INTRODUCTION TO WHMIS

advertisement

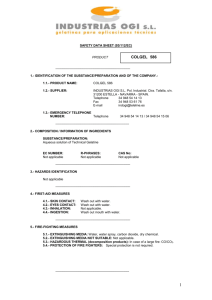

Part One - an Introduction to WHMIS INTRODUCTION TO WHMIS Whether we realize it or not, we are constantly coming into contact with hazardous materials in both the home and the work environment. A WIDE RANGE OF MATERIALS... There are a wide range of materials and products which you may come in contact with which can be hazardous to your health if they are not used properly. Cleaning products, solvents, paints, glues, and toners are just a sample of some of the materials which, if not used properly, can have adverse effects on your health. WHAT IS WHMIS? WHMIS is short form for "Workplace Hazardous Materials Information System". It is a nation wide system that was developed for the control and safe use of hazardous materials in the workplace. WHMIS provides us with a standard classification and information system to help ensure that everyone in the work environment understands their role. With WHMIS, information is provided to us through "product labels", "Material Safety Data Sheets"(MSDSs) and "worker education programs". It is important that everyone within the workplace has an awareness of the controlled products in their immediate work environment, as well as the safe handling, storage, and disposal procedures for these materials - and importantly, how to prevent or deal with an accident in the event of an emergency. IT IS THE LAW! Throughout North America, Occupational Health and Safety legislation has been shifting in recent years to a system of basic rights for workers. These basic rights include the "right to know" about the hazards a worker may encounter on the job. Occupational Health and Safety Law combined with WHMIS legislation, means that everyone has a right to know about the safety and health hazards of materials used in their workplace. WHMIS applies to a vast variety of products and materials but they must meet certain criteria which are outlined in the Controlled Products Regulations. Products meeting these criteria are referred to as "controlled products". WHMIS is legislated WHY WAS WHMIS CREATED? WHMIS came into effect as a result of meetings between knowledgeable representatives of government, labour and industry. These three parties worked together to ensure that the best interests of everyone involved were considered. WHMIS became law in Canada through the introduction of a series of federal, provincial and territorial legislation that came into effect in October of 1988. WORKPLACE RESPONSIBILITY Everyone in the workplace has responsibilities under the WHMIS legislation suppliers of controlled products, employers, and of course, the worker. The responsibilities of each of these parties will be discussed in greater detail later in the course. THE ROLE OF GOVERNMENT - PROVINCIAL In Canada, the Federal governement and each provincial or territorial department has responsibitlity for the administration and enforcement of its Occupational Health and Safety Act and supporting regulations within their jursidictions. One of these "regulations" provides for the WHMIS system. All WHMIS regulations are based on the same model. This is done to ensure consistency of WHMIS legislation throughout Canada. The role of government THE ROLE OF GOVERNMENT - FEDERAL Provincial WHMIS legislation does not apply to federal workplaces. In federal workplaces (i.e. banks, airports), provisions for WHMIS are found in the Canada Labour Code and the Canadian Occupational Safety and Health Regulations. All other work environments are covered by provincial and territorial WHMIS legislation. Peace Tower LEGISLATION AND YOUR WORKPLACE Under WHMIS legislation, all work environments that use, handle or store any controlled products are required to provide training to staff. WHMIS regulations should be stored in a common area in the workplace and easily accessible at all times by all employees. A copy of the WHMIS Regulations is available in the "Resource Links" section of this website located on the main page. A THREE-PART SYSTEM... WHMIS is a three-part information system that consists of the following: 1. Product Labels 2. Material Safety Data Sheets (MSDSs) 3. Worker Education Programs The purpose of these three components is to ensure that everyone in your work environment understands everything they need to know about the use, storage and disposal of hazardous materials in the workplace. By the end of this course you will have reviewed these three components and will have a much better understanding of how they will apply to your safety and workplace responsibilities. Part Two – Product Labels PRODUCT LABELS A WHMIS product label provides the basic information that you will need to know in order to handle a product safely. The WHMIS system standardizes the information that must be contained on the WHMIS product label. There are two types of labels you will find in your work environment: 1. Supplier Labels 2. Workplace Labels SUPPLIER LABELS Under the WHMIS system, a supplier of a controlled product is required to attach a label to all hazardous materials they supply before the materials are shipped. A "supplier" can be defined as a manufacturer, processor, or packager of a controlled product. A supplier also includes anyone who sells or imports a controlled product. SUPPLIER RESPONSIBILITIES With the WHMIS system, all "suppliers" are required to communicate all hazard information