The Method of Information Construction for Pit Support Structure

advertisement

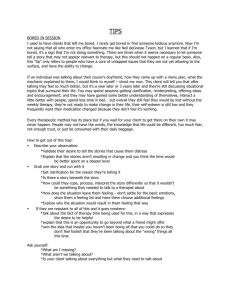

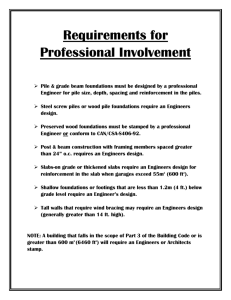

THE METHOD OF INFORMATION CONSTRUCTION FOR FOUNDATION PIT SUPPORT STRUCTURE Liu, Xiaoli Dou, Yuanming Yan, Chi Dept. of civil Engineering, North China Institute of Astronautics, Lang Fang, P.R. China School of Civil Engineering and Architecture, Hebei University of Technology, Tianjin, P.R. China School of Civil Engineering, Tian Jin university, Tianjin, P.R. China Introduction There are many foundation pit excavation engineering every year in China, but now the design method is still 1/3 based on it’s theory, 1/3 based on it’s experience, 1/3 based on it’s information feedback controlled. So there are two questions which based on design method be caused: (1) the result of design is too safety to supporting cost higher; (2) according to the theory method ,the structures is safety, but may is dangerous. It is reported that the foundation pit support structures failure or partly failure lead to the safety questions and surrounds questions ,and these questions are about 10%~15% in total engineering projects ,even in soft areas they about 20%. People always hope to find the balance between safety and economy for the pit-retaining structure which regard it as a temporary structure, that is, achieving the best result at least cost. The result of making a comparison the pit-retaining structure, pile foundation and ground treatment is: the pit-retaining structure being difficult, the designers can’t determine whether the design is really reasonable, can’t authentic appraise the safety and economy when the soil is digging after the pit-retaining construction is finished. So, one of the most effective ways is developing a computer controlling system at all time and on line, and the designers can immediately sort out and feedback the information data, thus gain a correct understand of the foundation pit about its developing trend and the regular of mutual relations. Then the features and state of foundation pit structure can be analyzed in a coming short time, the monitoring fully directs construction process. The safety of foundation pit structure can be pledged in the whole process. The Method of Information Construction for the Foundation Pit of a Office Building in Tianjin Engineering general situation The building locate in the Red Bridge District, Tianjin. It lies in the West of Dafeng Road, Stone Bridge Street is in the south of it. There is a large space in the north and west.25-storeyed up surface of the building and 3-storeyed in subsurface, the depth of the pit is 8.9m. The foundation bottom sheet size is 52m×37.6m. Design plan Plan 1: The bored piles make up the retaining wall; roundness ring supporting system and a row of rock Bolting is used in this structure. The bored pile are set up along the circumference of the foundation pit, the diameter of piles is 700mm, the distance between the piles is 750mm, the average length of the piles is 16m.One concrete roundness ring beam is set up on the top of the bored piles, the inter diameter of ring beam is 52m, the section size is 2000mm×600mm. The section size of the cap beam which locate on four corners of the foundation pit is 1000mm×600mm, the diameter of anchor rod is φ40, the horizontal distance between the rods is 1.5m, locate at 6m beneath the ring beam. There are two rows cement-soil piles interlocking each other are set outside the pitretaining piles. The cement-soil piles can being sealing installation to prevent the groundwater beyond the 127 pit. The effective length of cement-soil piles is 14.5m. This plan is designed through the data which come from investigation reports. Plan 2: Based on practical experience for a long time, the technical staff think: first, this pit-retaining structure is a temporary structure, it’s foundation is retaining soil; second, the parameters of soil mechanics, such as γ,φ,сare used in lower value. There parameters can be increased in the practical engineering. So all anchor rods can be canceled according to Plan 1, see Figure 2.1. For Plan 1 and Plan 2, the contract decides to adopt Plan 2 finally. Then the monitoring work seems much more important. The content and procedure of the pit-retaining structure