Fermentation: If oxygen is absent, many cells are still able to use

ةقيقدلا ءايحلأل ةيويحلا ةينقتلا

ريتسجاملا جمانرب

Dr. Nagwa M. Aref

Fermentation

: If oxygen is absent, many cells are still able to use glycolysis to produce ATP. Two ways this can be done are through fermentation and anaerobic respiration.

Fermentation

is the process by which the electrons and hydrogen ions from the NADH produced by glycolysis are donated to another organic molecule.

The point of fermentation

The reason this is done is to produce NAD+ which in tern is needed to keep glycolysis going. Remember, that unless the cell has some sort of electron transport system, the NADH is not usable. At the same time

NAD+ is needed for glycolysis and its much less expensive in terms of energy for the cell to simply take the NADH that would normally go to the mitochondrion and use it to regenerate the NAD+.

This is shown in the figure for

ethanol fermentation

in yeast.

Notice that the NADH produced by glycolysis donates it's hydrogen ions and electrons that in aerobic respiration would have ended up powering electron transport phosphorylation.

Other fermentation pathways

There are a number of fermentation pathways that different cells use. Yeast cells produce ethyl alcohol by fermentation. Certain cells of our body, namely muscle cells, use lactic acid fermentation, while depending on the organism some of the other products of fermentation include acetic acid, formic acid, acetone and isopropyl alcohol.

Fermentation and running

In our bodies certain muscle cells, called fast twitch muscles, have less capability for storing and using oxygen than other muscles. When you run and these muscles run short of oxygen, the fast twitch muscles begin using lactic acid fermentation. This allows the muscle to continue to function by producing ATP by glycolysis.

Fermentation

: If oxygen is absent, many cells are still able to use glycolysis to produce ATP. Two ways this can be done are through fermentation and anaerobic respiration.

Fermentation

is the process by which the electrons and hydrogen ions from the NADH produced by glycolysis are donated to another organic molecule.

1

The point of fermentation

The reason this is done is to produce NAD+ which in tern is needed to keep glycolysis going. Remember, that unless the cell has some sort of electron transport system, the NADH is not usable. At the same time NAD+ is needed for glycolysis and its much less expensive in terms of energy for the cell to simply take the NADH that would normally go to the mitochondrion and use it to regenerate the NAD+. This is shown in the figure for

ethanol fermentation

in yeast.

Notice that the NADH produced by glycolysis donates it's hydrogen ions and electrons that in aerobic respiration would have ended up powering electron transport phosphorylation.

White meat and dark meat

If you want to see what these muscles are like, when you eat chicken or turkey the white meat is fast twitch muscle. The dark meat is what is called slow twitch muscle. This meat is dark because it contains an oxygen holding protein called

myoglobin

. Note that the slow twitch muscles tend to be wing and leg muscles where long term endurance is required. The fast twitch muscles tend to be more common in the breast where quick response but not necessarily endurance is needed. Also, wild animals tend to have more slow twitch muscle than their domestic counterparts

The muscles get enough ATP for quick spurts or shall we say sprints, but quickly become fatigued as their stores of glycogen are used up. Eventually you cramp. This is in part because the muscles lack sufficient ATP to continue contracting. Also, lactic acid builds up and must be metabolized by the liver. Runners who sprint actually have more muscle cells specialized for lactic acid fermentation than do long distance runners.

Fermentation and Protein purification facility

Fermentor Protein purification

2

Figure 1. Sketch of the fermentor is shown with all the connection for monitoring and control of the continuous lactic acid fermentation process with continuous cell recycling.

F

1

: feed rate (the dilution rate was maintained by maintaining the feed rate);

F

2

: rate at which broth was taken out of the fermentor;

F

3

: rate of purging (the sample from the purge were regularly analyzed for biomass and metabolites concentrations inside the fermentor);

F

4

: rate at which permeate was taken out from the filtration unit;

F

5

: rate at which biomass was recycled back to the fermentor.

3

Figure 2. Schematic of lactic acid fermentation in fed-batch fomenter.

4

Citric acid fermentation by mutant strain of Aspergillus niger GCMC-7using molasses based medium

Ikram-ul-Haq *

Biotechnology Research Laboratories

Department of Botany

Faculty of Sciences

Government College

Lahore, Pakistan

Tel: 92 42 9211634

Fax: 92 42 7243198

E-mail: ikrhaq@yahoo.com

Sikander Ali

Biotechnology Research Laboratories

Department of Botany

Faculty of Sciences

Government College

Lahore, Pakistan

Tel: 92 42 9211634

Fax: 92 42 7243198

E-mail: alisbiotech@yahoo.com

Qadeer, M.A.

Centre of Excellence in Molecular Biology

Thokar Niaz Baig

C/B Road, Lahore, Pakistan

Tel: 92 42 7588977

Fax: 92 42 723198

E-mail: qadeerma@yahoo.com

Javed Iqbal

Department of Botany

University of the Punjab

Quaid-e-Azam Campus

Lahore, Pakistan

Tel: 92 42 5868367

* Corresponding author

Financial support: This work formed a part of research report of the project PSF/GC-Bio (283), Pakistan Science Foundation, Islamabad.

Keywords: Aspergillus niger , cane-molasses, citric acid, fermentation, mutant strain, production of citric acid.

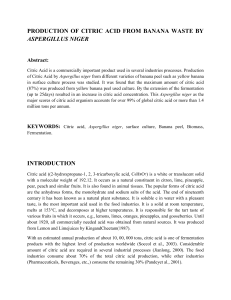

Abstract

Article

References

Abstract Reprint (BIP) Reprint (PDF)

Citric acid fermentation of cane-molasses by submerged fermentation in 15 L stirred fermentor

(working volume 9 L) was carried out. A hyper mutant strain of Aspergillus niger GCMC-7 was used in the present study which was obtained from the culture collection of our own labs.

Ferrocyanide treated molasses [K

4

Fe(CN)

6

200 ppm] medium containing sugar 150 g/l was employed as the basal fermentation medium. Different cultural conditions such as incubation temperature (30ºC), initial pH (6.0), air supply (1.0 l -1 l -1 min), agitation intensity (200 rpm) and time profile (144 h after inoculation) were optimised for enhanced citric acid production. Maximum amount of anhydrous citric acid obtained during the course of study was 106.65 g/l, with a sugar consumption of 107 g/l. Final pH, ferrocyanide concentration and dry cell mass were 2.1, 60 ppm and 16.5 g/l, respectively.

Article

5

Citric acid i.e.

