The production of olive kernel wood on Crete

advertisement

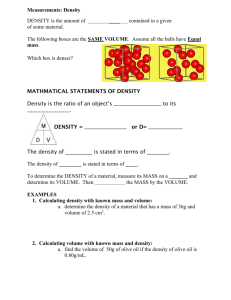

Possibilities of using olive kernel wood for power generation on Crete – Greece John Vourdoubas, TEI of Crete, Department of Natural Resources and Environment 3 Romanou Str., Halepa, Chania (73133), Crete – Greece e-mail: gboyrd@tee.gr Abstract. Solid biomass has been used in many countries for power generation or for cogeneration of heat and power. In Greece, where the olive tree is cultivated, during the processing of the olives the Olive Kernel Wood is produced. It has a high heating value and measures up to a very good fuel for heat or power generation. Today, it is used extensively on Crete for heat production; in the future, it has very good prospects for being used in power generation and/or heat and power cogeneration. Since a large proportion of power on Crete is generated today from wind energy, it is likely that, in the future, biomass will also contribute to the generation of green electricity Key words: biomass,olive kernel wood, power Introduction Today on Crete, various renewable energy sources are used for power generation, such as: Wind Energy Solar Energy (Photovoltaics) Hydropower Biogas (But not Solid Biomass) Biomass can be used for heat production, for power generation or for the production of vehicle fuels. Today in Greece, Solid Biomass is used mainly for heat production, in conjunction with combustion technologies. Although in other European countries Solid Biomass is used for power generation or for cogeneration of heat and power, this is not happening in Greece at present. Solid Biomass Combustion is a mature technology with numerous advantages. Although the efficiency from the solid biomass combustion process is low, the solid biomass gasification, which is derived from the combustion process, has a very high efficiency value. Soon, this too will adhere to many applications. The Olive tree is cultivated in many areas of Greece. During the processing of the olives, Olive Kernel Wood is produced. It has a significant heating value, is easily handled and its price, in relation to its heating value, is rather low. Thus, the Olive Kernel Wood is an attractive and lucrative option for producing fuel for various applications. Considering that Greece, the berth of the olive tree, imports oil in order to cover its energy needs, it is logical to derive energy from the Olive Kernel Wood, which is a local Renewable Energy Source. The generation of energy from the Olive Kernel Wood also has environmental advantages because its impacts to the Greenhouse Effect are neutral. Presently, Olive Kernel Wood is used for heating buildings, greenhouses and factories. It has positive prospects for being used for power generation and/or for heat and power cogeneration on a wider scale in Greece in the near future. The production of olive kernel wood on Crete The Olive tree is currently cultivated extensively on Crete, where a perfect quality of Olive Oil is produced. Olive Kernel Wood is produced during the extraction of the Olive Kernel Oil. During the production of Olive Oil, a semi-solid paste containing oil is produced. A second quality Olive Oil can be extracted from this in medium-sized plants and the Olive Kernel Wood is produced as a by-product. The total annual production of the Olive Kernel Wood on Crete is 110.000 tn. The Olive Kernel Oil processing plants operate seasonally every year from November until April. Table 1 presents the current production of Olive Kernel Wood on Crete. The flow diagram depicting the production of Olive Kernel Wood is presented below. Part of the produced Olive Kernel Wood is used at: a) The Olive processing plant for the production of hot water b) The Olive Kernel Oil production plant for the drying of the paste The energy value of the Olive Kernel Wood produced today on Crete is equivalents to the 21,09% of the total power consumption on the island. The overall potential from the total produced Olive Kernel Wood today on Crete (with combustion) is 97 GWh/ year. Table 1. Production of olive kernel wood on Crete Prefecture Olive Kernel Wood (tn/ year) Chania 32,110 Rethymnon 13,890 Heraklion 16,766 Lasithti 16,272 TOTAL 109,038 Current Uses of Olive Kernel Wood on Crete Olive Kernel Wood is mainly used for heating purposes today on Crete for: a) Houses b) Greenhouses c) Various small-sized industries Its heating value is 3500-4000 Kcal/ kg (with a moisture content of 12%) and its price is approximately 0,05 Euros/ kg; thus, it is a very attractive option as a fuel in comparison to oil. Olive Kernel Wood, however, has not yet found applications in power generation or cogeneration of heat and power in Greece. Because it can be easily burnt and the combustion technology is well known widely, it can be used as a solid fuel for power generation in the future. Presently, it is used in houses and in greenhouses for the production of hot water. Also, it