Shearing Energy - Wichita State University

advertisement

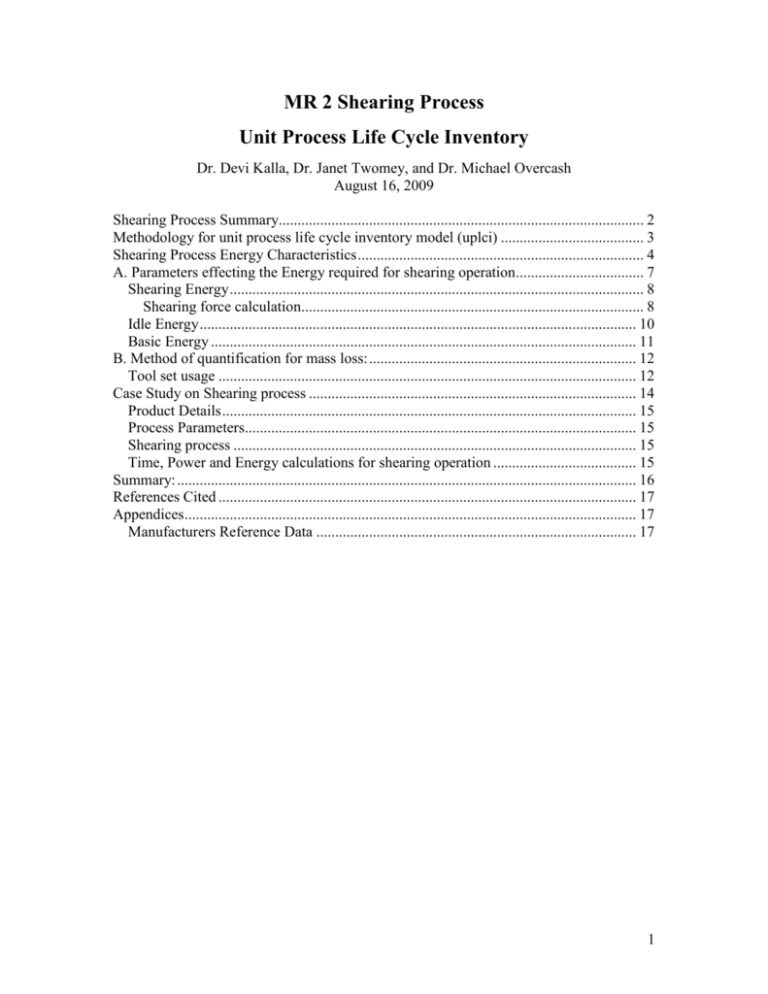

MR 2 Shearing Process Unit Process Life Cycle Inventory Dr. Devi Kalla, Dr. Janet Twomey, and Dr. Michael Overcash August 16, 2009 Shearing Process Summary................................................................................................. 2 Methodology for unit process life cycle inventory model (uplci) ...................................... 3 Shearing Process Energy Characteristics ............................................................................ 4 A. Parameters effecting the Energy required for shearing operation.................................. 7 Shearing Energy .............................................................................................................. 8 Shearing force calculation........................................................................................... 8 Idle Energy .................................................................................................................... 10 Basic Energy ................................................................................................................. 11 B. Method of quantification for mass loss: ....................................................................... 12 Tool set usage ............................................................................................................... 12 Case Study on Shearing process ....................................................................................... 14 Product Details .............................................................................................................. 15 Process Parameters........................................................................................................ 15 Shearing process ........................................................................................................... 15 Time, Power and Energy calculations for shearing operation ...................................... 15 Summary: .......................................................................................................................... 16 References Cited ............................................................................................................... 17 Appendices ........................................................................................................................ 17 Manufacturers Reference Data ..................................................................................... 17 1 Shearing Process Summary Shearing is a frequent metalworking unit process in manufacturing as a mass separating step, which involves cutting or shearing metals, as well as plates, bars, tubing of various cross sections without formation of chips. When the two cutting blades are straight, the process is called shearing. In the separating step, portions of the workpiece are “separated” from the workpiece. Hence this life cycle inventory is to establish representative estimates of the energy usage from the shearing unit process in the context of manufacturing operations for products. The shearing process is used as the preliminary step in preparing stock for stamping processes, or smaller blanks for CNC presses, Figure MR2-1. The shearing unit process life cycle inventory (uplci) profile is for a high production manufacturing operation, defined as the use of processes that generally have high automation and are at the medium to high throughput production compared to all other machines that perform a similar operation. This is consistent with the life cycle goal of estimating energy use and mass losses representative of efficient product manufacturing. Straight-blade shearing is used for squaring and cutting flat stock to a required shape and size. In straight-blade shearing, the work metal is placed between the stationary lower blade and a movable upper blade. As the upper blade is forced down, the work metal is penetrated to a specific portion of the thickness, after which the unpenetrated portion fractures and the work metal separates Figure MR2.2. Usually the clearance between the two blades is 5 to 10% of the thickness of the material, but is dependent on the