24-71-1-RV

advertisement

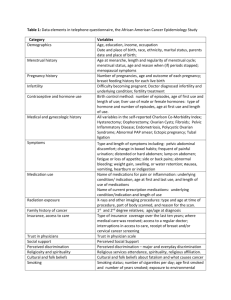

THE LUBRICANT PROPERTIES OF SOME LOCAL TALC DEPOSITS IN SOUTH WESTERN NIGERIA Tolulope O. Ajala 1, Oluwatoyin A. Odeku 2* 1 Department of Pharmaceutics and Pharmaceutical Technology, Faculty of Pharmacy, Olabisi Onabanjo University, Sagamu, Nigeria 2 Department of Pharmaceutics and Industrial Pharmacy, Faculty of Pharmacy, University of Ibadan, Ibadan, Nigeria *Corresponding Author pejuodeku@yahoo.com; o.odeku@mail.ui.edu.ng Tel: 234 8057320466 1 Abstract The lubricant properties of local talc samples from three different locations in south western Nigeria have been investigated in comparison with talc BP in lactose tablet formulations. The effect of the addition of 1% magnesium staterate on the lubricant activity of the local talc samples was also evaluated. Lactose tablets were formulated by wet granulation method and three concentrations (5, 7.5 and 10%w/w) of the local talc samples were mixed with the granules before compression. The three concentrations of local talc samples were also mixed with 1%w/w magnesium stearate and used as lubricant. The weight variation, crushing strength, friability, the crushing strength-friability ratio (CSFR) disintegration time tablets were assessed. The results showed that the crushing strength and disintegration time increased with increase in lubricant concentration while the friability decreased. The local talc samples were found to possess good lubricant activity similar to talc BP and the lubricant activity was improved by the addition of 1% w/w magnesium stearate although there was a significant (p<0.001) increase in the disintegration time of the tablets. The local talc samples could be useful as a lubricant in pharmaceutical tablet formulations. However, further processing might be necessary to improve their physicochemical properties and lubricant activity. Keywords: Talc, lubricant, tablets, magnesium stearate, mechanical properties, disintegration time 2 Introduction Most pharmaceutical formulations include a certain amount of lubricant to improve their flowability and prevent their adhesion to the surfaces of processing equipment. Lubricants reduce friction by interposing an intermediate layer between the tablet constituents and the die wall during compression and ejection. They also prevent sticking of granules to the tooling (antiadherent) and improve granule flow properties (glidant)1,2. A given lubricant may provide one or more of these actions to varying degrees but no one material is highly efficient in all categories. Accordingly combinations of lubricants are often selected to provide the necessary total lubricant effect and a careful selection is necessary since some lubricants may interact adversely when in combination3. Talc is used in the pharmaceutical industry as a lubricant in tablet formulations, drycoating of oral tablets and as filter medium. It is a naturally occurring hydrous magnesium silicate with the chemical formula Mg3Si4O10 (OH)2. Chemically, talc ores are made up of SiO2, MgO, Fe2O3 and minor Al2O3. Structurally, talc is comprised of a sheet of brucite or Mg (OH)2 sandwiched between SiO2 sheets. The elementary sheets are weakly bonded to each other. As a result the layers slide apart with minimal force giving talc its inherent softness and lubricity 4. Talc is naturally hydrophobic which contributes to its functional lubricity. It can withstand temperatures up to 1300ºC and has low electrical and thermal conductivity. Talc can be easily powdered, cut and sawn into any shape and size and is found in three forms: fibrous, non-fibrous and massive. The fibrous variety consists of rich proportions of tremolite, anthophyllite, and serpentine. The non-fibrous variety contains mostly of serpentine and carbonates5. Talc tends to form in plates and this platy structure gives its reinforcing performance properties in plastics6. Talc lubricant efficiency in plastic deforming binders/fillers increases with decreasing particle size and increasing surface area7. Magnesium stearate when used as tablet lubricant has been found to retard the dissolution of salicylic acid from model compressed tablets8. However, talc has been used effectively in combination with