in a standard manner to all purchasers of a controlled product. The WHMIS system requires suppliers to provide a "supplier label" on all controlled products or containers of controlled products. The Supplier must also provide more detailed information concerning the controlled product in the form of a "material safety data sheet" (MSDS). MSDSs will be examined in detail later in the course. Supplier labels are easily recognized by their distinctive "hatch mark" border. This border is used to ensure easy identification of a hazardous product by the user. The information found on the supplier label must also be bilingual (French/English). INFORMATION FOUND ON A SUPPLIER LABEL - GENERAL The package labeling that a supplier provides is referred to as a "Supplier Label". The following 7 sections of information are found on a "Supplier Label": 1. PRODUCT IDENTIFIER 2. MANUFACTURER/ SUPPLIER IDENTIFIER 3. WHMIS HAZARD SYMBOLS 4. PRECAUTIONARY STATEMENTS 5. RISK PHRASES 6. FIRST AID MEASURES 7. REFERENCE TO THE AVAILABILITY OF A MATERIAL SAFETY DATA SHEET (MSDS) Take a moment to become familiar with the 7 sections found on this type of label. We will now take a closer look at each of these. INFORMATION FOUND ON A SUPPLIER LABEL - PRODUCT IDENTIFIER 1. PRODUCT IDENTIFIER: This section should include all names associated with a controlled product. Proper identification of a product should include the common name, chemical name, trade name, generic name, or brand name of a product. In some cases, this information may be provided in the form of a number. The product name or number must always be identical to the "Product Identifier" on the Material Safety Data Sheet (MSDS). INFORMATION FOUND ON A SUPPLIER LABEL SUPPLIER IDENTIFIER The supplier must provide the purchaser of a controlled product with package labeling and a Material Safety Data Sheet (MSDS). INFORMATION FOUND ON A SUPPLIER LABEL - HAZARD SYMBOLS 3. HAZARD SYMBOLS The WHMIS "hazard symbol" system is an effective way to bring immediate attention to a hazardous product. This is a very important component of the WHMIS system and you should take care to familiarize yourself with these symbols. We have all become somewhat accustomed to the benefits of hazard labelling on products through the use of hazard symbols on household products. IDENTIFYING HAZARD SYMBOLS 3. HAZARD SYMBOLS (Cont.) The hazard symbol system used for WHMIS is subject to a number of regulatory specifications. For example, all hazard symbols must have a distinctive circular border, and must be displayed in a colour that will not be confused with the Transportation of Dangerous Goods (TDG) safety marks. The colours which are prohibited for use on controlled product symbols are contained in the WHMIS regulations. In most cases, the hazard symbols for WHMIS are found in black and white. INFORMATION FOUND ON A SUPPLIER LABEL - RISK PHRASES 4. RISK PHRASES Risk phrases are short explanations of the potential hazards associated with a controlled product. The following are examples of risk phrases: - Keep product away from heat and all sources of ignition. - Caution. Combustible liquid. - Product may form explosive vapour-air mixture. - Product may cause birth defects. Compressed Gas INFORMATION FOUND ON A SUPPLIER LABEL - PRECAUTIONARY STATEMENTS 5. PRECAUTIONARY STATEMENTS Precautionary statements contain the preventative information you must follow when working with or in close proximity to a controlled product: - Caution. Do not drop or roll (i.e. any type of compressed gas) - Keep product away from combustible materials. - Wear suitable protective clothing when handling product. - Do not add water to this product. - Avoid prolonged or repeated contact with skin. INFORMATION FOUND ON A SUPPLIER LABEL - FIRST AID PROCEDURES 6. FIRST AID PROCEDURES The first aid procedures on a supplier label outline the immediate general first aid procedures that you should follow when dealing with an accident involving a hazardous material. You will find more detailed first aid information in the Material Safety Data Sheet (MSDS). The following is an example of the first aid procedures found on a controlled product: First Aid: "Remove patient to fresh air. Flush exposed skin and eyes with water. Remove contaminated clothing. If product is ingested do not induce vomiting. Call a physician immediately." Ensure that the proper type and number of First Aid Kits are available Tip: Your work environment is required to contain the appropriate number and kind of first aid kits. Further information on the necessary first aid kit(s) is available in your First Aid Regulations. The regulations can be found in the "resource links" section of the website. INFORMATION FOUND ON A SUPPLIER LABEL - MSDS 7. REFERENCE TO A MATERIAL SAFETY DATA SHEET (MSDS) If a Material Safety Data Sheet is required, a reference advising of the availability of the MSDS must appear on the WHMIS supplier label: Remember, whenever you work with a controlled product it is important that you familiarize yourself with all of the information contained on the supplier label. When working with hazardous materials, "prevention" is always the best cure. SUPPLIER LABELS - BULK SHIPMENTS BULK SHIPMENTS of CONTROLLED PRODUCTS If a Controlled Product is shipped in containers of more than 454 litres (100 gallons) the supplier must do one or more of the following: Send the Supplier Label separately Add the