet oxidizers/sterilizers (UV) are cylindrical stainless steel flow chambers containing quartz sleeves with mercury lamps inside. Compression fittings connect the quartz sleeves to the flow chamber providing a waterproof seal. A perforated baffle surrounds the quartz sleeves and forces the inlet water to take a tortuous path before exiting. The turbulence created increases exposure time and surface area to the UV light. Ultraviolet processes serve different functions in a UPW system depending on their location and the wavelength of light emitted. Primary functions include: 185 nm UV light is typically used for the reduction of organic compounds. 254 nm UV light is typically used for destruction of bacteria. 254 nm UV light is typically used for the conversion of ozone and hydrogen peroxide to dissolved oxygen and water. All UV sterilization units are intended to provide in excess of 99.5% reduction of biological organisms. Ultrafilter Skid Spiral-wound ultrafilter (UF) membranes are similar to RO membranes. Ultrafilter membranes have a higher molecular weight cutoff than RO membranes but require less energy to produce equal volumes of permeate. Ultrafilter membranes are well suited for the removal of colloidal silica, endotoxins or pyrogens that may be created by other system components located upstream. They are employed towards the backend of a UPW system for these reasons. Typical UF membranes are spiral wound and maintain either a 6,000 or 10,000 molecular weight cut-off (MWCO) range, as opposed to the 100 MWCO for a standard RO membrane. Low pressure pumps supply the driving force necessary to divide the feedwater stream into two exit streams. Ninety-five percent of the feedwater is recovered as permeate. The remaining 5% is collected in the reject manifold but is also of very high quality. This UF reject can be recovered and sent to the feed water storage tank, or it can be used as feedwater to boilers, fab humidity control systems, the ion exchange regeneration loop, or other systems requiring high purity water.