Hearth, Patio & Barbecue Association Searches

advertisement

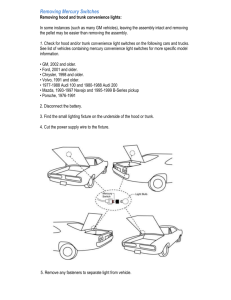

Hearth, Patio & Barbecue Association Searches March 28, 2007 HPBA New Fuego North America Serves an Upscale Consumer Niche Market **HPBA** Business Wire (press release) - San Francisco, CA March 27, 2007 Megan Lloyd-Jones Erica Saucedo Alternative Heating CU professor uses grass pellets as an alternative energy Ithaca Journal - Ithaca, NY March 28, 2007 Jennie Daley Oregon can be a leader in pellet and biofuel production Salem Statesman Journal - Salem, OR March 28, 2007 Harvey Gail New Fuego North America Serves an Upscale Consumer Niche Market **HPBA** Business Wire (press release) - San Francisco, CA March 27, 2007 Megan Lloyd-Jones Erica Saucedo Fuego 01 Grill Offers New Approach to Outdoor Cooking and Entertaining SAN FRANCISCO--(BUSINESS WIRE)--Driven by innovation and a desire to challenge the status quo, the creators of Fuego North America are successfully launching a new company, brand, and product line all at once. The Fuego 01 grill — the inaugural product in a revolutionary line of outdoor entertaining essentials — will be available nationwide through an exclusive network of distributors in March, 2007. Fuego’s founders are poised to rock the staid grilling and appliance industry to its very foundation: Alex Siow serves as company CEO. Siow founded Zephyr Ventilation, and was the first to create a signature designer line of kitchen ventilation hoods. Robert Brunner is the chief industrial designer for Fuego and former director of industrial design at Apple Computer. Brunner’s designs grace the permanent collections of both the New York and San Francisco Museums of Modern Art. Fuego’s target market consists of smart, design savvy urbanites who love to cook and entertain. Fuego is tapping into the trend in grilling and outdoor entertaining. According to the Hearth, Patio & Barbecue Association, three out of four households own a barbecue grill and more than 66 million individuals barbecued in 2005. The Fuego 01 transforms the traditional grill from a single-person chore to a stylish focal point for the outdoor kitchen. It is a social hub that allows guests to interact and enjoy, and it combines sophisticated design with a host of features that have never existed on any other grill. Features include: Crafted of brush stainless steel with natural teak and slate Two separate cast iron grilling surfaces Fully retractable weather lid that vanishes within the unit when not in use Modular accessory system Patented quick change drawer system with multiple fuel options (charcoal, gas and radiant infrared) Built in wheels for easy mobility The Fuego 01 is a recipient of the 2006 Chicago Athenaeum Good Design Award and the 2007 iF (International Forum) Product Design Award. CU professor uses grass pellets as an alternative energy Ithaca Journal - Ithaca, NY March 28, 2007 Jennie Daley ITHACA — Grass pellets sound more like rabbit food than a local, sustainable energy source, but a Cornell University professor hopes to change that perception. Jerry Cherney, the E.V. Baker professor of agriculture in the department of crop and soil sciences, has been working for about five years to pull together the pieces needed to create an industry around grass pellets and the stoves that burn them. The latest step toward that was the installation of a grass pellet stove in Cornell's Big Red Barn, which serves as the graduate and professional student center. “This technology holds so much promise and we wanted to draw some attention to it,” said Ethan Rainwater, Cornell's sustainability intern who helped facilitate the on-campus installation. On the mantel above the stove in the Big Red Barn is a large, informational poster that reads, “It takes 70 days to grow a crop for grass pellets. It takes 70 million years to make the fossilized grass in fossil fuels.” Grass pellet proponents appreciate this quality of the fuel as well as the fact that it's a product that can be grown locally, dramatically reducing transportation costs and potentially providing local jobs. Mike Rutzke, a senior research associate in Cornell's food science department, considered these advantages two years ago when he decided to buy a pellet stove that burns corn. Since his Danby home has acreage on which his neighbor grows corn, it was an easy decision for him and his wife to invest in a slightly more expensive stove that would burn what they grow. They quickly found that adding about a 20 percent ratio of grass pellets to their corn made for a cleaner burn, so