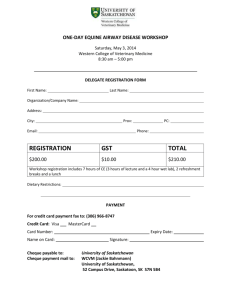

The Operations Plan - University of Saskatchewan

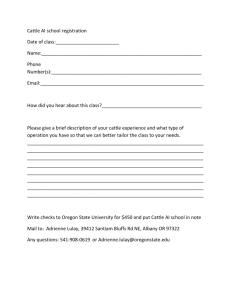

advertisement