Supplier Label information to the MSDS Send the information as a separate document SUPPLIER LABELS - SMALL CONTAINERS If a controlled product container holds 100 ml or less, the Supplier Label needs to show only the following information: Product Name Supplier Identifier Hazard Symbols Reference to the Availability of an MSDS WORKPLACE LABELS A workplace label is designed to provide the basic information a worker needs to identify and safely handle a controlled product in the workplace. An example of when a workplace label becomes necessary is when a controlled product is transferred from its original container into an unmarked container. After all, it is easy to understand the additional dangers associated with having unmarked hazardous materials in any workplace. INFORMATION FOUND ON A WORKPLACE LABEL The format for a workplace label can vary but it must contain the following three components: 1. Product identifier - The name or names associated with a product. To avoid confusion, you must ensure that the "product identifier" on all workplace labels is identical to the product identifier on the material safety data sheet of a product. 2. Information for the safe handling of the controlled product - this information must include the precautions necessary to reduce health risks and injury. 3. A statement advising that a Material Safety Data Sheet for the controlled product is available. Label all new containers WORKPLACE LABELS (cont.) The "information for the safe handling of a product" might include the hazard symbols and/or risk phrases associated with a controlled product. Both are acceptable as long as the worker is trained and knowledgeable in the necessary precautions associated with the product. It is also recommended, but not required, that the workplace label include the distinctive "hatch mark" border used for supplier labels. A workplace label may also be in the language of choice in a workplace. WHEN TO USE A WORKPLACE LABEL When any controlled product is transferred from a supplier container to any other container, the new container must be labeled with a "Workplace Label". WORKPLACE LABELS MUST BE USED IN THE FOLLOWING SITUATIONS: * On a storage container for receiving bulk shipments (not necessary if the supplier provides labels). * On a portable container into which a product has been transferred by a worker where the container is used by other workers or for longer than the worker's shift. * Piping or tubing systems transporting controlled products are also considered portable containers. In this circumstance a colour coded system is acceptable if the system is thoroughly communicated to all workers. * On a supplier container that has illegible, damaged or missing labels. In this circumstance, effort should be made to replace the original label. * On storage containers of all controlled products produced on site. ITEMS ON A WORKPLACE LABEL Take time to remember the three sections of information that are to be placed on a workplace label. 1. Product identifier (name) 2. Information for the safe handling of the product 3. A statement advising of the availability of a Material Safety Data Sheet (MSDS) PRACTICE EXERCISE Click Here to test your knowledge of workplace labels. This exercise is for practicing your skills and is not a requirement to complete the program. If you want to skip the exercise you may proceed directly to the section test by clicking the link in lower right portion of this page. HAZARD SYMBOLS Hazard symbols are useful as a visual aid in identifying hazardous materials. All hazardous materials must be labelled with at least one of the eight classes of symbols. Each "class" of hazardous materials has its own hazard symbol which is easily recognizable due to its symbol and the round border. Note: Some products from the USA may have similar labels without the round border. Be sure to familiarize yourself with this situation. THE EIGHT CLASSES of HAZARD SYMBOLS * CLASS A - Compressed Gas * CLASS B - Flammable & Combustible Materials * CLASS C - Oxidizing Materials * CLASS D1 - Poisonous and Infectious - Immediate and Serious Toxic Effects * CLASS D2 - Poisonous and Infectious - Materials Causing Other Toxic Effects * CLASS D3 - Poisonous and Infectious - Biohazardous Infectious Materials * CLASS E - Corrosive Materials * CLASS F - Dangerously Reactive Materials We will now take a look at each of these symbols and learn about each. CLASS A - COMPRESSED AIR This symbol indicates that the contents of the container are under pressure - anything done to weaken the structure of the container could result in an explosion or a dramatic release of pressure. A compressed gas is a material which is a gas at normal room temperature and pressure, and is packaged under compression. Helium and propane are common examples of materials that are supplied as a compressed gas. CLASS B - FLAMMABLE / COMBUSTIBLE MATERIALS "Flammable / Combustible" materials are solids, liquids or gases that will ignite and continue to burn if exposed to a flame or source of ignition. These materials may also be explosive in certain situations or react with other materials to produce a flammable material. Diesel and gasoline are examples of commonly used flammable materials. CLASS C - OXIDIZING MATERIALS These materials produce oxygen or another oxidizing substance which can cause or contribute to the combustion of another substance. Chlorine is an example