monitoring There are four monitoring works according to the practical engineering required: (1) monitoring the inter forces and deformation of the ring beam (2) monitoring the deformation along the bored piles length (3) monitoring the active earth pressure of bored piles (4) monitoring the settlement of ground surface around the foundation pit Monitoring points see in Figure 2.1. M T 9 S P M S 7 M 11 S M M M 10 12 8 M S 6 S S S T T M M P P S S the depth of pit –8.9m 13 5 T T M M P P S S T T M M 2 P 14 S P 16 S 4 M M3 15 S S 1 M S T P Figure 2.1 The shape of the pit and the arranging of monitoring points Procedure of the pit-retaining structure monitoring see in Figure 2.2. The result of monitoring and analysing There are two steps for the foundation pit excavation. First, excavate 4.1m depth from ground surface, the Directions is the from southern to the northern pit. Then, excavate 4.8m depth to the bottom of the pit. The direction is from western to the eastern of the pit. The monitoring of the ring beam bending moment Though the monitoring results, some regularities show as: (1) During excavating the pit, there is a little bending in the cap beam which at the top of bored piles locate on four corners. Comparatively, there is a higher bending moment in the ring beam. These shows that the ring beam mainly bears the loads which act on the top of the bored piles. The result accords with theory analysis. (2) On the ring beam, the monitoring points No.1 and No.9 all bear a little bending moment, see Figure 2.3. The reason is: first, the arranging shape of the bored piles is unanimous with the plane shape of the ring beam. They are all circular arc shape and are densely arranged, the forces in a circular arc shape is little than in a line shape; second, there is a partly soil in the pit still, and is set a slope along 128 the inside of the ring beam. At the same place, a retaining wall is built. So, a little forces act on the bored piles, and then a little bending moment act on the ring beam. Excavating 4.1m depth Excavating 7m depth Finishing excavation soil Finishing cushion Figure 2.3 The deformations of the ring beam (3) The southern and the northern of the piles are densely arranged in plane around the pit, and these piles are joined by the cap beam and the ring beam. The active soil pressures act on the ring beam though the cap beam, then the negative bending moment is created at the points of No.5 and No.13. (4) The largest positive bending moment is: M=270tm, act on the point No.8. And the largest negative bending moment is: M=-331tm, act on the point No.5. The reason is that there is a 0.9m depth in the southern of the pit than in the northern, the more soil loads act on the southern piles than the northern piles. (5) After finished the bottom plate, there is a decreased bending moment in the ring beam. Though the decreased value isn’t large, the result shows that the bottom plate begins to play the supporting role. (5) When the ring beam is cut off at No.10 and No.16, the ring beam bending moment changed: the bending moments of No.11, No.12 and no.15 are rapidly increased. Especially, the bending moment of No.11 is 2196tm. At that time, the constructors heard a loudly voice which came from No.11, and then the ring beam is cut off. The ring beam axial forces are set free to the cap beam though No.11, the cap beam bears too large force to creating the concrete failure. But the bottom plate and basement wall play the supporting role, the pit-retaining structure is still safe. The monitoring of the ring beam deformation During the whole construction process, the ring beam is monitored every each day. Its horizontal deformations see Figure.2.4. The largest value is 7mm at No.5. 