Water harvesting practices in the form of nadis, talabs, lakes and

advertisement

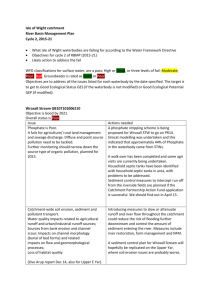

DRINKING WATER HARVESTING – ITS SIGNIFICANCE AND SCOPE IN DESERT ENVIRONMENT N.S.VANGANI Introduction Water harvesting practices in the form of nadis, talabs, lakes and tankas ( cistern ) had always remained the centre of main activity and struggle of all the prudent rulers of the Rajasthan state. These structures have been serving the human, livestock and wild life population besides very precisely supporting the system of irrigation. Unfortunately, due to ignorance and un towards attitude, these typical systems today stand defunct. The main reason is; planners and engineers are living in maniac paradise of ultra sophisticated technology ignoring the hard reality that these systems are best suited in the arid belt, where in most of the areas the ground water is saline and unsuitable for drinking , and rainfall is erratic and unpredictable. Water havesting systems are efficient, easy operative and cheap in the long run in many ways. Among the water harvesting systems narrated above, the tanka can be the answer for reliable and safe drinking water source. Its structural important features, optimize capacity, efficient catchment area characteristics, size required and after care are discussed here. 1. Structural Features: Tanka is a local term for the covered underground cistern, generally of masonry ( stone or brick ) or concrete, for collection and storage of surface runoff. The provision of tanka near religious centres and in village for community use is an ancient practice since 1607 A.D. However, now a days it is preferred to construct it at each hamlet on the individual ownership basis. It is mainly because in case of community tanka, the dominant group get individual supply of water to their homes which poor do not receive. Moreover, an access to water supply might be monopolized. Generally, community structures failed through poor workmanship and after care. 1 Capacity: It is simple to calculate the annual drinking water need of the family. For an example, a family consists of six persons; a bare minimum per capita per day requirement of 7 litres of water only for drinking is usually considered by the villagers that one has to have to live without distress. Clearly, a family needs 15.624 cum or say 16 cum of minimum storage to survive throughout the year solely using tanka water for drinking. However, in the case of unusual consumption of drinking water say 14 liters per capita per day during the summer period of 4 months, an additional provision of 5 cum. can be provided in the storage capacity of tanka. Therefore, an optimal capacity of can be fixed at 20 to 21 cum. Design Components: ( a ) Rainfall probability: Annual rainfall, distribution, amount, and intensity plays an important role in designing of catchment area and structure. Most of the times the structures designed on the basis of average rainfall do not serve the purpose because of frequent droughts in the arid region. In general, the water supply structures are either over designed or under designed. Since the peculiar rainfall conditions are existing in the arid and semi arid regions, it may be worthwhile to predict probability of dependable rainfall of that particular zone where the structure is being proposed. Experience indicates that the dependable annual rainfall occurring at 60 % probability worked out through the Log Pearson Type III distribution meets the criteria for suitably designing the catchment area for the tanka. By considering this probability of rainfall and catchment area needed, the tanka meets the water requirement throughout the year. ( b ) Design of Tanka: The circular cross section is the most economical form of the tanka. It has also been found to be more stable as the pressure exerted by the water is uniform radial pressure in all directions in the diametrical plane at right angle to the curved surface. The successful installation of tanka depends on the selection of site, particularly the catchment characteristics such as size, shape, topography, soil type, vegetation etc in case of natural catchment. The size of the catchment artificially 2 prepared should produce adequate runoff to meet the storage requirement of the tanka and at the same time it should cause minimum soil loss. The catchment area could be worked out by the relation ; Ac x Pd x C = m x d x Ao Where Ac = Catchment area Pd = Dependable rainfall C = Runoff coefficient ( found to be 0.3 ) m = Storage coefficient taken as unity for the tanka d = Depth of tanka below G.L. ( 3.0 m ) Ao = Cross sectional area of tanka The catchment area required for 21 cum capacity tanka is worked out to be 330 m2 After selection of the site and size of the catchment, in the case of natural catchment, it is imperative to carry out some minor treatment for augmenting the runoff. These treatments may be such as construction of earthen diversion bund, removal of bushes, increasing the land slope, compacting soil etc. However, in case of artificial catchment, it should be in the round in shape around the tanka, giving proper slope of 2.5- 3.0 % towards the tanka with