material. Clearance is defined as the vertical separation between the blades, measured at the point where the cutting action takes place and perpendicular to the direction of blade movement. It affects the finish of the cut (burr) and the machine power consumption. This causes the material to experience highly localized shear stresses between the two blades. Figure MR2.1. Computer numerical control (CNC) shearing machine (Photograph from Xinya Machine tool manufacture Co.Ltd, China) 2 Figure MR2.2. Shearing Process Schematic (Todd et al., 1994) Figure MR2.3 shows an overview of the developed environmental-based factors for shearing operations. Figure MR2.3. LCI data for shearing process Methodology for unit process life cycle inventory model (uplci) In order to assess a manufacturing process efficiently in terms of environmental impact, the concept of a unit operation is applied. The unit process consists of the inputs, process, and outputs of an operation. Each unit process is converting material/chemical inputs into a transformed material/chemical output. The unit process diagram of a shearing process is shown Figure MR2.4. 3 The transformation of input to output generates five lci characteristics, a. Input materials b. Energy required c. Losses of materials (that may be subsequently recycled or declared waste) d. Major machine and material variables relating inputs to outputs e. Resulting characteristics of the output product that often enters the next unit process. Machine tool, Fixing, Cutting Fluid Work Piece Cutting Tools Cutting Fluid Energy Shearing Product after shearing Noise Waste Coolant Scrap Mist Figure MR2.4. Input-Output diagram of a shearing process Shearing Process Energy Characteristics In shearing processes the tooling and setup are relatively simple. A shear machine basically consists of a shear table, shear blades both upper and lower, workpiece holding devices, and gaging devices. Because high production shearing is a semi-continuous process, the lci is based on a representative operational sequence, in which 1) Work set-up generally occurs once at the start of a batch in production. Set-up is made on the shearing machine as the first work piece is introduced into the machine. The work piece is positioned, all drawings and instructions are consulted, and the resulting program is loaded. The total set-up time must then be divided by the size of the batch in order to obtain the set-up time per sheared part. The energy consumed during this set-up period is divided by all the parts processed in that batch and is assumed to be negligible and is discussed in the example below. 2) During loading, the workpiece is fed onto the shear table and hold-down devices are used to fix the workpiece in position. At each cut hold-down devices used for the part to be positioned correctly with respect to the cutting tool. This is at the level of Basic energy and is labeled Loading. 3) Relative movement of the cutting tool and the workpiece occurs without changing the shape of the part body (Upper blade moving downwards), referred to as Idle Energy and is labeled Handling. 4) Actual shearing process occurs and is labeled Tip Energy. 5) Upper blade moves upwards and the workpiece is repositioned for subsequent cutting, thus the energy per piece is repeated. (Idle Energy for Handling and then Tip Energy for shearing). 4 6) Put workpieces away or rearrange them for other operation and typically sent forward to another manufacturing unit process. This is at the level of Basic Energy and is labeled Unloading. The machine considered in this study is a hydraulic shear machine because the degree of control is greater compared to other shear machines like mechanical, squaring machines etc. Hydraulic machinery are machines and tools which use fluid power to do work. Hydraulic shears are actuated by a motor driven pump that forces oil into a cylinder against a piston; the movement of the piston energizes the ram holding the upper knife. Hydraulic shears are designed with a fixed load capacity. This prevents the operator from shearing material that exceeds capacity and, therefore, saves costly damage to the machine structure; this is a basic advantage of hydraulic shear (ASM International, 