high-performance materials based on chemically modified

advertisement

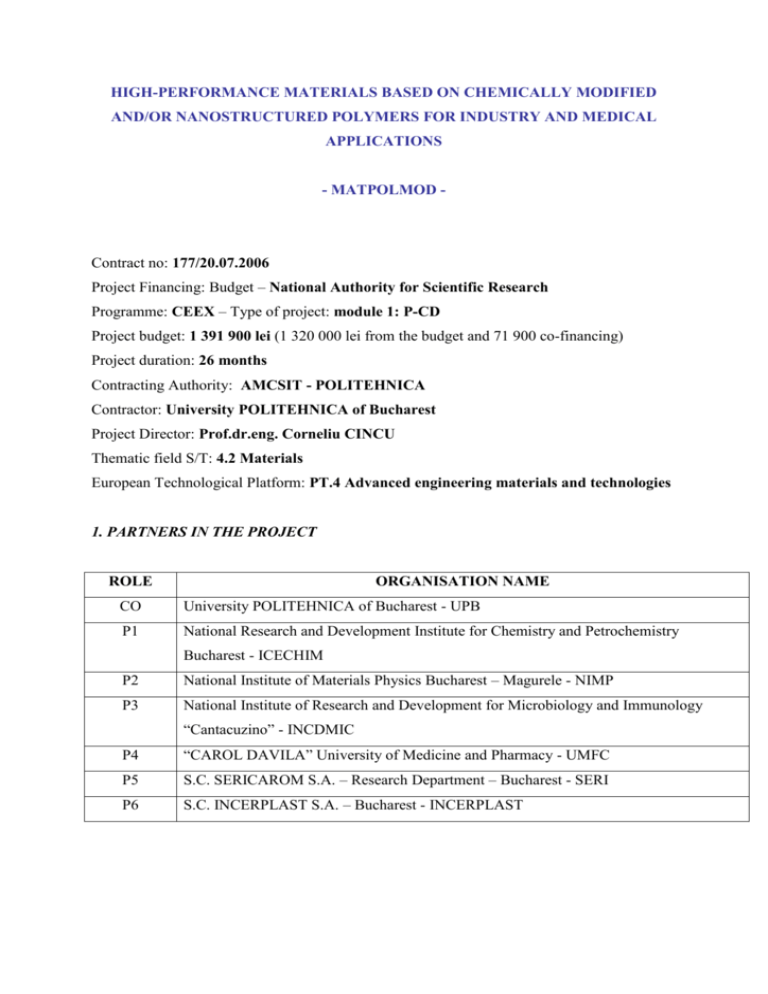

HIGH-PERFORMANCE MATERIALS BASED ON CHEMICALLY MODIFIED AND/OR NANOSTRUCTURED POLYMERS FOR INDUSTRY AND MEDICAL APPLICATIONS - MATPOLMOD - Contract no: 177/20.07.2006 Project Financing: Budget – National Authority for Scientific Research Programme: CEEX – Type of project: module 1: P-CD Project budget: 1 391 900 lei (1 320 000 lei from the budget and 71 900 co-financing) Project duration: 26 months Contracting Authority: AMCSIT - POLITEHNICA Contractor: University POLITEHNICA of Bucharest Project Director: Prof.dr.eng. Corneliu CINCU Thematic field S/T: 4.2 Materials European Technological Platform: PT.4 Advanced engineering materials and technologies 1. PARTNERS IN THE PROJECT ROLE ORGANISATION NAME CO University POLITEHNICA of Bucharest - UPB P1 National Research and Development Institute for Chemistry and Petrochemistry Bucharest - ICECHIM P2 National Institute of Materials Physics Bucharest – Magurele - NIMP P3 National Institute of Research and Development for Microbiology and Immunology “Cantacuzino” - INCDMIC P4 “CAROL DAVILA” University of Medicine and Pharmacy - UMFC P5 S.C. SERICAROM S.A. – Research Department – Bucharest - SERI P6 S.C. INCERPLAST S.A. – Bucharest - INCERPLAST 2. SUMMARY A major objective of this scientific research is the obtaining of performance polymeric materials starting from the existent ones by micro and nanostructuring and/or guided physicochemical modification. Nanostructured materials of different shapes and chemical compositions find spectacular applications in different activity domains: constructions, electronics, military and aerospace industry, medicine and biology, advanced research instruments. Guided chemical modification of some nanostructured block-copolymers with significant industrial applications leads to the obtaining of new improved materials, more reliable, which could be used in special fields of national importance. Recent researches showed interesting properties of polymeric composites tailoring fullerene nanoparticles. In many other applications, the contact surface of different types of materials (interface) lays a key role, so its guided modification could improve the practical behaviour. It is the case of implant biomaterials (where the substrate adherence, biocompatibility and micro-organism development on the surface are still not solved and they are present in the European research directions), of textile materials that come into direct contact with human body of adhesives, dyes and pigments, road coverings etc. Based on preliminary research studies, the research teams from this consortium propose activities in the following directions: i) Obtaining of some nanostuctured copolymers with guided chemical composition; ii) Obtaining of some polymeric nanocomposites with fullerene particles content; characterisation and applicative perspectives; iii) Physico-chemical modification in mass or surface modification of some polymeric materials to improve the main properties in specific applications. The project proposal comprises the above mentioned thematic areas as all the materials that will be obtained by physico-chemical modification, are new and eliminate some problems for use or contain a nanophase, which ensures some new and improved properties for the material. 