zero slope at inlet. After forming the shape of the cachment, it should be rammed and spreading 15 cm thick layer of calcium carbonate nodules ( murrum ) and again ramming. In case calcium carbonate nodules are not available, a layer of silt clay can be spread and rammed properly. Both the treatments on the artificial catchments will result in reduction in the intake rate of the soil. In both the cases of the treatments to the catchment, the maintenance is required every year. Moreover, during runoff, the treated surface is worn out and the materials are carried out as suspended load and deposited in the tanka. This deteriorates the quality of the stored water. To avoid these, a courtyard or open area of the hamlet is treated with cement plaster or cement tiles laid on the bare soil. In this case, the additional water is collected of better quality from the treated area. The coefficient of runoff becomes 0.9 instead of 0.3 due to pucca floor. Hence, maximum water is harvested from small area for storage. The runoff water is transferred through a pipe 3 net work to the tanka. The catchment requirement and the cost estimates will be presented later on. ( c ) Structural components of tanka : ( i )Catchment – It should be impermeable and smooth to obtain improved hydraulic efficiency. ( ii ) Silt collecting pit – It is provided to arrest the sediment load before the inlet point. ( iii ) Cemented apron – This is one of the main structural component provided to control seepage and also to prevent caving from sides. Suitable cement concrete 1: 3: 6 is being used for construction. ( iv ) Catch pit – This is made in the form of depression in the foundation slab of cement concrete 1 : 3 : 6 to facilitate drawing minimum available water from the tanka. ( v ) Top cover – It is required to control evaporative losses and to prevent pollution of water stored by foreign materials. An opening at top with G.I. cover to facilitates withdrawal of water. ( vi ) Inlets – There should be three inlets to collect the runoff , and will also prevent floating debris from entering into the tanka. Moreover, by providing these, there will be free access of air in the tanka which will prevent the bad odour of stored water. A suitable mesh with iron bars in the angle iron frame is to be provided in the inlets. ( vii ) Outlets – There is one outlet for letting out the extra water entering in to the tanka. (viii ) Guide walls – These are provided upstream of outlet for arresting all the available runoff from the catchment. ( ix ) Withdrawal arrangements – A stand with pulley at opening is provided for withdrawal of water with the help of rope and bucket. ( x ) Fencing of catchment area – Fencing of the catchment area is required to restricted animal entry. 4 ( d ) Constructional details : The construction materials used are, all locally available viz. stones or bricks, cement, iron sheet, etc. After selection of site and carrying out desired earth work in excavation; 3.25 m depth and 3.0 m diameter, cement concrete foundation 1 : 3 : 6 with 0.25 m thick should be laid. Entire construction of stone masonry in 1 : 6 cement mortar should be done with special care to ensure against any crack and leakage from floor and walls of the structure. This is achieved by providing cement concrete flooring and at least 1- 1.5 cm thick cement plaster on walls, incorporated with water proofing compounds or with 1 % soap solution in water (soap solution forms insoluble fillers on reaction with cement). Proper cementing of joints in the super structure should also be ensured, especially when further construction on a half finished work is resumed after the lapse of a few days. The tanka is covered with stone slab roofing with a suitable opening on the top for withdrawing the water. The inlets and outlet in the tanka should be placed 3.0 cm below the ground level that is the point where the artificial catchment ends with tanka wall. All the inlets and outlet should be made of angle iron frame with vertical iron bars spaced at 5 to 7 cm apart and expanded metal mesh to prevent entry of floating debris, birds and reptiles, etc. which attempt to approach the water, usually drop inside the tanka and spoil the water. The inward sloping cement concrete apron around the tanka with about 3 % slope helps in collection of even meager runoff. Moreover, this will also prevent the entry of runoff water along the outer face of tanka wall. and will reduce the possible damage to the structure during high runoff rate of heavy rainfall event. The masonry check wall nearer to the outlet ( both the sides ) of about 50 cm. high constructed across the apron will divert the water into the tanka. Thorn fencing may be provided around the catchment area to minimize pollution of the stored water with livestock wastes and other farm wastes. (e)Maintenance and after care: At least once in a year cleaning of tanka, ramming of its catchment, and painting of the inlets and the outlet is must for keeping it in good working condition. Also de silting of the tanka is necessary, which may be taken up before the onset of 5 the monsoon. Periodically use of oxidizing agents like potassium permanganate will prevent