magnesium stearate to restore the disintegration and dissolution properties impaired by magnesium stearate9. Talc deposits are available in several parts of Nigeria and an estimated reserve of over 100 million tons of talc has been obtained in Nigeria10. Research has shown that talc samples from some states in Nigeria complied with the British Pharmacopoeia (BP) standard11 indicating it’s potential as local source of pharmaceutical grade talc. However, the usefulness of this locally available talc in pharmaceutical formulations has remained widely uninvestigated. The development of local starch will provide a more readily available, cheaper alternative which could serve as valuable substitutes to the imported talc in the pharmaceutical industry. Thus in the present study, talc samples obtained from three locations in two states (Ogun and Osun) in Southwestern region of Nigeria have been evaluated as lubricant in lactose tablet formulations and compared with purified talc BP. The effect of the addition of 1% magnesium staterate on the lubricant activity of the local talc samples was also evaluated. Materials and Methods Materials The materials used were corn starch (Hopkins and Williams, Chadwell, Heath Essex, UK), lactose (DMV Veghel, Netherlands), purified talc B.P (Riedel-de Haen AG D-30167 Seelze, Germany) and magnesium stearate (Hopkin and Williams, Chadwell, Health, Essex, UK). All other reagents were analytical grade. The local talc samples were obtained from three 3 locations Apomu (Osun state), Iregun (Osun state)) and Oshosun (Ogun state)) in Nigeria and purified at the Department of Geology, Obafemi Awolowo University, Ile-Ife, Nigeria and referred to as TAP, TIR and TOS respectively according to their sources. The talc samples were crushed using a mortar and pestle and then sieve through a 250µm mesh sieve. Methods Physicochemical analysis of local talc samples The physicochemical properties of the local talc samples were determined to ascertain compliance with compendia specifications for purified talc BP. Tests carried out include macroscopy, microscopy, solubility and chemical tests (BP, 1998). Preparation of granules Batches of lactose granules were prepared with varying concentrations (5.0, 7.5 and 10.0%w/w) of the local talc sample (TAP, TIR, TOS) and purified talc B.P (TBP) (5% w/w) as a standard. Granules containing the local talc samples in addition to 1% w/w magnesium stearate were also prepared. Batches (200g) of a basic formulation of lactose (85% w/w) and cornstarch (10% w/w) were dry mixed in a Z-blade mixer (Erweka apparatebau AR 400, Germany) for five minutes and then moistened with 5% w/w of binder solution (corn starch mucilage). The wet masses were granulated by passing the wet mass manually through a number 12 mesh sieve (1400µm) (Endecotts Ltd, London, UK) and dried in a fluidized bed drier (7859 Glatt, Germany) at 450C until the moisture content as determined using an Ohaus moisture balance (Ohaus Scale Corporation, USA) was 1.3%. The granules were then screened through a No 16 mesh sieve (1000µm) and stored in air-tight containers. Preparation of Tablets To each batch of granules the appropriate amount of lubricant was added and dry mixed for 5minutes. Tablets (600mg) were prepared from the granules (500-1000 µm) by compressing the materials at a pressure of 75Kg/cm2 in a single punch tabletting machine fitted with a 12mm flat faced punch and die set (Diaf Copenhagen NV, Denmark). After ejection, the tablets were stored over silica gel for 24hours to allow hardening and elastic recovery. Weight Uniformity, Crushing Strength and Friability Tests The weight of ten tablets was determined by weighing each tablet individually on an electronic balance and the mean weight calculated. The Crushing Strength (CS) of the tablets was determined at room temperature by diametral compression using a PTB 301 hardness tester (Pharmatest, Switzerland). The friability (F) of the tablets were determined using a Friabilator (Model TF 20, Scientific Equipment Ltd., Bombay, India) operated at 25 revolutions per minute for 4 minutes. Disintegration Test The disintegration time (DT) of the tablets was determined in distilled water at 37±0.5ºC using an Erweka disintegration test apparatus (Model: Copley ZT2, Erweka Apparatebau GMBH, Heusenstamm, Germany). 