of an oxidizing material. CLASS D - POISONOUS / INFECTIOUS MATERIALS Class D materials refer to materials which are known to be poisonous and/or infectious. These materials are further separated into three categories D1, D2, and D3. Let's have a closer look at each of these Poisonous / Infectious material symbols. CLASS D1 - MATERIALS CAUSING IMMEDIATE and SERIOUS TOXIC EFFECTS The effects of Class D1 materials are very harmful based on short-term exposures. Very little exposure can produce serious toxic effects or possibly death. These materials are classified for toxicity based on information such as the lethal dose and the lethal concentration. Cyanide is an example of a material that causes immediate and serious toxic effects. CLASS D2 - MATERIALS CAUSING OTHER TOXIC EFFECTS Class D2 substances can produce many different toxic effects. They also have a wide variety of classifications. For example, D2 substances can be classified as carcinogens, teratogens, reproductive toxins, respiratory tract sensitizers, irritants, or chronic toxic hazards. Exposure effects range from short term (e.g. dizziness, difficulty breathing), to long term (cancer, lung disease). Asbestos is an example of this class of material. CLASS D3 - BIOHAZARDOUS INFECTIOUS MATERIALS Class D3 materials refer to any organism, or the toxins produced by these organisms, that have been shown or are believed to be a biological hazard in either humans or animals. These materials are usually limited to laboratory and testing environments. CLASS E - CORROSIVE MATERIALS Class E materials are corrosives that can cause decomposition of other materials (e.g. metals) or damage human tissue. Sulphuric Acid and Ammonia are examples of corrosive materials. CLASS F - DANGEROUSLY REACTIVE MATERIALS Class F materials may react with other substances to produce a wide range of negative reactions. These reactions can range from decomposition to condensation. The stability of these materials may be adversely affected by exposure to certain elements such as water, pressure, or temperature. Ozone is an example of a dangerously reactive material. PRACTICE EXERCISE Click Here to test your knowledge of the WHMIS hazard symbols. This exercise is for practicing your skills and is not a requirement to complete the program. If you want to skip the exercise you may proceed directly to the section test by clicking the link in the lower right portion of this page. WHAT ARE MATERIAL SAFETY DATA SHEETS? A Material Safety Data Sheet (MSDS) is a technical document that provides the information everybody needs to know about a controlled product. The MSDS is the main source of information for obtaining knowledge on a controlled product. An MSDS contains all of the information found on supplier labels, but it also includes a large amount of detailed data that is useful to everyone involved - for example, the MSDS contains technical information which would also be very useful to lab technicians or emergency personnel. All controlled products have MSDS information. If you are unsure about any product ask the supplier/manufacturer for more info, and of course, an MSDS. WHAT SHOULD YOU KNOW ABOUT MSDSs? Certain sections of the MSDS will be more important to some than others. However, everyone should know the name of the chemicals they are handling, the hazards associated with use, the safe handling, storage and disposal procedures, and, what to do in the event of an emergency. INFORMATION FOUND ON AN MSDS An MSDS contains a large amount of important data. Briefly, the information you will find on an MSDS is as follows: * Detailed information on the product, including who made it * Hazards of a product * How to use a product safely * What will happen if the hazard information is not followed * What to do if an accident occurs * How to recognize adverse health effects * Spill control and disposal information THE MSDS IN YOUR WORKPLACE All "controlled products" must have an MSDS that is specific to each individual product or material. The product name and the supplier name on the MSDS must correspond with the material in use in the workplace. MSDS - SUPPLIER RESPONSIBILITIES It is the supplier's responsibility to produce and supply an up to date and comprehensive Material Safety Data Sheet for all controlled products in both official languages. Be sure that you have access to all MSDSs for all controlled products in your work environment. MSDS - EMPLOYER RESPONSIBILITIES It is the employer's responsibility to obtain all MSDSs (bilingual) from their suppliers' for all controlled products found in their work environment. MSDSs must be available to all employees at all times, at all worksites. This information can be provided on computer providing all employees have access to and are trained on using the computer system. A hard copy must also be provided to any employee upon request. To comply with legislation, the employer must ensure that all MSDSs are updated if there are any changes to a product, and, that they are no more than three years old. If a controlled product is made in the workplace the employer has a responsibility to produce a bilingual MSDS. MSDS RESPONSIBILITIES All employees are responsible for taking the time to familiarize themselves with the information found on an MSDS for each controlled product found in their work environment. INFORMATION FOUND ON AN MSDS An MSDS can be provided in varying formats but they