Questionnaire ( doc - 243 Ko )

advertisement

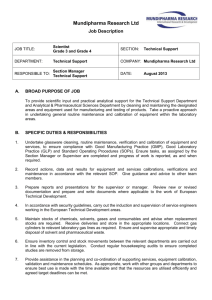

SELF EVALUATION QUESTIONNAIRE FOR LABORATORIES IN ACCORDANCE WITH ISO 17025 rev1 – 2010-10-28 SELF EVALUATION QUESTIONNALRE IN ACCORDANCE WITH EN ISO/I EC 17025: LABORATORIES Answer each question, using one of the response options explained in the introduction and identify possible deviations Page 1 of 12 SELF EVALUATION QUESTIONNAIRE FOR LABORATORIES IN ACCORDANCE WITH ISO 17025 rev1 – 2010-10-28 CONTENTS INTRODUCTION ________________________________________________________ 3 I. QUESTIONNAIRE ___________________________________________________ 3 I.1 II. Organisation ...................................................................................................................... 3 QUALITY MANAGEMENT SYSTEM _____________________________________ 4 II.1 II.2 II.3 II.4 II.5 II.6 II.7 II.8 General ............................................................................................................................. 4 Checking the documents ................................................................................................... 4 Revisions by the management .......................................................................................... 4 Internal audits.................................................................................................................... 5 Checking non-compliant test/calibration work .................................................................... 5 Corrective actions ............................................................................................................. 5 Preventive actions ............................................................................................................. 5 Claims ............................................................................................................................... 6 III. REVISIONS OF REQUESTS, OFFERS AND CONTRACTS___________________ 6 IV. PURCHASE OF SERVICES AND SUPPLIES ______________________________ 6 V. SUBCONTRACTING TESTS AND CALIBRATIONS ________________________ 6 VI. PERSONNEL _______________________________________________________ 6 VII. TEST AND CALIBRATION METHODS, VALIDATION OF METHODS __________ 7 VII.1 General ............................................................................................................................. 7 VII.2 Estimating the uncertainty of measurement ....................................................................... 7 VII.3 Validation .......................................................................................................................... 8 VIII. SAMPLING ________________________________________________________ 8 IX. HANDLING TEST/CALIBRATION OBJECTS ______________________________ 8 X. INSTALLATIONS AND ENVIRONMENTAL CONDITIOPNS __________________ 8 XI. EQUIPMENT _______________________________________________________ 9 XII. TRACKING THE MEASUREMENTS ____________________________________ 10 XII.1 General ........................................................................................................................... 10 XII.2 External tracking ............................................................................................................. 10 XII.3 Internal calibration ........................................................................................................... 10 XIII. ENSURING THE QUALITY OF THE TEST RESULTS AND CALIBRATIONS ____ 11 XIII.1 Inter-comparisons ........................................................................................................... 11 XIII.2 Quality control ................................................................................................................. 11 XIV. RECORDS AND REPORTS OF RESULTS _______________________________ 11 XIV.1 Records........................................................................................................................... 11 XIV.2 Control of data................................................................................................................. 11 XIV.3 Reporting results ............................................................................................................. 