Quantitative Analysis of Azimilide and One of its

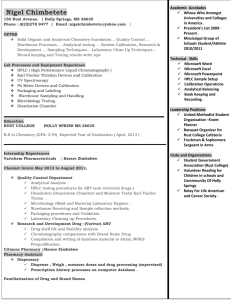

advertisement

Quantitative Analysis of Azimilide and One of its Metabolites in Mouse Blood by HPLC with UV Detection James J. Bao, P&G Pharmaceuticals, 8700 Mason-Montgomery Road, Mason, OH 45040-9462, USA* Abstract A high performance liquid chromatography (HPLC) method was developed and validated for the quantitative analysis of azimilide and one of its major metabolites, NE-10171, in mouse blood. NE-10133 was used as the internal standard. The samples were prepared by freezethawing the mouse blood in an acetone/dry ice bath, followed by protein precipitation in a mixture of acetonitrile : methanol : ammonium acetate buffer (8:2:1 v/v/v). The supernatant was separated, dried, and the residue was reconstructed in mobile phase. The reconstituted sample was ultrafiltered and injected onto the C8 reversed HPLC column. Azimilide and NE-10171 were separated with an isocratic mobile phase and detected at 340 nm. An analyte/internal standard ratio was used to quantitate azimilide and NE-10171. The lower limits of quantitation were 19.2 ng/ml for azimilide and 19.8 ng/ml for NE-10171. Three orders of magnitude linear response curves were obtained for both azimilide (from 19.2 ng/ml to 19.2 g/ml) and NE-10171 (from 19.8 ng/ml to 19.8 g/ml). The method was successfully applied to quantitate azimilide and NE-10171 in mouse blood in support of an azimilide safety study. Keywords: Azimilide, HPLC, metabolite * Current Address: Advanced Medicine, Inc., 901 Gateway Boulevard, South San Francisco, CA 94080, 001-650808-3715. C:\116103242 2/12/2016 1 of 31 1. Introduction Azimilide dihydrochloride (commercial name Stedicor, see Frig 1) is being developed as a new Class III antiarrhythmic and antifibrillatory drug for the treatment of cardiac arrhythmias[1-5]. The free base, azimilide, selectively prolongs the action potential duration and increases the effective refractory period of the heart [6-7]. The prolongation of the action potential duration is thought to result from the blockage or slowing of potassium ion current [8]. Both clinical and non-clinical studies have demonstrated that azimilide can be developed as a potent yet sate drug. During both pre-clinical and clinical studies, azimilide, when administrated to either animal or human, undergoes complicated metabolism resulting in several metabolites. The metabolic profile is different in different species, i.e. human vs. animals. The pharmacological functions of these metabolites were investigated [4]. One of the major metabolites, the desmethyl metabolite, NE-10171 (see Fig 1), was present in the blood of both humans and animals in significant amounts. Therefore, the analysis of this metabolite along with azimilide itself in biological fluids is of importance. In order to support the development of azimilide, various analytical methods are needed to quantitate azimilide and its metabolites in blood and other matrices. Even though high performance capillary electrophoresis (HPCE) has shown some unique advantages [9], most of the bioanalytical methods for azimilide are high performance liquid chromatography (HPLC) based methods. Further, to meet the stringent regulatory requirement, these methods have to be very well validated before they can be applied to support real sample analyses. Therefore, to support the dose ranging study of azimilide in mice, developed and validated a HPLC method for the analysis of azimilide and NE-10171 in mouse blood using NE-10133 as the internal standard (see Fig 1). C:\116103242 2/12/2016 2 of 31 Azimilide, NE-10171 and NE-10133 were extracted from mouse blood by freeze-thawing the blood samples in an acetone/dry ice bath, followed by protein precipitation in a mixture of acetonitrile, methanol, and ammonium acetate buffer. The supernatant was separated and dried. The residue was reconstituted with mobile phase, and chromatographed via reversed phase HPLC on a 5-micron C8 column to complete separate these three compounds. The compounds were detected and quantiated by ultraviolet (UV) absorbance at 340 nm. Quantitation was done by comparing the ratio of peak areas of azimilide and of NE-10171 to that of NE-10133. The concentrations of azimilide and NE-10171 in the samples were determined from calibration curves generated with spiked matrix standards. The lower limit of quanititation (LLOQ) was around 20 ng/ml based on a 200 l. One significant achievement of this method was the fact that, by properly placing the calibration standards along the calibration curve, we were able to achieve three orders of magnitude of linearity in a single method with the calibration standards and the quality control (QC) samples satisfying all of the preset