, 2-hydroxy 1,2,3 propane tricarboxylic acid

(CH

2

COOH.COH.COOH.CH

2

COOH) is ubiquitous in nature and exists as an intermediate in the citric acid cycle when carbohydrates are oxidized to carbon dioxide. Citric acid is solid at room temperature, mel ts at 153ºC and decomposes at higher temperatures into other products ( Rajoka et al. 1998 ). It is responsible for the tart taste of various fruits in which it occurs, i.e.

lemons, limes, figs, oranges, pineapples, pears and goose-berries. Citric acid can be recovered from its calcium salt by adding sulfuric acid ( Anon, 1975 ). It is nontoxic and easily oxidized in the human body. Because of its high solubility, palatability and low toxicity, it can be used in food, biochemical and pharmaceutical industries. These uses have placed greater stress on increased citric acid production and search for more efficient fermentation process. The worldwide demand of citric acid is about 6.0 x 10 5 tons per year and it is bound to increase day by day

( Ali et al. 2001 ).

The production of citric acid by Aspergillus niger is one of the most commercially utilized examples of fungal overflow metabolism. Many microorganisms such as fungi and bacteria can produce citric acid.

The various fungi, which have been found to accumulate citric acid in their culture media, include strains of Aspergillus niger, A. awamori,

Penicillium restrictum, Trichoderma viride, Mucor piriformis and

Abstract

Article

Materials and Methods

Organisms and culture maintenance

Vegetative inoculum

Clarification of molasses

Fermentation technique

Assay methods

Results and Discussion

Sugar concentration

Time profile of citric acid fermentation

Incubation temperature

Initial pH

Concluding Remarks

Figure 1

Figure 2

Figure 3

Figure 4

Figure 5

Figure 6

References

Yarrowia lipolytica ( Arzumanov et al. 2000 ). But Aspergillus niger remained the organism of choice for the production of citric acid. The mutant strains might show several fold increase in citrate production as compared to wild-type cultures ( Mattey and Allan, 1990 ; Ali et al. 2001 ). Although the surface culture process is still being used, most of the newly built plants have adopted the submerged fermentation process. Kamal et al. (1999) reported the effect of oxygen transfer rate on the citric acid production by

Aspergillus niger under submerged fermentation. In submerged fermentor, either purified compressed air or oxygen along with agitation is used ( Moreira et al. 1996 ). Molasses is a desirable raw material for citric acid fermentation because of its availability and relatively low price.

Incubation temperature plays an important role in the production of citric acid. Temperature between 25-

30ºC was usually employed for culturing of Aspergillus niger but temperature above 35ºC was inhibitory to citric acid formation because of the increased the production of by-product acids and also inhibition of culture development. Sanjay and Sharma, 1994 reported that citric acid production by Aspergillus niger is sensitive to the initial pH of the fermentation medium. The maximum production of citric acid (6.5%) was obtained at pH 5.4 in molasses medium. The appropriate pH is important for the progress and successful termination of fermentation. Arzumanov et al. 2000 reported that the citric acid produced by Aspergillus niger is extremely sensitive to trace metals present in molasses. The trace metals such as iron, zinc, copper, manganese present a critical problem in submerged fermentation. The organisms need major elements such as carbon, nitrogen, phosphorus and sulphur in addition to various trace elements for growth and citric acid production. The present work is concerned with the optimisation of cultural conditions for enhanced production of citric acid by mutant strain of Aspergillus niger GCMC-7 in stirred fermentor.

Materials and Methods

Organism and culture maintenance.

The mutant strain of Aspergillus niger GCMC-7 was used for citric acid fermentation. It was obtained from the culture collection of Biotechnology Research Labs.,

Government College Lahore, Pakistan . The culture was maintained on 4.0% sterilized potato dextrose agar medium (BDH Germany), pH 4.8. The slant cultures of Aspergillus niger were stored at 5ºC in the refrigerator. All the culture media, unless otherwise stated, were sterilized at 121ºC (15 lbs/inch 2 pressure) for 15 minutes.

6

Vegetative inoculum.

Hundred ml of molasses medium (Sugar 15%, pH 6.0) containing silica gel chips

(0.75 mm dia) in 1.0 L cotton wool plugged Erlenmeyer flask, was sterilized. Small amount of conidia from the slant was aseptically transferred with the help of inoculating needle. The flask was incubated at 30ºC in a rotary incubator shaker ( Gallenkamp, UK ) at 300 rpm for 24 h.

Clarification of molasses.

Cane molasses obtained from Chunian Sugar Mills (pvt) Ltd., Pakistan was clarified according to the method of Panda et al. 1984 . After neutralization with calcium hydroxide solution

(1.55%), the sugar concentration was maintained at different required levels. The clarified cane-molasses was kept under dark in a sterilized UV-chamber (Perkins Elmer, USA).

Fermentation technique.

A laboratory scale stainless steel stirred fermentor (0012 M1E, New Brunswic,

USA) of 15 L capacity with working volume of 9 L was used for citric acid fermentation. The fermentation medium consisting; clarified cane molasses 300.0 (sugar 15%), K

4

Fe(CN)

6

200 ppm at an appropriate initial pH. The vegetative inoculum was transferred to the production medium at a rate of 5% (v/v) based on total working volume of the fermentation medium. The incubation temperature was varied during different batches. Air supply was maintained at different levels from an aeration pump (MLK5, Pak.

Made). Necessary agitation intensity was also maintained. Sterilized silicone oil (Antifoam AE-11, Merck,

Germany) was used to control the foaming during fermentation. All the experiments were run parallel in triplicates.

Assay methods. Mycelial dry weight was determined according to the procedure of Haq and Daud,

1995 . Sugar was estimated spectrophotometrically by DNS method ( Tasun et al. 1970 ). A UV/VIS scanning spectrophotometer (Cecil-700 series, UK) was used for measuring colour intensity at required wavelength. Anhydrous citric acid was estimated using pyridine-acetic anhydride method as reported by

Marrier and Boulet, 1958.

The statistical analyses (Spss-10, version-4, The Netherlands) were based on

Duncan's multiple range tests ( Panda et al. 1984 ). Standard deviation was calculated for three different parallel replicates and was presented in the form of standard error bars.

Results and Discussion

A successful process depends both on an appropriate strain and optimisation of fermentation parameters.

In the present work, cultural conditions such as sugar concentration, time profile of citric acid synthesis, incubation temperature, initial pH, agitation intensity and air supply were optimised by a mutant strain of

Aspergillus niger GCMC-7 in a laboratory scale stirred fermentor.