must comply with WHMIS regulation by containing the necessary information for nine sections. No section can be omitted. The MSDS is separated into these nine sections so that the user can easily and quickly find the information they need. NINE SECTIONS ON AN MSDS 1. Product Identification and Use 2. Hazardous Ingredients 3. Physical Data 4. Fire and Explosion Data 5. Reactivity Data 6. Toxicological Properties (Health Effects) 7. Preventive Measures 8. First Aid Measures 9. Preparation Information We will now take a closer look at each of these sections. SECTION 1 - PRODUCT IDENTIFICATION and USE Information in this section of the MSDS will include the product name, identification number and the intended use of the product. The info should include all names used to identify a product - trade names, generic names, common names, chemical names, brand names, code names or code numbers used in the products identification. In this section of the MSDS you will also find important information about contacting the supplier or manufacturer including business name, address, and a 24 hour emergency telephone number. The person who prepared the MSDS will also be identified. All MSDSs contain the date on which the document was prepared. Remember, by law an MSDS for a controlled product is obsolete if it is more than three years old. If the MSDS date of preparation is more than three years old the supplier should be immediately contacted for an updated MSDS. SECTION 2 - HAZARDOUS INGREDIENTS In this section, all hazardous ingredients as well as the concentration of the ingredient must be identified. When available, a Chemical Abstracts Registry Number (CAS) will be included to help identify hazardous ingredients. This section also contains information on lethal doses (ingested or applied to skin) and lethal concentrations (inhalation) of the ingredients. SECTION 3 - PHYSICAL DATA The physical data section of an MSDS contains detailed information on the physical description of a product. Providing this information is important for the safe handling, storage, and transportation of a controlled product because how a chemical reacts is subject to change according to the environment. It is important to have a thorough understanding of how the chemicals you use can react differently due to environmental changes (temperature, pressure, etc.). For example, it is important to understand when a liquid can become a gas because it could then pose a breathing or explosion hazard. The information provided in this section will include terms used to physically describe a controlled product such as appearance (colour/texture), physical form (solid, liquid or gas), specific gravity, vapour pressure, boiling point, freezing point, or melting point. SECTION 4 - FIRE and EXPLOSION DATA This section of the MSDS contains information on the conditions of flammability - the circumstances in which a controlled product may catch fire or explode. Fire and explosion data is designed to provide you with the knowledge on how to avoid these situations, what to expect if the information is not followed, as well as information for properly extinguishing a fire. Be sure to understand the situations in which any material in your work environment may become a fire and/or explosion hazard as well as the proper techniques and equipment for extinguishing different types of fires. SECTION 4 - FIRE and EXPLOSION DATA (cont.) FLASH POINT: The flash point of a controlled product refers to the minimum temperature at which a liquid gives off enough vapour to ignite in test circumstances. When you find a controlled product with a low flashpoint it means that the material presents a higher hazard of catching fire or exploding. UPPER FLAMMABLE LIMIT / LOWER FLAMMABLE LIMIT: These limits represent the amount of gaseous vapours that mix with air to produce a threat of explosion. AUTO IGNITION TEMPERATURE: The auto ignition temperature refers to Fire Safety the temperature that a hazardous material will ignite on its own due to spontaneous combustion. A low auto ignition temperature indicates a higher likelihood of ignition or explosion. SECTION 4 - FIRE and EXPLOSION - TYPE Fires are categorized into four different classes - Class A, B, C and D Familiarize yourself beforehand with what type of fires you may encounter in your work environment. Ensure that the proper fire extinguisher(s) are available, that they are properly and regularly serviced, and that everyone knows where they are located. Also ensure that fire prevention and evacuation plans are in place. Know the Types of Fire before they happen If you are unsure about anything relating to fire extinguishers or fire prevention contact your manager, Workplace Health and Safety Committee member, Site Health and Safety represenative or the OH&S Program. SECTION 4- FIRE and EXPLOSION DATA (cont) * EXPLOSION DATA This section of the MSDS contains specific information on the factors that could lead to a material being an explosion hazard. For example, in this section you will find information on a material's sensitivity to mechanical impact or static discharge. * SPECIAL CONSIDERATIONS This section of the MSDS is where you can find additional fire/explosion hazard information which may be specific to a particular product. For example, some controlled products may pose additional fire or explosion hazards when mixed with other products - others may produce dangerous