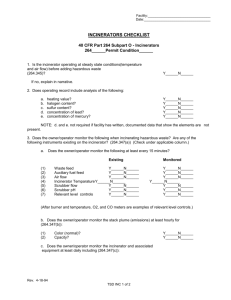

3. The hospital waste incinerator lines

advertisement

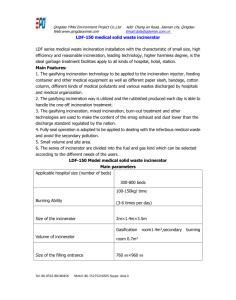

The new hospital waste incineration line at the central municipal waste incinerator of Bielefeld-Herford Author: Jan-Gerd Kühling Christoph Achtel ETLog EnviroTech & Logistics GmbH Brunnenstraße 164 10119 Berlin, Germany Tel.: +49 / 30 / 443187-30 Fax: +49 / 30 / 443187-49 E-mail: Info@etlog.com Internet: www.etlog.com The waste incineration system Bielefeld-Herford Table of contant 1. Initial Situation ................................................................................................3 2. The central waste incinerator ........................................................................4 General description of the incineration process............................................ 4 The flue gas treatment system ..................................................................... 5 Energy and material balance of the MVA Bielefeld-Herford ......................... 7 Residues of the thermal process .................................................................. 8 2.1. 2.2. 2.3. 2.4. 3. The hospital waste incinerator lines ...........................................................10 4. 4.1. 4.2. 4.3. 5. The hospital waste incinerator EK 500 CL..................................................12 General description of the incineration process.......................................... 12 Main technical data of the hospital waste incinerator ................................. 13 Process description of the Envikraft incinerator.......................................... 15 Evaluation and effects to the environment .................................................17 Table of illustrations Page Picture 1: The patch of the central waste incineration plant Bielefeld-Herford, left – collection area for municipal waste 3 Picture 2: Overview of the central incinerator of Bielefeld-Herford 4 Picture 3: General way of working – waste incinerator Bielefeld-Herford 5 Picture 4: Illustration of the 8-stage flue gas treatment system 5 Picture 5: Emission 2002: Comparison between limit values and emission 7 Picture 6: Waste-to-energy concept of waste incinerator in Bielefeld-Herford 8 Picture 7: Waste-to-energy concept of waste incinerator in Bielefeld-Herford 9 Picture 8: Screen-shot of the PC/SPS-control system. 12 Picture 9: Side-view of the hospital waste incinerator system 14 Picture 10: Loading device for bins 15 Picture 11: View of the incinerator system 15 Picture 12: Top-view of the incinerator 16 Table of charts Table 1: Table 2: Hospital waste to be treated in the hospital waste incinerator Hospital waste to be treated in the municipal waste incinerator -2- 10 11 1. Initial Situation The central municipal waste incineration plant of the Bielefeld-Herford GmbH is a private operated company, situated in Ostwestfalen-Lippe. Target of the incinerator is the safe and ecological friendly treatment of domestic and industrial waste, bulk refuse, sewage sludge, and hospital waste from about 1,5 million citizen and thousands of business enterprises. All together about 300,000 tons of waste must be treated per year. Picture 1: The patch of the central waste incineration plant Bielefeld-Herford, left – collection area for municipal waste As it can be seen in the above picture, municipal waste is collected in an area of about 80 km around the treatment plant, however hospital waste is collected from an area of up to 150 km (red line). Partly, private disposal companies are bringing hospital waste from hospitals, more than 200 km far away. The plant operates 365 day per year, including Sundays and holidays, in a three shift system. Currently, 127 people are employed. The tasks of the plant are to treat the waste in an environmental friendly way by a thermal process, to generate energy from this process, and to exploit the remaining residues form the incineration process. On the premise of the incineration waste plant, three independent operating incineration lines are situated. Each line consists of a municipal waste incinerator and boiler, a hospital waste incinerator, a flue gas cleaning, and a chimney. For energy generation out of the thermal process, two turbines and two heat exchangers are connected. The turbines generating energy for about 38,000 households and the heat exchangers generating heat energy for about 28,000 households. The waste incineration system Bielefeld-Herford Chimneys, 107 m high Flue gas treatment Hospital waste incinerator system Municipal waste incinerator Entrance area with scales Picture 2: 2. Overview of the central incinerator of Bielefeld-Herford The central waste incinerator 2.1. General description of the incineration process To be incinerated waste is brought by municipal or private waste disposal companies to the treatment plant. After the transportation vehicles are weight at the entrance scale, the trucks can drive to the unload area at the waste bunker. After the waste is controlled, the trucks can dump there load at 10 dumping areas for normal waste or at 2 dumping areas for bulk waste. The waste is dumped directly in the waste bunker (Total capacity: 13.000 m3). The waste will be mixed, to reach an average heating