GC determination of % yield of ester

advertisement

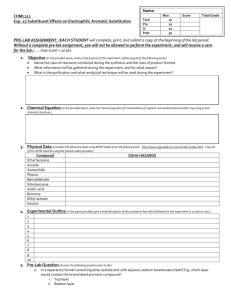

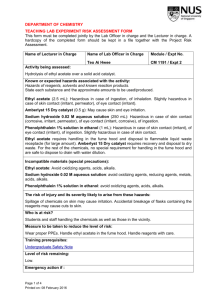

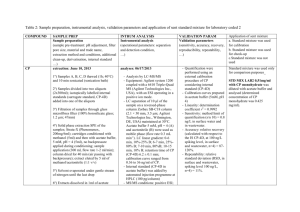

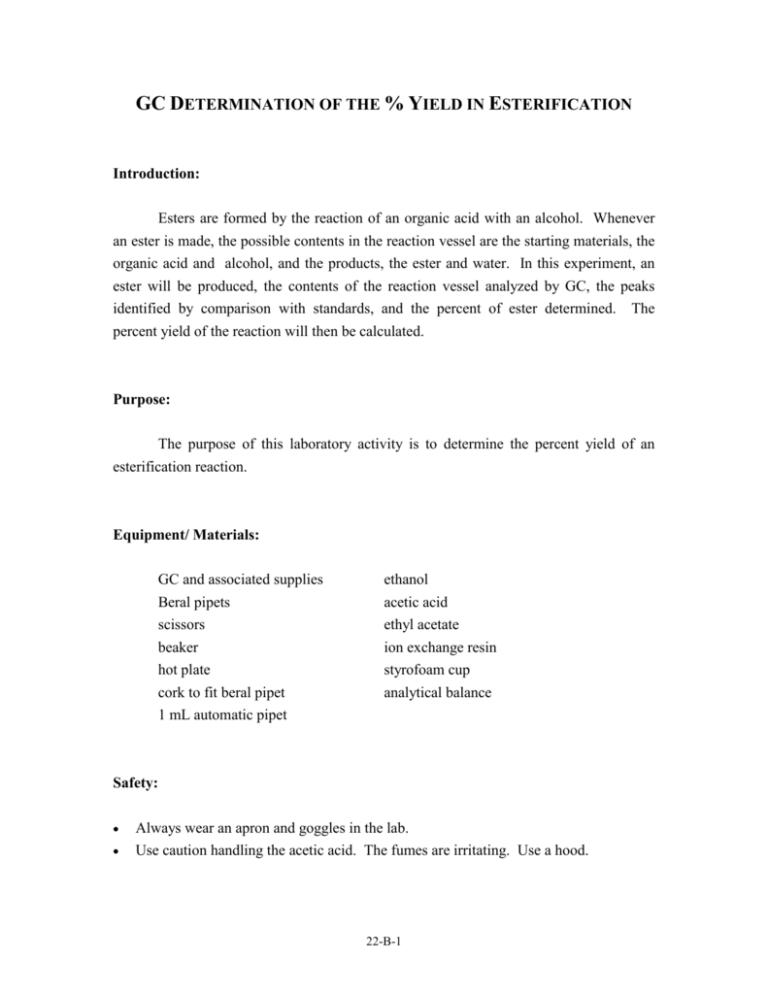

GC DETERMINATION OF THE % YIELD IN ESTERIFICATION Introduction: Esters are formed by the reaction of an organic acid with an alcohol. Whenever an ester is made, the possible contents in the reaction vessel are the starting materials, the organic acid and alcohol, and the products, the ester and water. In this experiment, an ester will be produced, the contents of the reaction vessel analyzed by GC, the peaks identified by comparison with standards, and the percent of ester determined. The percent yield of the reaction will then be calculated. Purpose: The purpose of this laboratory activity is to determine the percent yield of an esterification reaction. Equipment/ Materials: GC and associated supplies Beral pipets scissors beaker hot plate cork to fit beral pipet 1 mL automatic pipet ethanol acetic acid ethyl acetate ion exchange resin styrofoam cup analytical balance Safety: Always wear an apron and goggles in the lab. Use caution handling the acetic acid. The fumes are irritating. Use a hood. 22-B-1 Procedure: 1. Prepare a hot water bath by placing about 100 mL of water in a beaker and heating it to 80 ºC on the hot plate. 2. Obtain three small test tubes and label them 1-3. 3. Add a small amount of ion exchange resin to test tube 1. Insert a cork gently into the test tube. 4. Record the mass of test tube 1, cork, and contents. 5. Remove the cork and add 2.000 mL of ethanol. Replace the cork and record the mass of test tube 1, cork, and contents. 6. Remove the cork and add 1.000 mL of acetic acid. Replace the cork and record the mass of test tube 1, cork, and contents. 7. Repeat steps 3-6 using test tubes 2 and 3. 8. Inject a 5 microliter sample of the reactant mixture in test tube 1 into a GC. Record GC and chart recorder settings. 9. Repeat step 8 using test tubes 2 and 3. 10. Pour the hot water into a styrofoam cup to serve as a constant temperature hot water bath. 11. Place the test tubes into the hot water bath at 70-80 ºC for 15-20 minutes. While heating, continue with steps 10-12. 12. Inject 5 microliter samples of ethanol, acetic acid, ethyl acetate, and water into the GC. Record GC and chart recorder settings. 13. Inject 4, 3, 2, and 1 microliter samples of ethyl acetate into the GC. 22-B-2 14. Carefully cut out the ethyl acetate peaks for the 1-5 microliter samples and record the mass of each peak. 15. After the 15-20 minute reaction time is concluded, remove the test tubes from the hot water bath, and dry the outside of the tubes. 16. Record the mass of each test tube, cork, and product mixture. 17. Inject a 5 microliter sample of the product mixture from test tube 1 into the GC. Identify each peak. 18. Carefully cut out the ethyl acetate peak and record the mass of the peak. 19. Repeat steps 17 and 18 for test tubes 2 and 3. 20. Prepare a graph by plotting the mass of ethyl acetate peak (y) vs. volume of ethyl acetate used (x). 21. Determine the amount of ethyl acetate in the product. 