2002). The hold-downs are the devices that hold the workpiece firmly in position to prevent movement during shearing. The hold-down pressure must be greater than the force generated in cutting the material. These forces depend on the knife clearance, rake angle, and depth of material back piece. The back gages are adjustable stops that permit reproducibility of dimensions of sheared workpieces in a production run. Most gages are controlled electrically. The operating speeds of hydraulic shears are limited to speeds of 8-21 strokes per minute and capable of shearing a 1.5 inch plate up to 420 inch long. Computer numerically control (CNC) system permits dimensional accuracy and repeatability, increased productivity, and hands-off safe operations. For thin sheet, magnetic overhead rollers eliminate sag and support the sheet for accurate gaging. In this representative unit process, the life cycle characteristics can be determined on a per shear basis or on a per piece basis if there are multiple shearing steps per piece. Since this is a high production process, the start up (at the beginning of a batch or shift) is deemed to be small and not included. In this uplci, there are three typical power levels that will be used, Figure MR2.5. Correspondingly, there are times within the shearing sequence from which these three power levels are used, Figure MR2.5. 5 P Servo motor for axis drive Idle Energy Tip Energy Basic Energy Ptotal Pidle Pbasic tshearing t tidle tbasic Figure MR2.5. Determination of power characteristics and energy requirements of Shearing machines. The steps 2), 3), 5), and 6) are estimated as representative values for use in this unit process lci and energy required of cutting material by shearing, step 4), is either measured using shearing force values. High production shearing operation involves multiple sub-operations illustrated in Table MR2.1. There are thus many variables which have some influence on the overall energy of the shearing unit process. The system boundaries are set to include only the use phase of the shearing machine, disregarding materials processing, production, maintenance and disposal of the machine. Stock decoilers, straighteners, feeders, part handling, and scrap removal systems are known as shearing machine auxiliary equipments. Moreover, the functioning of the manufacturing machines is isolated, disregarding the influence of the other elements of the manufacturing system, such as material handling systems, feeding robots, etc. Other consumables such as lubricants and coolants are included. 6 Table MR2.1 Machine Units and its functions Energy Consuming Units M1 M2 Hydraulic pump1 (Main Pump with continuous circulation) Hydraulic pump2 Drives Axis Movement servo motors PC computer+control panel1 (screen etc) Machine operation (pedal with instruments) Functions Type of Energy Move the pistons connected to the blades basic Clamp the dies basic Move backguage with respect to the table idle basicControl Panel2 basic The energy consumption of shearing is calculated as follows. Etotal = Pbasic * (tbasic ) + Pidle * (tidle) + Pshearing * (tshearing) (Basic energy) (Idle energy) (Shearing energy) (1) where power and time are illustrated in Figure MR2.5. A. Parameters effecting the Energy required for shearing operation An approximate importance of the many variables in determining the shearing energy requirements was used to rank parameters from most important to lower importance as follows: 1. Thickness of the material 2. Mechanical properties of the sheet metal 3. Length of shearing 4. Knife penetration 5. Speed of the punch 6. Clearance 7. Bottom force 8. Geometry 9. Production rate 10. Friction at the punch, die, and workpiece interfaces. 11. Machine energy during standby and idling From this parameter list, only the top 5 were selected for use in this unit process life cycle with the others having lower influence on energy. Energy required for the overall shearing process is also highly dependent on the time taken for idle and basic operations. 