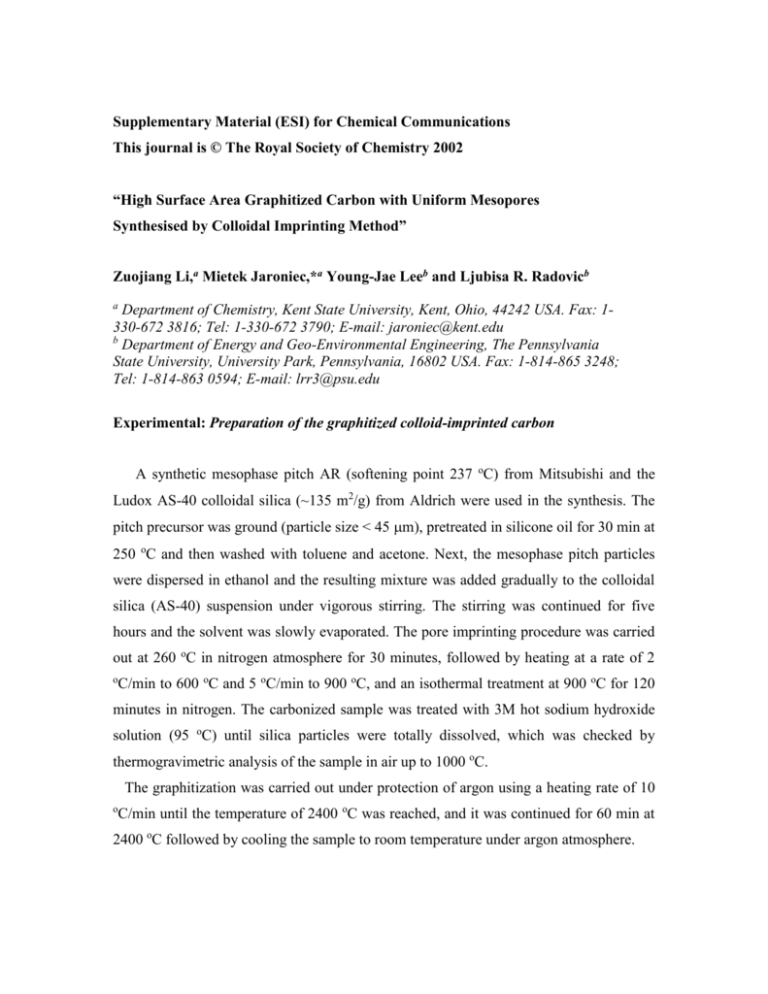

preparation of the graphitized colloid

advertisement

Supplementary Material (ESI) for Chemical Communications This journal is © The Royal Society of Chemistry 2002 “High Surface Area Graphitized Carbon with Uniform Mesopores Synthesised by Colloidal Imprinting Method” Zuojiang Li,a Mietek Jaroniec,*a Young-Jae Leeb and Ljubisa R. Radovicb a Department of Chemistry, Kent State University, Kent, Ohio, 44242 USA. Fax: 1330-672 3816; Tel: 1-330-672 3790; E-mail: jaroniec@kent.edu b Department of Energy and Geo-Environmental Engineering, The Pennsylvania State University, University Park, Pennsylvania, 16802 USA. Fax: 1-814-865 3248; Tel: 1-814-863 0594; E-mail: lrr3@psu.edu Experimental: Preparation of the graphitized colloid-imprinted carbon A synthetic mesophase pitch AR (softening point 237 oC) from Mitsubishi and the Ludox AS-40 colloidal silica (~135 m2/g) from Aldrich were used in the synthesis. The pitch precursor was ground (particle size < 45 m), pretreated in silicone oil for 30 min at 250 oC and then washed with toluene and acetone. Next, the mesophase pitch particles were dispersed in ethanol and the resulting mixture was added gradually to the colloidal silica (AS-40) suspension under vigorous stirring. The stirring was continued for five hours and the solvent was slowly evaporated. The pore imprinting procedure was carried out at 260 oC in nitrogen atmosphere for 30 minutes, followed by heating at a rate of 2 o C/min to 600 oC and 5 oC/min to 900 oC, and an isothermal treatment at 900 oC for 120 minutes in nitrogen. The carbonized sample was treated with 3M hot sodium hydroxide solution (95 oC) until silica particles were totally dissolved, which was checked by thermogravimetric analysis of the sample in air up to 1000 oC. The graphitization was carried out under protection of argon using a heating rate of 10 o C/min until the temperature of 2400 oC was reached, and it was continued for 60 min at 2400 oC followed by cooling the sample to room temperature under argon atmosphere.