Standard Operating Procedures - Environmental Health & Safety

advertisement

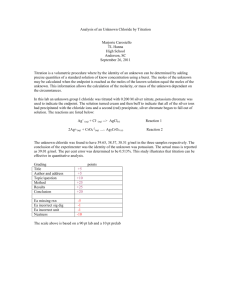

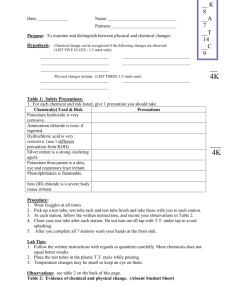

Standard Operating Procedures Laboratory Specific Chemical: Vinyl Chloride (Monomer) Please fill out the form completely. Print a copy and insert into your Laboratory Safety Manual and Chemical Hygiene Plan. Refer to instructions for assistance. _____________________________________________________________________________ Department:________________________ Date when SOP was written:_______ Date when SOP was approved by the lab supervisor: ___________________ Principal Investigator:___________________________________________________ Internal Laboratory Safety Coordinator/Lab Manager:___________________________________ Laboratory Phone:____________________ Office Phone:_____________________ Emergency Contact:____________________________________________________ (Name and Phone Number) Location(s) covered by this SOP:__________________________________________ (Building/Room Number) _____________________________________________________________________________ Type of SOP: Process Hazardous Chemical Hazardous Class Purpose Vinyl Chloride (Monomer) is a regulated carcinogen. It is highly toxic, flammable and carcinogenic (causes liver cancer). In the very first study about the dangers of Vinyl Chloride (VC), published by Patty in 1930, it was disclosed that exposure of test animals to just a single short-term high dose of VC caused liver damage. According to the US EPA, "vinyl chloride emissions from polyvinyl chloride (PVC), ethylene dichloride (EDC), and vinyl chloride monomer (VCM) plants cause or contribute to air pollution that may reasonably be anticipated to result in an increase in mortality or an increase in serious irreversible, or incapacitating reversible illness. Vinyl chloride is a known human carcinogen that causes a rare cancer of the liver." Polyvinyl chloride is very stable, storable, and less acutely hazardous than the monomer. General Information: Vinyl chloride is a colorless flammable gas that evaporates very quickly. Higher than normal levels of vinyl chloride may be present inside new cars as the chemical evaporates from new vinyl products. Vinyl chloride can be formed in the environment when soil organisms break down "chlorinated" solvents. In the environment, the highest levels of vinyl chloride are found in air around factories producing vinyl products. Vinyl chloride that is released by industries or formed by the breakdown of other chlorinated chemicals can enter the air and drinking water supplies. Vinyl chloride is a common contaminant found near landfills Uses: Vinyl chloride is a chemical intermediate, not a final product. Due to the hazardous nature of vinyl chloride to human health, there are no end products that use vinyl chloride in its monomer 1 form. Vinyl chloride liquid is fed to polymerization reactors where it is converted from a monomer to a polymer PVC. The final product of the polymerization process is PVC in either a flake or pellet form. From its flake or pellet form PVC is sold to companies that heat and mold the PVC into end products such as PVC pipe and bottles. Tens of billions of pounds of PVC are sold on the global market each year. Vinyl Chloride is used to make polyvinyl chloride (PVC) pipes, wire coatings, vehicle upholstery, and plastic kitchen ware. Physical & Chemical Properties/Definition of Chemical Group Vinyl Chloride is an extremely flammable gas under pressure. Color: Colorless Physical State: Compressed, liquefied gas Odor: Sweet Signal Word: DANGER PRECAUTIONARY STATEMENTS: Keep away from heat, sparks and flame. Wash thoroughly after handling. Avoid contact with eyes, skin and clothing. Do not breathe vapors or spray mist. Do not eat, drink or smoke in areas where this material is used. Use only outdoors or in a well-ventilated area. Do not handle until all safety precautions have been read and understood. Use personal protective equipment as required. Store in well-ventilated place. Keep container tightly closed. Color: Colorless Odor: Sweet Odor Threshold: Not reliable to prevent excessive exposure Molecular Weight: 62.5 Molecular Formula: C2ClH3 Flash point: -108 F (-78 C) Lower Flammability Level (air): 3.6 % Upper Flammability Level (air): 33.0 % Boiling Point/Range: 7 F (-14 C) Freezing Point/Range: No data available Vapor Pressure: 2660 mmHg @ 25 C Vapor Density (air=1): 2.15 Specific Gravity (water=1): 0.91 @ 25/25 C Water Solubility: 2.7 g/L pH: Not applicable Volatility: 100% 2 VOC Content(%): 100% Evaporation Rate (ether=1): >15 Partition Coefficient (noctanol/water): Log Kow = 1.36 Potential Hazards/Toxicity Inhalation: Several minutes of exposure to high, but attainable concentrations (over 1000 ppm) may