requirements. With this method, levels in mouse blood were quantitated over three orders of magnitude for both azimilide (from 19.2 ng/ml to 19.2 g/ml) and NE-10171 (from 19.8 ng/ml to 19.8 g/ml). Data reported here demonstrates the specificity, linearity, accuracy and precision, sensitivity, recovery and robustness, and stability of this method. This method was applied to the analysis of mouse blood samples under good laboratory practice (GLP) conditions. The pharmacokinetic data obtained was used to evaluate the safety of azimilide. C:\116103242 2/12/2016 3 of 31 2. Experimental 2.1 Materials and reagents Certified reference compounds for azimilide, NE-10171, and NE-10133 were synthesized by medicinal chemists at Procter & Gamble Pharmaceuticals, Inc (P&GP). Ammonium acetate (ACS grade), methanol and acetonitrile (HPLC grade) were from Fisher Scientific (Fair Lawn, NJ). Triethylamine (TEA) was from Kodak (Rochester, NY). Saline solution was USP standard from McGaw, Inc (Irvine, CA). Blank mouse blood in heparin was obtained from Pel-Freez Biologicals (Rogers, AR). The HPLC system consisted of a Gilson XL autosampler and programmable 305 and 306 solvent delivery modules (Gilson, Middleton, WI). The detector was an Applied Biosystem 785A UV detector (Applied Biosystem, Foster City, CA). Exsil octyl analytical columns (5-m, 250x4.6 mm) were purchased from Keystone Scientific, Inc (Bellefonte, PA). The pre-column filter containing a replacable 2-micron frit was obtained from Upchurch Scientific (Oak Harbor, WA). A PE/Nelson 900 series digital interface along with TurboChrom software from Perkin-Elmer Corp (Norwalk, CT) was used to record the data. The Z-spin, a micrcentrifuge filter unit with 0.2-micron pore size, was purchase from Gelman Sciences (Ann Arbor, MI). An automatic environmental SpeedVac (AES 2000) with VaporNet was from Savant Instruments, Inc (Holbrook, NY). A Turbo Vap, LV was from Zymark Corp (Hopkinton, MA). A Milli-Q reagent water system from Millipore Corp (Bedford, MA) was used for the purification of deionized (DI) water. An ammomium acetate buffer (32 mM ammonium acetate with 36 mM TEA, pH 5.0) was prepared in-house. The protein precipitation solvent was a mixture of acetonitrile : methanol : ammonium acetate buffer (8 : 2 : 1, v/v/v). The mobile phase was acetate buffer : methanol : acetronitrile (65: 5 : 30, v/v/v). It was filtered through a 0.45-m C:\116103242 2/12/2016 4 of 31 Nylon-66 filter membrane (47 mm), and degassed under vacuum before use. While being used, the mobile phase was degassed with a slow stream of helium. 2.2 Preparation of aqueous/saline standards Standard stock solution (1.0 mg/ml) of azimilide and NE-10171 (free base) were prepared by dissolving proper amounts in a mixture of saline, methanol, and acetonitrile (80:10:10, v/v/v). Specifically, the samples were first added into a 50 ml volumetric flasks with 5 ml methanol, 5 ml of saline, and 5 ml of acetonitrile. Then, the solution was brought to the final volume with saline and mix well. Working standards and blood spiking solutions were prepared from these stock solutions by subsequent dilutions with DI water or saline, respectively. The primary NE-10133 solution (100 g/ml) was prepared by dissolving a proper amount of NE-10133 in 50 ml volumetric flasks with 5 ml methanol (10% of the total final volume), 5 ml of acetate buffer (10% of the total final volume), 5 ml of DI water. Then, the solution was brought to the final volume with DI water. The working NE-10133 solution (10 g/ml) was prepared by diluting the primary NE-10133 solution with DI water. The instrument validation solutions were prepared by diluting proper amounts of azimilide, NE-10171, and NE-10133 solutions with the HPLC mobile phase. 2.3 Preparation of blood calibration standards and quality control samples Calibration standards and QC samples were prepared by spiking blank mouse blood with the appropriate amount of azimilide and NE-10171 saline solutions. Separate stock solutions were used to prepare calibration standards and quality control samples. The blood calibration standard levels were 20, 40, 200, 3,000, 10,000, 15,000, 18,000, 19,000, and 20,000 ng/ml. The blood QC levels were 20, 60, 8,000 and 16,000 ng/ml. Which were referred to as limit of quantitation (LOQ), low, medium, and high QC samples, C:\116103242 2/12/2016 5 of 31 respectively. In addition, the calibration curve also included matrix blank (matrix only) and zero standards (matrix plus internal standard). The spiked blood standards and QC samples were stored, along with the study samples, at –20 ºC until use. For stability evaluation, some of the spiked high and low QC samples were stored at –70 ºC for comparison. 