value of the waste of 9.210 kJ/kg. Afterward, the waste will be transferred via a crane onto the grate stoker furnace and will be incinerated on this counter direction, above shear grate. The bed ash and the slag will be collected in the slag bunker. The heat generated during the incineration process will be partly recovered via an corner tube boiler with an heating surface of 3.800 m². The maximum treatment capacity of the incinerator and the boiler system is 19.3 tons per hour, which will result in the generation of about 52,4 ton steam per hour. The steam will be transferred at a turbine to 6 MW/h of electrical energy. Generated flue gas will be afterwards treated in the flue gas treatment system. -4- The waste incineration system Bielefeld-Herford 1 Waste delivery 2 Waste Bunker 3 Slag (Bed ash) bunker 4 Grate furnace 5 Steam boiler 6 Turbines 7 Start of the flue gas treatment 1 Picture 3: 2 3 4 5 6 7 General way of working – waste incinerator Bielefeld-Herford 2.2. The flue gas treatment system The central waste incineration plant started to operate in 1981. Those days, the flue gas treatment of each process line consisted of a two stage electric filter and a flue gas scrubber. Because of the introduction of new emission standards and laws in 1986 (Technical Guidance Air 86) and in 1991 (17. Federal Emission Protection Law), the plant had to adapt the existing equipment according to the new standard and regulations. These requirements have been fulfilled with an investment volume of 115 million € in 1996. Since 1996 the plant disposes of three flue gas treatment systems with eight stages. 1 Electric Filter I 4 Pre Scrubber 7 Catalyst 2 Spray Dryer 5 Main Scrubber 8 Tissue Filter 3 Electric Filter II 6 Aerosol Separator Picture 4: Illustration of the 8-stage flue gas treatment system -5- The waste incineration system Bielefeld-Herford 1. The flue gas leaves the incinerator with a temperature of about 230°C and pass the electric filter I. At this stage, the dust from the flue gas will be separated. 2. Afterwards, the flue gas streams into the spray dryer and evaporates the contaminated wash water from the pre-and main scrubber. Solid reaction salts are remaining as residues. In the spray dryer, all process water of the waste incineration plant evaporates. This means, the entire systems runs without any waste water. 3. Now the flue gas is cooled down to 175°C and goes into the electric filter II. Here, the dust residues and the reaction salts are separated. 4. Following this, the flue gas goes into the two stage flue gas scrubber, consisting of pre-and main scrubber. As wash fluid, process water (waste water from the adjacent purification plant) is used. The wash fluid goes in a circle through the scrubber. In the pre-scrubber, mainly hydrogen chloride, hydrogen fluoride, as well as mercury are removed. At this stage, process water is mixed with lime water. 5. Through the addition of a heavy metal precipitant, sulphur dioxide is separated from the flue gas. Due to the addition of the heavy metal precipitant, the in the wash fluid solved heavy metals are converted in acidand temperature resistant compounds, such as mercury. These mercury compounds can be evaporate in the spray dryer of the three process lines. 6. In the aerosol separator a micro washing and a water separation in a polypropylene tissue is carried out. The flue gas has now a temperature of about 65°C. 7. Before the flue gas can be cleaned in the catalyst, it must be pass the flue gas heat exchanger and a flue gas pre-warming unit in order to warm up the flue gas up to 240°C. The catalyst consists of three layers. In the first layer nitrogen oxide is converted with the help of ammoniac water into molecular nitrogen (part of air) and water. In the second and third layer dioxin and furan will be destroyed through oxidation. Also other hazardous organic substances will be destroyed during this process. After the passing of the three layers the flue gas goes into the flue gas heat exchanger. Here the outgoing flue gas gives the heat to the in the catalyst streaming flue gas. 8. Now the flue gas has a temperature of about 95°C. It goes first into the plenum chamber. At this stage the flue gas is mixed via a spray unit with adsorbents (mixture of lime and coke). This mixture adsorbed remained heavy metals, dioxins and furans. Concluding, the flue gas streams through the tissue filter. After this 8-stage process, the cleaned flue gas can be relased to the atmosphere via a 107 m high chimney. The strict German emission limits are followed as the next graph will show: -6- The waste incineration system Bielefeld-Herford Limit values 17. Federal Emission Protection Law Emission MVA Bielefeld-Herford GmbH Picture 5: Emission 2002: Comparison between limit values and emission Due to the 8-stages flue gas treatment, the legal emission requirements (17. Federal Emission Protection Law) from the German government are under bided for 90%. 