4 Statistical Analysis Data analyses were done using Analysis of Variance (ANOVA). At 95% confidence interval, p-values less than or equal to 0.05 were considered significant. Results and Discussion The physicochemical properties of the talc samples are shown in Table 1. The results indicate that the local talc samples appear to be similar in terms of their physical and chemical properties. However, there were differences in their % loss on drying and the average plate length. TOS exhibited the highest moisture content as measured by the loss on drying indicating higher moisture content compared to the other talc samples. It has been found that talc samples from different locations vary in their physicochemical properties such as colour, size and moisture content4. The local talc samples passed all the official tests for talc except that the colour was not pure white like that of purified talc BP. This may be due to incomplete removal of the impurities during the purification process. This also affected the appearance of all tablets compressed with local talc as lubricants which were grayish in colour compared to the white tablets obtained with purified talc BP. The intensity of the colour increased with increase in the concentration of local talc used. Lubricants such as magnesium stearate have been shown to form monolayer which could prevent granule separation with subsequent reduction in weight variation1. The results of the properties of the lactose tablets produced using the various talc samples as glidant are presented in Table 2. The result shows that the tablets complied with the BP standard for weight variation in that not more than 5% deviation was observed from the mean except for tablets prepared using 10%w/w local talc samples which had deviations of about 8 %. However, tablet prepared using purified talc BP as lubricant showed 1% deviation. It has been reported that any tablet excipient which can improve flowability of tablet granulation would produce hard and less friable tablets because the granules become more compact13. The results indicate that the crushing strength (CS) and CSFR (Crushing StrengthFriability Ratio) of the tablets increased with increase in the concentration of the lubricants while the friability (F) decreased. The ranking of the parameters for the talc samples obtained from the different sources depended largely on the source and concentration of talc used in the formulation. The ranking of CSFR was generally TIR>TOS>TAP. Thus, TIR which showed the lowest plate length (61.27micron) gave tablets with higher mechanical properties. The platy nature of talc, the slipperiness that results from its crystalline structure, its softness and hydrophobicity have been shown to contribute to its performance as a glidant and lubricant in tableting. The effectiveness of talc glidant activity has been shown to be dependent particle size, surface area and the concentration of the fine particles14. The lower the particle size, the better the performance15. However, there was no significant (p<0.05) difference between the CSFR values of the tablets prepared using the various lubricants. Furthermore, it was observed that during the compression of tablets containing 5%w/w talc lubricant, a loud screeching sound was made by the tableting machine and there was about 4.5% capping of the tablets which was not observed with tablets made with talc BP. There was a reduction in the sound and capping with an increase in the concentration of the local talc samples. Tablets containing 10%w/w of the local talc samples gave smoother and glossier tablets compared to the tablets prepared using lower concentration of lubricant. 