is used in various industries for drying purposes and/or for the production of hot water. Greece exports small quantities to other European countries each year, where Olive Kernel Wood is used for fuel. The required machinery for the Olive Kernel Wood combustion is the boiler( including the burner), which is quite simple to use and not expensive. These boilers are reliable and made locally. Olives Processing Olive Oil Liquid Wastes Drying and Extraction Olive Kernel Wood Olive Kernel Oil Fig. 1. Production of Olive Oil, Olive Kernel oil and Olive Kernel Wood from Olives to the Factory Paste containing Oil Olive Kernel Oil Processing Plant Olive Kernel Oil Combustion Olive Kernel Wood P O W E R to the Grid Fig.2. Power generation from olive kernel wood Olive Kernel Wood can be used for power generation or cogeneration of heat and power on Crete, since it presents many advantages, such as: 1. There is no need for harvesting of raw materials and transport of them because it is produced in the Olive Kernel Oil processing plants. 2. Its moisture content is very low and its heating value is high. 3. Its price is rather low in comparison with its heating value. 4. The combustion technology is well known. Since it is granular, either fixed bed reactors or fluidized bed reactors can be used. 5. The generated power can be consumed either inside the plant or can be sent to the grid. 6. The Greek Government offers good subsidies for investments in the field of Renewable Energy Sources and, of course, in Biomass. 7. The use of Biomass for power generation on Crete will reduce the CO2 emissions on the island. 8. In the case that such a plant should be created, various other solid agricultural residues can be used with the Olive Kernel Wood as raw materials. 9. The creation of such a plant will help in the generation of power to and from small-decentralized plants instead of larger centralized power plants that exist today on Crete. 10. The sulphur content of Olive Kernel Wood is minimal. 11. The efficiency of small-sized combustion plants is very low. The Olive Kernel processing plants operate seasonally. The produced heat from Olive Kernel Wood should be used at the time that cogeneration of the heat and power is obtained (during its operational period which is from November – April), or outside the plant for nearby heat-requiring operations. 12. Initially, the price of the Olive Kernel Wood will rise, due to an initial local deficit of this Biomass source. Table 2 shows the characteristics of a power plant on Crete consuming Olive Kernel Wood as a fuel. Table 2 Characteristics of a power plant consuming olive kernel wood as a fuel on Crete NOMINAL POWER 3 MW Operating hours/ year 8000 hours/ year Energy generation 24,000 MWH/ year Plant efficiency 20% Olive Kernel Wood consumption 27,180 tn/ year Heating Value of the Olive Kernel Wood 3800 Kcal/ kg Capital Cost of the plant Euros 4,8 million Subsidies (40%) 1,92 million Euros Cost of Olive Kernel Wood/ year year 1,359,000 Consumption of Olive Kernel Wood in the plant CO2 emissions which are avoided Energy generation from the plant as % of total Energy Consumption on Crete Euros/ 3,4 tn/ hour 29,137 tn/ year 1,04% Conclusions Olive Kernel Wood is produced in large quantities on Crete, Greece as a byproduct of the Olive Oil producing industry. It is used at the moment for heat generation in buildings, greenhouses and in industries; however, not for power generation. Since its heating value is high and it does not need any harvesting or transport, it can be used for power generation by combustion. The price of Olive Kernel Wood at the moment is rather low in comparison to its heating value. Olive Kernel Wood is granular and it can be easily burnt. There is no published data about its gasification, which is an alternative and more efficient method for generating power from it. References 1. Pitcher, K., “Turning Willow into Megawatts – The ARBRE Project”, Renewable Energy World: Vol. 3, No. 6, Nov.-Dec. 2000, pp. 34-45. 2. Overend, R.P., “Biomass Gasification – The Enabling Technology”, Renewable Energy World: Sept.-Oct. 2000, pp. 27-37. 3. White Paper for a Community Strategy and Action Plan – Energy for the Future: Renewable Sources of Energy. 4. Roithmayer, H., “Trigen on Track – A high-tech Ski Manufacturer Turns to Wood Fuel”: Cogeneration and On-site Power Production, Vol.2, No. 3, May-June 2001, pp. 45-48. 5. Sims, Ralph E.H., The Brilliance of Bioenergy in Business and in Practice: James & James, London, 2002. 6. Werebo-Brobby, C.Y.; Hagen, E.B., Biomass Conversion and Technology: J. Wiley & Sons, 1996. 7. Klass, D.L., Biomass for Renewable Energy, fuels and Chemicals, Academic Press, London, 1998. 8. Merino, Louis, “A Pressing Problem and an Energy Solution”, Renewable Energy World: March-April 2002, pp. 98-103. 9. Egger, C.; Ohlinger, C.; Dell, G., “Pellets – Clean, Convenient and Carbon-neutral”, Energy World: September-October 2003, pp. 82-89.