2.4 Preparation of blood samples The frozen (-20 ºC) mouse blood samples, calibration standards and QC samples were thawed in a 40 ºC water bath for 5 minutes and then allowed to come to room temperature. After vortexing, 250 l each sample was transferred into polypropylene tubes (5 ml) with a Pipetman digital micropipette (Rainin Instrument Co, Inc., Woburn, MA). The tubes were inserted with swirling motion into a dry ice/acetone bath to freeze for 30 seconds and then removed and placed into a water bath at 40 ºC to thaw for 1 min. The same freeze-thaw procedure was repeated a second time. The internal standard (100 l) was added to each of the samples except the matrix blank. Next, the protein precipitation solvent (3 ml) was added and the samples were vortexed on a multi-tube vortex mixer (MTV) for 4 min. Sample tubes were inverted and vortexed another 4 min on the MTV and then 30 seconds on a Genie vortex. The samples were then centrifuged at 3000 g for 15 min at room temperature. The supernatants (2-3 ml) were carefully transferred into clean amber glass vials (4 ml). The sample vials were dried either in a SpeedVac under vacuum or in a Zymark Turbo Vap at room temperature. The dried samples were reconstituted with mobile phase (300 l), vortexed gently, and transferred carefully into a low volume filtration device (Z-spin) for filtration. The Z-spins were placed in an Eppendorf 5415 micro-centrifuge and centrifuged at 10,000 g for 10 min until all liquid passed through the filter membrane. Finally, the samples were transferred to 350 l inserts, which were placed in 2-ml wide mouth amber glass sample vials. The vials were capped and loaded onto the Gilson XL autosampler. C:\116103242 2/12/2016 6 of 31 2.5 Chromatography An Exsil octyl analytical column (5-m, 250x4.6 mm), along with a pre-column filter containing disposable 2-micron frits, was used for chromatography at room temperature. A 200-l aliquot of each blank, spiked standard, sample, or appropriate system suitability solution was injected. An isocratic solution at a flow rate of 1.5 ml/min was sufficient to separate azimilide, NE-10171 and NE-10133. Chromatograms were recorded and processed by the TurboChrom program. Data reduction was achieved using an in-house program, CustomStat, which was based on Microsoft Excel macros. Peak areas for azimilide, NE-10171, and NE10133 were obtained from the chromatograms. The peak area ratios (azimilide/NE-10133 and NE-10171/NE-10133) were calculated for each standard and sample. 3. Results and Discussion The quality of analytical data is critical to the success of a drug development program. The progress of method development and validation has a direct impact on the quality of these data. Method development is the process to work out conditions suited for the determination of the compounds of interest. For HPLC method, this translates into finding conditions capable of separating and quantitating the corresponding compounds from other potential interfering compounds. Method validation is the process of proving that an analytical method is suitable for its intended purpose [10-11]. For HPLC method, this is to make sure that the method can meet certain predetermined acceptance criteria for the calibration standards and the QC samples. Since method development process has been very well documented, we will focus on the method validation process in the following discussions. 3.1 How to validate an HPLC method In general, analytical method involved in regulatory submission must meet all of the criteria established in the United States Pharmacopeia (USP) [12]. These criteria include C:\116103242 2/12/2016 7 of 31 specificity, linearity, accuracy, precision, range, detection limit, quantitation limit, and robustness. Usually, different approaches are used to meet these criteria for different methods. For an HPLC-based bioanalytical method, the method validation usually requires a minimum of three analytical batches. At least one, and preferably all of these batches must contain the number of samples similar to the number of study samples that will be analyzed in a batch. The first batch is the precision and accuracy (PA) batch, which assesses the precision and accuracy of the spiked standards and the QC samples. This PA batch also checks the specificity and sensitivity of the method. This very first PA batch contains duplicated calibration standards and QC samples at each level. Subsequent batches contain only one set of calibration standards and may include additional QC sample s for stability evaluation. All calibration standards are included in the regression analysis, rejection outliners where appropriate. The criteria for rejecting the regression standards were established in our standard operation procedures (SOPs) and discussed later in this paper (see Linearity section). At