7 Shearing Energy Shearing time (tshearing) and power (Pshearing) must be determined for the shearing energy and it is calculated from the more important parameters given above. Shearing setup is illustrated in Figure MR2.6. Actual shearing process time is the thickness of the sheet metal divided by shear blade velocity (shear speed, mm/sec). In order to shear a sheet metal, the blade must pass through the thickness of the workpiece. This means the travel of the blade is more than the thickness of the sheet. Thus in actual practice, we add the thickness of the sheet “T” to the length of approach and length of shear to give overtravel for the calculation of total time. Figure MR2.6. Shearing setup Shear blade velocity mm/sec (in/sec) = V workpiece thickness mm(in) = T Length of the cut mm (in) = L Feed rate of stock to be sheared mm/sec (in/sec) = F Width of the stock to be sheared mm (in) = W T Shearing time (tshearing) = V (2) Shearing force calculation Shearing force for straight-knife is basically the product of the shear strength of the sheet metal and the cross-sectional area being sheared. Shearing force Fs for straight blades in metalworking can be determined by (George et al., 2000): S * P * T 2 *12 P (3) Fs 1 R *100 2 Where, Fc = Shearing force lbf S= shear strength of the sheet metal, Psi T= stock thickness, in. and R = rake of the knife blade, in./ft. Standard blade rakes are 1/4, 3/8, 1/2, 5/8, 3/4 and 7/8 in./ft. P = penetration of knife into material, fraction of T (range 0 – 1) Rake is the angular slope formed by the cutting edges of the upper and lower knives. It has been found that increase in rake leads to a corresponding nearly linear decrease in shearing force (Cincinnati, Inc and Hydrapower International, personal communications, 8 2009). Thus the energy equation can be simplified, so that a rake angle does not have to be specified. Thus the effective energy FS is dependent on S, P, and T as given in (4). S * P * T 2 *12 P Fs 1 100 2 (4) Where, Fs = Shearing force lbf S= shear strength of the sheet metal, Psi T= stock thickness, in. and P = penetration of knife into material, fraction of T (range 0 – 1) For metric usage, the force is multiplied by 4.448 to obtain newtons (N). Table MR2.2. Values of percent penetration and shear strength for various materials (Kalpakjian, et al., 2008) Material Lead alloys Tin Alloys Aluminum Alloys Titanium Alloys Zinc Cold worked Magnesium alloys Copper Cold worked Brass Cold worked Tobin bronze Cold worked Steel, 0.10%C Cold worked Steel, 0.40%C Cold worked Steel, 0.80%C Cold worked Steel, 1.0%C Cold worked Silicon steel Stainless steel Nickel Percent Penetration (%) 50 40 60 10 50 25 50 55 30 50 30 25 17 50 38 27 17 15 5 10 2 30 30 55 Shear Strength, psi (MPa) 3500 (24.1) – 6000 (41.3) 5000 (34.5) – 10,000 (69) 8000 (55.2) – 45,000 (310) 60,000 (413) – 70,000 (482) 14,000 (96.5) 19,000 (131) 17,000 (117) – 30,000 (207) 22,000 (151.7) 28,000 (193) 32,000 (220.6) 52,000 (358.5) 36,000 (248.2) 42,000 (289.6) 35,000 (241.3) 43,000 (296.5) 62,000 (427.5) 78,000 (537.8) 97,000 (668.8) 127,000 (875.6) 115,000 (792.9) 150,000 (1034.2) 65,000 (448.2) 57,000 (363) – 128,000 (882) 35000 (241.3) 9 Shearing force Fs for all non-straight tools in metalworking can be determined by: Fs=LTS (for any shape cut) Where L is sheared length, in inches (mm); T is material thickness, in inches (mm); S is shear strength of material, in pounds per square inch (MPa); and D is diameter, in inches (mm). So for circular shear Fs=πDTS (for round holes) The product of force and the distance moved gives the energy associated with that particular operation. Using the shearing force calculated in the above, we can estimate the energy required to perform the operation by using the following: E = Fs L (5) Where: E = Energy (inch lbf /shear) Fs = Shearing force, lbf L = sheared length, in. For metric usage, the energy is multiplied by 0.113 (4.448*25.4/1000) to obtain joules (J). Power required for shearing process P = Fs*V Where V = shear blade speed in/sec or (mm/sec) (machine specification) The shearing energy is thus E (Joule/shear) = shearing time*Pshearing With a given material to be sheared, shear strength given in Table MR2.2. Thus with only the material to be sheared, the thickness of the workpiece, and the length of shear, one can calculate the lci shearing energy per shear, equation 5. This then must be added to the idle and basic energies, see below. Idle