2. -Glucosidase supplementation (Novozyme

advertisement

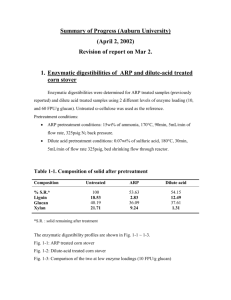

USDA /IFAFS Project Status Report (Auburn University, April 2003) Pretreatment with Aqueous Ammonia at Room Temperature During this project period, we have investigated on a pretreatment method drastically different from the conventional ARP process. The method is quite simple. Corn stover is soaked in 30% aqueous ammonia and left at room temperature for extended period (1-30 days). It is done without agitation under atmospheric pressure in a closed vessel. The purpose of this work was to see if this method could alleviate two main problems of the conventional ARP. The first problem is the high-energy input (high temperature and relatively high liquid throughput). The second problem is that about half of hemicellulose (4060%) is removed during the ARP process along with lignin. The ARP effluent therefore has to be reprocessed for maximum utilization of hemicellulose sugars, which is a significant cost factor. The room temperature treatment method has a potential to resolve these problems because of no heat input during the treatment phase and limited interaction of ammonia with hemicellulose at room temperature. In our previous work, we have also found that high degree of delignification is not a necessary condition to achieve high enzymatic digestibility. Experimental Procedure Ground corn stover (9-30 mesh) was treated with 29.5 wt% of aqueous ammonia in capped glass lab bottles at room temperature for 1-30 days. The solid-to-liquid ratio was kept at 1:12 for 1–10 days bottles and at 1:15 for 20–30 days bottles. After the soaking, the solids were separated by filtering, washed with cold water, and subjected to enzymatic digestibility test as described in Table 1. Table 1. Treatment conditions Items Temperature Reactor Treatment time Ammonia concentration Solid liquid ratio (S:L) Conditions Room temperature (22–24ºC) Tight seal vessel (Pyrex glass laboratory bottle) 1-30 days 29.5 wt% 1:8 to 1:15 Enzymatic hydrolysis conditions: (same as previous reports) 1. Cellulase enzyme (Spezyme CP, Lot 301-00348-257, activity: 31.2 FPU) : 15 FPU/g of glucan loading 2. -Glucosidase supplementation (Novozyme 188, 40 IU/g of glucan) 3. Conditions: 0.05M citrate buffer (pH 4.8), 50C, 150 rpm. 4. -Cellulose (Sigma, Lot No. 11K0246) Summary of Results Composition: Figure 1 summarizes the time progression of composition data upon ammonia soaking. The major change of composition is that of lignin. Lignin removal by soaking process was in 35–67% range. Delignification over 10-day period is 59.1%. It has steadily increased to 67.2% after 30 days. The glucan content is well preserved showing no significant changes up until 20 days. Approximately 10% of total initial xylan was removed in 4 days. Xylan removal increased slightly with soaking time reaching 13% after 30 days of soaking. This is in sharp contrast to 40–60% dissolution of xylan in the conventional ARP. Enzymatic Digestibility: The digestibility test results are summarized in Figure 2. The digestibilities of the samples treated for 8–30 days are 89–94% with 60 FPU/g of glucan of enzyme loading. With 15 FPU/g of glucan, the digestibilities were somewhat lower being in the range of 82–87%. The 10-day sample shows 83.8% of digestibility with 15 FPU/g of glucan. In direct comparison with the ARP samples, the digestibility of the room temperature soaking was lower, but only by 2-4%. Delignification and digestibility generally increase with the soaking time. However, increases after 10 days were rather insignificant. Effect of L/S Ratio: Tests with varying L/S ratio (Fig. 3) indicate that lignin removal and enzymatic digestibility increase slightly when the L/S ratio was increased from 8 to 15 (54→59% for delignification, 82→84% for digestibility @ 15 FPU/g of glucan). Xylan removal increased only by 1%. Concluding Remarks Room temperature soaking with aqueous ammonia appears to be a feasible pretreatment method applicable for corn stover. In direct comparison with the ARP, the process is simple, less energy intensive, and retains higher fraction of xylan. The enzymatic digestibility of this method is only slightly lower than the ARP. On the downside, the processing time is long and requires higher amount of ammonia and total liquid per unit mass of feedstock. The latter would increase the cost of ammonia recovery. Actual consumption of ammonia, however, is expected to be lower than the ARP due to reduced acetate generation. It is of our utmost interest to see how the process economics of this method measures up. The literature information implies that the major occurrence of alkaline treatment of lignocellulosic biomass at room temperature is swelling of cellulose. What is unusual in our finding is that treatment over extended period causes not only swelling but also a significant delignification, both factors contributing to improved digestibility. 40 36.1 36.3 36.7 Composition [%] 35 36.4 36.4 35.5 36.3 36 34.8 30 Glucan Xylan 25 20.4 20.1 20 19.3 18.8 18.4 18.2 17.8 18.1 17.8 15 10 0 5 10 15 20 25 30 Reaction time [d] 20 Lignin 17.2 Composition [%] 15 11.12 10 9.83 8.82 7.52 7.88 5.71 7.02 5 5.64 0 0 5 10 15 20 25 30 Reaction time [d] .Figure 1. Variation of solid composition with soaking time. Note. 1–8 days; solid:liquid ratio=1:12, 10–30 days; solid-liquid ratio=1:15, reaction temperature=22–24ºC (room temperature), 29.5 wt% ammonia. All sugar and lignin content based on the oven-dry untreated biomass. 100 100 8-30 day-60 FPU 90 80 Enzymatic digestibility [%] Enzymatic digestibility [%] 90 4 day-60 FPU 70 1 day-60 FPU 60 50 40 30 Untreated-60 FPU 20 80 70 40 30 20 0 0 48 72 96 1 day-15 FPU 50 10 24 4 day-15 FPU 60 10 0 8-30 day-15 FPU Untreated-15 FPU 0 24 72 96 Time [h] Time [h] Untreated-60 FPU 1 d- 60 FPU 8 d-60 FPU 20 d-60 FPU 48 α-Cellulose-60 FPU 4 d-60 FPU 10 d-60 FPU 30 d-60 FPU Untreated-15 FPU 1 d-15 FPU 8 d-15 FPU 20 d-15 FPU α-Cellulose-15 FPU 4 d-15 FPU 10 d-15 FPU 30 d-15 FPU Figure 2. Effect of soaking time on enzymatic hydrolysis. Note. 1–8 days; solid:liquid ratio=1:12, 10–30 days; solid:liquid=1:15, reaction; reaction temperature=22–24ºC (room temperature); 29.5 wt% ammonia; solid and liquid ratio is based on wt. 50 85 Digestibility at 72 h 40 83.4 83.8 83.0 81.9 80 Glucan Composition [%] 35 36.5 36.9 35.7 36.0 30 75 25 Xylan 20 15 19.1 19.1 18.7 10 5 70 18.1 65 K-Lignin 7.9 7.6 7.6 15 FPU Digestibility at 72 h [%] 45 7.0 0 60 1:8 1:10 1:12 1:15 Solid : Liquid [-] Glucan Xylan Lignin 72 h digestibility Figure 3. Effect of solid to liquid ratio on solid composition and digestibility. Note. Reaction time= 10 days (240 h); reaction temperature=22–24ºC (room temperature); 29.5 wt% ammonia; solid-liquid ratio is based on wt. All sugar and lignin content based on the oven-dry untreated biomass. Enzymatic digestibility; 15 FPU/g of glucan, digestibility at 72 h.