12 Page 2 of 12 SELF EVALUATION QUESTIONNAIRE FOR LABORATORIES IN ACCORDANCE WITH ISO 17025 rev1 – 2010-10-28 INTRODUCTION This self evaluation questionnaire is intended for laboratories seeking to obtain accreditation in accordance with ISO 17025 standard requirements. It will help get an idea of the degree of compliance with the aspects evaluated during accreditation. This questionnaire is for internal use only. The questions are considered to be the most suitable for evaluation purposes and are grouped by sections in an order which does not coincide with the presentation in the standard. The section of the standard to which the question refers is indicated in brackets after each question (preceded by a “C” if it refers to the General Accreditation Criteria). Also, those questions referring to new aspects of ISO 17025 regarding the EN 45001 are highlighted. These questions are designed to be answered easily by ticking the answers from the following categories: 0. YES/NO 1. DI: System Defined with documents1 and effectively Implemented2 2. DNI System Defined with documents but not effectively Implemented 3. DNU: System Not Defined with documents but there are Updates which seek to resolve the matter 4. NONU: No system has been defined nor are there Updates on the matter 5. NA: Not Applicable to the laboratory3 There are also questions with text answers which are used to give more details on some aspects. These must be included in the existing document for the system used in the laboratory. The gap left after each question is designed for the laboratory to note down as a cross reference, the internal document or documents which respond to the question (Quality Manual, General procedure, Specific Procedure… sections). For the next step in this self evaluation, the laboratory should carry out those actions which seek to correct the deficiencies detected. The most appropriate system to implement these actions is by using the establishment of an Action Plan defining the action to be taken for each of the detected deficiencies and the managers to carry them out and to track them. I. QUESTIONNAIRE I.1 1.1 1.2. 1.3. 1.3.1. 1.3.2. 1.3.3. 1.4. Organisation Is the legal status of the laboratory established in a Quality Manual? (4.1.1) Are documents available (constitution documents, founding decree …) which define the laboratory’s legal entity? In the event that activities are undertaken which are different from testing and/or calibration (4.1.4) Have possible conflicts of interest been identified? (4.1.4) Have appropriate measures been taken to avoid identified conflicts of interest? (4.1.4, note 1) Have the responsibilities of key personnel4 been defined, (4.1.4) Has the laboratory established rules to guarantee the confidentiality of information obtained from tests and/or calibrations, including a formal written commitment to keep to these rules? 1 The degree of definition and extent of the system defined may give rise to different interpretations Effectively implemented is understood to mean when it is applied normally (each time it is necessary) and when it achieves the required objective 3 Whether this is applied or not may be due to different interpretations 4 key personnel are understood to mean personnel with the appropriate technical competence to ensure that the activities within the scope of the accreditation are effectively undertaken 2 Page 3 of 12 SELF EVALUATION QUESTIONNAIRE FOR LABORATORIES IN ACCORDANCE WITH ISO 17025 rev1 – 2010-10-28 (4.1.5.c) Is there an updated organisational chart for the laboratory and for the higher organisation in which it is located? (4.1.5.e) Are there documents which state the functions and responsibilities of each person undertaking activities which affect the quality of the test, avoiding overlaps and omissions of responsibility? (4.1.5.e) Do the personnel carrying out the technical Direction have a job description? (4.1.5.h) State those people involved in Technical Direction together with their area of responsibility and how they are linked with each other. Has the laboratory management defined a person responsible for managing the Quality System implemented? Does this person have access to management? (4.1.5.i) Have replacements been designated for key personnel? (4.1.5.j) 1.5. 1.6. 1.7. 1.8. 