the growth of microscopic organisms, and development of bad taste, odour and colour of the water. Alum helps in settling the dirt in suspension. At least a few cm of water column should always be maintained in the tanka to avoid development of cracks etc. (f) Expected life – It is expected that this tanka will last at least for 30 years Tankas Constructed By WfI: General Condition: It is unpleasant truth that water availability in the arid region of Rajasthan is limited and inadequate, even after a hypothetical consideration that all utilizable water resources are developed. Further with increasing population and modernization, the scarcity of water will go on increasing and per capita water availability will be decreasing. Moreover, in less than normal rainfall years the situation is much more critical. Nonetheless, the importance of the old tradition of water conservation / harvesting was reflected in the seventeenths century when the structures were developed. So far, particularly in the rural areas, the water harvesting structures have served as the best solution in mitigating the drinking water problem. But the fact remains these water harvesting systems should be revived and encouraged at Government level. Water Demand and Consumption: Estimating the demand of drinking water and water needed for cooking is the prime important for designing any runoff storage structure. The field investigations indicates that an average daily water consumption which includes animal consumption is 10.75 litres / day and 23.54 litres / day in Pabupura and Bhalu Rajwan cluster villages respectively. It is about two times the consumption at Bhalu Rajwan than at Pabupura cluster of villages. In reality it is very difficult to separate out the water consumption by human and livestock. It may be only approximation. However, as per the WHO, minimum water quantity standard is 20 liters per day for human survival. (WHO, 2000). 6 Basically, the runoff water stored in the tanka is meant for human drinking and cooking only. Animals are not supposed to be provided water from this structure. If the water is used by both, than the size of the tanka will be large or tanka is to be refilled by transported water which may be uneconomical to the poor rural population. The size of tanka, for a single family, of capacity of 21000 liters for drinking only is sufficient. As per the report, the Wells for India has considered only 3 liters of water required by animals per head per day. It is too less. In case the provision cooking and animals drinking water is required then the requirement can be calculated as follows; Table Livestock water consumption: Type of animal Age Water consumption Liters per day 1. Heifer 1- year 10 2. Heifer 1-3 years 15 3. Cow, bullock _ 35 4. Buffalo 1- year 20 5. Buffalo 1-3 years 30 6. Buffalo more than 3 years 49.5 7. Sheep 1-year 4 8. Sheep more than 1 year 4.5 9. Goat 1-year 3 10.Goat more than 1 year 4.5 11.Horse young stock 20 12.Horse more than 3 years 48 13. Donkey - 20 14.Camel - 49.5 The requirement of drinking water for different type of animals can be assed by the above table and for human consumption and for cooking, 20 liters per capita per day could be considered ( WHO ). Based on these data, at initial stage approximately the capacity of the tanka can be decided for each family. However, by collecting data on actual consumption of water per capita per day and by animals on average basis , it 7 will be possible to standardized the construction size of tanka for given number of family members and animals along with extra allowance. The estimation of consumption by human could also be done by the following method : Estimation of consumption : The maximum yield possible from rain water catchment system is directly proportional to the catchment area, its runoff coefficient ( i.e. the ratio of harvestable rainfall to total rainfall ) and rainfall probability. Thus, for a full hydrological year, the main daily yield is given by the equation : Y = fi x Ri -------365 Where Y = mean daily catchment yield, litres / m2 fi = runoff coefficient Ri = probable rainfall , mm The runoff coefficient depends on the catchment treatment material and age of the catchment surface. Theoretically, the consumption can be set at constant level of Y liters / m2 /day if adequate storage is available for dry season requirement. This is based on the assumption that evaporation and other losses from storage are negligible. Per capita consumption from catchment is calculated by : Y C = --N Where C = per capita consumption , liters / m2 /day N = number of persons served by the catchment Y = mean daily catchment yield , liters / m2 Example : 8 Six persons are to be served by tanka stored water, having treated catchment area of 500 sq.m ( f = 0.2 ). Rainfall probability is 212 mm Mean yield--- Y = 212 x 0.2 ----------- = 0.116 liters / m2 / day 365 Per capita consumption C=Y/ N 0..116 x 500 / 6 = 9.66 liters per day Therefore for six member family the annual requirement will be = 21.155 cu.m Size and Runoff Efficiency of Catchment Areas : Due to the high variability of hydro meteorological phenomena it is not possible to harness the available rainfall to