least one more PA batch is needed to determine the precision and accuracy, sensitivity and specificity between batches. Each of the PA batches contains two pre-assigned QC samples at each level for between batch precision and accuracy determination. The last batch is the method evaluation (ME) batch, which determines the within batch precision and accuracy, the potential of injector carryover, sensitivity, specificity, and recovery. The ME batch contains 10 QC samples at each level and the within batch precision and accuracy is determined using all QC samples. These QC samples can also be used to determine the stability of the analytes on the autosampler. Two pre-assigned QC samples at each level are used with the QC samples from the previous PA batches to determine between batch precision and accuracy. Special attention should be given to the sequence of a few specific samples in the ME batch. The two reagent blanks are followed by the calibration standards, which are randomly C:\116103242 2/12/2016 8 of 31 distributed among all of the samples, except for the six matrix blanks. These blanks are distributed so that three blanks immediately follow the highest standard and three blanks follow the second highest standard or the highest QC sample. The three blanks in each group are placed in consecutive order (see Note b in Table 1). This HPLC method was validated in multiple batch following the above procedures and applied for the analysis of azimilide and NE-10171 in mouse blood. Table 1 lists the number of samples in each batch for this study. The performance of this method was evaluated for specificity, linearity, accuracy and precision, sensitivity, recovery, ruggedness, and stability of azimilide, NE-10171 and NE-10133 based on the data obtained from these batches. 3.2 Chromatographic specificity The chromatographic specificity of an HPLC method requires the absence of interfering peaks and good resolution. In our study, the absence of interfering peaks required that the blank had no interfereing peaks at the retention times of azimilide, NE-10171, or NE-10133. In addition, the reference solution at the beginning of each new run should give baseline resolution (resolution = 1.5) for the analytes (azimilide and NE-10171) and the internal standard (NE-10133). The chromatographic parameters obtained from the separation of azimilide and NE-10171 in a system suitability solution (Fig 2) are summarized in Table 2. The resolution between the individual analytes and the internal standard (Fig 2) was larger than 1.5 (Table 2). Representative chromatograms (Fig 3a-c) of a matrix blank, a zero blank (spiked with internal standard only), and a calibration standard show litter interference from the matrix blank at the retention times of the analytes and/or the internal standard. Therefore, this method met all of the aforementioned specificity requirements. C:\116103242 2/12/2016 9 of 31 3.3 Linearity The linearity of a method is defined by the relationship between the response ratios of the analytes to the internal standard and the analyte concentrations in the standards. The response (peak area) of azimilide and NE-10171 to that of the internal standard were used for quantitation. Usually, a calibration curve includes one blank (matrix only), 1-2 zero standards (matrix plus internal standard), and one standard at each level of the calibration curve, with 1-2 standards at both the lowest and the highest levels. Since the calibration curve covers a broad concentration range, from 20 ng/ml to 20 g/ml for both azimilide and NE-10171, linear regression with a weighting factor (1/x2) has to be applied to the non-zero standards. The goodness-of-fit of the standards to the calibration curve is reflected in the coefficients of determination (r2) obtained from the weighted regression. The average coefficients of determination (r2) were 0.998 for azimilide and 0.996 for NE-10171 in these batches. In addition to r2, based on our SOPs, the acceptability of these calibration curves for the analyses of study samples was based on two criteria. First, the percent relative error (%RE) of the individual standards computed from the linear regression curve should be less than 15% (20% for LOQ standard). Second, the pooled % relative error (%PRE) of all calibration standards that define the curve should be less than 10%. The %RE of the spiked standard is defined as: %RE (X - X o ) x 100% Xo (Eq. 1) where X is the computed standard concentration and Xo is the nominal concentration of the standard. If a standard was out of the acceptable %RE range, it was rejected and the regression was performed on the remaining standards until all of the standards met the acceptance criteria for C:\116103242 2/12/2016 10 of 31 individual standards. Table 