1.9. II. QUALITY MANAGEMENT SYSTEM II.1 General 2.1.1 2.1.2 2.1.3 2.1.4 2.1.5 Does the Quality Manual describe the structure of the documents for the system? (4.2.3) Does the System include the technical units and activities for accreditation? (4.2.1) Are the documents described by the system maintained in accordance with the current situation of the laboratory? (4.2.1 and 4.3.2.2.b) Are the policies and aims of the laboratory in terms of quality stated in writing? (4.2.2) Does the quality policy statement contain the minimum information required by the standard? Is it approved and signed by a person with the capacity to do so? (4.2.2) II.2 Checking the documents 2.2.1 2.2.2 2.2.3 2.2.4 2.2.5 2.2.6 2.2.7 2.2.8 2.2.9 2.2.10 2.2.11 Has the laboratory defined in the documents both internal and external which must be submitted for checking, including documents on computer software? (4.3.1) Is there a list of current documents? (4.3.2.1) Has the use of distribution lists been implemented or is there another similar procedure in use? (4.3.2.1) Has authorised personnel been delegated to revise and approve the different documents? (4.3.2.1) Have obsolete documents been withdrawn from use? (4.3.2.2.c) Do the documents comply with the minimum requirements in terms of format, including: (4.3.2.3) Unique identification Date of issue or revision number Page number Total pages or end of document marked Person responsible for circulating the document Has a system been introduced for modifying the documents, including computerised documents? (4.3.3) Has a system been established to correctly identify, collect, code; access, file, store, maintain and destroy quality and technical records? (4.12.1.1) Have the appropriate measures been taken to avoid damage, suppression and unauthorised access? Are the records easily readable and recoverable? (4.12.1.2 and 4.12.1.3) Has a minimum period of five years been established for storing the records? (C 4.12.1.2) When the laboratory produces records of electronic documents, have appropriate measures been taken to store them so that they be protected against mishandling, deterioration and stop unauthorised access? Are backup copies periodically made? (4.12.1.4) II.3 Revisions by the management 2.3.1 2.3.2 Have requirements to revise the Quality System been established and is there a system to undertake this? (4.14.1) Does this system contain all the necessary aspects? (4.14.1) Management and supervisory boards Page 4 of 12 SELF EVALUATION QUESTIONNAIRE FOR LABORATORIES IN ACCORDANCE WITH ISO 17025 rev1 – 2010-10-28 2.3.3 2.3.4 2.3.5 2.3.6 2.3.7 Results of recent internal audits Corrective actions Preventive actions Audits undertaken by external organisations Results of cross comparisons Changes in the volume and type of work Return of information to clients Claims Other relevant factors such as quality control activities, resources and staff training Based on all of the above, analysis of the ideal nature of the policies and procedures Are they undertaken annually? (4.14.1, note 1) Do the managers take part in this revisions (Senior management for the laboratory)? (4.14.1) Have objectives and action plans for the following year been established as a result of the revision? (4.14.1, note 2) Are records of these revisions (minutes of meetings, actions to be implemented etc.) kept and are they complete? (4.14.2) Are agreed actions carried out in accordance with the established time period? (4.14.2) II.4 Internal audits 2.4.1 2.4.2 2.4.3 2.4.4 2.4.5 2.4.6 2.4.7 Has the requirement for carrying out internal audits each year been established and is there a system to carry them out? Are they carried out in accordance with the programme written by the Quality manager? Do these audits cover each aspect of the Quality System implemented, including test and calibration activities? Is a record kept of: areas of activity audited, results of the audit and corrective actions undertaken? Is there a proper tracking of the current status of deviations arising from previous audits? Are the audit results distributed to laboratory management and to the managers of the areas audited? When the audit results question the validity of the test/calibration results are the relevant “immediate actions” carried out and are the customers informed in writing? (4.13.2) II.5 Checking non-compliant test/calibration work 2.5.1 2.5.2 2.5.3 2.5.4 2.5.5 Has a system been established to identify and handle non-compliant work? (4.9.1 and 4.9.2) Have managers been designated to handle non-compliant work as well as to restart work? (4.9.11a, 4.9.1.b and 4.9.1.e) Is immediate action taken, if necessary? Is the work interrupted and the customer informed, if necessary? (4.9.1.d) Is the process of collective action started if the above happens? (4.9.2) II.6 Corrective actions 2.6.1 2.6.2 2.6.3 2.6.4 Has a system been established to identify