they now also use some of the grass pellets Cherney provides. While Rutzke is thrilled with the performance and cost of his new heating system, he's seeing clear signs that more needs to happen to improve the industry. He said there is a long wait for new stoves, suggesting anyone who wants one for next winter should order now. He has also found that securing grass pellets is tough if you don't know someone like Cherney. Yet even for Cherney it's tough. He had to send grasses to Canada for his latest batch of pellets. Infrastructure issues such as these are ones he feels could be overcome with some government support of the industry such as what he has seen in Pennsylvania and Vermont. Middlebury College in Vermont recently decided to invest $11 million in a biomass plant that is fueled by wood chips, grass pellets and willows. They hope state grants will offset some costs. The plant will provide heat for the college and is part of its initiative to be carbon neutral by 2012, meaning it will produce all of its own clean energy locally. “Trying to start a whole new energy system is tough,” Cherney said, especially when New York state recently dedicated significant resources to ethanol production. “I'm trying to get everything together to get an industry going where there's supply and demand but you can't do that on your own. Most things start up with some sort of government support.” The New York State Energy Research and Development Authority, NYSERDA, said that they have no programs supporting the development of grass pellets in part because it's not a new technology. While not novel, there are still barriers that Cherney thinks government funds could help overcome, for instance subsidizing the purchase of pellet machines in areas where they could be shared by several farmers. Once a farm had a way of creating pellets, there would be little required for it to produce a heating source, according to Cherney. Most farms already grow and harvest grasses and it's a plant that can grow on marginal soils that aren't well suited for other crops. Cherney noted that interest in grass pellets seems to be driven by two things, the price of fuel oil and the weather. He said he gets fewer inquiries in the warmer months and when fuel costs are low. Also, the availability of wood pellets affects interest. While wood pellet stoves aren't equipped to burn grass pellets, many people wonder about that possibility when wood pellet supplies become limited. The relatively higher ash content of grass pellets makes them incompatible with wood stoves. When the ash gets heated it can melt and form a mass that blocks air flow and ash removal. Many corn-burning stoves have some type of rotating device to prevent this. While incompatible in stoves, Cherney said the existing research demonstrates that the amount of heat from grass pellets is comparable to that of wood and the two should be comparable in cost, too. Rutzke has found his stove to be efficient and cost-effective. “We think it's a much better alternative to fossil fuels than converting biomass to ethanol because there are fewer steps, it's more direct and it's a technology that already exists,” Rutzke said. Oregon can be a leader in pellet and biofuel production Salem Statesman Journal - Salem, OR March 28, 2007 Harvey Gail Your viewpoint that Oregon should embrace biofuels is right on. But your editorial failed to recognize Oregon already has a "commercially practical" method for turning waste forest products into fuel. Meet the other biofuel -- pellets. Oregon produces about 200,000 tons of pellets a year, and the bulk of it is exported. What's more, thousands of Oregonians heat their homes with pellet stoves or pellet furnaces and have since they were pioneered in Oregon more than 20 years ago. The truth is you probably don't even know your neighbor has a pellet stove because they produce no visible smoke. These appliances are an environmentally sustainable home heating option and are recognized by the Oregon Department of Environmental Quality and Environmental Protection Agency as clean-burning and efficient home-heating appliances. Pellet stoves also are engineered to burn straw pellets, corn and even hazelnut shells. Gov. Kulongoski's energy package is a major step in helping Oregon to be a leader in biodiesel and pellet fuel production. With these incentives Oregon can increase production to prevent shortages caused by their rapid increase in popularity as a home heating option in the Northeast and Midwest. So give credit to Oregon's original biofuel - pellets. -- Harvey Gail, Salem