cause central nervous system depression with effects such as dizziness, drowsiness, disorientation, tingling, numbness or burning sensation of the hands and feet, impaired vision, nausea, headache, difficulty breathing, cardiac arrhythmias, unconsciousness, or even death. Skin contact: May cause irritation. Rapid evaporation of the material may cause frostbite. Eye contact: May cause irritation. Rapid evaporation of the material may cause frostbite. Chronic Effects: Causes damage to the liver, musculoskeletal system, and peripheral nervous system through prolonged or repeated exposure. Interaction with Other Chemicals Which Enhance Toxicity: Alcohol may enhance toxic effects Medical Conditions Aggravated by Exposure: Hepatitis B infection OSHA lists Vinyl Chloride Monomer (VCM) as a Class IA Flammable Liquid, with an NFPA Flammability Rating of 4. Because of its low boiling point, liquid VCM will undergo flash evaporation (i. e., auto-refrigerate) upon its release to atmospheric pressure. The portion vaporized will form a dense cloud (more than twice as heavy as the surrounding air). The risk of subsequent explosion or fire is significant. According to OSHA, the flash point of VCM is -78 C (108 F). Its flammable limits in air are: lower 3.6 volume % and upper 33.0 volume %. Fire may release toxic hydrogen chloride (HCl) and carbon monoxide (CO). Vinyl chloride is very toxic. People should avoid contact with this chemical. The following health effects can occur after several years of exposure to vinyl chloride: Damage to the nervous system Changes in the immune system Cancer: Exposure to vinyl chloride may increase a person's risk of developing cancer. Human and animal studies show higher rates of liver, lung and several other types of cancer. Reproductive Effects: People exposed to levels of 1,000 ppm or more in air may have an increased risk of miscarriage and birth defects. Damage to male sperm-producing organs has occurred in laboratory animals. Organ Systems: Being exposed to vinyl chloride can affect a person’s liver, kidney, lung, spleen, nervous system and blood. Bone: Long-term exposure to high levels of vinyl chloride can result in a decrease in bone strength in fingers, arms, and joints. In general, chemicals affect the same organ systems in all people who are exposed. However, the seriousness of the effects may vary from person to person. 3 A person's reaction depends on several things, including individual health, heredity, previous exposure to chemicals including medicines, and personal habits such as smoking or drinking. It is also important to consider the length of exposure to the chemical; the amount of chemical exposure; and whether the chemical was inhaled, touched, or eaten. Breathing: Most exposure to vinyl chloride occurs when people breathe contaminated air. If a water supply is contaminated, vinyl chloride can enter household air when the water is used for showering, cooking or laundry. Drinking/Eating: People can be exposed to vinyl chloride if they drink or cook with contaminated water. Touching: Vinyl chloride can be absorbed through the skin. This can occur when people handle vinyl products, contaminated soil, or bathe in contaminated water. However, skin absorption is probably a minor route of exposure. Vinyl chloride is known to cause cancer and other serious health problems in people who are exposed to it. The circulatory, nervous, and immune systems can all be affected. The severity of harm typically corresponds to the level of exposure. Short-term, low level contact may cause temporary lightheadedness, fatigue, and confusion. Brief exposure to higher levels of vinyl chloride can cause more serious health problems, including death in extreme cases. Exposure over a long duration can lead to the development of a number of life-threatening diseases, including liver cancer, brain cancer, lung cancer, and angiosarcoma. Personal Protective Equipment (PPE) PERSONAL PROTECTIVE EQUIPMENT: Eye Protection: Wear safety glasses with side-shields. If eye contact is likely, wear chemical resistant safety goggles. Provide an emergency eye wash fountain and quick drench shower in the immediate work area (accessible within 10 seconds). Skin and Body Protection: Fire/flame resistant lab coat (100% cotton based) Cotton based clothing/attire. Full length pants or equivalent Close toed shoes Hand Protection: Wear appropriate chemical resistant gloves. Handle with Silver Shield / Laminate Film gloves (i.e., Heavy duty gloves). http://www.ansellpro.com/download/Ansell_8thEditionChemicalResistanceGuide.pdf Gloves must be inspected prior to use. Respiratory Protection: Refer to 29 CFR 1910.1017 for selection of respirators for vinyl chloride. A respiratory protection program that meets 29 CFR 1910.134 must be followed whenever