Sugar concentration

The effect of different sugar concentrations (120-180 g/l) on citric acid production by Aspergillus niger was carried out ( Figure 1 ). The maximum amount of citric acid (92.50 g/l) was obtained in the medium containing 150 g/l sugar. The consumption of sugar and dry mycelial weight were 104 and 24.0 g/l, respectively. The initial sugar concentration has been found to determine the amount of citric acid produced by filamentous fungi Aspergillus niger . Reduction in citric acid formation was observed when the sugar concentration of molasses was increased. It may be due to the over growth of the mycelium, which resulted in increased viscosity of the medium. Mattey and Allan, 1990 described that with the increase of mycelial formation in the medium, there was reduction in the yield of citric acid. Pazouki et al.

2000 pointed out that a sugar concentration higher than 16-18% leads to greater amount of residual sugars, making the process uneconomical; while a lower sugar concentration leads to lower yields of citric acid due to the accumulation of oxalic acid in the culture broth.

7

Figure 1. Effect of different sugar concentrations on the production of citric acid by Aspergillus niger GCMC-7 in stirred fermentor.

Agitation intensity: 200 rpm.

Air supply: 1.0 l/l/min.

Initial pH: 6.0.

Incubation temperature: 30ºC.

Fermentation period: 168 h.

The error bars indicate the standard deviation among the three parallel replicates.

Time profile of citric acid fermentation

Figure 2 shows the time profile of citric acid fermentation by Aspergillus niger . The fermentation was carried out for 216 h. Citric acid production of 7.5 g/l was observed after 24 h and it reached a maximum of 93.62 g/l after 144 h of incubation. The sugar consumption and dry mycelial weight obtained after 144 h were 113 and 17.5 g/l, respectively. The optimum time of incubation for maximal citric acid production varies both with the organism and fermentation conditions. In batch-wise fermentation of citric acid, the production starts after a lag phase of one day and reached maximum at the onset of stationary phase or late exponential phase. Further increase in incubation period did not enhance citric acid production. It may be due to the age of fungi and depletion of sugar contents in the culture broth ( Arzumanov et al.

2000 ). Vergano et al. 1996 reported the maximum yield of citric acid i.e.

, 64.12 g/l, 7 days after the inoculation. So our finding is more significant as compared to previous workers because reduction of the incubation period reduced the cost of citric acid production.

8

Incubation temperature

The production of citric acid by Aspergillus niger at different temperatures (2540ºC) was carried out in the fermentor ( Figure 3 ). Maximum production of citric acid (95.80 g/l) was obtained when the temperature of the medium was maintained at 30ºC. The sugar consumption was 108 g/l while dry mycelial weight was

14.5 g/l. The temperature of fermentation medium is one of the critical factors that have direct effect on the production of citric acid. When the temperature of medium was low, the enzyme activity was also low, giving no significant impact on the enhancement of citric acid production. But when the temperature of medium was increased above 30ºC, the biosynthesis of citric acid was decreased. It may be due to that the high temperature can cause denaturation of enzyme citrate synthase and accumulation of other byproducts such as oxalic acid and enzyme catabolite repression ( Panda et al. 1984 ). A temperature of

40ºC is most favourable for oxalic acid production while citric acid accumulation completely inhibits at this temperature ( Hang and Woodams, 1998 ).

Figure 3. Effect of different temperatures on the production of citric acid by

Aspergillus niger GCMC-7 in stirred fermentor.

Sugar added: 150 g/l.

Agitation intensity: 200 rpm.

Air supply: 1.0 l/l/min.

Initial pH: 6.0.

Fermentation period: 144 h.

The error bars indicate the standard deviation among the three parallel replicates.

9

Initial pH

Figure 4 shows the effect of different initial pH (5.0-7.0) on the production of citric acid. Maximum amount of citric acid (98.92 g/l) was achieved when the initial pH of fermentation medium was kept at 6.0. The sugar consumption was 112 g/l while dry mycelial weight was 14.5 g/l. When the pH was further increased from 6.0, the production of citric acid decreased, gradually. The maintenance of a favourable pH is very essential for the successful fermentation of citric acid. Decrease in pH caused reduction in citric acid production. At low initial pH, the ferrocyanide ions may be more toxic for the growth of mycelium in the medium. This finding is an agreement with the observations of Pessoa et al. 1982 . A higher initial pH leads to the accumulation of oxalic acid as reported by Shadafza et al. 1976 . In addition, low pH of cane-molasses has been found inhibitory for the growth of A. niger .

Figure 4. Effect of different initial pH on the production of citric acid by

Aspergillus niger GCMC-7 in stirred fermentor.

Sugar added: 150 g/l.

Agitation intensity: 200 rpm.

Air supply: 1.0 l/l/min.

Incuba tion temperature: 30ºC.

Fermentation period: 144 h.

The error bars indicate the standard deviation among the three parallel replicates.

10

Agitation intensity and air supplyThe effect of different agitation rates (120-240 rpm) and aeration rates

(0.25-1.5 ll -1 min -1 ) on citric acid production by Aspergillus niger was carried out ( Figure 5 and Figure 6 ).

The maximum amount of citric acid (106.65 g/l) produced when the agitation intensity and aeration rate was kept at 200 rpm and 1.0 ll -1 min -1 , respectively. It may be due to that proper aeration and agitation are necessary to ensure an appropriate oxygen supply and to maintain DO levels in the stirred fermentor. The sugar consumption and dry mycelial weight were 107 and 16.5 g/l, respectively. Similar type of findings has also been reported by other workers ( Dawson et al. 1986 ; Sanjay and Sharma, 1994 ). The degree of agitation and aeration depends upon the organism, the medium composition and the size of fermentor.

Normally the oxygen demand of a fermenting culture is so high that the amount of oxygen in a saturated aqueous medium is inadequate ( Sanjay and Sharma, 1994 ). Wieczorek and Brauer, 1998 determined the effect of air on citric acid production by A. niger in 5 L jar fermentor. The effective aeration was found to be 3.0x10

-6 moles O

2

/ml/min, with about 6.88% yield of citric acid on the basis of sugar used. Hence, our finding (10.66%) is more encouraging than the previous workers.

Figure 5. Effect of agitation intensity on the production of citric acid by

Aspergillus niger GCMC-7 in stirred fermentor.

Sugar added: 150 g/l.

Air supply: 1.0 l/l/min.

Initial pH: 6.0.

Fermentation period: 144 h.

Incubation temperature: 30ºC.

The error bars indicate the standard deviation among the three parallel replicates.