Energy Energy-consuming peripheral equipment included in idle power (Pidle) are shown in Table MR2.1. The idle power characterizes the load case when there is relative movement of the tool and the work-piece without separating the metal (e.g. axis movement) - Handling. For shearing, the handling times are the air time of approach and retraction after shearing. The idle time (tidle) is the sum of the handling time (thandling) and the shearing time (calculated above as tshearing, equation 1), see Figure MR2.5. For shearing machines, the handling times are the air time of approach and retraction after shearing. We can calculate the handling times and energy as follows. Idle energy = [ timehandling + timeshearing]* Pidle (6) During the shearing process, the tool is considered to be at an offset of 6 times the thickness above the work piece and so the approach distance is 6T. We also assume the overtravel is 6T. Every time while shearing a sheet the blade comes down from a height of 6T and again retracts back to an offset position after completing the shearing process with a vertical traverse speed (VTR). The approach and overtravel distance used here is 10 12 times the thickness of the sheet and so the shearing approach and overtravel time is 12*T/ V. While the retraction time may be longer than the shearing time, this is estimated as the sum of the approach, overtravel, and shearing times. We use the machine retract rate (mm/sec) and the approach and overtravel distances to establish the handling time. In the handling time, the feeding time is also be added for continuous processes, but this uplci is for the more common batch loading. From Figure MR2.6 Approach distance mm(in) = A Overtravel distance mm(in) = O Retract rate mm/sec (in/sec) = R Feeding time = W/F for next cut Time for handling is Approach + Overtravel + retraction times = timehandling (7) AO Approach and overtravel time = = 12*T/ V V T AO Retract time = = 13*T/ VTR VTR The shearing time was previously calculated and is not included in the handling time. timeidle = thandling + tshearing (8) From these calculations the idle energy for shearing with a single shear cut is E (Joule/shear) = (tapproach/overtravel + tretraction) + tshearing]* Pidle (9) The average idle power Pidle of automated CNC shearing machines is between 400 and 10,000 watt*. (* This information is from the CNC manufacturing companies, see Appendix 1). Approximately Handling time will vary from 0.1 to 10 min. Basic Energy The basic energy of a shearing machine is the demand under running conditions in “stand-by mode”. Energy-consuming peripheral equipment included in basic energy are M1, M2 and PC from Table MR2.1. There is no relative movement between the tool and the work-piece, but all components that accomplish the readiness for operation (e.g. machine control unit (MCU), unloaded motors, servo motors, pumps) are still running at no load power consumption. Most of the automated CNC shearing machines are not switched off when not shearing and have a constant basic power. The average basic power Pbasic of automated CNC machines is between 400 and 6,000 watt* (* From CNC shearing machine manufacturing companies the basic power ranges from 1/8th to 1/4th of the maximum machine power, see Manufacturers Reference Data in Appendix). The largest consumer is the hydraulic power unit. Ostwald, 1986 has shown that the time to load a blank or part into a machine and then remove the part is proportional to the perimeter of the rectangle which surrounds the part. This time can be given by t = 3.8 + 0.11 (L + W) (seconds) Where L, W = rectangular envelope length and width, cm. In summary, the unit process life cycle inventory energy use is given by 11 Etotal = Pbasic * (tbasic ) + Pidle * (tidle) + Pshearing * (tshearing) (10) This follows the power diagram in Figure MR2.5. With only the following information the unit process life cycle energy for shearing can be estimated. 