workplace conditions warrant use of a respirator. Note: All personnel intending to use/wear a respirator mask must be training and fit-tested by EH&S. This is a regulatory requirement. (http://map.ais.ucla.edu/go/1003938#Respirator_Training_and_Fit_Testing_) 4 Engineering Controls ENGINEERING CONTROLS: Use closed systems when possible. Provide local exhaust ventilation where vapor may be generated. Ensure compliance with applicable exposure limits. Regulatory Exposure limit(s): Component - Vinyl chloride CAS Number - 75-01-4 OSHA Final PEL TWA - 1 ppm OSHA Final PEL STEL - 5 ppm OSHA Final PEL Ceiling ----OEL: Occupational Exposure Level; OSHA: United States Occupational Safety and Health Administration; PEL: Permissible Exposure Limit; TWA: Time Weighted Average; STEL: Short Term Exposure Limit First Aid Procedures INHALATION: If adverse effects occur, remove to uncontaminated area. Give artificial respiration if not breathing. If breathing is difficult, oxygen should be administered by qualified personnel. If respiration or pulse has stopped, have a trained person administer basic life support (CardioPulmonary Resuscitation and/or Automatic External Defibrillator) and CALL FOR EMERGENCY SERVICES IMMEDIATELY. SKIN CONTACT: If frostbite or freezing occur, immediately flush with plenty of lukewarm water (100-105 F, 38-41 C). GET MEDICAL ATTENTION IMMEDIATELY. EYE CONTACT: Immediately flush eyes with a directed stream of water for at least 15 minutes, forcibly holding eyelids apart to ensure complete irrigation of all eye and lid tissues. Washing eyes within several seconds is essential to achieve maximum effectiveness. GET MEDICAL ATTENTION IMMEDIATELY. INGESTION: Not a likely route of exposure. Notes to Physician: Cardiac stimulants such as epinephrine should not be given to persons overexposed to chlorinated hydrocarbons. Note: Vinyl chloride can be found in urine and body tissues after recent exposures. However, test results may not accurately reflect the level or duration of the exposure, or predict future health effects. Function tests of bone marrow, liver, kidney, and nerves may be useful in determining the effects of vinyl chloride exposure. Seek medical advice if you have any symptoms that you think may be related to chemical exposure. Special Handling and Storage Requirements Reactivity/ Stability: Stable at normal temperatures and pressures. Conditions to Avoid: Avoid air and sunlight. Avoid heat, flames, sparks and other sources of ignition. Containers may rupture or explode if exposed to heat. Incompatibilities/Materials to Avoid: Oxidizing agents, Oxides of nitrogen, Metals, Aluminum, Aluminum alloys, Copper, Metal alkyl complexes and alkali metals such as sodium, potassium and their alloys 5 Hazardous Decomposition Products: Oxides of carbon, Chlorine, Hydrogen chloride, Phosgene Hazardous Polymerization: Polymerization can occur. Avoid elevated temperatures, oxidizing agents, oxides of nitrogen, oxygen, peroxides, other polymerization catalysts/initiators, air and sunlight. Storage Conditions: Keep container tightly closed and properly labeled. Store in a cool, dry area. Store in a well-ventilated area. Do not enter confined spaces unless adequately ventilated. Avoid heat, flames, sparks and other sources of ignition. May be subject to storage regulations: U.S. OSHA 29 CFR 1910.106. Handling Procedures: Avoid breathing vapor or mist. Avoid contact with skin, eyes and clothing. Keep away from heat, sparks and flame. Ground any equipment used in handling. Use non-sparking tools and equipment. All energized electrical equipment must be designed in accordance with the electrical classification of the area. Accidental Release Remove sources of ignition. Ventilate closed spaces before entering. Stop leak if possible without personal risk. Vapors or gases may ignite at distant ignition sources and flash back. Reduce vapors with water spray. Keep unnecessary people away, isolate hazard area and deny entry. Keep out of water supplies and sewers. Wear appropriate Personal Protective Equipment (as mentioned in the PPE section) Releases should be reported immediately to EH&S at 310-825-9797. Fire Hazard: Severe fire hazard. Vapor/air mixtures are explosive. Vapors or gases may ignite at distant sources and flash back. Containers may rupture or explode if exposed to heat. Extinguishing Media: Stop flow of gas before extinguishing fire. Use carbon dioxide, regular dry chemical, foam or water. Use water spray to keep containers cool. Fire Fighting: Move container from fire area if it can be done without risk. For fires in cargo or storage area: Cool containers with water from unmanned hose holder or monitor nozzles until well after fire is out. If this can’t be done, then take the following precautions: Keep unnecessary people away, isolate hazard area and deny entry. Let the fire burn. Withdraw immediately in case of rising sound from venting safety device or any discoloration of tanks due to fire. For tank, rail car or tank truck: Stop leak if possible without personal risk. Let burn unless leak can be stopped immediately. Wear NIOSH approved positive-pressure self-contained breathing apparatus (SCBA) operated in pressure demand mode. Sensitivity to Mechanical Impact: Not sensitive. 