11

Figure 6. ffect of different air supply on the production of citric acid by Aspergillus

niger GCMC-7 in stirred fermentor.

Sugar added: 150 g/l.

Agitation intensity: 200 rpm.

Initial pH: 6.0.

Fermentation period: 144 h.

Incubation temperature: 30ºC.

The error bars indicate the standard deviation among the three parallel replicates.

Concluding Remarks

Cultural conditions for citric acid production by fungi vary from strain to strain and also depend on the type of process. The optimisation of cultural conditions is the key for high and consistent yields of metabolites like citric acid. In the present study, the mutant strain of Aspergillus niger GCMC-7 supported maximum production of citric acid (106.65 g/l) without supplements which is substantial. The addition of nitrogen sources and minerals like calcium and phosphate may further increase the production of citric acid, as required for an industrial process.

References

ALI, S.; HAQ, I. and QADEER, M.A. Effect of mineral nutrient on the production of citric acid by

Aspergillus niger . Online Journal of Biological Sciences.

April 2001, vol.32, no. 1, p. 31-35.

12

ANON, P. Food additives solvent extraction process for citric acid. United States Drug Administered and

Fed Registered Drug Report , April 1975, vol. 40, no. 4, p. 9080-9082.

ARZUMANOV, T.E.; SHISHKANOVA, N.V. and FINOGENOVA, T.V. Biosynthesis of citric acid by

Yarrowia lipolytica repeat-batch culture on ethanol. Applied Microbiology and Biotechnology , March 2000, vol. 53, no. 5, p. 525-529.

DAWSON, M.W.; MADDOX, I.S. and BROOKS, J.D. Effect of interruption to the air supply on citric acid production by Aspergillus niger . Biotechnology , February 1986, vol. 8, no. 1, p. 37-40.

HANG, Y.D. and WOODAMS, E.E. Production of citric acid from corncobs by Aspergillus niger .

Bioresourse Technology , March 1998, vol. 65, no. 3, p. 251-253.

HAQ, P.B. and DAUD, D.A. Process of mycelial dry weight calculation for citric acid. Journal of

Biotechnology , March 1995, vol. 9, p. 31-35.

KAMAL, K.P.; VERMA, U.N.; NAG, A.K. and SINGH, S.P. Effect of antifoam and oxygen transfer rate on citric acid production by submerged fermentation. Asian Journal Chemistry , October 1999, vol. 11, no. 3, p. 1020-1022.

MARRIER, J.R. and BOULET, M. Direct determination of citric acid in milk with an improved, pyridine acetic anhydride method. Journal of Dairy Sciences , October 1958, vol. 41, p. 1683.

MATTEY, M. and ALLAN, A. Glycogen accumulation in Aspergillus niger . Transient Biochemical Solicits ,

January 1990, vol. 18, no. 5, p. 1020-1022.

MOREIRA, M.T.; SANROMAN, A.; FEIJOO, G. and LEMA, J.M. Control of pellet morphology of filamentous fungi in fluidized bed bioreactors by means of a pulsing flow. Enzyme and Microbial

Technology , March 1996, vol. 19, p. 261-266.

PANDA, T.; KUNDU, S. and MAJUMDAR, S.K. Studies on citric acid production by Aspergillus niger using treated Indian cane molasses. Journal of Microbiology , September 1984, vol. 52, no. 2, p. 61-66.

PAZOUKI, M.; FELSE, P.A.; SINHA, J. and PANDA, T. Comparative studies on citric acid production by

Aspergillus niger and Candida lipolytica using molasses and glucose. Bioprocess Engineering , December

2000, vol. 22, no. 4, p. 353-361.

PESSOA, D.F.; DIASDE, C. and ANGELA, C. Production of citric acid by Aspergillus niger. Microbiology

Reviews , August 1982, vol. 13, no. 2, p. 225-229.

RAJOKA, M.I.; AHMAD, M.N.; SHAHID, R.; LATIF, F. and PARVEZ, S. Citric acid production from sugarcane molasses by cultures of Aspergillus niger . Biologia , October 1998, vol. 44, no. 1, p. 241-253.

SANJAY, K. and SHARMA, P. A highly performance fermentation process for production of citric acid from sugarcane molasses. Journal of Microbiology, April 1994, vol. 23, p. 211-217.

SHADAFZA, D.; OGAWA, T. and FAZELI, A. Comparison of citric acid production from beet molasses and date syrup with Aspergillus niger . Hakko Kogaku Zasshi , June 1976, vol. 54, p. 65-75.

TASUN, K.; GHOSE, P. and GHEN, K. Sugar determination of DNS method. Biotechnology and

Bioengineering , April 1970, vol. 12, p. 921.

13

VERGANO, M.G.; FEMANDEZ, N.; SORIA, M.A. and KERBER, M. S. Influence of inoculum preparation on citric acid preparation by Aspergillus niger. Journal of Biotechnology , April 1996, vol. 12, no. 6, p. 655-

656.

WIECZOREK, S. and BRAUER, H. Continuous production of citric acid with recirculation of the fermentation broth after production recovery. Bioprocess Engineering , December 1998, vol. 18, p. 1-5 .

Note: EJB Electronic Journal of Biotechnology is not responsible if on-line references cited on manuscripts are not available any more after the date of publication.

14

Production of citric acid by Aspergillus niger using cane molasses in a stirred fermentor

Sikander Ali*

Biotechnology Research Laboratories

Department of Botany

Government College

Lahore, Pakistan

Tel: 92 42 9211634

Fax: 92 42 7243198

E-mail: alisbiotech@yahoo.com

Ikram-ul-Haq

Biotechnology Research Laboratories

Department of Botany

Government College

Lahore, Pakistan

Tel: 92 42 9211634

Fax: 92 42 7243198

E-mail: ikrhaq@yahoo.com

Qadeer, M.A.

Centre of Excellence in Molecular Biology

Thokar Niaz Baig

C/B Road, Lahore, Pakistan

Tel: 92 42 7588977

Fax: 92 42 723198

E-mail: qadeerma@yahoo.com

Javed Iqbal

Department of Botany

University of the Punjab

Quaid-e-Azam Campus

Lahore, Pakistan

Tel: 92 42 5868367

*Corresponding author

Financial support: Pakistan Science Foundation, Islamabad and GCU, Lahore, Pakistan.

Keywords: Aspergillus niger , blackstrap molasses, citric acid, fermentation, filamentous fungi, kinetic study.