bi-products when burning. SECTION 5 - REACTIVITY DATA This section of the MSDS contains information on the conditions under which a controlled product may become chemically unstable. For example, some controlled products become dangerous when they are mixed with water. In this section you will find the name of any substance, or class of substance, with which a product is incompatible. You will also find information on the conditions of reactivity and any hazardous decomposition products associated with the product. SECTION 6 - TOXICOLOGICAL PROPERTIES (Health Effects) The " Toxicological Properties" section of the MSDS contains detailed data on how a hazardous material may affect your health. You will find information relating to how hazardous materials enter the body, as well as the health effects associated with different types of exposure. Information can be found on the following: * ROUTES OF ENTRY - potential routes of entry are many and include skin contact, skin absorption, eye contact, inhalation and ingestion information * TOXIC EFFECTS OF ACUTE EXPOSURE - Toxic effects of acute exposure are changes experienced within a short period of time following an exposure (e.g. minutes, hours) * TOXIC EFFECTS OF CHRONIC EXPOSURE - Toxic effects of chronic exposure are changes experienced over a long period of time following repeated exposure (e.g. months, years) Use the proper Personal Protection Equipment (PPE) * EXPOSURE LIMITS * IRRITANCY OF PRODUCT/ SENSITIZATION OF PRODUCT * CARCINOGENICITY - this term refers to the ability of a product to cause cancer. * REPRODUCTIVE TOXICITY - this term refers to the ability of a hazardous product to affect reproductive processes upon exposure. * TERATOGENICITY - this term refers to a products ability to cause congenital birth defects. * MUTAGENICITY - this term refers to a products ability to cause changes to the genes of the user upon exposure. * NAME OF TOXICOLOGICALLY SYNERGISTIC PRODUCTS - these product names may be necessary due to lack of information on a product. The information provided may include a comparison of the toxic effects other products have in common with the product you are using. SECTION 7 - PREVENTIVE MEASURES This section of the MSDS contains information on the "control measures" associated with a products handling. For example, here you will find info on personal protective equipment (e.g. gloves, respirators) and the work procedures associated with a products use. In addition to personal protective equipment, the preventive measures section will also provide information on: - Handling procedures - Specific engineering controls (e.g. ventilation system requirements) - Containment of leaks or spills - Waste disposal and waste container design - Storage requirements - Special shipping information SECTION 7 - PREVENTIVE MEASURES (cont) SPILL CONTROL and HAZARDOUS MATERIAL DISPOSAL Spill control measures and emergency procedures are found in the Material Safety Data Sheet for a hazardous product. It is necessary to ensure that designated individuals receive instruction in specific spill control procedures as it applies to the use and concentration of materials found in the workplace. Containment and neutralization, using acceptable compounds intended for that purpose, are preferred methods of spill control. Only when you are thoroughly familiar with the substances and the steps necessary to contain and clean up a spill should you attempt to do so. All incidents should also be immediately reported to the workplace Manager and proper disposal information consulted and followed. SECTION 7 - PREVENTATIVE MEASURES (cont) SPILL CONTROL and HAZARDOUS MATERIAL DISPOSAL If you are not familiar with a substance or unable to deal with a spill, the following steps must be adhered to: * Notify all colleagues in the immediate area that a spill or leak has occurred. * When necessary, evacuate staff and visitors from the surrounding area - gather at designated assembly points. * Report the location, quantity, and composition of the spill to the necessary parties - manager/ emergency personnel/ government. Call 1-888-295-5549 for Emergency Spill Response assistance. * Individuals that are not thoroughly familiar with the material involved must never attempt to control of a hazardous spill. * If you work in "proximity" to any hazardous material you must familiarize yourself with all spill control and evacuation procedures associated with a product. * Even a small amount of a spilt hazardous substance should be properly cleaned up, disposed of and reported to the Safety Officer/ Manager (i.e. mercury thermometer break}. * No hazardous material should be disposed of without consulting the MSDS. SECTION 7- PREVENTATIVE MEASURES (cont) Further information concerning spill control or waste disposal of specific chemicals can be requested from the government department responsible for occupational health and safety in your workplace. SECTION 8 - FIRST AID MEASURES This section of the MSDS sheet contains the information you will need to know on immediate first aid treatment in case of an accident. Remember: Always be sure you know the appropriate first aid measures associated with a product BEFORE you use it! Ensure that the proper type and number of First Aid Kits are available SECTION 9 - PREPARATION INFORMATION This section contains information on who prepared the MSDS, when the MSDS was prepared, and/or a revision date. Remember - an MSDS, in order to be considered up to date, must be no more than three years old! WHO IS RESPONSIBLE FOR WHMIS TRAINING? Everyone in the work environment has a responsibility in the WHMIS education process. 