3 lists the mean values of the computed concentrations of azimilide and NE-10171 based on the regression results. It is noted that some of the batches had less than nine acceptable standards. However, all of the curves met the requirement that at least five different levels of standards were used to construct a calibration curve (Table 4). The %PRE is the square root of the average of the square of individual differences. Since one degree of freedom is lost in the square, the average is calculated by using N-1 rather than N, i.e. %PRE N 1- N (X i - X io ) 2 (Eq. 2) N 1 where Xi is the computed ith standard concentration and Xio is the nominal concentration of the ith standard. Table 4 lists the %PRE for all the batches. The goodness of fit was demonstrated by the small %PRE (less than 6% for azimilide and less than 8% for NE-10171 for all batches). These data demonstrated that the calibration curves were acceptable based on our SOPs. It is worth to note that the success in obtaining the three orders of magnitude linearity is attributed to the fact that the calibration standards are distributed within the calibration range based on statistic errors. It is well known that the variance near the ends of the calibration curve is usually larger than that in the middle of the calibration curve. This effect becomes significant when the calibration range is large. The key is to control this phenomenon with proper distribution of the calibration standards. In previous work, the calibration standards were diluted three-fold each consecutively from the highest standard to make the calibration curve. Based on that curve, the range between the highest and the second highest standards is more than 66% of the full calibration range. There was no standard between these two. Any slight variation in the highest standard will change the whole curve dramatically. Therefore, the %RE for some of the C:\116103242 2/12/2016 11 of 31 lower calibration standards could be 1000% even the coefficients of determination (r2) was more than 0.999. When using that calibration curve, the best linearity we could achieve was two orders of magnitude. Two separate calibration curves had to be used in order to cover three orders of magnitude. By placing more standards near the ends, we were able to reduce the variance near the ends of the calibration curve and have better accuracy and precision. 3.4 Accuracy and precision Azimilide and NE-10171 levels in mouse blood samples were calculated from the above spiked calibration standard curves. The relatively small %RE of the calibration standards indicated that this method had good accuracy and precision. To further assess the accuracy and precision of these calculations, QC samples were included in each batch. QC samples of known concentrations were prepared from separately prepared standards. Four levels of QC samples were used. The lowest QC concentration (LOQ QC, 20 ng/ml) was equal to the concentration of the standard at the lower limit of quantitation (LOQ) of the calibration curve. The low QC (LQC, 60 ng/ml) was lower than 3xLOQ but higher than the second lowest standard of the calibration curve. At the same time, Low QC can’t be the same as any standard. The medium QC (MQC, 8,000 ng/ml) was approximately midway between the low and high QC concentrations. The high QC (HQC, 16,000 ng/ml) was 70-90% of the highest calibration standard, yet lower than the second highest standard, but not the same as any standard. Further, the LOQ QC was used only during the method validation batches while the other QC samples were used throughout the study. If the QC samples are made in saline instead of DI water, the corresponding HQC, MQC, and LQC will be called SHQ, SMQ, and SLOQ (Table 1). Saline is more compatible with blood than water does. The percent relative recovery (%REC) for QC samples is defined as: C:\116103242 2/12/2016 12 of 31 %REC Y x 100 Y0 (Eq. 3) where Y and Y0 are the measured and the expected concentrations of the QC sample, respectively. %REC represents the accuracy of the method when used for unknown sample analysis. Table 5a summarizes the %RECs of QC samples pre-assigned for between batch accuracy and precision evaluation. The %REC for 2 QC samples at each of three levels between a total of 10 batches was very high, between 99.4% and 101.1% for azimilide, and between 88.1 and 94.3% for NE-10171, respectively. The relatively small percent coefficient of variation (%CV) for the QC samples indicates that the recovery was quite consistent. Table 5b indicates that within batch precision and accuracy for the three QC samples was also very high. The %REC of the 10 QC samples at each level within the batch was between 108% and 114% for azimilide and between 104 and 111% for NE-10171. 