Operating Procedure / Work Instruction

advertisement

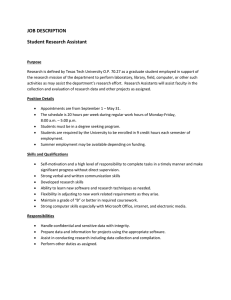

Document Title: Company Confidential Job Description Document Number: NEO-FRM-625 Revision: A DCO Number: 2014-146 Page Number: 1 of 2 Effective Date: 2014 Jun 02 This document and the information expressed therein is confidential and privileged information of Neovasc, Inc. Any unauthorized dissemination or copying is strictly prohibited. Confidential and privileged information is not open to the public and requires special precautions to protect it from unauthorized use, disclosure, modification or destruction. Neither receipt, nor possession of this document transfers any right to reproduce or disclose this document or any part thereof, including any information contained therein, or to practice any method or process described there in, except by written permission from or written agreement with Neovasc, Inc. Job Title: Manufacturing Engineering Manager Reports To: Chief Operations Officer Location: 13562 Maycrest Way, Suite 5138 Richmond, BC Date: 2015 Dec 07 Purpose/Role A brief description of the primary responsibilities for which the employee is accountable The Manufacturing Engineering Manager will support the development of the Tiara projects with a focus on optimizing efficacy and transfer to manufacturing. This position will provide overall leadership to the Manufacturing Engineers in the Richmond facility and manage all activities related to production line processes, equipment and maintenance to ensure products are assembled in an efficient and safe manner. Position Description A listing of the deliverables to be accomplished, including specific duties/activities that make up the job The Manufacturing Engineering Manager will: Develop new and improved manufacturing processes. This may be completed by analyzing and improving plant layout, purchasing new and more efficient equipment, and finding ways to reduce manufacturing costs Ensure production documentation such as bills of material (BOM), work instructions, process flow and all other documentation associated with the manufacturing processes are diligently created and are accurate Ensure production processes are well-defined, implemented and proven Provide guidance to the manufacturing engineers to ensure their priorities are well established The Manager will ensure all activities are taking place as planned in each project schedule The Manager will coach the manufacturing engineers to ensure they have adequate knowledge to fulfill their responsibilities and to ensure they acquire new skills to bring the manufacturing practices to the next level Manage and prioritizes multiple complex manufacturing engineering projects, ensuring projects meet or exceed requirements, are on-time and within budget Lead/champion LEAN/continuous improvement within manufacturing that include equipment/fixture design and/or process changes Monitor and reports on items such as cost reductions, downtime and capital expenditures Partners with the Quality team to ensure products and associated documentation meet requirements Prepare cost estimates and capital requests for proposed projects and evaluates cost factors Talent management (recruitment, training, development, retention) NEO-TMP-004 Rev B, Effective Date: 2014 Mar 07 Document is UNCONTROLLED COPY unless it is stamped CONTROLLED COPY. Document Title: Job Description Document Number: NEO-FRM-625 Company Confidential, Neovasc Inc. Revision: A Effective Date: 2014 Jun 02 Page Number: 2 of 2 Qualifications Represents the desired qualifications but may not reflect the employee’s existing qualifications Education A Bachelor’s Degree in Engineering is required (Mechanical, Manufacturing or Biomedical) Experience A history of successful completion of technical projects Minimum 5 years of management experience in pilot or commercial manufacturing, preferably in medical devices Working knowledge of Lean Manufacturing/Six Sigma Working knowledge AutoCad, ProEngineer, and MiniTab Strong knowledge of GMP, ISO, Health and Safety regulations and validation requirements Experience with any of the following is considered an asset: Medical Plastic Extrusion/Molding, Polymer Bonding, Balloon Manufacturing, Assembly Fixturing and Automated Equipment Design & Validation Skills Strong problem-solving and computer skills Strong communication and organizational skills Ability to provide leadership as well as work well in a team environment The purpose of this description is to provide a concise statement of the major responsibilities of this position in a standardized format. It is not intended to describe all the elements of the work that may be performed and should not serve as the sole criteria for personnel decisions and action. Approvals: _____________________________________ Employee (signature) _________________________________ Date _____________________________________ Manager (signature) _________________________________ Date NEO-TMP-004 Rev B, Effective Date: 2014 Mar 07 Document is UNCONTROLLED COPY unless it is stamped CONTROLLED COPY.