1. material of part being manufactured 2. Thickness of the sheet 3. Length of the shear 4. Table MR2.2 B. Method of quantification for mass loss: For ordinary shearing operations such as straight cutting, coolant oil is not commonly used. Hydraulic shearing machines use fluid power to do work. In this machine, high pressure liquid called hydraulic fluid is transmitted throughout the machine to various hydraulic motors and hydraulic cylinders. In addition to transferring energy, hydraulic fluid needs to lubricate components, suspend contaminants and metal filings for transport to the filter, and to function well to several hundred degrees Fahrenheit. Hydraulic fluid replacement occurs so infrequently that on a per shear or per 1,000 shear basis, this mass loss is neglected. Lubricant oil is commonly (but not always) used on the metal surface in contact with the knife. Lubricant is applied along the sheared line and then is some subsequent processing step, it is removed before a final product is used. In order to link this mass loss directly to shearing, it is included here. Note the energy or ancillary waste for lubricant removal (solvent degreasing, rag wipe, etc) would be captured in the uplci of those processes and only the lubricant mass is assigned to shearing. Lubricant applied and removed is estimated (Madavan, Wichita State University, 2009, personal communication) as 5cm width x L (cm) x (2.54/1000) cm thickness x 0.9 g/cm3 = 0.11 g/cm length of shear. Tool set usage Tool Life information can be found from the cutting tool manufacturer. For shearing harder or thicker metals, blades with hardnesses nearer the low end of this range are used in order to compensate for increased shock loading. Table MR2.3 gives some typical hardnesses of blades used in ten different plants for cold shearing of specific ferrous and nonferrous products. Service data on life of shear blades are scarce because maintenance programs employed in most high-production mills call for removal and redressing of blades, regardless of condition, during scheduled shutdowns. Available data report blade life in terms of number of cuts, linear footage (in slitting), tonnage, or time between redressings. The service data in Table MR2.3 encompass all of these variables. Hard-faced blades are satisfactory, and in some plants are used exclusively, for hot shearing. Table MR2.4 summarizes data on blade life in one steel plant where hard-faced blades are used for most hot shearing operations (ASM International, 2002). With these 12 large number of shear cuts between regrind and even longer between actual replacement of the shearing blades, the shearing blade as is not included as a waste. Table MR2.3. Service data for shear blades (ASM International, 2002). Type of Shear Material Thickness of material sheared mm Blade steel Blade Blade service Hardness before regrind HRC Cold shearing of steel Sheet metal Low-carbon steel 5 W2 58-60 30,000 cuts Sheet metal Low-carbon steel 5 A2 58-60 55,000 cuts Sheet metal Low-carbon steel 5 D2 58-60 100,000 cuts Bar shear 1025 & 1040 steel 25 W2 58-60 20,000 cuts Bar shear 1025 & 1040 steel 25 L6 40,000 cuts Bar shear 1025 & 1040 steel 25 S5 100,000 cuts Sheet and strip 1010 steel 5 D2 58-60 150,000 cuts Sheet and strip Stainless steel 12 D2 58-60 65,000 cuts Sheet 2 to 5% silicon steel 0.8 D2 58-60 45,000 cuts Slitter carbon, silicon and galvanized 0.16-4 D2 58-60 1 week (a) Slitter Stainless steel 0.8-1.5 D2 58-60 15,000 ft Blade 1.5 x 100 x 25 mm Stainless silicon steel 2-2.5 D2 60-62 2 weeks (b) steels Hot shearing of steel Slab shear various steels 30,000-40,000 tons Cold shearing of copper alloys Sheet Brass 0.16-5 S1 54-58 5,000 cuts Slab Brass 25-60 S1 54-58 25,000 cuts upto 45 H11 42 15,000 cuts Hot shearing of copper alloys Slab Brass Hot shearing of aluminum alloys Automatic flying cutoff shear Aluminum, alloys 7 H25 43-46 10,000 cuts 75 mm shear Aluminum, alloys 76-140 H25 43-46 17,000-20,000 Cuts (a) Blades were reground weekly, with about 0.025 mm of stock being removed. (b) Maximum. Blades usually were changed weekly. 13 Table MR2.4. Life of hard-faced blades for hot shearing of steel in a specific steel mill (ASM International, 2002). Steel for blade Hard facing Blade life, tons of steel Type of shear (a) body alloy sheared Billet, 300 by 300 mm (12 1030 cast by 12 in.) 1B new, 2B repair, 29,000 3A ribs Billet, 250 by 250 mm (10 1030 forged by 10 in.) 2B 5,800 Billet duplex 1030 cast None; inserts of H21 or M2 26,000 Billet H21 None 3,584 Bloomer, 1 m (40 in.) 1045 plate 1B new, 2B repair 7,680 Bloomer, 1.1 m (44 in.) 1045 plate 1B 87,000 Slab, 900 mm (36 in.) 1045 plate 1B 71,000 Plate 6150 (mod) None 6,000 Rail, 250 by 250 mm (10 by 10 in.) 1030 cast 1B new, 2B repair, 12,960 3A ribs Rail 1045 plate 2B 5,400 Billet 1045 plate 2B 10,800 (a) Nominal compositions. Alloy 1B: 0.5 C, 0.9 Si, 4.75 Cr, 1.2 W, 1.4 Mo, rem Fe. Alloy 2B: 0.75 C, 0. 