Abstract

Article

References

Abstract Reprint (PDF)

The present investigation deals with the kinetics of submerged citric acid fermentation by

Aspergillus niger using blackstrap molasses as the basal fermentation media. A laboratory scale stirred fermentor of 15-L capacity having working volume of 9-L was used for cultivation process and nutritional analysis. Among the 10 stock cultures of Aspergillus niger, the strain GCBT7 was found to enhance citric acid production. This strain was subjected to parametric studies. Major effects were caused due to oxygen tension (1.0 l/l/min), pH value (6.0) and incubation temperature

(30ºC). All fermentations were carried out following the growth on 150 g/l raw molasses sugars for

144 hours. Ferrocyanide (200 ppm) was used to control the trace metals present in the molasses medium. Ammonium nitrate (0.2%) was added as nitrogen source. Maximum citric acid production

(99.56 ± 3.5a g/l) was achieved by Aspergillus niger GCBT7. The dry cell mass and sugar consumption were 18.5 and 96.55 g/l, respectively. The mycelia were intermediate round pellets in their morphology. The specific product ivity of GCBT7 (qp = 0.074 ± 0.02a g/g cells/h) was several

15

folds higher than other strains. The specific production rate and growth coefficient revealed the hyperproducibility of citric acid using mutant GCBT7.

Article

16

Citric acid fermentation is one of the rare examples of industrial fermentation technology where academic discoveries have worked in tandem with industrial know-how, in spite of an apparent lack of collaboration, to give rise to an efficient fermentation process. The current world market estimates suggest that upwards of 4.0 x 10 5 tonnes citric acid per year may be produced ( Kristiansen et al. 1999 ). Citric acid is a major product but the upward trend in its use seen over many years is an annual 2-3% increase. The demand for this particular metabolite is increasing day by day which requires a much more efficient fermentation process for higher yield product ( Moreira et al. 1996 ). When applied to appropriate mass balances, it is possible to predict the utilization of substrates and the yield of individual products. Fermentation media for citric acid biosynthesis should consist of substrates necessary for the growth of microorganism, primarily the carbon, nitrogen and phosphorus sources. Moreover, water and air can be included as fermentation substrates ( Singh et al. 1998 ; Haq et al. 2001 ). The basic substrates for citric acid fermentation using submerged technique of fermentation are beet or cane-molasses ( Pazouki et al. 2000 ). The present investigation deals with the kinetic study of citric acid fermentation. Cane-molasses was employed as the basal fermentation media in the stirred fermentor under the submerged fermentation conditions. The study revealed the nutritional status of the organism and basic fermentation parameters.

Abstract

Article

Materials and Methods

Organism and culture maintenance

Pre-treatment of molasses

Vegetative procedure

Fermentation technique

Estimation methods

Results and Discussion

Screening of stock-cultures of...

Nitrogen limitation

Rate of citric acid fermentation

Incubation temperature

Initial pH of fermentation medium

Inoculum size

Ferrocyanide ion concentration

Table 1

Table 2

Table 3

Figure 1

Figure 2

Figure 3

Figure 4

Figure 5

Figure 6

Concluding Remarks

Acknowledgments

References

Materials and Methods

Organism and culture maintenance. Twelve stock cultures of Aspergillus niger were obtained from the culture collection of Biotechnology Research Laboratories, Government College, Lahore. These cultures have previously been developed (in our labs) by alternate treatment of ultraviolet irradiations (1.6 x 10 2

J/m 2 /S) and nitrosomonas (100 mg/ml) for different time intervals (5-45 min). The cultures of Aspergillus niger were maintained on sterilized potato dextrose agar medium (Diced potato 200 g/l, Dextrose 20 g/l and Agar 15 g/l), pH 4.5 and stored at 5ºC in the refrigerator. All the culture media, unless other wise stated, were sterilized in autoclave at 15-lbs/inch 2 pressure (121ºC) for 15 min.

Pre-treatment of molasses. Cane molasses obtained from different Pakistani Sugar Mills was used in the present study. Cane molasses contains water 20%, sugar contents 62%, non-sugar contents 10%, and inorganic salts (ash contents) 8%, making a blackish homogenous liquid with high viscosity. Ash contents include ions such as Mg, Mn, Al, Fe and Zn in variable ratio ( Prescott and Dunn's, 1987 ). Sugar content was diluted to about 25% sugar level. The molasses solution, after adding 35 ml of 1N H

2

SO

4

per litre, was boiled for half an hour, cooled, neutralized with lime-water (CaO) and was left to stand over night for clarification ( Panda et al. 1984 ). The clear supernatant liquid was diluted to 15% sugar level.

Vegetative procedure. Hundred ml of molasses medium (Sugar 15%, pH 6.0) containing glass beads, in

1L cotton wool plugged conical flask was sterilized. One ml of conidial suspension (6.5 × 10 6 conidia) from the slant culture was aseptically transferred. The conidial count was made by Haemocytometer Slide

Bridge. The flask was then incuba ted at 30ºC in an incubator shaker at 200 rpm for 24 hours.

Fermentation technique. Stainless steel fermentor of 15 L capacity with working volume of 9-L (60%) was employed for citric acid fermentation. Vegetative inoculum was transferred to the production medium at a level of 5% (v/v). The incubation temperature was kept at 30 ± 1ºC throughout the fermentation

17

period of 144 hours. Agitation speed of the stirrer was 200 rpm while aeration rate was maintained at 1.0-

4.0 l/l/min. Sterilized silicone oil was used to control foaming during fermentation.

Estimation methods. 'Mycelial dry weight' was determined according to Haq and Daud, 1995 . 'Sugar' was estimated colorimetrically by Duboise method (1956) . A double beam UV/Vis scanning spectrophotometer (Model: CE Cecil-7200 series, UK) was used for measuring colour intensity.

'Anhydrous citric acid' was estimated using pyridine-acetic anhydride method as reported by Marrier and

Boulet, 1958 . Kinetics of the research work was studied after Pirt, 1975 .

Results and Discussion

Screening of stock-cultures of Aspergillus niger and molasses media

Twelve cultures of Aspergillus niger ( Table 1 ) were screened for citric acid production, following growth on

150 g/l molasses sugar and incubated at 30ºC for 144 hours (found optimum). Of these cultures,

Aspergillus niger GCBT7 produced higher citric acid (84.95 ± 4.0 g/l). Dry cell mass and sugar consumption were 20.05 and 91.45 g/l, respectively. Mycelial morphology was in the form of intermediate size round pellets. Three cultures gave 58.14 ± 2.7 - 78.18 ± 3.5 g/l, while four cultures produced 18.86 ±

1.8 - 42 .56 ± 2.0 g/l citric acid. The citric acid productivity was greater than the 34 cultures studied by

Grewal and Kalra, 1995 . Cane-molasses obtained from different Pakistani Sugar Mills was screened for citric acid fermentation using the best culture of Aspergillus niger GCBT7 ( Table 2 ). The range of citric acid produced was 34.68 ± 2.0f - 85.56 ± 3.5a g/l. The molasses obtained from Kamalia Sugar Mills gave highest yield of citric acid (85.56 ± 3.5a g/l) followed by Premier Sugar Mills (77.65 ± 4.0b g/l). The higher producers of citric acid i.e.