2.3. Energy and material balance of the MVA Bielefeld-Herford The central waste incineration plant Bielefeld-Herford is an advanced example for “waste to energy” principle, followed in Germany. It is one important module of the energy supply concept of the city Bielefeld. About 38000 households are supplied with energy and 28000 households are supplied with heat energy. Thus significant amounts of fossil fuels can be safe. In total, this leads to an annual saving of about 77 million litre heating oil and in this connection, reduction of the emission of 206,000 tons of carbon dioxide. The state of the art flue gas cleaning ensures that the energy is generated in an environmental friendly manner. During the incineration process, a temperature of about 1000 °C is generated. This thermal energy is transfused to the medium water/steam. The 380°C hot water steam is lead with a pressure of 40 bars through steam turbine with the connected power generator, in order to generate energy. Furthermore, the steam passes two heat exchangers to generate community heating. The generated energy is used to feed the public power supply and the generated community heating is fed into the community heating supply of the city of Bielefeld. The 130°C hot community heating water is transported via high isolated double pipes to the clients and back to the MVA Bielefeld-Herford. -7- The waste incineration system Bielefeld-Herford Ecological energy generation from waste 2002 Own consumption 38,1 Million kwh Power generation 153,5 Million kwh Delivery 314 Million kwh Approx. 38.000 household s Waste 333,014 t Community heating 314 Million kwh Delivery Approx. 28.000 households Saving of 774 Million kwh primary energy (77 Million Litre heating oil) Saving of 206.000 t CO2 - emission Picture 6: Waste-to-energy concept of waste incinerator in Bielefeld-Herford 2.4. Residues of the thermal process During the incineration of wastes approximately 25 to 30% of slag is generated. The slag consists mainly of non-combustible parts of the waste, such as ash, metal, stones, etc. This slag is a realisable product. After the internal or external treatment of the slag in slag reprocessing plant, the slag will be used as filling material for road constructions or for the construction of landfills. The MVA Bielefeld-Herford has its own advanced slag processing plant. In this special plant, non-ferrous metal is separated from ferrous metal. Because of the separation, the quality of the slag is improved. Other residues of the process are flue ash from the electric filter I and the bed slag. These residues are transported by a pneumatic transportation unit into a storage silo. Afterwards, the material is used as stowing material for backfilling of hollows in salt mines. Furthermore, during the evaporation of washing water inside the spray dryer and the three following electric filters II, a salt mixture (calcium chloride, sodium sulphate) is generated and separately stored in a special silo. This mixture is used as building material for the construction industry. During the last stage of the flue gas cleaning, tissue filter dust and old adsorbents material is generated. This material consists of 90% lime and 10% coke and is also stored in the silo for flue ash. It is also used as stowing material for backfilling of hollows in salt mines. During the incineration of one ton wastes, approximately 300 kg of residues are generated. This means a reduction of the mass of approx. 70% and a reduction of the volume of approx. 90%. -8- The waste incineration system Bielefeld-Herford 1 ton wastes Slag reprocessing Metal scrab Flue ash separation Flue gas scrubber Tissue filter Flue ash Salt mixture Old adsorbents Approx. 300 kg recyclable materials Picture 7: Waste-to-energy concept of waste incinerator in Bielefeld-Herford -9- 3. The hospital waste incinerator lines The MVA Bielefeld decreed of three in the general treatment plant integrated hospital waste incinerators. The incinerators treat the hospital waste from healthcare facilities in the area Ostwestfalen-Lippe, but also from other areas. In total, the three lines all together can treat up to 1,550 kg hospital waste per hour. Based on an average generation of 0,15 kg per hospital bed and day (including packing material), the incinerators are able to serve during an 2-shift operation up to 100.000 hospital beds. With this, the plant is one of the largest treatment places for hospital waste in Germany. The hospital waste will be picked up by governmental approved disposal companies from the hospitals. The hospital waste is collected in certified 30 litres and 60 litres one way plastic bins and transported to the MVA Bielefeld-Herford in special cooled trucks for hospital waste. The hospital waste incinerators of the MVA Bielefeld treat the following hospital waste groups (according to classification of the European waste catalogue): Waste Code 07 05 13 18 01 02 18 01 03 18 01 06 18 01 08 18 02 02 18 02 05 18 02 07 20 01 31 Table 1: Waste Group Pharmaceutical waste Examples Expired or contaminated pharmaceutical products Pathological waste Body parts, organs, blood bottles, etc. Infectious waste from patients All wastes from infectious care patients, infectious lab waste Hazardous chemical Cytotoxic and Cytostatic Expired or contaminated pharmaceuticals cytotoxic and cytostatic pharmaceuticals from cancer treatment Infectious wastes from the All wastes from infectious research, diagnostic, treatment, animals and care of animals Hazardous chemical from the research, diagnostic, treatment, and