5 Mn, 0.65 Si, 4 Cr, 1 V, 1.2 W, 8 Mo, rem Fe. Alloy 3A: 3 C, 1 Si, 28 Cr, 4 Mo, rem Fe Case Study on Shearing process In this report we analyze the detailed energy consumption calculations in shearing process. The shearing process is performed on BAILEIGH CNC shearing machine (BP – 5060). The machine specifications are listed below: Table MR2.5 Machine specification Specifications BAILEIGH Model Number BP-5060 Max. shearing force, kN 500 Approach Speed, in/sec 3.15 Shearing Speed (V), 0.28 in/sec Return Speed, in/sec 2.4 Main motor, kW 3.7 Motor 2, kW 0.4 3 Axes motor 0.75 output(X,Y,Z), kW Total Maximum Power 6kW consumption 14 Product Details For this example we are assuming a steel sheet (0.1 Carbon cold worked) as the work piece. The work piece is of sheet-metal part of 0.25 X 120 X0.8 (T x L x W) in. has a shear strength of 43,000 psi. The steel chart also tells us for this grade steel the elongation factor is 38%. The term “rake” is used to designate the angel of the upper blade and is usually expressed in inches per foot. A 1/4-inch rake means that the upper blade slopes at a rate of 1/4 inches per foot of length. The objective of the study is to analyze the energy consumption in shearing machine. Process Parameters The shearing conditions and the process parameters are listed in Table MR2.6. Table MR2.6. Process Parameters for Example Case Process Conditions Sheet thickness (T) 0.25 in Shear strength (S) 43,000 psi Penetration 38% Rake, in/ft 0.25 Length, in 120 Width, in 0.8 Feed, F in/sec 0.4 Shearing process During shearing operation the tool is considered to be at an offset of 1.5 in (6 times the workpiece thickness) above the workpiece. Every time while shearing the blade comes down from a height of 1.5 in. Similarly we assume the overtravel to be 1.5 in. It retracts (T+1.5+1.5) in. back to the offset position after completing the shearing process. Time, Power and Energy calculations for shearing operation The total processing time can be divided into the 3 sub groups of basic time (Load and Unload), idle time (Handling), and shearing time. Shearing time: The time for shearing is determined by ts = (T)/V (sec) Where V is the Shear blade speed in mm/sec, and T is the thickness in mm. T = 0.25 in V = 0.28 in/sec Time to shear will be, ts = (0.25)/ 0.28 = 0.9 sec/shear Energy required for each shear, E = L * Fs 15 The force required for shearing a 0.135 in thick and 120 inch long of a steel sheet (0.1 Carbon cold worked) can be estimated using the following calculation: S * P * T 2 P 1 Fs R 2 Fs = 43,000 * (0.38) * (0.25)2 *12 * (1-0.38/2) = 39,706 lb or 176.62 kN 0.25 Shearing energy for each shear E = 39,706 * 120 = 47,64,720 inch-lbf or 538.34 kJ Power required P = Fs * V = 39,706 * 0.28 = 11,117.68 in-lb/sec or 1.26 kW Idle Time: Handling Time: The air time for shearing is approach, feeding and retracts time Approach time = 0.7/3.15 = 0.225 sec Retracts time = 18 + D /60 = 25.5/60 = 0.425 sec Total air time = 0.65 sec Total idle time = tshearing + tair = 0.65+0.9 = 1.55 sec Idle power from Appendix 1 can be assumed as = 2.5 kW Idle energy = 2.5 * 1.55 = 3.875 kJ/shear Basic time: Loading and unloading time t = 3.8 + 0.11 (L + W) = 3.8 + 0.11 (304.8 + 2) = 37.55 sec Pbasic = 1.25 kW Ebasic = Pbasic * ttotal ttotal = tbasic + tidle = 37.55 + 1.55 = 39 sec Ebasic = 1.25 * 39 = 48.75 kJ Etotal = 538.34 + 3.875 + 48.75 = 590.96 kJ Summary: This report presented the models, approaches, and measures used to represent the environmental life cycle of shearing unit operations referred to as the unit process life cycle inventory. The four major environmental-based results are energy consumption, shearing process, lubricant oil, and cutting tool. Calculations for product manufacturing are presented, based on knowing only the cutting length, number of cutting, and the material sheared. The life cycle of shearing is based on a typical high production scenario (on a CNC shearing machine) to reflect industrial manufacturing practices. The energy can be calculated from a basic list of variables, likely to be known for each part to be brake formed 1. material of part being sheared and Table MR2.2 2. thickness of the material 3. length of the sheet to be sheared 4. Shearing speed, using representative manufacturers’ values 16 References Cited 1. Abele, E.; Anderl, R.; and Birkhofer, H. (2005) Environmentally-friendly product development, Springer-Verlag London Limited. 