, GCBT2, 7 and 8 have been compared on the basis of citric acid formation parameters [Qp (g/l/h), Yp/s (g/g), Yp/x (g/g) and qp (g/g cells/h)] and substrate consumption parameters

[µ (h -1 ), Yx/s (g/g), Qs (g/l/h), Qx (g/g cells/h) and qs (g/g cells/h)]. The values of specific rate constants

(Qp, Qs and Qx in g/l/h) are more significant in case of Aspergillus niger culture GCBT7 over the other cultures ( Table 3 ). The specific growth and product yield coefficients of GCBT7 i.e.

, Yx/s = 0.219 ± 0.03b,

Yp/s = 0.763 ± 0.05b and Yp/x = 5.229 ± 1.20a g/g are highly significant. In the present study, the specific growth rate (µ = 0.540 ± 0.03b h -1 ) of GCBT7 is several folds higher as compared with the studies of Pirt,

1975 and Rajoka et al. 1998 .

Table 1. Screening of stock cultures for citric acid production. All the fermentations were carried out at

30ºC following growth on 150 g/l initial sugar concentration. The initial pH of the molasses medium was kept constant at 6.0 throughout the fermentation period of 6-days.

Stock cultures of

Aspergillus niger

GCBT1

GCBT2

GCBT3

GCBT4

GCBT5

GCBT6

GCBT7

GCBT8

Dry cell mass (g/l)

16.53

14.95

18.24

16.25

23.72

14.75

20.05

19.12

Sugar consumed

(g/l)

94.65

102.40

78.04

81.52

67.82

87.64

91.45

97.60

Citric acid monohydrate (g/l)

42.56

78.18

15.25

6.62

27.69

11.04

84.95

72.98

GCBT9

GCBT10

GCBT11

GCBT12

20.14

22.68

18.04

19.55

90.00

105.28

99.06

89.95

18.86

58.14

41.02

13.34

* based on the sugar consumed. Molasses was obtained from Madina Sugar Mills.

% Yield*

44.96

Mycelial morphology

76.35

Intermediate pellets

19.54

8.12

40.83

12.60

Small shiny pellets

Gelatinous mass

Viscous

Dumpy mass

Viscous

92.89

Intermediate pellets

74.77

Mixed pellets

20.96

55.22

41.41

14.83

Gummy mass

Small round pellets

Fluffy mass

Viscous

18

Table 2. Screening of molasses media obtained from different Pakistani Sugar Mills by Aspergillus

niger GCBT7. All the fermentations were carried out at 30ºC following growth on 150 g/l initial sugar concentration. The initial pH of the molasses medium was kept constant at 6.0 throughout the fermentation period of 6-days.

Sugar Mills

Madina Sugar Mills

Pattoki Sugar Mills

Kamalia Sugar Mills

Premier Sugar Mills

Rahwali Sugar Mills

Chunian Sugar Mills

* based on the sugar consumed.

Citric acid anhydrous (g/l)

57.60

46.15

85.56

77.65

34.68

62.55

% Yield*

61.54

54.87

91.90

88.32

43.70

75.24

Mycelial morphology

Small round pellets

Fine pellets

Intermediate pellets

Mixed pellets

Gummy mass

Mixed broken mycelia

Table 3. Kinetic parameters for citric acid production from molasses sugars following growth of

Aspergillus niger strains.

Kinetic parameters

Citric acid formation parameters

Qp (g/l/h)

Yp/s (g/g)

Yp/x (g/g) qp (g/g cells/h)

Substrate consumption parameters

µ (h -1 )

Yx/s (g/g)

Qs (g/l/h)

Qx (g cells/l/h) qs (g/g cells/h)

Kinetic parameters:

Qp: g citric acid produced/l/h;

Yp/s: g citric acid produced/g substrate consumed:

Yp/x: g citric acid produced/g cells formed;

Qp: g citric acid produced/g cells/h;

µ(h -1 ): specific growth rate;

Yx/s: g cells/g substrate utilized;

Qs: g substrate consumed/l/h;

Qx: g cell mass produced/l/h;

Qs: g substrate consumed/g cells/h.

GCBT2

0.543

0.763

5.229

0.036

0.540

0.219

0.711

0.104

0.047

GCBT7

-

0.590

0.929

4.237

0.029

-

0.589

0.219

0.635

0.139

0.032

GCBT8

0.507

0.748

3.817

0.026

0.506

0.196

0.678

0.133

0.035

Nitrogen limitation

Nitrogen constituent has a profound effect on citric acid production because nitrogen is not only important for metabolic rates in the cells but it is also the basic part of cell proteins. Effect of different concentrations of ammonium nitrate (as nitrogen source for mycelial growth) on citric acid productivity by Aspergillus niger GCBT7 is shown in Figure 1 . The maximum amount of citric acid (89 .64 ± 1.5a g/l) was obtained when the concentration of NH

4

NO

3

was kept at 0.2%. Any increase or decrease other than this concentration, resulted in the disturbance of fungal growth and subsequently citric acid production. The growth rate constant (µ = 0.548 ± 0.02a g

-1 ) indicated that enzyme to substrate ratio was optimum at

0.2% NH

4

NO

3

. Kristiansen and Sinclair, 1979 used continuous culture and concluded that nitrogen limitation is necessary for citric acid production. Pellet formation in filamentous fungi has been discussed in many cases and among the factors considered to induce it, is the limitation of particular nutrients,

19

including nitrogen. In the present study, the highest values of kinetic parameters i.e.

, Yp/s = 0.908 ± 0.05a g/g, Qp = 0.618 ± 0.02a g/l/h and qs = 0.036 ± 0.01b g/g cells/h were observed at 0.2% NH

4

NO

3

.

Figure 1. Effect of different concentrations of ammonium nitrate (as nitrogen source for mycelial growth) on citric acid productivity by Aspergillus niger GCBT-7. All the fermentations were carried out at 30ºC following growth on 150 g/l initial sugar concentration. The initial pH of the molasses medium was kept constant at 6.0 throughout the fermentation period of 6-days. Yp/s = g citric acid produced/g substrate consumed, Qp = g citric acid produced/l/h, µ (h -1 ) = specific growth rate, qs = g substrate consumed/g cells/h.