and handle non-compliances and to take corrective actions? Is this system taking into account non-compliance with technical aspects and the implementation of the Quality System? (4.10.1) Is an investigation carried out into the causes and consequences of these non-compliances? (4.10.2) Are corrective actions and their effectiveness recorded and their implementation tracked? (4.10.3 and 4.10.4) Does the system allow for the option to undertake additional audits whenever necessary? (4.10.5) II.7 Preventive actions 2.7.1 2.7.2 2.7.3 Has the laboratory established a system to identify area of improvement or possible sources of non-compliance as well as establishing the appropriate preventive measures? (4.11.1) Have areas of improvement or possible sources of non-compliance been detected? (4.11.1) Have the necessary preventive actions been implemented? Is their effectiveness checked? Page 5 of 12 SELF EVALUATION QUESTIONNAIRE FOR LABORATORIES IN ACCORDANCE WITH ISO 17025 rev1 – 2010-10-28 (4.11.2) II.8 Claims 2.8.1 2.8.2 Does the laboratory have a written procedure for handling claims? (4.8) Do the system/procedures record the claims then the investigations and actions carried out to resolve them? (4.8) III. REVISIONS OF REQUESTS, OFFERS AND CONTRACTS 3.1 3.2 3.3 3.4 3.5 3.6 Has the laboratory documented the system for the revision of requests, offers and contracts? (4.4.1) Does this system ensure that: Customer requirements are documented and interpreted correctly; The laboratory has the necessary capacity and resources; The selected test or calibration method is appropriate (dies it meet customer requirements)? Prior to starting any work, has the laboratory settled the differences between the request or offer and the contract? (4.4.1) Is there documentary evidence of acceptance of the contract (or communication) from the customer? (4.4.1) Is a record kept of all revisions and conversations with customers? (4.4.2) If there are deviations (of any type) with the contract, is there evidence that the customer has been informed and that his permission has been obtained? (4.4.4) IV. PURCHASE OF SERVICES AND SUPPLIES 4.1 4.2 4.3 4.4 Has the system been documented which selects and purchases services and supplies? Does the laboratory have procedures for purchasing, receipt and storage of reactive agents and consumable materials? (4.6.1) Is there evidence of the technical revision and approval of purchase documents? (4.6.3) Is a record kept of the inspections/verifications carried out on supplies, reactive agents and consumable products to check that they meet the established requirements? (4.6.2) Does the laboratory have a list of suppliers for consumables, supplies and critical services which has been evaluated and approved plus a record of their evaluation, (4.6.4) V. SUBCONTRACTING TESTS AND CALIBRATIONS 5.1 5.2 5.3 5.4 Are the criteria and system for subcontracting established in writing, (4.5.1) Has the requirement been established to communicate with the customer in writing about the tests and/or calibrations which have been subcontracted in order to obtain their approval? (4.5.2) Has it been established that the laboratory assumes responsibility for tests which have been subcontracted? (4.5.3) Has the requirement to subcontract work only to accredited laboratories been met? (C 4.5.4) Are records kept on the subcontractors which have been used? Are subcontracted tests duly identified in reports, (5.10.6) VI. PERSONNEL 6.1 6.2 Are there descriptions of staff employment positions and are they updated? Have minimum requirements been established for knowledge, experience, aptitude and necessary training to carry out each position? (5.2.4) Have managers been designated for the following activities: Checking documents Approval of contracts Purchases Closure of a corrective actions Page 6 of 12 SELF EVALUATION QUESTIONNAIRE FOR LABORATORIES IN ACCORDANCE WITH ISO 17025 rev1 – 2010-10-28 6.3 6.4 6.5 6.6 6.7 6.8 6.9 Training Approval and modification of methods Sampling Validation of methods Test/calibration quality evaluation Signing reports/certificates Has the system been established to qualify and authorise staff? (5.2.1) Has the laboratory issued authorisations for each type if activity? (Tests/calibrations, internal calibrations, sampling, validation and internal audits) (5.5.5) Has the system been established to identify training requirements and to train staff? (5.2.2) Do key personnel in the laboratory form part of the