care of animals Cytotoxic and Cytostatic Expired or contaminated pharmaceuticals from the cytotoxic and cytostatic research, diagnostic, treatment, pharmaceuticals from cancer and care of animals treatment Cytotoxic and Cytostatic Expired or contaminated pharmaceuticals cytotoxic and cytostatic pharmaceuticals Hospital waste classes to be treated in the hospital waste incinerator The waste incineration system Bielefeld-Herford Next to the above mentioned waste groups, following kinds of waste as well as disinfected hospital waste can be treated in the normal, municipal waste incinerators: Waste Code 18 01 01 18 01 04 18 02 01 18 02 03 Table 2: Waste Group Sharps Examples Needles, scalpels, blades, cannulae, broken glass Non-infectious, hospital With blood or other body waste fluids contaminated waste Sharps from the research, Needles, scalpels, blades, diagnostic, treatment, and cannulae, broken glass care of animals Potential infectious waste With blood or other body from the research, fluids contaminated waste diagnostic, treatment, and care of animals Hospital waste classes to be treated in the municipal waste incinerator Additional different kinds of pharmaceutical waste are treated in the normal waste incinerators. Excluded from the treatment through the MVA Bielefeld-Herford are: Disinfectants Solvents Materials with a high fluid compartments Big amounts of non-combustible materials Materials with a halogen content >1% Fluorine contending plastics The flue gas of the hospital waste incinerators are combined with the flue gas treatment of the municipal waste incinerators, by this an extra flue gas treatment system for this incinerators is not necessary. As the capacity of the hospital waste incinerators were not sufficient, in the beginning of 2000 the operators of the MVA Bielefeld-Herford decided to install a new incinerator line with an additional capacity of 500 kg/h. After a tendering process, the decision was taken to install a new hospital waste incinerator from the company Envikraft, Denmark. - 11 - The waste incineration system Bielefeld-Herford 4. The hospital waste incinerator EK 500 CL 4.1. General description of the incineration process The hospital waste incinerator operates fully automated. The PC/SPS-system monitors, steers, and controls the entire incineration process. The incineration process will be monitored via a special PC-monitoring program, based on Windows/FIX. All necessary data, such as oxygen content, carbon monoxide, etc. can be considered as graphs or schema on a monitoring screen and be saved on a computer. Outlet to the fluegas treatment Loading of the waste bins 1st incineration chamber 2nd incineration chamber Heat recovery / Boiler system Bottom ash automatic removal system Picture 8: Screen-shot of the PC/SPS-control system. The hospital waste incinerator is integrated in the municipal waste incinerator system. Infectious waste, delivered in the waste bins is put on the loading system and will be automatically loaded into the first incineration chamber. The waste will be incinerated in this primary chamber at a temperature of 800 - 1050°C. The bottom ash will be transported via a double screw system into the general slag bunker of the incinerator plant. The flue gas from the first chamber will be incinerated again in the Secondary chamber at a temperature of min. 900°C. Afterwards the heat of the flue gas will be recovered by a boiler system and the flue gas will be treated in the central flue gas treatment system of the incinerator plant. - 12 - The waste incineration system Bielefeld-Herford 4.2. Main technical data of the hospital waste incinerator Type of Waste: Used adhesive tape, plaster Disposable equipment Textiles Rubber Plastics (PVC, PE, PP etc.) Syringes, needles, ampoules Bones, organs, viscera Carcasses of small animals Infected litter, old pills, broken glass Packing, containers of paper, cardboard Infectious fluids Volatile fluids Specific heat content of waste 3500 kcal/ kg 14,5 MJ/ kg Throughput by weight 500 kg/h 1100 lbs/h Incinerator Operating Cycle Continuously Operating Temperatures Primary Chamber 800 - 1050 °C Secondary Chamber min. 900 °C Thermal Design Capacity of Waste 1,750 Mcal/h 7,330 MJ/h Auxiliary Burners Primary Burner 800 kW Secondary Burner 1700 kW Flue Gas Treatment System Heat recovery boiler/district heating Electrostatic precipitation – 2 stages Wet Scrubber Baghouse filter with addition of neutralising and adsorption reagents - 13 - The waste incineration system Bielefeld-Herford Emissions EU Waste Directive 2000/76/EC German 17. BImSchV Control system Fully automatic Supervisory, Control, and Data Aquisition and Reporting System 2nd Burner system Loading of the waste bins 1st Burner system Picture 9: Side-view of the hospital waste incinerator system - 14 - 4.3. Process description of the Envikraft incinerator Loading of the hospital waste incinerator Hospital waste is collected inside the hospitals in 30 and 60 litre non reusable plastic container and is brought to the hospital waste incinerator of the MVA Bielefeld-Herford. The containers are placed on an automatic conveyer. The conveyer leads the containers to the lifting device, next to the incinerator. The lifting device is raised the