optimum level, unless feasible measures are taken. For generating reliable runoff, a water harvesting catchment needs to be impermeable and smooth. The perfect sealing of the soil surface is little bit expensive, therefore, some infiltration losses must be accepted. In many cases, ground forming can increase the runoff yield by improving the hydraulic efficiency of the catchment and thus reduce the time available for infiltration to take place. The observations on rainfall and runoff from artificial prepared catchments around tankas were recorded from the year 2001 to 2004 ( WfI ). The runoff observations were recorded at 21 tankas of Pabupura cluster of villages and at 6 tankas in Bhalu Rajwan cluster of villages. However the rain gauge station was only one for all the observation sites. The rainfall data used for interpretation ( rainfall- runoff relationship ) were largely erroneous due to spatial variability in rainfall distribution. Even in the same period of the year the results were highly variable at different sites. Moreover, the year 2001 and 2002 were drought years. There after, under monitoring programme in 2004, a net work of seven and four rain gauging stations was established in Pabupura and Bhalu Rajwan cluster of villages respectively. Compacted murrum is the universal choice for catchment surfaces which was adopted in Pabupura and Bhalu Rajwan villages but the quality of material varied considerably. Along with rainfall observations, other data are being collected on ( i ) depth of runoff water collected in the tanka of each rainfall event ( ii ) quantity of water withdrawal for human and livestock consumption ( iii ) runoff efficiency of the 9 catchment area. The ultimate aim is to find out the catchment requirement for every cubic metre of water collection and self sufficiency of drinking water availability of each household . The details of tankas selected for monitoring at Pabupura cluster of villages are as follows : Details of selected tankas in Pabupura cluster of villages : ( rainfall at 60% probability = 212 mm ) Tanka Name of village capacity Available Required catchment No. ( cu.m ) Catchment area ( m2 ), fi = 0.3 Area ( m2 ) 1. Mayakhor 46.061 263 724 2. Mayakhor 40.457 358 636 3. Mayakhor 37.910 467 596 4. Pabupura 23.857 358 375* 5. Pabupura 24.007 358 377* 6. Pabupura 24.007 265 377 7. Narayanpura 23.707 338 373 8. Narayanpura 32.860 358 517 9. Narayanpura 26.108 358 410* 10. Loona 25.183 358 396* 11. Loona 25.323 358 398* 12. Loona 31.627 358 497 13. Lumbasar 30.963 358 487 14. Lumbasar 32.973 358 518 15. Lumbasar 28.173 358 443 16. Mithadia 22.414 358 352* 17. Mithadia 20.175 358 317* 18. Mithadia 27.022 358 425 19. Chakoo 39.363 358 619 20. Chakoo 44.350 358 697 21. Chakoo 44.350 358 697 10 * The variation in the catchment area is about + !0 % of the required for generating the runoff to the capacity of tanka. These can serve the purpose. However, at all other locations either the catchment treatment is to be altered as cementing surface or spray of polymer solution or to be enlarged as per the requirement. The details of the tanka selected for monitoring in Bhalu Rajwan cluster of villages are presented in the following table : Tanka Name of beneficiary Capacity Available Required catchment No. catchment area ( m2 ), fi = 0.3 ( cu.m ) area ( m2 ) 1. Sugani 49.664 141 781 2. Chandani 27.610 129 434 3. Sugan 30.490 141 479 4. Shanti 23.933 141 377 5. Loon 30.685 212 482 6. Palriya ka 49.652 234 781 In all the above cases, the alteration in the catchment area is must for generating the runoff to the capacity of the tanka. In case the same catchment area and same treated surface is to be kept, then nearly the runoff storage will be around 18.06 % to 43.93 % of the tanka capacity ( 56.07 to 81.94 % storage will remain empty ). Catchment treatment Normally the poor rural population can not afford the expenses on the treatment of catchment surface for generating the runoff. But, they can be advised to either go for enlargement of the existing catchment with same type of murrum treatment so as to harvest the runoff up to the capacity of the tanka constructed by WfI. or use tanka water for human drinking and cooking only. As usual they must take their animals either to the other water point such as village tank, or near by water supply scheme. In case the size of the existing catchment can not be altered then the surface of the catchment should made smooth which may have 0.8 or 0.9 runoff coefficient. Several experiments on use and efficiency of different materials has been carried out in different countries. Such treatment materials are; spray able asphalted compounds, plastic and metal films bounded to the soil, soil compaction and dispersion field 11 fabricated asphalt, fiberglass membrane, sodium salts, gravel covered plastic membranes and melted wax, bentonite and few chemical treatments. It can be cemented surface also. The life of continue cemented surface in open area is less durable and cracks develop on the top of it. To avoid this problem, cemented tiles of 30 x 30 cm on bare sandy soil can be provided without cement joints. Such surface will improve efficiency of the catchment area in