5 Lubricants are often used in combination to improve their efficiency and provide better total lubricant effect. Magnesium stearate, one of the most frequently used lubricants, is hydrophobic and is capable of forming films on other tablet excipients during prolonged mixing, leading to a prolonged drug liberation time, a decrease in hardness, and an increase in disintegration time16. Talc has been used effectively in combination with magnesium stearate to restore disintegration and dissolution properties impaired by magnesium stearate9. Thus, the effect of 1% magnesium stearate on the lubricant activity of the local talc samples was investigated and the results of the tablet properties are presented in Table 3. The results show that CS increased with increase in the concentration of lubricant while the friability decreased and the screeching sound produced by the tableting machine was reduced and more elegant tablets were obtained. There was also a decrease in the weight variation of the tablets indicating better glidant activity. The addition of 1%w/w of magnesium stearate to the local talc samples led to a slight increase in the mechanical properties of the tablets but a significant (p<0.001) increase in the disintegration time of the tablets. This could be due to the effect of magnesium stearate which has the ability of forming a monolayer and subsequent prevention of granule separation thus production of more compact tablets17. Hence, the addition of magnesium stearate improved the glidant properties of the local starch samples. The CSFR/DT ratio has been found to be a better index for measuring tablet quality because in addition to measuring tablet strength (crushing) and weakness (friability), it simultaneously evaluates the negative effects of these parameters on disintegration time18. In general, higher values of the CSFR/DT ratio indicate a better balance between binding and disintegration properties19. The CSFR/DT of the tablets generally increased with increase in the percentage of the lubricant when only local talc samples was used. However, when 1% w/w magnesium stearate was added the values of CSFR/DT reduced significantly (p<0.001), indicating less balance between the binding and disintegration properties of the tablets. On the other hand, the glidant mixture of talc BP and magnesium stearate still showed a better balance. Conclusion The results indicates that the local talc samples possess good lubricant activity similar to talc BP and the lubricant activity was improved by the addition of 1% w/w magnesium stearate although there was a significant increase in the disintegration time of the tablets. The local talc samples could be useful as lubricant in pharmaceutical tablet formulations. However, further processing might be necessary to improve their physicochemical properties and lubricant activity. References 1. Train, D., Hersey, J.A. The use of laminar lubricants in compaction processes, J. Pharm. Pharmacol., 1960, 12, 97T-104T. 2. Staniforth, J. N., Aulton, M. E. Powder flow. In: Aulton’s Pharmaceutics. The design of medicines. Aulton, M. E., (Ed.), 3rd edn. Harcourt Publishers Ltd. Philadelphia USA, 2007, pp: 169 - 179. 3. Moody, G., Rubinstein, M. H., Fitz Simmons, R. A. Tablet lubricants I. Theory and modes of action, Int J Pharm Int. J. Pharma 1981, 9(2), 75-80. 4. Nkoumbou, C. F., Villieras, O. B., Bihannic, M. P., Razafitianamaharavo, A. V., Metang, C. Y., Njopwouo, D., Yvon J. Physicochemical properties of talc ore from Pout-Kelle and Memel deposits (central Cameroon) Clay Minerals, 2008, 43 (2), 317-337. 6 5. Turner, F. J. International Series in the Earth and Planetary Sciences. 2nd Ed Hill Book Company, US. 1969, pp. 160 -168. 6. http://www.specialtyminerals.com/our-minerals/what-is-talc/ Last assessed on March 15, 2011. 7. Rawlins, E.A Bentley’s Textbook of Pharmaceutics 8th edition, English Language Book 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. Society, UK, 1977, pp. 269-289 Levy, G., Gumtow, R. H. Effect of certain tablet formulation factors on dissolution rate of the active ingredient III. Tablet lubricants. J Pharm Sci. 1963, 52 (12), 1139-1144, http://www.specialtyminerals.com/specialty-applications/specialty-markets-forminerals/nutritional-supplements/talc-as-a-glidant-lubricant/ Last assessed on March 15, 2011. http://farriconsultingng.blogspot.com/2010/07/talc-deposits-in-nigeria-opportunities.html. Last assessed on March 15, 2011. Olabanji, S.O., Ige, A.O., Mazzoli, C., Ceccato, D., Ajayi, E.O.B. , De Poli, M., Moschini, G. Quantitative elemental analysis of an industrial mineral talc, using accelerator-based analytical technique. Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms, 2005, 240 (1-2), 327-332. British Pharmacopoeia, Her Majesty’s Stationary Office, London. 