workforce? (C 5.2.3) Is there a contractual relationship with staff who are not part of the workforce? (5.2.3) Is there suitable supervision of trainees or staff who are not part of the workforce? (5.2.1 and 5.2.3) Does the laboratory have updated records on qualifications, experience and training of staff? (5.2.5) VII. TEST AND CALIBRATION METHODS, VALIDATION OF METHODS VII.1 General 7.1.1 7.1.2 7.1.3 7.1.4 7.1.5 7.1.6 Is there a list of documents which the laboratory uses to undertake tests/calibrations (standards, procedures …) including date and number of revisions? Does the laboratory have procedures/test/calibration standards for all work included within the scope of the requested accreditation? (6.4.1) Does the laboratory work with the latest version of the procedures / test / calibration standards? (5.4.1) If not, how is this justified? (5.4.1) When working with standards, has the system been established to march working practices to the new versions of the standards? (C 5.4.2) Where necessary, has the laboratory set up procedures which cover gaps in these methods? (For example: interpretations, clarifications arising from experience, inter-laboratory agreements, etc.) (C 5.4.4) Do the procedures used (including internal calibrations) contain sufficient information to allow the proper undertaking of test/calibrations and their repeatability? (5.4.4) a) Appropriate identification b) Field of application c) Description of the type of object submitted for test/calibration d) Parameters or magnitudes and ranges to be determined e) Apparatus, equipment and reactive agents, including technical specifications f) Reference guides and necessary reference materials g) Required environmental conditions. Stabilisation periods h) Description of the procedure: Preparation of objects to be tested/calibrated Attaching identification marks, transport and storage Preliminary checks Preparation of equipment (adjustments, verification, etc;) Test/calibration actions Method of recording observations and results i) Acceptance and rejection criteria (control parameters) j) Data which must be recorded and calculation method and presentation k) Uncertainty or calculation process VII.2 Estimating the uncertainty of measurement 7.2.1 7.2.2 7.2.3 Does the laboratory have the appropriate procedures to estimate the uncertainty associated with internal calibrations? (5.4.6.1) Does the laboratory have the appropriate procedures to estimate the uncertainty of measurements associated with the test/calibration results for customers? (5.4.6.1 and 5.4.6.2) Are the estimated uncertainty values appropriate to the tolerances for the results of the Page 7 of 12 SELF EVALUATION QUESTIONNAIRE FOR LABORATORIES IN ACCORDANCE WITH ISO 17025 rev1 – 2010-10-28 test/calibrations? (5.4.6.2, note 1) Is the presentation of results coherent with the test/calibration uncertainty? (for example in terms of decimal points) (5.4.6.2, note 1) 7.2.4 VII.3 Validation This section applies to test laboratories non standardised methods or methods used outside the field of application envisaged or standardised methods which do not contain sufficient information. 7.3.1 7.3.2 Has the system been established to validate the methods? (validation procedure) (5.4.5.2) Does the system include “a priori” requirements to specify requirements which these methods must meet. (5.4.5.3 Note 1) Is it carried out in every case5? (5.4.5.2) Is validation broad enough to take into account the application requirements or the field of application of the methods? (5.4.5.2) Are records kept of all activities undertaken? (5.4.5.2) 7.3.3 7.3.4 7.3.5 VIII. SAMPLING This section is applied to test laboratories that carry out sampling (G 5.7.1) 8.1 8.2 Has the laboratory established a system to carry out sampling activities? (5.7.1) Does this system include factors to be checked to ensure the validity of the test results? (5.7.1) Does this system describe the selection, obtaining and preparation of samples? (5.7.1, note 2) Are the necessary documents to carry out the sampling available at the location where the sampling is done? (5.7.1) If changes have been made to the sampling procedure are these recorded and indicated on all documents which contain the results together with the sampling data? (5.7.2) Are complete records kept of the sampling activities carried out? (5.7.3) 8.3 8.4 8.5 8.6 IX. HANDLING TEST/CALIBRATION OBJECTS 9.1 Where necessary, does the laboratory have procedures to