3. OBJECTIVES The general objectives of the present project are: - Obtaining of new performance polymeric materials with special properties to eliminate some practical drawbacks or to be used in other domains; - Accumulation of knowledge and results concerning the synthesis, properties and behaviour of these materials for high-tech domains. The specific objectives, detailed accordingly to the three research directions, are the following: 3.a. - Set-up of a modern synthesis technology for new thermoplastic elastomers based on styrene-butadiene copolymers with guided vinyl microstructure of polybutadiene block (CoSB) by sequential anionic mechanism polymerisation technique combined with active centres modification technique (with Lewis bases); - Obtaining of copolymers and polyethylene-CoSB composites using modern synthesis technologies; - Obtaining of bitumen-CoSB composites with high exploitation performance. 3.b. - Establishing the optimum dispersion conditions of carbon nanoparticles (fullerene0in ultra high molecular weight polyethylene. Characterisation of the obtained nanocomposites. Study of the potential applications in high-tech domains for science and technology; - Obtaining of C60/poly(methyl methacrylate) (methyl methacrylate copolymers) nanocomposites, characterisation and potential uses in medicine and biology; - Obtaining C60/poly(hydroxyethyl methacrylate) and HEMA copolymers nanocomposites, C60/poly(N-vinyl pyrrolidone and its copolymers nanocomposites, C60/natural proteins (fibroin) nanocomposites. Physico-chemical characterisation and potential applications; - Biocompatibility tests (in vitro, in vivo) for the materials with potential medical applications (bone pathology, dentistry, surgery, neurology); - Testing the mechanical resistance of some medical devices (dental prostheses) and evaluation of the possible tension points. 3.c. - Establishing the optimum conditions for chemical modification of polymers with medical interest (ultra high molecular weigh polyethylene, poly(vinyl chloride), poly(methyl methacrylate) and its copolymers) in order to change some properties fro specific uses. - Physico-chemical characterisation of the modified materials. High-tech applications possibilities; - Superficial chemical modification (by grafting) of fibroin with vinyl monomers to obtain new materials with industrial and medical uses; - Biological testing (biocompatibility, microbiologic problems). Bacterial adherence and biofilms’ formation are very important phenomena from industrial, ecological and medical point of view. The present study has as objective the investigation of the possibility of improving the microbial anti-adhesive properties by chemical modification of the surface with medical polymers. Partners P3 and P4 will study the effect of these modifications upon microorganisms problem, as they have the necessary devices and experience and they will establish the strategy of an inter-disciplinary cooperation prosthetic-microbiology-chemistry. Partner P3 will test the response of the cells coming in contact with the surface of the new materials. The proposed objectives within this project are in good agreement with the objectives and priorities of the programme (Annex 1), but also with the actual tendencies in European research Frame Work (FP7).