22-B-3 Name ______________________________ Period ______________________________ Date _______________________________ GC DETERMINATION OF THE PERCENT YIELD OF ESTERFICATION Table 1: Test tube 1 Test tube 2 Test tube 3 Mass of test tube, cork, and ion exchange resin Mass of test tube after ethanol addition Mass of test tube after acetic acid addition Mass of test tube after heating Table 2: retention time ethanol retention time acetic acid retention time ethyl acetate mass ethyl acetate peak in standard mass of ethyl acetate peak in product % Ethyl acetate in product Table 3: Ester sample size (microliter) mass of peak 5 4 3 2 1 22-B-4 amount of ethy acetate (g) Table 4 Trial 1 Mass of ethanol used Mass of acetic acid used Mass of reactant mixture Mass of product mixture Mass of H2O peak in 5 L react mix Volume of H2O in 5 L reactant mix % of H2O in reactant mixture Mass of H2O in reactant mixture Theoretical mass of H2O produced Theoretical mass of ethyl acetate produced Mass of H2O peak in 5 L product mixture Volume of H2O in 5 L product mix % H2O in product mixture Mass of H2O in product mixture Mass of H2O produced % yield H2O Mass of ethyl acetate produced % yield of ethyl acetate Average % yield water ______________________ Average % yield of ethyl acetate _______________ GC Conditions: injection port temp:__________ column temp:_________ outlet temp:_________ bridge current:__________ detector temp:_________ attenuation:__________ chart speed:__________ 22-B-5 Trial 2 Trial 3 Questions: 1. What factors would cause a low yield of the ester? 2. What difficulties were encountered in identifying the peaks? 3.. If 1.3 g of 95 % ethanol and 1.2 g of 99% acetic acid were used, how many g of ethyl acetate would be produced if the % yield were the same as in this experiment? Show work. 22-B-6 Calculations: 1. Calculate the mass of ethanol used. 2. Calculate the mass of acetic acid used. 3. Calculate the mass of the reactant mixture. 4. Calculate the mass of the product mixture. 5. Determine the retention time for each peak. 6. From the graph, determine the volume of water in the 5 L reactant mixture. 7. Calculate the percent of water in the reactant mixture. 8. Calculate the mass of water in the reactant mixture. 9. Calculate the theoretical mass of water that could be produced. 22-B-7 10. Calculate the theoretical mass of ethyl acetate that could be produced. 11. From the graph, determine the volume of water in the 5 L product mixture. 12. Calculate the percent of water in the product mixture. 13. Calculate the mass of water in the product mixture. 14. Calculate the mass of water produced. 15. Calculate the percent yield of water. 16. Calculate the mass of ethyl acetate produced. 17. Calculate the percent yield of ethyl acetate. 18. Calculate the average percent yield of water 19. Calculate the average percent yield of ethyl acetate. 22-B-8 Questions: 1. What factors would cause a low yield of the ester? 2. What difficulties were encountered in identifying the peaks? 3. If 1.3 g of 95% ethanol and 1.2 g of 99% acetic acid were used, how many g of ethyl acetate would be produced if the % yield was the same as in this experiment? Show work. 22-B-9 GC DETERMINATION OF THE % YIELD IN ESTERIFICATION TEACHER NOTES Standards Met: 3.1.12.A – Apply concepts of systems, subsystems, feedback and control to solve complex technological problems. Evaluate the causes of a system’s inefficiency. 