transport, receive, handle, protect, store or destroy objects for test/calibration? (5.8.1) Are the objects for test/calibration and subdivisions correctly identified to avoid confusion between objects or references to them in the records? (5.8.2) Are anomalies or deviations to the receipt conditions for the objects recorded? (5.8.3) 9.2 9.3 X. INSTALLATIONS AND ENVIRONMENTAL CONDITIOPNS 10.1 Are the installations suitable (including auxiliary installations) for the type of test/calibration and volume of work carrier out? (5.3.1) Has the laboratory established a system of measurement and control so that it guarantees the maintenance of the pre-established environmental conditions? (5.3.1 and 5.3.2) Indicate the environmental conditions to be taken into account: O temperature / O humidity / O pressure / O light / O vibrations / O dust / O air currents / O elec. fields / O mag. fields / O others For “in situ” test/calibrations, has a system been established which ensures the fulfilment of the requirements on environmental conditions? (5.3.1) Are records on environmental conditions established during procedures kept when necessary? (5.3.2 and C 5.3.2) Are suitable measures taken in the event of detecting variations in environmental conditions 10.2 10.3 10.4 10.5 5 In the event that the laboratory uses standardised methods, it must not be forgotten that it must have the records which ensure that their application to real sampling, its capacity satisfactorily comply with all requirements established for these methods has been verified / updated. Page 8 of 12 SELF EVALUATION QUESTIONNAIRE FOR LABORATORIES IN ACCORDANCE WITH ISO 17025 rev1 – 2010-10-28 which may endanger the results of the test/calibrations? (5.3.2) When incompatible activities are carried out in different areas of the laboratory, is there an effective separation which avoids cross contamination? (5.3.3) Are there access controls to areas which may influence the quality of tests/calibrations? (5.3.4) 10.6 10.7 XI. EQUIPMENT 11.1 Is there an updated list of equipment, auxiliary material and reference material in the laboratory to carry out tests/calibrations under the terms of the accreditation? Does the laboratory have equipment and material required for carrying out tests/calibrations? (5.5.1). If not, list the shortfalls detected. Has the laboratory checked that the design, quality and accuracy of equipment and software are those stated in the test/calibration methods? (5.5.2) When alternative equipment or material is used, is there a comparative study? (5.5.2) When equipment is used which is not subject to permanent control; does the laboratory ensure that it always meets the requirements of the standard? (5.5.1) Has all equipment included in the calibration program been calibrated before being put into operation? (5.5.2) Are updated instructions on the use, handling and transport of equipment and reference materials available to laboratory staff? (5.4.1; 5.5.3; 5.5.6 and 5.6.34) Has each piece of equipment and software used to undertake tests/calibrations been identified? (5.5.4) Has the equipment requiring calibration been labelled or similar to indicate its calibration status? (5.5.8) If any piece of equipment has left the direct control of the laboratory at any time, is there evidence of the subsequent checking operations? (5.5.9) Where necessary, are there procedures to carry out intermediate calibration? (5.5.10) Has a procedure been established to ensure that the transfer of correction factors for equipment is carried out on all necessary documents including software? (5.5.11) Has test/calibration equipment been protected against uncontrolled adjustments6? (5.5.12) Where adjustments are made, has the equipment been calibrated (including master references) before and after the adjustments? (5.6.3.1) Has any situation been envisaged where the master references may be used as work references? (5.6.3.1) If it is so, can it be demonstrated that its use as a master reference is not invalidated? Has a process been defined and implemented to be followed in the event of detecting damaged and/or defective equipment, or equipment out of calibration, etc.? (5.5.7) Is its use limited to necessary tasks; is the situation identified and the equipment placed out of service? Are the causes and possible consequences of the situation investigated? (5.5.7 and 4.9) Are the necessary records kept updated for measuring and testing equipment, software, auxiliary equipment, masters, reference