6 Sensitivity to Static Discharge: Electrostatic charges may build up during handling and may form ignitable vapor-air mixtures in storage containers. Ground equipment in accordance with industry standards and best practices such as NFPA 77 [Recommended Practices on Static Electricity (2007)] and American Petroleum Institute (API) RP Recommended Practice 2003 [Protection Against Ignitions Arising our of Static, Lightning, and Stray Currents (2008)]. Lower Flammability Level (air): 3.6 % Upper Flammability Level (air): 33.0 % Flash point: -108 F (-78 C) Autoignition Temperature: 882 F (472 C) Hazardous Combustion Products: Oxides of carbon, Hydrogen chloride, Phosgene Chemical Release Dial 911 (or 310-825-1491 from cell phone) and x59797 Accidental Release – Help contaminated or injured persons. Evacuate the release area. Avoid breathing vapors. Eliminate sources of ignition. Keep others from entering this area (e.g., use caution tape, barriers, etc.). Contact with body or clothes – Remove clothing and rinse body thoroughly in emergency shower for at least 15 minutes. Seek medical attention. Notify supervisor and EH&S at x59797 immediately. Contact with Eyes – Immediately rinse eyeball and inner surface of eyelid with water for 15 minutes by forcibly holding the eye open. Seek medical attention. Notify supervisor and EH&S at x59797 immediately. Medical Emergency Dial 911 or x52111 Life Threatening Emergency, After Hours, Weekends And Holidays – Dial 911 (or 310-825-1491 from cell phone) or contact the Ronald Reagan UCLA Medical Center (emergency room) directly at x52111 (located at 757 Westwood Plaza, enter from Gayley Avenue). Note: All serious injuries must be reported to EH&S at x59797 within 8 hours. Non-Life Threatening Emergency– Go to the Occupational Health Facility (OHF), x56771, CHS room 67-120 (This is on the 6th floor, 7th corridor, room 120. Enter through the School of Dentistry on Tiverton Drive and proceed to the “O” elevator to the 6th floor.)Hours: M F, 7:30 a.m. to 4:30 p.m. At all other times report to Ronald Regan UCLA Medical Center (emergency room) at x52111. Note: All serious injuries must be reported to EH&S at x59797 within 8 hours. Decontamination/Waste Disposal Procedure General hazardous waste disposal guidelines: Label Waste 7 o Affix an on-line hazardous waste tag on all waste containers using the Online Tag Program http://otp.ucop.edu/ as soon as the first drop of waste is added to the container Store Waste o Store hazardous waste in closed containers, in secondary containment and in a designated location o Double-bag dry waste using transparent bags http://map.ais.ucla.edu/go/1002774 o Waste must be under the control of the person generating & disposing of it Dispose of Waste o Dispose of regularly generated chemical waste within 90 days o Call EH&S at x61887 for questions o Empty Containers Dispose as hazardous waste if it once held extremely hazardous waste (irrespective of the container size) http://ehs.ucla.edu/Pub/ExtremelyHazardousWaste.pdf o Consult waste pick-up schedule http://ehs.ucla.edu/pub/HazWaste%20Pickup%20Schedule.pdf o Prepare for transport to pick-up location Check on-line waste tag Write date of pick-up on the waste tag Use secondary containment Wear eye protection & closed toe shoes; bring gloves Material Safety Data Sheet (MSDS) Location (State the location of MSDS) Hardcopy & electronic copy must be available for Vinyl Chloride (Monomer) Online MSDS can be accessed at http://msds.ehs.ucla.edu. Protocol/Procedure (Add specific description of procedure) Any deviation from this SOP requires approval from PI. Documentation of Training (signature of all users is required) Prior to conducting any work with Vinyl Chloride (Monomer), designated personnel must provide training to his/her laboratory personnel specific to the hazards involved in working with this substance, work area decontamination, and emergency procedures. The Principal Investigator must provide his/her laboratory personnel with a copy of this SOP and a copy of the Vinyl Chloride (Monomer) MSDS provided by the manufacturer. The Principal Investigator must ensure that his/her laboratory personnel have attended appropriate laboratory safety training or refresher training within the last two years. I have read and understand the content of this SOP: Name Signature 8 Date