1998. Desai, D., Zia, H., Quadir, A, Evaluation of selected micronized poloxamers as tablet lubricants. Drug Deliv, 2007, 14(7), 413-426. Jones, T. M. The effect of glidant addition on the flowability of bulk particulate solids, J Soc Cosmetic Chemists, 1970, 21(7), 483-500. Holzer, A.H., Sjogren, J. Evaluation of some lubricants by the comparison of friction coefficients and tablet properties. Acta Pharm Suec. 1981, 18, 139-145. Uzunovic, A., Vranic, E. Effect of magnesium stearate concentration on dissolution properties of ranitidine hydrochloride coated tablets. Bosnian J Basic Med Sci, 2007, 7(3), 279-83. Strickland, W. A., Nelson, E., Busse, L. W., Higuchi, T. The physics of tablet compression IX. Fundamental aspects of tablet lubrication. J Ame Pharm Assoc, 1956, 45, 51–55. Okunlola, A, Odeku, O. A. Comparative evaluation of starches from Dioscorea species as intragranular tablet disintegrant. J. Drug Del Sci. Tech, 2008, 18 (6), 444-447, Odeku, O.A. Assessment of Albizia gum as binding agent in tablet formulations. Acta Pharm. 2005, 55, 263-276. 7 TABLE 1: PHYSICOCHEMICAL PROPERTIES OF LOCAL TALC SAMPLES PROPERTIES AND TESTS TAP TIR TOS 1. Colour Grey Grey Grey 2. Odour Slight Slight Slight 3. Texture Greasy to the touch Greasy to the touch Greasy to the touch MACROSCOPY Insoluble in water, Insoluble in water, Insoluble in water, SOLUBILITY dilute acid and alkali dilute acid and alkali dilute acid and alkali 1. Carbonate ++ ++ ++ 2. Chloride ++ ++ ++ 3. Iron ++ ++ ++ 4. Readily Carbonisable Grey residue Grey residue Grey residue 1.0 0.0 7.0 CHEMICAL Matter 5. Loss on drying (%) MICROSCOPY 1. Description of mount Transparent irregular Transparent irregular Transparent irregular plates with jagged plates with jagged plates with jagged laminated ends. 2. Appearance polarized laminated ends. laminated ends. under Shone brightly on a Shone brightly on a Shone brightly on a light dark background 3. With 0.1% w/w methylene Plates blue in 96% ethanol dark background remain Plates dark background remain Plates unstained unstained unstained 70.27 61.27 82.78 4. average length of plates (µm) ++ ---Positive 8 remain Table 2: Properties of Lactose tablets formulated with different Local Talc Samples as Lubricant (mean±SD, n=10) Lubricant Concentration Tablet wt Tablet Crushing Friability code (%w/w) (mg) Thickness Strength (CS) (F) (%) (mm) (N) CSFR Disintegration CSFR/DT time (min) TAP 5.00 557.80±1.72 3.50±0.00 52.33±14.78 0.94±1.10 55.67 2.50±0.04 22.27 TAP 7.50 582.20±1.90 3.50±0.01 58.60±10.68 0.88±0.01 66.59 2.55±0.02 26.11 TAP 10.00 581.60±8.41 4.00±0.01 70.95±10.98 0.82±0.01 86.52 2.65±0.04 32.64 TIR 5.00 555.30±1.78 4.00±0.01 55.08±18.33 0.80±0.04 68.85 2.42±0.03 28.45 TIR 7.50 584.40±1.95 3.50±0.01 59.78±7.06 0.76±0.04 78.66 2.48±0.07 31.72 TIR 10.00 581.30±8.39 4.00±0.04 72.23±7.74 0.72±0.03 100.31 2.51±0.05 39.96 TOS 5.00 556.90±1.63 3.50±0.04 41.36±15.88 0.96±0.01 43.08 2.18±0.11 19.76 TOS 7.50 581.40±1.83 3.50±0.03 54.98±9.89 0.82±0.02 67.05 3.60±0.12 18.63 TOS 10.00 582.10.±8.43 4.00±0.01 72.32±8.13 0.79±0.11 91.54 4.80±0.02 19.07 TBP 5.00 554.60±1.02 3.50±0.01 53.12±7.55 0.75±0.01 70.83 2.35±0.01 30.14 9 Table 3: Properties of Lactose Tablets Formulated with different Local Talc Samples and 1% w/w Magnesium Stearate as Lubricant (mean±SD, n=10) Lubricant Concentration Tablet wt Tablet Crushing Friability code (% w/w) (mg) Thickness Strength (CS, (F) (%) (mm) (N) CSFR Disintegration CSFR/DT Time (min) TAPM 5.00 581.60±0.17 3.50±0.02 48.02±11.86 0.85±0.02 56.49 8.24±0.03 6.86 TAPM 7.50 599.10±0.72 3.50±0.01 67.72±10.09 0.82±0.02 82.58 15.22±0.51 5.43 TAPM 10.00 614.90±5.50 4.00±0.08 47.04±8.72 0.79±0.02 59.54 16.20±0.64 3.68 TIRM 5.00 580.50±0.93 3.50±0.03 47.80±8.89 0.83±0.07 57.59 8.68±0.42 6.63 TIRM 7.50 599.40±0.63 3.50±0 .02 64.88±7.35 0.83±0.03 78.17 16.10±0.41 4.86 TIRM 10.00 615.60±6.51 3.50±0.02 79.38±9.90 0.80±0.01 99.23 16.25±0.55 6.11 TOSM 5.00 581.20±0.34 3.50±0.01 45.08±14.79 0.76±0.03 59.32 7.30±0.21 8.13 TOSM 7.50 599.80±0.55 3.50±0.04 63.21±6.76 0.80±0.01 79.01 12.40±0.36 6.37 TOSM 10.00 617.10±5.56 3.50±0.04 80.95±6.57 0.75±0.93 107.93 15.22±0.48 7.09 TBPM 5.00 580.60±0.12 3.50±0.01 55.17±8.13 0.70±0.01 78.81 3.50±0.10 22.52 10