3.7.10.B – Apply appropriate instruments and apparatus to examine a variety of objects and processes. Describe and use appropriate instruments to gather and analyze data. Explain the need to estimate measurements within error of various instruments. 3.4.10.A – Explain concepts about the structure and properties of matter. Understand that carbon can form several types of compounds. 3.4.10.B – Analyze energy sources and transfers of heat. Determine the efficiency of chemical systems by applying mathematical formulas. 3.7.12.A – Apply advanced tools, materials and techniques to answer complex questions. Evaluate and use technological resources to solve complex multistep problems. Lab Time: 60 minutes Preparations: Time: 15 minutes T: Make a set of equipment and materials available to each student. T: Turn on the GC and allow it to warm up. The settings should be: Outlet Temperature 70oC Column Temperature 110 oC Detector Temperature 145 oC Injection Port Temperature 140 oC Bridge Current 140 mA Flow Rate 1 mL/sec V: The van can supply equipment and materials as requested. 22-B-10 Answers to questions: 1. What factors would cause a low yield of the ester? Low yields may be due to either too low or too hight temperatures and to too short reaction times. The product tends to decompose at high temperatures. The reaction is slower at low temperatures. Not enough reaction time also would result in a low yield. 2. What difficulties were encountered in identifying the peaks? Answers will vary. Usually difficulties are encountered if retention times are similar. The ethanol and ethyl acetate peaks tend to have about the same retention time and may not be able to be distinguished. 3.. If 1.3 g of 95 % ethanol and 1.2 g of 99% acetic acid were used, how many g of ethyl acetate would be produced if the % yield were the same as in this experiment? Show work (numbers are left in calculator until final answer). C2H5OH + HC2H3O2 --> CH3COOCH2CH3 + H2O Ethanol 1.3 g x 0.95 = 1.2 g 1.2 g ethanol x 1 mol ethanol/46 g ethanol = 0.027 mole ethanol 0.027 mol ethanol x 1 mole ethyl acetate/1 mol ethanol = 0.027 mol ethyl acetate acetic acid 1.2 g x .99 = 1.2 g acetic acid 1.2 g acetic acid x 1 mol acetic acid/60 g acetic acid =0.020 mol acetic acid 0.020 mol acetic acid x 1 mol ethyl acetate/1 mol acetic acid = 0.20 mol ethyl acetate acetic acid is limiting reagent. 22-B-11 0.20 mol ethyl acetate x 88 g ethyl acetate/1 mol ethyl acetate = 1.7 g ethyl acetate If the % yield = 75% the 1.74 g ethyl acetate x .75 = 1.3 g ethyl acetate produced at a 75% yield Considerations: At the most it is only necessary for each group of students to run one set of standards. If time is limited, have students share standards or run the standards before class. Be sure to run a complete set of standards on each GC used, as results may vary from one instrument to another. Be certain that the students understand that % composition data obtained from the GC is not the same as % yield, since more than one product is produced. Because of the high temperatures being used, some of the peaks overlap and thus are not visible on the chromatograph. The pure sample injections should have the same retention time as the corresponding component in the mixture. Last updated 11-02 22-B-12