Rate of citric acid fermentation

The optimal time of incubation for maximum citric acid production varies both with the organism and fermentation conditions. The rate of citric acid biosynthesis was studied ( Figure 2a ) and the maximum yield of citric acid (94.93 ± 4.2a g/l) was achieved, 144 hours after inoculation. In batch-wise fermentation of citric acid, the production starts after a lag phase of one day and reached maximum at the onset of stationary phase or late. The sugar consumption and dry mycelial weight were 92.94 and 16.15 g/l, respectively. Further increase in incubation period did not enhance citric acid production. It might be due to the decreased available nitrogen in fermentation medium, the age of fungi and depletion of sugar contents. Similar type of work has also been reported by Wieczorek and Brauer, 1998 . The kinetics of citric acid production was studied using cultures of Aspergillus niger GCBT2 and GCBT7 and the results have been shown in Figure 2b . The produ ct formation rate of GCBT7 (Qp = 0.659 ± 0.03a g/l/h) was 1.46

20

folds higher as compared with GCBT2 (Qp = 0.417 ± 0.05c g/l/h). Rajoka et al. 1998 obtained 0.0506 ±

0.06 g/l/h product formation rate, which is 1.58 times lower than the present results.

Figure 2a. Time course study during citric acid fermentation by Aspergillus niger GCBT7 in blackstrap molasses. All the fermentations were carried out at 30ºC following growth on 150 g/l initial sugar concentration. The initial pH of the molasses medium was kept constant at 6.0.

21

Figure 2b. Comparison of specific product formation rate Qp (g/l/h) during citric acid fermentation by GCBT2 and GCBT7 strains of Aspergillus niger.

All the fermentations were carried o ut at 30ºC following growth on 150 g/l initial sugar concentration. The initial pH of the molasses medium was kept constant at 6.0 throughout the fermentation.

Incubation temperature

The temperature of fermentation medium is one of the critical factors that have a profound effect on the production of citric acid. A temperature of 30ºC was found to be the best for citric acid fermentation (Qp =

0.667 ± 0.02a g/l/h) in present studies ( Figure 3 ). When the temperature of medium was low, the enzyme activity was also low, giving no impact on the citric acid production (Yp/s = 0.444 ± 0.08ef g/g at 24ºC).

But when the temperature of medium was increased above 30ºC, the biosynthesis of citric acid was decreased (Yp/s = 0.528 ± 0.06d at 36ºC). It might be due to the accumulation of by-products such as oxalic acid. The value of specific product formation i.e.

, Yp/x = 6.020 ± 0.02a g/g by Aspergillus niger

GCBT7 is highly significant. D ifferent workers have also used 30ºC as the cultivation temperatures and obtained higher values of actual product ( Vergano et al. 1996 ; Arzumanov et al. 2000 ). But when values were divided by the time of fermentation, all values were lower than the one supported by the isolate used in these studies.

22

Figure 3. Relative tolerance of temperature for citric acid production by Aspergillus niger GCBT7.

All the fermentations were carried out at 30ºC following growth on 150 g/l initial sugar concentration. The initial pH of the molasses medium was kept constant at 6.0 throughout the fermentation period of 6-days.

Qp = g citric acid produced/l/h, Yp/s = g citric acid produced/g substrate consumed, Yp/x = g citric acid produced/g cells formed.

Initial pH of fermentation medium

The maintenance of a favourable pH is very essential for the successful production of citric acid. Effect of different pH (4.5 - 7.0) on the citric acid production was studied and maximum yield (96.12 ± 3.5a g/l, anhydrous citric acid) was obtained when initial pH of the fermentation medium was kept at 6.0 ( Figure 4 ).

Decrease in pH caused reduction in citric acid production (Qp = 0.319 ± 0.03f g/l/h). It might be due to that at low pH, the ferrocyanide ions were more toxic for the growth of mycelium. This finding is an agreement with Pessoa et al. 1982 . A higher initial pH leads to the accumulation of oxalic acid. In fact, a low pH in cane molasses medium has been found inhibitory for the growth of A. niger (Yp/x = 3.286 ±

0.04e g/l). The highest value of product yield coefficient i.e.

, Yp/s = 1.010 ± 0.05a g/g at initial pH 6.0 was much improved by culture GCBT7.

23

Figure 4. Relative tolerance of initial pH of the fermentation medium for citric acid production by

Aspergillus niger GCBT7. All the fermentations were carried out at 30ºC following growth on 150 g/l initial sugar concentration. The initial pH of the molasses medium was kept constant at 6.0 throughout the fermentation period of 6-days. Yp/s = g citric acid produced/g substrate consumed, Yp/x = g citric acid produced/g cells formed, Qp = g citric acid produced/l/h.

Inoculum size

Among the factors that determine morphology and the general course of fungal fermentations, the type and size of inoculum is of prime importance. In the present study, Figure 5 shows the effect of vegetative inoculum size (0.5 - 3.5%) on citric acid production by Aspergillus niger GCBT7 in stirred fermentor.

Maximum citric acid production (96.86 ± 4.0a g/l) was obtained with 1.0% inoculum size. All the kinetic parameters i.e.

, cells yield coefficient (Yx/s = 0.153 ± 0.03g g/g), product formation rate (Qp = 0.507 ±

0.04d g/l/h), volumetr ic rate of substrate consumption (Qs = 0.680 ± 0.02c g/l/h) and specific rate constant for product formation (qp = 0.034 ± 0.007c g/g cells/h) showed 1.0% vegetative inoculum to be adequate for optimal production of citric acid. This is in accordance with the findings of Van-Suijdam et al. 1980 .

24

Figure 5. Effect of different inoculum size on citric acid production by Aspergillus niger GCBT7. All the fermentations were carried out at 30ºC following growth on 150 g/l initial sugar concentration. The initial pH of the molasses medium was kept constant at 6.0 throughout the fermentation period of 6-days. Yx/s = g cells/g substrate utilized, Qp = g citric acid produced/l/h, Qs = g substrate consumed/l/h, qp = g citric acid produced/g cells/h.

Ferrocyanide ion concentration

In the present investigation, the effect of different concentrations of ferrocyanide on the production of citric acid by Aspergillus niger GCBT7 was carried out and their kinetic relations have been shown in Figure 6 .