containers up to the lock stage. From here, the containers are transported via a second conveyer to the lock chamber where the containers applied into the main combustor. Afterwards the lifting device is brought down and ready for the next containers. Picture 10: Loading device for bins The charging lock The lock consists of a lock chamber, two trap doors, and a funnel with an isolated, locked oven door. The lock is fitted with an automatically flue gas extraction. The charging process operates automatically (pneumatically): The upper lock door is opened automatically. The lifting device will bring the containers into the lock chamber. The lock door will close and the lifting device will drive down to the bottom position. The oven door will be lifted now pneumatically up and is placed in horizontal position. The two trap doors are opened pneumatically and the containers are falling down into the primer combustion chamber. Than the incinerator door is closed again. The flue gas extraction will be started and the flue gas is removed from the charging chamber and leaded into the secondary combustion chamber. The primary combustion chamber The primary combustion chamber is build out of fire proof brick work. It is positioned on a fully welded steel construction. Furthermore, the primer combustor is fitted with an oven door, two ash screw conveyers, and a monitoring door. To heat the primer combustion chamber, a gas burner is fixed on the front of the oven. After the charging of the primer chamber with the waste, the temperature controlled primer burner is heating up the primary chamber to the treatment tempPicture 11: View of the incinerator system The waste incineration system Bielefeld-Herford erature. Via air channels, the primary combustion chamber is supplied with the necessary air. These air channels are located on the chamber walls. The air supply is controlled by the SPS-system. The primary combustion chamber is fitted with a twoscrew conveyer on the bottom to remove the bottom ash after the incineration process. Connected with and next to the primary chamber, the ash cauterization chamber is located. The screw-conveyors will transport the ash to this chamber. During the transportation the temperature of the ash will cool down. Via an air proof oven flap, the ash can be transported out of the cauterization chamber. The screwconveyors are made out of heat resistant steel (253 MA). The secondary combustion chamber In the secondary combustion chamber, the flue gases will be controlled burned. For this, the retaining time, the temperature and the turbulence is controlled. To get an optimum out burning of the flue gasses, also the secondary chamber is equipped with a burner system to ensure a permanent temperature of >900°C. Picture 12: Top-view of the incinerator Air system The air supply for the burning processes is done via a regulated air piping system, which is connected with a distribution device from the secondary combustion chamber. The distribution device is coupled with a blower which will be started together with the combustion process. The air system as integral part for a clean burning process is connected and steered via the PC/SPS system. Heat recovery system The heat recovery system is used for the fast cooling down of the flue gas from 1000°C (entrance side) down to 250°C (exit side). It consists out of a cross-flow, water cooled heat exchanger. After leaving the heath exchanger, the flue gasses will be mixed with the flue gasses from the main waste incinerator and be treated via the central flue gas treatment system. - 16 - The waste incineration system Bielefeld-Herford 5. Evaluation and effects to the environment Already short after the start of the operation, the new hospital waste incinerator could be fully operated. During 2001 – 2003, no major problems could be noticed and the plant is operated to the full satisfaction of the investor. As the incinerator is connected with the advanced, central flue gas treatment system of the MVA Bielefeld, no emissions problems have so far occurred, as it can be seen on Picture 5. The integration of the new incinerator in the existing concept went smoothly. Out of this it can be said that the combination of a municipal waste incinerator with a medical waste incinerator is an attractive alternative to sole municipal or hospital waste incinerators, as secondary facilities like the flue gas treatment and the slag bunker can be shared. As negative point, the lifting device, which is only able to handle waste packed in waste bins must be noted. The average costs for a 60 litre approved one-way waste bin for hospital waste is about 3,5- €. A waste bin contains about 7 kg of waste, the treatment cost of 1 kg waste are less than 0,5 €. By this, the packing costs are as high as the treatment cost. Last but not least it must be mentioned that also a combination between sterilization plant and municipal waste incinerator would be possible. By this combination, steam generated by the municipal waste incinerator could be used for the sterilization of the hospital waste and the sterilized hospital waste could be incinerated in the municipal waste incinerator. Out of internal reasons, this was however no option for the MVABielefeld-Herford. - 17 -