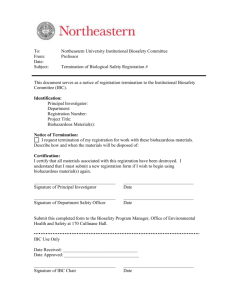

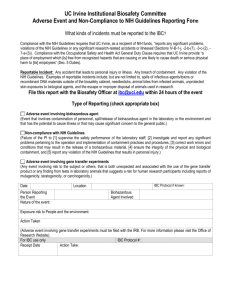

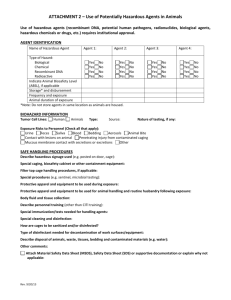

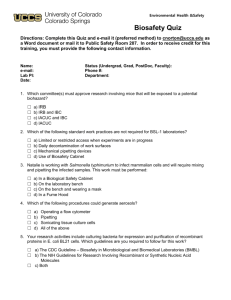

SECTION II - Biohazardous Research - URSA

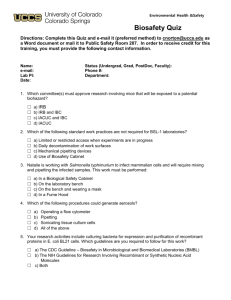

advertisement