SA-EMF - Emfuleni - Leakage reduction and water conservation

advertisement

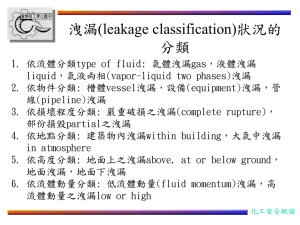

Case Study SA-EMF LEAKAGE REDUCTION AND WATER CONSERVATON All aspects of the water cycle draws benefit from water conservation and demand management. Two principles apply: i) any form or magnitude of leakage reduction will have a proportional energy demand; and ii) leakage is driven by pressure. This case study considers pressure management as 1st order intervention to reduce leakage and increase energy efficiency. Pressure Management as Water Demand Management Intervention Description of Process: Water leakage accounts for a significant portion of energy along the value chain of the water cycle. Infrastructure which has neglected through inadequate maintenance and replacement resources are particularly inefficient and gives cause for even high efficiencies downstream of the water cycle. Leakage is driven by water pressure. Hence, any reduction in pressure will result in lower leakage and reduced damage to pipes and pumps. The efficiency benefits are almost outweighed by the monitory benefits, especially in municipalities with a poor pollution and tax base. Pressure Management is therefore one of many possible WDM interventions that has successfully been applied in South Africa. The project involved the design, installation and commissioning of a pressure reduction chamber with appropriate sizing, fitting and operation of the valves, pipes, meters, strainers and monitoring equipment. The project involved cutting into existing water mains and replacing section with smaller diameter pipes and equipment. The chamber was operated to reduce pressure during off peak periods and restore to higher pressure during high demand period. Potential Interventions Pressure reduction is a 1st order intervention to be followed in series or parallel with complimentary actions within a holistic Leakage Management strategy Proactive reduction of water losses to a target value, reducing pressures to minimum targets in identified areas, pursuing asset renewal projects, metering to check and monitor supply zones for losses, and minimise repair times for visible and detected leaks Reactive pressure control would imply a response is only afforded once the municipality becomes aware of a supply or pressure problem in an area. be to respond timeously to reported bursts, consumer complaints, and unexpected changes in flow or pressure. Performance contracting to water supply is key to low capacity municipal suppliers. Range of potential savings Reported leakage for a well managed system is typically below 15% whereas in Sebokeng it was estimated to be in excess of 70% due to a number of factors including many years of low investment and poor maintenance. The reported cost saving from this project has been US$ 3.8 million/annum, 14 million kWh/annum and 8 million kiloliter water saved. The annual GHG emissions avoided was 12,000 tonnes. Payback on investment was 3 months. Case Study SA-EMF Case Study SA-EMF Case Study SA-EMF LEAKAGE REDUCTION AND WATER CONSERVATON Case Study SA-EMF Ref Response information, description and remarks 1 Location: South Africa, Emfuleni Local Municipality to the south of Johannesburg in industrial and urban area. 2 Sector: Clean water 3 Works Owner or Operator: The supply systems are owned and operated by Metsi-a-Lekoa, an entity established to manage the supply of potable water to the 1.2 m residents in the Sebokeng and Evaton area. The set up of the project was done via investment made by the developer (private sector) in a PPP arrangement over 5 years. 4 Size: 1.2 million residents are served in the Sebokeng and Evaton area, as well as >120 industries (ERWAT). Some 70 000 low income households are connected to the system with individual water supply and waterborne sewage. The leakage at the start of the project was 2800 m3/hour. 5 Energy Provider: Power is in form of electricity, provider by the national electricity agency, ESKOM. Energy cost has increased drastically from 2010 onwards and an average annual increase of 13% per annum is announced. Retail tariffs is at R 52 c/kWh (2011/12) and 65 c/kWh (2012/13) whilst municipal tariffs is as high as 22 c/kWh for >600 kWh consumers. 6 Process: No biological or chemical agents involved in case. Physical in so far as new / renewed infrastructure involved as under item 9. 7 Component: Involved the cut-in to a 1.2m diameter and 700mm diameter main and the construction of a large chamber to house the various valves and fittings needed to control the water pressure. 8 Motivation for the case study: All water used in the area has been pumped by approximately 400m and so any savings in water create direct energy savings through the reduced pumping. 9 Process/Plant changes: All plant used for composting with a bulking agent was used in the new operation. The existing inclined face compost turners were converted to sludge turners at a third of the cost of new machinery. Only 12 year old tub grinders were scrapped. 10 Civil/Physical Changes: Reduced pressure, water quality remains constant, reduced pressure has positive impact on life expectation of the infrastructure. 11 Operational Changes: As a result of the reduction in leakage, it was possible to address many long-term outstanding problems such as pockets of intermittent supply which have improved the level of service to the 500 000 residents. 12 Risks and Dependencies: Private sector investment was required to bridge financing constraints. Active community participation is crucial to ensure acceptability of initiative and negate vandalism and create awareness. The success of the project created awareness of the problems in the area which has acted as a catalyst for further funding support. 13 Implementation: The project was procured as a Private Public Partnership Project where the investment was repaid over 5 years from savings from the project. Design, build and installation was done by the PPP partner – WRP Consulting, Operation was undertaking by Emfuleni municipality operations utility Metsi-a-lekoa. 14 Energy Efficiency gains: An estimated 14 million kWh has been saved annually and gains are still ongoing and estimated at this rate. The energy savings translate to 65 000 tonnes of CO2 per over the 5 year period. 