2. ASM International. (2006) Metalworking: Sheet Forming Hand book, Vol. 14B, American Society of material. 3. Clarens, A.; Zimmerman, J.; Keoleian, G.; and Skerlos, S. (2008) Comparison of Life Cycle Emissions and Energy Consumption for Environmentally adapted Metalworking Fluid Systems, Environmental Science Technology, 10.1021/es800791z. 4. Erik Oberg. (2000) Machinery’s Handbook, 26th Edition, Industrial Press. 5. George, F.S; and Ahmad, K. E. (2000) Manufacturing Processes & Materials, 4th Edition, Society of Manufacturing Engineers. 6. Groover, M.P. (2003) Fundamentals of Modern Manufacturing, Prentice Hall. 7. Kalpakjian, S.; and Schmid, S. (2008) Manufacturing Processes for Engineering Materials, 5th Edition, Prentice Hall. 8. Piacitelli, W.; Sieber, et. al. (2000) Metalworking fluid exposures in small machine shops: an overview, AIHAJ, 62:356-370. 9. Phillip Ostwald. (1991) Engineering cost estimating, 3rd Edition, Prentice Hall. 10. Schuler GmbH. (1998) Metal forming Handbook, 1st Edition, Springer. 11. Todd, R.; Allen, D.; and Alting, L. (1994) Manufacturing processes reference guide, Industrial Press, New York. 12. Tschatsch, Heinz. (2006) Metal forming practice: Processes-machines-tools, Springer. 13. Wlaschitz, P. and W. Hoflinger. (2007) A new measuring method to detect the emissions of metal working fluid mist, Journal for Hazardous Materials, 144:736-741. Appendices Manufacturers Reference Data The methodology that has been followed for collecting technical information on CNC machines has been largely based in the following: The documentation of the CNC shearing machine and the technical assistances collected from the manufacturing companies through internet. The shearing machines are brakeforming machines with a change in the moving tool and so the same machine data as brakeforming is included here. Several interviews with the service personnel of the different CNC manufacturing companies have been carried out. After collecting the information from the different companies it has been put together in the relevant document that describes the different approaches the different companies have regarding the technical information on the CNC shearing machine. Telephone conversations allowed us to learn more about basic power and idle power. Companies that involved in our telephone conversations are Baileigh, Ronmack, Trumpf, and Cincinnati. These companies manufacture different sizes of 17 CNC machines, but this report shows the lower, mid and highest level of sizes. For our case study we picked machine at the highest-level. Specifications Model Number Shearing force, kN Approach Speed, mm/sec Shearing Speed, mm/sec Return Speed, mm/sec Main motor, kW Motor 2, kW 3 Axes motor output(X,Y,Z), kW Specifications Model Number Shearing force, kN Approach Speed, mm/sec Shearing Speed, mm/sec Return Speed, mm/sec Main motor, kW Motor 2, kW 3 Axes motor output(X,Y,Z), kW Specifications Model Number Shearing force, kN Approach Speed, mm/sec Shearing Speed, mm/sec Return Speed, mm/sec Main motor, kW Motor 2, kW 3 Axes motor output(X,Y,Z), kW Specifications Model Number BP-3360 330 80 7 60 2.2 0.4 0.75 RM-2050 600 120 9 100 5.5 1 1 TB V-50 560 150 12 120 6 1 1 90MX6 BAILEIGH BP-5060 500 80 7 60 3.7 0.4 0.75 RONMACK RM-3100 1500 120 9 80 11 1 1 TRUMPF TB V-130 1440 150 12 120 18 1 1 CINCINNATI 175MX10 BP-9078 900 80 7 60 7.4 0.4 0.75 RM-8000 5000 120 9 80 37 1 1 TB V-320 3570 150 12 120 35 1 1 350MX12 18 Shearing force, kN Approach Speed, mm/sec Shearing Speed, mm/sec Return Speed, mm/sec Main motor, kW Motor 2, kW 3 Axes motor output(X,Y,Z), kW 500 300 1200 275 4000 250 30 200 15 2 1 25 180 20 2 1 20 150 25 2 1 19