3.5 Sensitivity The sensitivity of the method was determined by evaluating the precision and accuracy of standards near the detection limit [10]. The LOQ of this method was 19.2 ng/ml for azimilide and was 19.8 ng/ml for NE-10171. A typical chromatogram for a 20 ng/ml calibration standard shows a peak significantly larger (S/N > 6) than the background noise (Fig 4). When control blood was spiked with 19.2 ng/ml of azimilide and assayed, the mean was 19.75 ng/ml with a CV% of 6.68%. Similarly, when control blood was spiked with 19.8 ng/ml of NE-10171 and assayed, the mean was 19.8 ng/ml with a CV% of 7.1%. 3.6 Recovery and ruggedness The absolute recovery (AR) of this HPLC method was determined by comparing the peak area of both the aqueous and the blood samples, i.e. C:\116103242 2/12/2016 13 of 31 %AR Signal of the blood sample x 100 Signal of the aqueous sample (Eq. 4) The AR through the clean-up steps, estimated from external standard curves, was 56% 77% for azimilide and 49% - 59% for NE-10171 for the spiked calibration standards (Table 6). The ARs of multiple QC samples (n=8) at the same concentration level (LOQ) were 69.09 ± 5.81, 55.62 ± 3.28, and 62.77 ± 1.34 for azimilide, NE-10171, and NE-10133, respectively. Different analysts have repeated this method in a different lab and achieved similar results. Therefore, the performance of this method was rugged enough to transfer to other labs. However, as this method was applied to the analyses of mouse blood samples from in-house azimilide studies, several different batches of columns were used. The retention times for some of these analytes shifted a little due to column variation from batch to batch. Nevertheless, the quality of the separation remained sufficiently high throughout this study. 3.7 Stability As part of the method validation, we evaluated the short-term (14 hours at room temperature) and freeze-thaw (3 cycles between –20 ºC and room temperature) stability of azimilide and NE-10171 in mouse blood. To ensure that there was no significant change in the stability of azimilide and NE-10171 during the course of sample analysis for this study, the longterm (182 days at –20 ºC) storage stability of azimilide and NE-10171 in mouse blood was also evaluated. The long-term stability tests were performed at 1, 3, 9, 17, 24, 60, 99, and 182 days with two samples at each level for each day. In addition, an autosampler (44 hours at room temperature) for the processed sample to ensure the stability of azimilide and NE-10171 in the reconstituted solution was also evaluated. The data in Figure 5a-b showed that azimilide was stable over the course of this study. NE-10171 had similar stability (data not shown). The short-term stability was evaluated by C:\116103242 2/12/2016 14 of 31 checking QC samples at room temperature for 0, 2, 4, 6, 8, and 14 hours. Fig 5c indicated that azimilide low QC samples were stable under the tested conditions. The azimilide high QC as well as NE-10171 QC samples showed similar stability. The autosampler stability was evaluated based on the stability of the processed QC samples in the autosampler at room temperature at 0, 2, 4, 8, 12, 18, 24, 30, and 44 hours. Figure 5d showed that the azimilide low QCs were stable during the period of the sample sitting on the autosampler. Again, azimilide high QC and NE-10171 QC samples had similar stability. In addition, we also evaluated the freeze-thaw stability by alternating freezing and thawing the QC samples between –20 ºC and room temperature for three cycles and analyzing two QC samples after each cycle. The results are within the expected range. 4. Conclusions The method described in this paper is specific, accurate, precise, and sufficiently sensitive for the quantitation of azimilide and its metabolite, NE-10171, in mouse blood. The sample preparation steps involve only freeze-thaw, protein precipitation, and solvent evaporation. All of these steps are easy to perform. These procedures are suitable for the analysis of azimilide in mouse blood samples. A significant achievement in this method is that a linearity of three orders of magnitude was achieved from a single calibration curve. This distribution of calibration standards in this calibration curve was deigned based on the statistics associated with physical measurements. By having more calibration standards near both ends of the calibration curve, we were able to overcome some of the problems associated with previous methods, where the calibration standards were equally diluted three times from one level to the next. Based on these calibration curves, the %RE of the lower standards could be off dramatically. C:\116103242 2/12/2016 15 of 31 In contrast, good linearity with broad calibration range can be obtained with acceptable results for the calibration standards when they are distributed according to our calibration curve. Since the distribution of calibration standards in our method has statistic background, it has broad applicability. 