materials and consumable material? (5.5.5) Identification Manufacturer Model Serial number (or other unique identification) Locator (where used) Manufacturer’s instructions Maintenance history, damages, breakdowns etc; Calibration, adjustment history etc. Are there suitable written instructions for the proper implementation of maintenance activities where they are judged necessary? (5.5.6) Are these activities carried out in a scheduled way (5.5.5.g) 11.2 11.3 11.4 11.5 11.6 11.7 11.8 11.9 11.10 11.11 11.12 11.13 11.14 11.15 11.16 11.17 11.18 see above: if, as a result of a calibration, it is decided to adjust the equipment’s response; recordings of the response before and after each adjustment must be maintained in order to know its origin. 6 Page 9 of 12 SELF EVALUATION QUESTIONNAIRE FOR LABORATORIES IN ACCORDANCE WITH ISO 17025 rev1 – 2010-10-28 11.19 11.19.1 11.19.2 11.19.3 11.19.4 Does the program include all equipment and auxiliary installations requiring maintenance? (5.5.6) Are records kept of the maintenance activities carried out?(5.5.5.g) Reference Materials This section is applied to test laboratories which use and reference materials. Does the laboratory have the necessary reference materials to carry out the tests? (5.5.1) Are the reference materials duly labelled and stored? (5.5.4) Prior to use, are new lots of reference materials compared to old lots? Does the laboratory have complete information for each reference material used? (C 5.6.3.2) Value of the property. Uncertainty (or standard deviation or other information which delineated the property nine) Expiry date Methods(s) used to establish the property value Laboratories which have participated in the comparison (where available) XII. TRACKING THE MEASUREMENTS XII.1 General 12.1.1 Has a general written system been established to carry out calibration actions (calibration plan)? (5.6.1 and 5.5.2) Is this plan complete (including test/calibration equipment, internal calibration and sampling)? (5.6.1) If not, details the shortfalls detected: Are these activities carried out in accordance with a pre-established schedule with suitable recalibration intervals? (5.5.2 and 5.6.1) Have acceptance and rejection criteria been established for the calibration results for each piece of equipment? In the event that equipment does not require calibration, has the test laboratory demonstrated that the equipment used may give uncertain measurement results which are compatible with this lack of requirement? (5.6.2.2.1) 12.1.2 12.1.3 12.1.4 12.1.5 XII.2 External tracking Have external calibrations been carried out in suitable laboratories 7? (C 5.6.2-1.1) Has the laboratory checked that the calibration results are appropriate? (see question 12.1.4) (5.6.1) When one of the recognised masters cannot be tracked, can evidence be supplied to validate the results by inter-comparisons, aptitude tests etc.? (5.6.2.1.2 and 6.2.2.2). Specify how. 12.2.1 12.2.2 12.2.3 XII.3 Internal calibration 12.3.1 Are internal calibrations carried out in accordance with the appropriate written instructions? (see question 7.1.6) (5.4.1) Are records kept of the internal calibrations which have been carried out? (4.12.2.1) Are they complete? (4.12.2.1) Identification of reference equipment Identification of the equipment to be calibrated Environmental conditions Personnel Date of calibration Data and calculations uncertainty Has the laboratory checked if the results of the calibrations are appropriate? (see question 12.1.4) (5.6.1) 12.3.2 12.3.3 12.3.4 7 calibration laboratory for the magnitude and range of application accredited by an organisation which has signed the EA or ILAC agreements or by the National Institute of Metrology Page 10 of 12 SELF EVALUATION QUESTIONNAIRE FOR LABORATORIES IN ACCORDANCE WITH ISO 17025 rev1 – 2010-10-28 XIII. ENSURING THE QUALITY OF THE TEST RESULTS AND CALIBRATIONS XIII.1Inter-comparisons 13.1.1 Does the laboratory have policies and procedures which ensure its participation in intercomparisons covering all types of test/calibrations within the scope of the accreditation? (C 5.9) Does it participate periodically and in a scheduled way? Does the schedule cover all types of test/calibrations? (C 5.9) Have a system and responsibilities been established to evaluate the results obtained and to take appropriate actions? (C 5.9) Are records of evaluations of the results obtained during inter-comparisons kept by appropriate staff? Where necessary, are the appropriate measures taken? 