129 The exploration survey on-site Forecasting dangerous and preparing for dangerors conditions Construction plan Deciding the contents of monitoring Choosing the monitoring equipments Arranging the monitoring points and equipments constructing/monitoring Whether the dangerous be controlled Information form Doing the plan Feedback to interrelated department Analyzing the reason, deciding the treatment plan Whether has a warn Whether finished the construction Whether the design is optimation end Figure 2.2 The process of the information construction monitoring Figure 2.4 The horizontal deformations of the ring beam 130 Optimation design deformation (mm) 0 0 20 40 60 80 -4 pile length (m) -8 -12 -16 excavation -4.1m depth excavation -7.0m depth excavation -8.9m depth placing concrete cushion placing concrete bottom plate Figure 2.5 The curve of the bored pile deformation The monitoring of the deformation along the bored piles length The deformations along the bored pile length are see Figure 2.5. Some regularities show as: (1) The shape of every bored pile deformation is same during the excavation stage, that is, the shape is bulgy belly, the middle is bigger, the both ends are smaller. The largest deformation value locate on -8.2m~ -9.5m from ground surface; and all less than 35mm. The result tally with the theory design regularity. (2) It takes 7d~15d that placing concrete cushion. During the 7d~15d, due to soil can creep, the bored piles have a 15mm~25mm deformation again. The time is longer, the deformation is larger. (3) It takes 16d that placing concrete bottom plate. There is a 8mm deformation during 16d. The result shows that the bottom plate play a very important role for the supporting of the bored piles. (4) After finished the bottom plate, the bottom plate play a horizontal supporting role at -8.3m depth , then the bored piles deformation tend to become stability. At that time, the largest deformation is less than 60mm. (5) After cutting off the ring beam, the bored piles deformation is increasingly. But the displacement increment at the top of the bored piles is only 15mm~25mm.The largest deformation is still at 8.2m~ -9.5m depth, and the deformation shape doesn’t be changed. The monitoring of the active earth pressure of bored piles The monitoring point is set at every 2 meters along the bored pile length. The active earth pressure at the back of pit-retaining wall can’t reach the limited state, due to the bored pile deformation is small. So the active earth pressure is less than the Rankine active earth pressure, see Figure 2.6, this value compare with E0, the reduced volume at the top of bored piles is more than at the bottom of bored piles. The result is similar to the examples in the reference1. earth pressure(KPa) 0 40 80 120 -8 160 earth pressure(KPa) -12 0 -16 -4 0 pile length(m) pile length(m) -4 0 40 80 120 160 -8 -12 -4.1m depth excavating excavating -7.0m depth excavating -8.9m depth placing concrete cushion -16 placing concrete bottom plate -4.1m depth depth Figure 2.6excavating The curve of active soil excavating pressure-7.0m distribution excavating -8.9m depth placing concrete cushion placing concrete bottom plate The monitoring of the ground surface settlement around the foundation pit The result of the monitoring, see Figure.2.7. The settlements of points are between 30mm to 40mm. 131 distance beside the pit(m) -20 settlement(mm) 0 2 4 6 8 10 12 14 -30 survey No.9 -40 survey No.13 survey No.5 Figure 2.7 The ground surface settlement around the foundation pit Conclusion (1) The stress and strain in the pit-retaining structure are monitored during the whole construction process. The pit is enough safe, Plan 2 is reasonable. The anchor rods cost more than a half million RenMin Yuan, and it is saved. The economy effect is notable. (2) The concrete cushion can prevent the soil creep. So placing concrete cushion must early set up when excavating to the bottom of the pit. (3) The inflection point of the bored pile placement doesn’t appear. The soil pressure before the bored piles is passive, and the soil pressure back of the bored piles is still active. (4) After finished the construction of the basement, the basement becomes a horizontal supporting for the bored piles. When the ring beam is cut off, the structure is still safe. Suggestion (1) The construction method around No.1 and No.9 is a good way. The monitoring results show that there is a little force in the bored piles. When the condition is allowable, some plan can be design like this. It can reduce the cost. The result should be pay attention. (2) The ring beam is a reasonable supporting structure, it make the pit-retaining wall safety and trustiness. Reference Dezhang Feng. The monitoring result of clayey soil pressure on the pit-retaining pile. The third Conference of Soil Mechanics & Foundation Engineering Paper Collection. Beijing, China, 1981. 132