5. Acknowledgment The author wishes to thank Dr. N. J. Parekh and Ms. P. Fitzpatrick for their help and suggestions in completing this work. The author would also like to thank Dr. R. M. Deibel for her comments on this manuscript. C:\116103242 2/12/2016 16 of 31 References: 1. a) P. Light, Drugs, 3 (2000) 1534-1544. b) D. Clemett and A. Markham, Drugs, 59 (2000) 271-277. c) H. T. Tran, Heart Dis. 1 (1999) 114-116. 2. A. E. Busch, B. Eigenberger, N. K. JurkiewicZ, J. J. Salata, A. Pica, H. Suessbrich, and F. Lang, Br. J. Pharmacol. 123 (1998) 23-30. 3. S. W. Mittelstadt, A. E. Maynard, D. R. Benn, E. R. Lowe, and D. R. Kostreva, Cardiovasc. Drugs Ther. 11 (1997) 591-598. 4. A. Corey, J. Agnew, J. Bao, P. Bryson, P. Comer, S. Griffith, and J. Li, J. Clin. Pharmacol. 37 (1997) 946-953. 5. A. E. Busch, G. L. Busch, E. Ford, H. Suessbrich, H. –J. Lang, R. Greger, K. Kunzelmann, B. Attali, and W. Stuhmer, Br. J. Pharmacol. 122 (1997) 187-189. 6. J. M. Van Opstal, J. D. M. Leunissen, H. J. J. Wellens, and M. A. Vos, Eur. J. Pharmacol. 412 (2001) 67-76. 7. W. E. M. Vaughan, J. Clin. Pharmacol. 24 (1984) 129. 8. A. E. Busch, K. Malloy, W. J. Groh, M. D. Varnum, J. P. Adelman, and J. Maylie, Biochem. Biophys. Res. Commun. 202 (1994) 265-70. 9. J. J. Bao, N. J. Parekh, and A. Shuja, J. Chromatogr. B 720 (1998) 129-140. 10. E. L. Inman and E. C. Richard, J. Chromatogr. 447 (1988) 1-12. 11. J. M. Green, Anal. Chem. News and Features 305-309A, 1996. 12. U.S. Pharmacopeia 23/National Formulary 18 (United States Pharmacopeial Convention, Inc., Rocjville, Maryland, 1995), Chapter <1225>, pp. 1982-1984. C:\116103242 2/12/2016 17 of 31 Table 1 Number of analytical samples in each validation batch Sample Ragent Blank PA Batch a ME Batch b Sample Analysis - 2 - 3 or more 3 or more 3 or more Matrix Blank c 1 or 2 6 0 or 1 Zero Blank c 1 or 2 1 0 or 1 Standard 1 to 10 1 or 2 1 1 HQC/MQC/LQC 4 10 2 LOQ QC 4 10 0 Subject samples - - 36-42 Stability: HQC, LQC 0-18 - 0-2 Total blood samples c 26-58 58 58 - 2 2d Instrument Validation Saline QC: SHQ/ SMQ/SLOQ a The calibration curve contains two standards at each level for the first PA batch and one standard at each level for the second PA batch. Two of the four QC samples are pre-assigned for computation of between batch precision and accuracy. b The six matrix blanks are to evaluate carryover. The ten QCs at each level are to assess the within batch precision and accuracy. The two saline QCs at each level are optional for recovery purposes only. c The Matrix Blank and Zero Blank are only needed in the first PA batch when a new matrix is used. The number of samples in each analysis batch may vary depending on whether the matrix, zero, and the stability samples are used. The stability sample may vary depending on the need. The total number of blood samples in the PA batch and the sample analysis batch may be less, but no more than, that of the ME batch. d These QC samples are included only if the absolute recovery information is needed. C:\116103242 2/12/2016 18 of 31 Table 2 HPLC parameters for the analysis of azimilide and NE-10171 Analytea Resolution NE-10133 Retention Time 9.62 Tailing Factor Capacity Factor k' Theoretical Plates N --- 1.144 5.212 8983.10 NE-10171 11.96 5.106 1.273 6.715 8934.59 Azimilide 14.57 4.520 1.368 8.399 8057.50 Rs a The parameters listed above were obtained from the system suitability solution on one specific column. There were some migration time shift when columns from different batches were used. C:\116103242 2/12/2016 19 of 31 Table 3 Concentrations of azimilide and NE-10171 in the standard curve Azimilide Std 9a Std 8 Std 7 Std 6 Std 5 Std 4 Std 3 Std 2 Std 1 Nominal 19.2 38.3 192 2874 9580 14370 17244 18202 19160 Mean 20.1 38.1 176 2918 10188 15363 17435 18671 20217 %RE 5.06 -0.60 -7.96 1.53 6.35 6.91 1.11 2.58 5.52 SD 0.42 1.90 8.37 63.8 113 431 586 504 358 CV% 2.10 4.99 4.75 2.19 1.11 2.81 3.36 2.70 1.77 N 9 7 4 8 10 9 10 10 10 NE-10171 Std 9 Std 8 Std 7 Std 6 Std 5 Std 4 Std 3 Std 2 Std 1 Nominal 19.8 39.7 198 2973 9911 14867 17840 18831 19823 Mean 20.5 36.7 187 2893 10152 15483 17687 18843 20142 %RE 3.55 -7.39 -5.87 -2.72 2.43 4.15 -0.86 0.06 1.61 SD 0.60 1.87 27.4 102 247 546 794 565 683 CV% 2.93 5.11 14.7 3.53 2.43 3.53 4.49 3.00 3.39 N 9 8 4 7 10 9 10 10 10 a Std = standard C:\116103242 2/12/2016 20 of 31 Table 4 Pooled percent relative error (%PRE) of the standards in the calibration curves for azimilide and NE-10171 Azimilide C:\116103242 NE-10171 Batch %PRE N %PRE N 1 2 3 4 5 6 7 8 9 10 3.41 5.94 3.11 2.33 2.57 5.99 4.54 4.93 4.69 5.55 7 