Th e addition of ferrocyanide was made, 24 hours after the inoculation. Maximum citric acid yield (98.28 ±

4.5a g/l, anhydrous citric acid) was obtained at 200 ppm. Further increase in the concentration of ferrocyanide, both the citric acid and the amount of residual sugars were decreased. The amount of

25

mycelial dry weight was continuously decreased by increasing the concentration of ferrocyanide beyond

200 ppm. The specific product formation rate i.e.

, Yp/x (4.889 ± 0.03d g/g) is highly significant and is 2.56 folds improved as compared with Pirt, 1975 . Similarly, the values of growth yield coefficient (Yx/s = 0.191

± 0.05c g/g) and product formation rate (Qp = 0.611 ± 0.04b g/l/h) indicated higher yields of the product and lower substrate consumption rates. The work is substantiated with the findings of Rajoka et al. 1998 .

Figure 6. Effect of different Ferrocyanide concentration on citric acid production by Aspergillus

niger GCBT7. All the fermentations were carried out at 30ºC following growth on 150 g/l initial sugar concentration. The initial pH of the molasses medium was kept constant at 6.0 throughout the fermentation period of 6-days. Qp = g citric acid produced/l/h, Yp/x = g citric acid produced/g cells formed, qp = g citric acid produced/g cells/h.

Concluding Remarks

The culture of Aspergillus niger GCBT7 was selected as the best mould to support maximum production of citric acid without supplements. The observation indicates that it might be possible to manipulate the morphology parameters in order to improve bioreactor performance and process yields. Substrate requirement as well as biomass and product yields are some of the basic parameters that need to be

26

considered in determining the feasibility of the fermentation process. All the kinetic parameters i.e

., product and growth yield coefficients (Yp/s, Yp/x and Yx/s in g/g), volumetric rates (Qp, Qs and Qx in g/g cells/h) and specific rate constants (qp, qs and qx in g/g/h) are highly significant.

Acknowledgments

The authors are thankful to the officials of Pakistan Science Foundation for financial assistance. Special thanks are due to Dr. M.I. Rajoka, PSO (NIBGE, Fasialabad) for his help in the statistical analysis and kinetic studies.

Abstract

Article

References

References

ARZUMANOV, T.E.; SHISHKANOVA, N.V. and FINOGENOVA, T.V. Biosynthesis of citric acid by

Yarrowia lipolytica repeat-batch culture on ethanol. Applied Microbiology and Biotechnology , October

2000, vol. 53, no. 5, p. 525-529.

DUBOISE, K. Sugar determination by phenol sulphuric acid method. Biotechnology and Bioengineering,

March 1956, vol. 10, p. 721-724.

GREWAL, H.S. and KALRA, K.L. Fungal production of citric acid. Biotechnology Advances , April 1995, vol. 13, no. 2, p. 209-234.

HAQ, I.; KHURSHID, S.; ALI, S.; ASHRAF, H.; QADEER, M.A. and RAJOKA, M.I. Mutation of Aspergillus niger strain for enhanced citric acid production by black-strap molasses. World Journal of Microbiology and Biotechnology , April 2001, vol. 17, no. 1, p. 35-37.

HAQ, P.B. and DAUD, D.A. Process of mycelial dry weight calculation for citric acid. Journal of

Biotechnology , May 1995, vol. 9, p. 31-35.

KRISTIANSEN, B.; MATTEY, M. and LINDEN, J. Citric Acid Biotechnology , Taylor & Frances Ltd.,

London, UK. February 1999, p. 7-9.

KRISTIANSEN, B. and SINCLAIR, C.G. Production of citric acid in continuous culture. Biotechnology and

Bioengineering , March 1979, vol. 21, p. 297-315.

MARRIER, J.R. and BOULET, M. Direct determination of citric acid in milk with an improved, pyridine acetic anhydride method. Journal of Dairy Sciences , March 1958, vol. 41, p. 1683.

MOREIRA, M.T.; SANROMAN, A.; FEIJOO, G. and LEMA, J.M. Control of pellet morphology of filamentous fungi in the fluidised bed bioreactors by means of a pulsing flow: Application to Aspergillus niger and Phanerochaete chrysosporium . Enzyme and Microbial Technology , April 1996, vol. 19, no. 4, p.

261-266.

PANDA, T.; KUNDU, S. and MAJUMDAR, S.K. Studies on citric acid production by Aspergillus niger using treated Indian cane-molasses. Journal of Microbiology , October 1984, vol. 5, p. 61-66.

27

PAZOUKI, M.; FELSE, P.A.; SINHA, J. and PANDA, T. Comparative studies on citric acid production by

Aspergillus niger and candida lipolytica using molasses and glucose. Bioprocess Engineering, November

2000, vol. 22, no. 4, p. 353-361.

PESSOA, D.F.; DIASDE, C. and ANGELA, C. Production of citric acid by Aspergillus niger . Revista de

Microbiologia , March 1982, vol. 13, no. 2, p. 225-229.

PIRT, S.J. Principles of Microbe and cell cultivation . 1 st Edition. Blackwell Scientific Publication, London,

UK, April 1975, p. 115-117.

PRESCOTT, S. and DUNN'S, A. Industrial Microbiology, 4 th edition. CBS Publishers and Distributors,

New Dehli, India, August 1987, p. 710-715.

RAJOKA, M.I.; AHMAD, M.N.; SHAHID, R.; LATIF, F. and PARVEZ, S. Citric acid production from sugarcane molasses by cultures of Aspergillus niger . Biologia , May 1998, vol. 44, no. 1, p. 241-253.

SING, S.P.; VERMA, U.N.; KISHOR, M. and SAMDANI, H.K. Effect of medium concentration on citric acid production by submerged fermentation. Orient Journal of Chemistry , March 1998, vol. 14, no. 1, p. 133-

135.

VAN-SUIJAM, J.C.; KOSSEN, N.W.F. and PAUL, P.G. An inoculum technique for the production of fungal pellets. European Journal of Applied Microbiology , December 1980, vol. 8, p. 353-359.

VERGANO, M.G.; FEMANDEZ, N.; SORIA, M.A. and KERBER, M.S. Influence of inoculum preparation on citric acid preparation by Aspergillus niger . Journal of Biotechnology , April 1996, vol. 12, no. 6, p. 655-

656.

WIECZOREK, S. and BRAUER, H. Continuous production of citric acid with recirculation of the fermentation broth after product recovery. Bioprocess Engineering , January 1998, vol. 18, no. 1, p. 1-6.

Note: Electronic Journal of Biotechnology is not responsible if on-line references cited on manuscripts are not available any more after the date of publication.

28