runoff generation to the extent up to 90 %. The CAZRI, Jodhpur, on field experiment bases recommended the spray of sodium carbonate at the rate of 1 kg. / 10 sq.m as efficient and cheap treatment material which generated, on an average of four years, 66.32 % of rainfall as runoff ( 37.32 % more runoff than the untreated soil ). Catchment area needed for one cum. of runoff from cement tile surface : Assuming ; Capacity of tanka = 40.0 cum. Ri = Rainfall at 60 % probability = 212 mm ( Phalodi Tehsil ) fi = runoff coefficient = 0.9 Ca = Catchment area ( m2 ) Capacity ( runoff ) = Ri x fi x catchment area 40 .0 = 0.212 x 0.9 x Ca Ca = 209.64 m2 Therefore, for 40 cum of runoff , 209.64 m2 area is needed Hence for one cubic metre of runoff , 5.24 m2 area is needed. The cement tiles can be used in open area as well in court yard of the dhanis’. Before the on set of monsoon, the surface is to be cleaned properly . In case of court yard, run off is carried to tanka through cement pipe. No one should be allowed to walk on cemented tile surface. Cost estimates of paved cement tiles surface: By adopting paved cement tiles surface, the requirement of the catchment area will be reduced. The runoff coefficient will be around 0.9. Considering the rainfall pattern already stated as 212mm and the existing storage capacity, the catchment requirement at observation sites to be paved with cement tiles at Pabupura and Bhalu Rajwan 12 cluster of villages is presented in the following tables. As per the market rates The cost of cement tiles is about Rs. 45.00 per sqm. Pabupura cluster of villages Tanka No. Beneficiary Catchment area ( m2 ) Cost estimates ( Rs. ) 1 Meera 241.41 10,863 2. Tulsi 212.04 9542 3. Kistri 198.69 8941 4. Mangi 125.03 5626 5. Bhoori 125.82 5662 6 Mohini 125.82 5662 7 Gawari 124.25 5591 8. Jethi 172.22 7750 9. Kamala 136.83 6157 10. Shanti 131.98 5939 11. Lichmo 132.72 5972 12. Kamala 165.76 7459 13. Chagani 162.28 7302 14. Kama 172.81 7776 15. Lichmo 147.65 6644 16. Dhapoo 117.47 5286 17. Seeta 105.74 4758 18. Nainu 141.62 6373 19. Paru 206.30 9283 20. Surjee 232.44 10460 21. Tulsi 232.44 10460 Catchment area ( m2 ) Cost estimates ( Rs. ) Bhalu Rajwan cluster of villages Tanka No. Beneficiary 1. Sugani 260.29 11713 2. Chandani 144.70 6512 3. Sugan 159.80 7191 4. Shanti 125.43 5644 13 5. Loon 160.82 7237 6. Palriya ka 260.23 11710 The above two tables revealed that the estimated cost of paved cement tiles is bit high. On an average it is Rs. 7310 and Rs. 8334 per tanka in Pabupura and Bhalu Rajwan cluster villages. This could be the additional amount towards the cost of tanka construction. Polymer treatment The National Geophysical Research Institute and the Indian Institute of Chemical Technology have discovered that polymers are a cost effective way to increase runoff water, based non toxic polymer solution that permeate in the high porous sandy soils . These polymers acts as binders and reduce permeability and infiltration rate on the sandy soil. Use of water repelling chemicals, combination with these binding agents, results in even better runoff. The cost of this polymer treatment is approximately one quarter of the traditional catchment construction cost. (Bisht, 2001). The rate of polymer spray is about Rs. 3 /- per sq m. The polymer spray could be done on the murrum formed surface of the catchment. The efficiency of the catchment on average would be 60 % for the first 4 years. In the case of Pabupura cluster of villages the average catchment size is 353 sq m. Hence the additional expenditure will be Rs.1059 in every 4 years at each site. Similarly, For Bhalu Rajwas cluster of villages the additional expenditure will be 166 x 3 = Rs. 498 for each site. The life of polymer spray is about four years. Therefore, it must be reapplied after this period. Although, the initial construction cost is little bit higher, in case of treated murrum surface with a polymer spray but will increase the runoff yield which in turn will be cost effective. Conclusion: The concept of water harvesting is not new in arid region of Rajasthan, where acute problem of drinking water exist. It has been a traditional practice since last four centuries. Runoff is being harvested from natural catchments, in the form of dugout ponds or impoundage reservoirs and from roof tops or artificial catchments in the form of cisterns ( tankas ). However, no sizable work on water harvesting from treated catchments have been initiated in the region. The limitation to use of treated 14 catchments has been the cost per unit of water produced. Nevertheless, there is importance of the treating the catchments so as to render the soil surface impermeable, there by, eliminating infiltration and generate more runoff for water harvesting structures. The research investigations have revealed that water harvesting efficiency up to 60 % can be achieved at affordable cost. On murrum surface layer, polymers may be spread to augment the surface runoff. Second, alternative could be; the use of cement tiles in the catchment area (Coefficient 0.9). Though, the initial cost will increase on runoff generation component but there will be assured availability of water in the tanka. 15