1. THE EMPLOYER With respect to worker education, the employer has the duty of providing WHMIS training to all employees who work "with" a controlled product, or "in proximity" of a controlled product. The employer must also be educated to understand the WHMIS system themselves EMPLOYER RESPONSIBILITIES The employer must meet the following responsibilities in the development of a WHMIS program: * On each controlled product in the workplace, the employer must provide the worker with all hazard information received from the supplier, and any additional information they have available concerning the use, storage and handling of a controlled product. Hazard information must be accessible to all employees during all shifts. * If an employer makes material safety data sheets (MSDSs) available on a computer terminal, the employer must provide all employees with access to a working computer at all times, as well as training in the access of computer stored MSDSs. EMPLOYER RESPONSIBILITIES - WHMIS TRAINING WHMIS TRAINING - The employer is responsible for implementing a program of instruction on controlled products. This program needs to include the following five components: 1. WHMIS training for employees on labelling and MSDSs. 2. Training in the procedures for safe use, storage, handling, and disposal of controlled products. 3. Training in the procedures to be followed in the case of an emergency involving a controlled product. (cont) EMPLOYER RESPONSIBILITIES - WHMIS TRAINING (cont) 4. Training in the use of the "methods of identification" used in each workplace that involve controlled products not found in a typical container. Products which are being "held" or "transferred" need to be identified and a system of identification must be developed. Methods may include warning signs, symbols, or colour, number, or letter codes. These methods are typically used when transferring controlled products in pipes, piping systems, process and reaction vessels, tank cars and tank trucks, conveyor belts, etc. (cont) EMPLOYER RESPONSIBILITIES - WHMIS TRAINING (cont) 5. Instruction on the procedures to be followed when "fugitive emissions" are present. A fugitive emission is a term used to describe a small amount of a controlled product that is known to escape from process equipment or emission control equipment. EMPLOYER RESPONSIBILITIES - DEVELOPMENT and REVIEW If your organization has 20 or more employees, the employer must consult with the joint health and safety committee, or the health and safety representative, about the content and delivery of the WHMIS program in the workplace. This is to help ensure that the training program is meeting the needs of the work environment and results in a worker being able to apply the information they learn. Regardless of the number of employees, the employer is responsible for reviewing the workplace WHMIS program at least once a year. This must be done more often if conditions at the workplace change, or if new hazard information becomes available. 2. THE SUPPLIER As we discussed earlier in the course, a supplier has no direct responsibilities for the education of workers. However, the supplier does play an important role in the education process by providing up to date and comprehensive Supplier Labels and Material Safety Data Sheets to the employer. 3. THE EMPLOYEE The employee plays an important role in the WHMIS process. Part of your responsibilities are being fulfilled by taking this course. Another part of your responsibilities will be fulfilled by using the information you learn in the course in your workplace. The EMPLOYEE (cont.) All staff have the potential of being adversely affected by hazardous products. If you take the time to note the number of controlled products you run into during a day you may be surprised. For example, something as inconspicuous as changing photocopy toner or printer ink can have adverse health effects if you do not adhere to the appropriate information. There are a wide variety of common products that staff may come into contact with while working. For example, glues, solvents, lubricants, paints and cleaning products. Take the time to learn about the products that affect you and your work environment. MORE INFORMATION ABOUT WHMIS The Workplace Hazardous Materials Information System regulations apply to all workplaces that use, store, or handle controlled products. There are a few circumstances involving potentially hazardous products where the WHMIS regulations do NOT apply. They are as follows: · "WHMIS Exemptions" · Restricted Applications · Hazardous Wastes We will now take a closer look at each of these categories. WHMIS EXEMPTIONS WHMIS legislation, both federally and provincially, does not apply to: * WOOD OR PRODUCTS MADE OF WOOD - this includes products such as lumber, plywood, particle board, and wood products coated with additives such as paint or preservatives. Additives may however be subject to WHMIS legislation before they are included in the finished product Some chemical products made from wood, but lacking the physical properties of wood, are not considered wood products and therefore are subject to WHMIS requirements (e.g. Turpentine). * TOBACCO