13.1.2 13.1.3 XIII.2Quality control 13.2.1 Has a system been established to carry out quality control activities on the results of the test/calibrations? (5.9) Are these activities carried out periodically and in a scheduled and effective way? Does the program cover all of the tests/calibrations or groups of tests? Is the data obtained appropriately recorded? Is the information obtained from these activities used? XIV. RECORDS AND REPORTS OF RESULTS XIV.1 14.1.1. 14.1.2 14.1.3 14.1.4 14.1.5 Records Are records kept for at least 5 years? (4.12.2.1 and C 4.12.2.1) Is the information kept on the preparation of objects presented for test/calibration to be carrier out? (4.12.2.1) In general, is sufficient information filed to allow, if necessary, the repetition of the test/calibration/sample? (4.12.2.1) Date of receipt of the object for test/calibration Date of test/calibration (at least start and finish) Identification of equipment used Personnel undertaking the test/calibration Personnel verifying if the results are correct Environmental conditions Identification and description of the object being tested/calibrated Test/calibration/sampling methods Date and calculations Can information on a test/calibration be tracked through the available record on it, Give details: (4.12.2.2) Is the system used suitable for carrying out modifications in the records, including computer records8? (4.12.2.3) XIV.2 Control of data This section is applied to laboratories which use computers or automated equipment for purchasing, processing, recording, publication, storage or recovering data on test/calibrations; 14.2.1 14.2.2 Is the software developed by the laboratory correctly validated? (5.4.7.2) Does the system used guarantee the integrity and confidentiality of the data at all times 9? (5.4.7.2) 8 in such a way that none of the original data is lost Page 11 of 12 SELF EVALUATION QUESTIONNAIRE FOR LABORATORIES IN ACCORDANCE WITH ISO 17025 rev1 – 2010-10-28 XIV.3 14.3.1 Reporting results Do the reports/certificates issued comply with requirements established by your national Accreditation Body in terms of content? (5.10) Name and address of the laboratory Location (if this is different to the laboratory) Identification of the report and page numbers Name and address of customer Identification of the methods Description and identification of the object Date of receipt (if this is critical) Date of test/calibration Results Name, position of signatory Deviations from the procedure (see question 14.3.3) Declaration of uncertainties, if applicable (5-10.3.1.c) Environmental conditions, if applicable Declaration of uncertainty according to CEA-LC/02 Uncertainty ≥ Optimal Measurement Capacity Declaration of single test object Declaration of conformity, if applicable Additional information, if necessary: sampling procedure, date of sampling, identification of sample object, location of sampling, environmental conditions, if applicable Deviations from the method, if applicable Are these reports/certificates in accordance with the data taken during their implementation and are they clear, concise and easily understood by the final user? (5.10.1) Whenever there have been deviations from the methods, are they documented, justified, authorised by the manager and accepted by the customer? (5.4.1) In the event of issuing simplified reports/certificates is all information available 10? (see question 14.3.1) (5.10.1) Has the laboratory designed a suitable format for each type of test/calibration? (5.1.a) Has a suitable system been established to implement, if necessary, changes to reports/certificates which have already been issued? (5.1.9) When the results are to be transferred electronically, has a system been defined which guarantees the integrity and confidentiality of the information? (4.1.5, 5.4.7 and 5.10.7) When the laboratory issues calibration certificates which contain a declaration of noncompliance with specifications, do the requirements comply with section 5.10.4.2? When the laboratory has justified that is has tested/calibrated in terms of obsolete revisions of the standards, do the reports/certificates indicate that the addition does not correspond to the latest published version? (G 5.1.2) 14.3.2 14.3.3 14.3.4 14.3.5 14.3.6 14.3.7 14.3.8 14.3.9 pay special attention to network Systems with access from area not included in the laboratory’s Quality System 10 simplification must only affect formal contents 9 Page 12 of 12