15 Cost/Benefit analysis: The project cost is recorded at R 10m (Euro 1 millin) to construct and operated of a 5 year period. The project achieved audited water savings of 50 million m3 over this period, which represent >R150 million (US$3.8 million) in reduce water purchases by the local municipality. A pay-back period of < 3 months was confirmed. 16 Project review: Longer term investments required, ensure sufficient O&M budgets and technical and managerial skills in place before PPP closes out. 17 Confidence grade: High confidence, data focus on financial aspects with supportive data and information. However, audited results would imply that engineering and scientific fact is in place and factual. Water savings were accurately monitored and accounted for. The associated energy savings are calculated directly from the water savings, based on conservative calculations. Emfuleni Local Municipality is located to the south of Johannesburg in the industrial heartland of South Africa. A separate water utility called Metsi-a-Lekoa was established to manage the supply of potable water to approximately 1.2 million residents of the Municipality of which 450 000 are located in the Sebokeng and Evaton areas. Water is in turn supplied to Metsi-a-Lekoa from the local bulk water provider, Rand Water, which is one of the largest providers of potable bulk water in the world. Leakage measurements indicated figures as high as Minimum Night Flows of 2 800 m3/hr. No storage in the Sebokeng and Evaton areas, either at bulk reticulation level or domestic property level. The high MNF was therefore almost completely due to leakage, most of which occurs inside the properties and is therefore not evident from normal visual inspection. It should also be noted that since most of the leakage occurs inside the households, the leaking water returns to the sewage treatment plant through the sewer network which is often overloaded to such an extent that spillages of raw sewage into local river courses are a common occurrence in the area. Estimates concluded that 80% of the water supplied to the area was lost, which in turn represented an annual water bill of approximately R120 million per year in 2003 ( ± Euro 15 million). Figures: i) Minimum Night Flow for Sebokeng/Evaton; ii) MNF where leaks are well managed (Dr R Mckenzie, 2011) Description of Process In 2004, the Municipality appointed WRP Pty Ltd to design and commission an advanced pressure management installation, as the first phase of a long term strategy to reduce wastage in the area. The project involved no financial input from the Municipality, as the full investment was made by the Project Team based on a risk-reward model. A 10m x 10m x 5m chamber was built containing the various pipes and valves required to manage the water pressures into Sebokeng and Evaton. Since leakage is driven by water pressure, any reduction in pressure, even if only for a short period each day, will result in lower leakage as well as fewer new burst pipes. If water pressures can be lowered significantly during the off-peak periods (especially at night) then very significant savings can often be achieved. The installation involved cutting into the two existing water mains and replacing a short section with a series of smaller pipes and associated valves, meters, strainers etc. The water pressures can be reduced during off peak periods and restored to the original high pressures during periods of high demand. In this manner, the leakage from the system as well as the incidence of new burst pipes was greatly reduced. Figure: Schematic representation of the pressure management installation (Watergy, 2007) Potential Interventions Pressure reduction is a 1st order intervention to be followed in series or parallel with complimentary actions within a holistic Leakage Management strategy Proactive pressure management imply the reduction of water losses to a target value, reducing pressures to minimum targets in identified areas, pursuing asset renewal projects, metering to check and monitor supply zones for losses, and minimise repair times for visible and detected leaks Reactive pressure control would imply a response is only afforded once the municipality becomes aware of a supply or pressure problem in an area. be to respond timeously to reported bursts, consumer complaints, and unexpected changes in flow or pressure. Conformance to the SA Presidential targets which include “50% reduction in water losses by 2014”. The project has been recognised both for its initial design as well as for the 5-year PPP model which were used over the 5 year project period. Sasol has recognised the model and will be applying the same principles in future project where the industry water footprint can be offset or reduced via similar initiatives. Benefits derived from case study: The most significant benefit from the project was the savings in water purchases by the Municipality from the bulk water provider due to the reduced leakage in the Sebokeng and Evaton areas. The final audited savings achieved by the project are as shown in the following table: The key results are summarised as follows: Comparison of Savings between SASOL and Sebokeng Projects (A Meyer, 5th WWF & UN CEO Water Mandate Workshop, Istanbul, March 2009) Performance contracting applied to the water supply Payback period of <3 months Annual cost savings: US$ 3.8 million Annual energy savings: 14 million kWh Annual water savings: 8 million kl Annual GHG emissions avoided: 12,000 tonnes Pressure management technology reduced water losses by > 30%. Cost Saving In financial terms, the project has saved in excess of R30 million per annum (ZAR) due to the reduced water purchases by the Municipality from the bulk water provider. These figures are based on the average cost of water of R3/m3 which was applicable during the 5-year PPP. It should be noted that the cost of water is almost R5/m3 (2012) and will increase substantially in future. The project cost approximately R10 mil ($1.5 mil) to construct and operate for the duration of the 5-year PPP project period. Acknowledgement: Watergy - Alliance to Save Energy (Feb 2007); Interview Dr Ronnie McKenzie, (2011).