Module 18: Land Use/Reclamation/Fish and Wildlife

5600-PM-BMP0324 2/2012

Module 23: Mine Openings

Instructions: Designs, reports, and specifications for mine openings and mine seals must be certified by a licensed professional engineer and licensed professional geologist.

23.1 Inventory

Complete Form 23.1A describing all mine openings which will be constructed or otherwise used as part of this operation.

23.2 Designs a. For each shaft, slope, or drift entry provide a drawing showing those features which are relevant to protecting the hydrologic balance. The drawing should include: i. The physical dimensions of excavations and entry lining material; ii. The type of entry lining material; iii. The measures which will be used to seal the annulus between the entry lining and adjacent rock. iv. Water rings and conductor pipes; and v. Elevation of land surface, coal seam, and any other mine workings penetrated by the structure. b. For each borehole or group of boreholes which will be constructed in a similar manner provide a sketch indicating: i. The depth (or depth range) and diameter of each drill hole; ii. The depth (or depth range) and diameter of each casing string, type and thickness of casing material in each string, and spacing of collars and any centralizers; iii. Intervals to be cemented, grouted or otherwise sealed and the method of placement; iv. Any geophysical logging which is proposed; and v. The names or numbers of boreholes to which the sketch applies.

23.3 Sealing Plans a. Provide a series of drawings showing the manner in which each opening or group of openings will be sealed upon mine closure. Drawings must include adjacent entry configurations where necessary to describe seal design. For guidance on the seal design configuration, refer to “Reference Drawing 23.3A” on page 23-3, and reflect the following concerns: i. The type and grade of materials to be used for backfilling and the intervals in which they will be used; ii. Sections of casing or entry linings to be demolished; iii. Sealing of water rings and appurtenant piping; iv. Design of hydraulic seals, including construction material, reinforcing, method of placement, design thickness, and method of anchoring; v. Design of gas ventilation piping that will be incorporated in seal design; and vi. Finished grading at land surface. b. For each shaft, drift, or slope seal which must withstand hydraulic head provide an engineering and hydrologic justification of the seal design.

23.4 Temporary Seals

In the event the mine is temporarily closed or abandoned, provide information on temporary seals to be constructed to prevent entry to all mine openings. Include an appropriate timetable for construction of these seals. (Refer to 89.68 and the technical guidance titled “Sealing Bituminous Mine Openings” for procedures regarding notification of DEP during temporary cessation.).

23 - 1

5600-PM-BMP0324 2/2012

Operator:

Operation Name:

Opening Name/No. Type Use

FORM 23.1A: MINE OPENINGS

Permit No.:

Date:

Dimensions

Construction

Date Surface Elev. Seam Elev. Seal Elev.

23 - 2

5600-PM-BMP0324 2/2012

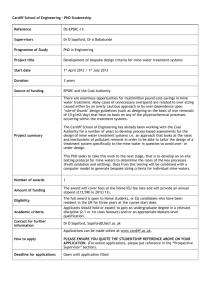

REFERENCE DRAWING 23.3

Details of a General Configuration of a Mine Seal

Competent Material

Reinforcement Bar Mat: 12”x12” OC / Epoxy Coated

(The rebar must be notched into the roof, ribs and floor a minimum of 6” or into competent material.)

Competent Material

The concrete block wall must be a minimum of 1’4” thick and notched into competent material in the roof.

--------------------

Outby from seal backfill with inert materials.

The footer must be notched into competent material.

--------------------

Concrete or

Expandable

Grout

Concrete or

Expandable

Grout

The concrete block wall must be a minimum of 1’4” thick and notched into competent material in the roof.

--------------------

Inby from seal.

The footer must be notched into competent material.

--------------------

Competent Material Competent Material

Concrete or Expandable Grout area varies in width

(Minimum thickness: 3.0 ft.)

Notes:

1. A ventilation seal can exist as a blockwall without the grout in the center.

2. The size and placement of the rebar and number of rebar mats will be determined during the design of the mine seal.

3. The strength of concrete or expandable grout will be determined during the design of the mine seal.

23 - 3