9 7 5 8 9 8 9 7 8 5.96 7.00 6.42 4.06 7.94 5.03 6.64 4.26 4.52 4.94 7 9 8 5 9 7 9 8 7 8 2/12/2016 21 of 31 Table 5 a) between batch precision and accuracy of QC samples for azimilide and NE-10171 Azimilide NE-10171 Batch LQC MQC HQC LQC MQC HQC Nominal (ng/ml) 59.3 7904 15808 59.5 7928 15856 Mean (ng/ml) 59.9 7858 15790 56.1 6987 14049 SD (ng/ml) 6.70 277 445 6.52 437 775 CV% 11.2 3.52 2.82 11.6 6.26 5.52 N 20 18 20 20 18 20 %REC 101 99.4 99.9 94.3 88.1 88.6 b) within batch precision and accuracy of QC samples for azimilide and NE-10171 Azimilide NE-10171 Sample LQC MQC HQC LQ C MQC HQC Nominal (ng/ml) 59.3 7904 15808 59.5 7928 15856 Mean (ng/ml) 64.8 9009 17028 65.9 8778 16476 SD (ng/ml) 11.1 1220 614 5.4 1223.8 648.1 CV% 17.2 13.5 3.60 8.20 13.94 3.93 N 10 10 10 10 10 10 %REC 109 114 108 111 111 104 C:\116103242 2/12/2016 22 of 31 Table 6 C:\116103242 Absolute recoveries of azimilide and NE-10171 in calibration standards Azimilide % Recovery NE-10171 % Recovery NE-10133 % Recovery STD 9 56.2 48.0 63.4 STD 8 66.9 54.7 63.1 STD 7 65.8 53.8 63.7 STD 6 76.3 57.6 60.6 STD 5 73.2 57.4 64.0 STD 3 70.2 56.5 62.9 STD 2 71.8 58.9 63.9 STD 1 72.5 58.0 60.5 2/12/2016 23 of 31 Figure captions Figure 1. Structures, names, formulas of azimilide, NE-10171, and NE-10133 Figure 2. A chromatogram showing the separation of azimilide, NE-10171, and the internal standard, NE-10133 from a system suitability sample. Experimental conditions: 340 nm UV detection; mobile phase: 65% 32 mM ammonium acetate with 36 mM TEA buffer (pH 5.0), 5% MeOH, and 30% ACN. Figure 3. Chromatograms of a) blank mouse blood matrix, b) zero blank, and c) the calibration standard (20,000 ng/ml) in mouse blood. Experimental conditions are the same as in Figure 2. Figure 4. Chromatogram of LOQ of azimilide, NE-10171, and NE-10133 in mouse blood. Sample contained 19.2 ng/ml azimilide and 19.8 ng/ml NE-10171 with internal standard NE-10133. Insert is the whole chromatogram without expansion. Experimental conditions: the same as in Figure 2. Figure 5. Stability data of azimilide QC samples. The low and high limits are 2.5 standard deviation (SD) of the nominal values as determined during the validation of the method. a) long-term stability of low QC azimilide in mouse blood; b) long-term stability of high QC azimilide, and c) short term stability of low QC azimilide, and autosampler stability of low QC in reconstituted buffer, and d) autosample stability of low QC samples. The measured concentrations of the QC samples are plotted along with the 2SD limit lines above and below the Mean. C:\116103242 2/12/2016 24 of 31 Figure 1 Structures, names, formulas of azimilide, NE-10171, and NE-10133 O Cl CH=N N N O (CH2)4 N (CH2)4 N CH3 N O Azimilide O Cl CH=N N N O N H . 2 HCl O NE-10171 O Cl CH=N N N O (CH2) 3 N N (CH2) O H . 2 HCl 2 O NE-10133 Azimilide: 1-[[[5-(4-Chlorophenyl)-2-furanyl]methylene]amino]-3-[4-(4-methyl-1-piperazinyl)butyl]-2,4-imidazolidinedione. Empirical formula: C23H28ClN5O3, FW = 457.97. The commercial name Stedicor refers to azimilide dihydrochloride. NE-10171: 1-[[[5-4 Chlorophenyl)-2-furanyl]methylene]amino]-3-[4-(4-methyl-1-piperazinyl) butyl]-2,4-imidazolidinedione dihydrochloride. Empirical formula: C22H26ClN5O3*2HCl. Molecular weight: 516.86. NE-10133: 1-[[[5-(4-Chlorophenyl)-2-furanyl]- methylene]amino]-3-[3-[4-(2-roxyethyl)-1piperazinyl)propyl]-2,4-imidazolidinedione dihydrochloride. Empirical formula: C23H28ClN5O32*2HCl. Molecular weight: 546.89. C:\116103242 2/12/2016 25 of 31 Figure 2 Chromatogram of azimilide, NE-10171, and NE-10133 in a system suitability solution. C:\116103242 2/12/2016 26 of 31 Figure 3a Chromatogram of blank mouse blood Figure 3b C:\116103242 Representative chromatogram for a zero blank mouse blood extract spiked with NE-10133 2/12/2016 27 of 31 Fig 3c Chromatogram of reference standard of azimilite and NE-10171 at 20,000 ng/ml analytes along with NE-10133 C:\116103242 2/12/2016 28 of 31 Figure 4 Representative chromatogram of LOQ azimilide and NE-1071 mouse blood sample along with NE-10133 C:\116103242 2/12/2016 29 of 31 Figure 5 a) Long-term stability of azimilide low QC in mouse blood azimilide LQC 80.00 Con. (ng/ ml) 70.00 60.00 50.00 40.00 30.00 20.00 10.00 0.00 1 1 3 3 9 9 17 17 24 24 60 60 99 99 182 182 Days Figure 5 b) Long-term stability data for azimilide HQC in mouse blood azimilide HQC Con. (ng/ ml) 20000.00 15000.00 10000.00 5000.00 182 182 99 99 60 60 24 24 17 17 9 9 3 3 1 1 0.00 Days C:\116103242 2/12/2016 30 of 31 Figure 5 c) Short-term stability data for azimilide LQC in mouse blood Con. (ng/ ml) azimilide LQC 80.00 70.00 60.00 50.00 40.00 30.00 20.00 10.00 0.00 0 0 2 2 4 4 6 6 8 8 14 14 Hours Figure 5 C:\116103242 d) Autosampler stability data for azimilide LQC in mouse blood 2/12/2016 31 of 31