OR ANY PRODUCT MADE OF TOBACCO - these materials are governed by their own federal legislation WHMIS EXEMPTIONS (cont) MANUFACTURED ARTICLES - A "manufactured article" refers to any item that is formed to a specific shape or design during its manufacture, whose intended use depends on its shape or design, and under normal conditions of use will not expose people to a controlled product * PRODUCTS WHICH ARE BEING TRANSPORTED or HANDLED UNDER the REQUIREMENTS of the TRANSPORTATION of DANGEROUS GOODS ACT (T.D.G.) These materials are covered by the T.D.G. act and regulations while in transit, but become subject to the WHMIS regulations at the point of loading and unloading. RESTRICTED APPLICATIONS - PARTIALLY EXEMPT PRODUCTS Partially exempt products are materials which are exempted from the WHMIS legislation because they are subject to labelling and information requirements under other federal legislation. As a result of this federal exemption, the employer is not required to obtain supplier labels or MSDSs to use these materials. An employer must still deliver training on the safe handling of these materials. Workplace labels must also be used when these materials are present or used in the workplace, or when they are transferred to different containers. If an MSDS sheet is available for any product it should always be made available. The guidelines for the use, storage, handling and disposal of these products are covered under their respective acts. PARTIALLY EXEMPT PRODUCTS PARTIALLY EXEMPT PRODUCTS FALL INTO THE FOLLOWING CATEGORIES: * PRODUCTS WITHIN THE MEANING OF THE EXPLOSIVES ACT (EXPLOSIVES) - Explosives and blasting agents are excluded from WHMIS because they are regulated by the Explosives Act and Regulations. * A COSMETIC, DEVICE, DRUG OR FOOD WITHIN THE MEANING OF THE FOOD AND DRUG ACT (COSMETICS AND PRESCRIPTIONS) - In order for a "cosmetic" material to qualify for an exemption under WHMIS it must be sold and presented for use as a cosmetic. If intended for use other than this purpose the WHMIS requirements apply. For example, Acetone is found in consumer nail polish remover products and in this form is exempt from WHMIS requirements. When used as an industrial cleaning agent, this same material becomes subject to the WHMIS requirements. The Food and Drug Act is administered by Health Canada. PARTIALLY EXEMPT PRODUCTS (cont) * A CONTROLLED PRODUCT WITHIN THE MEANING OF THE PEST CONTROL PRODUCTS ACT (PESTICIDES) - The Pest Control Products Act is administered by Agriculture Canada. * A CONTROLLED PRODUCT WITHIN THE MEANING OF THE ATOMIC ENERGY CONTROL ACT (RADIOACTIVE SUBSTANCES) - These substances are strictly controlled and are used primarily in medicine and dentistry or in testing and laboratory environments. The transportation and usage of these hazardous materials is administered by the Atomic Energy Control Board. (Canadian Nuclear Safety Commission) PARTIALLY EXEMPT PRODUCTS (cont) * A RESTRICTED MATERIAL THAT IS PACKAGED AS A CONSUMER PRODUCT - The partial exemption for consumer goods applies to products that are packaged for sale to consumers through the retail system. WHMIS requirements may still apply to these products. For example, bleach, when sold as a consumer product is partially exempt, however, becomes subject to WHMIS requirements when used in the workplace. WHMIS EXCEPTIONS Under the WHMIS regulations, a controlled product cannot be used, stored or handled in the workplace unless the employer has complied with the WHMIS requirements regarding labels, Material Safety Data Sheets and worker training. What would you do if a hazardous material arrived at your workplace and you do not fulfill these requirements? WHMIS EXCEPTIONS (cont) Under the WHMIS system the employer is allowed to store a controlled product in the workplace while trying to obtain a label or MSDS from a supplier or while trying to obtain the information needed to produce a workplace label or MSDS. This is considered acceptable if the employer affixes either a workplace label or a label stating that the product is hazardous and cannot be used or handled at the workplace until further information is obtained. If a supplier informs you that labels or an MSDS are not available for a controlled product you should immediately notify the government department responsible for OH&S in your jurisdiction. WHMIS EXCEPTIONS (cont) You may also receive a controlled product that has been imported into Canada and shipped directly to your workplace that does not have the proper WHMIS labelling. In this circumstance the employer is required to label the controlled product with a label that meets the requirements of a supplier label as outlined in the Controlled Products Regulations. HAZARDOUS WASTE The WHMIS regulations have limited applications with respect to hazardous waste. Where any hazardous waste is generated or stored in the workplace, the employer is expected to: * Identify all containers containing hazardous waste * Develop a method of hazardous waste container identification that is understood by all workers. This may include a number of methods (e.g. colour coding, or warning signs) * Train any worker who may be exposed to hazardous waste regarding the materials safe handling and storage While the employer is required to comply with the above, they are not required to provide workplace labels or material safety data sheets for containers of hazardous waste.