Flume Procedure MCEN

advertisement

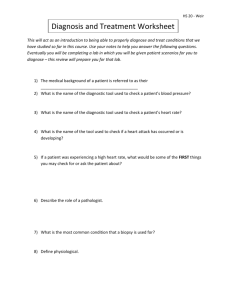

Updated: 09-16-08 Flume The Flume as shown in figure one is a useful tool in analyzing the flow in an open channel. In this lab students will determine the relationship between upstream head and flow rate for water flowing over a “sharp crested” weir and under an “undershot” weir (also known as a sluice gate). The discharge coefficient will then be found for both weirs. Figure 1: Flume Diagram Sharp Crested Weir Equipment (Figure 1) Flume Sharp Crested weir Hook and Point level gauge, 300mm scale Stopwatch if measuring flow rate using the volumetric tank Page 1 of 10 Updated: 09-16-08 Summary of Theory/Background Figure 2: If the aeration pipe of the rectangular weir is plugged/blocked, a clinging nappe forms. Using Bernoulli’s equation the following equation can be derived for a rectangular sharp crested weir: 3 2 Q C d bh 2 2 g 3 (1) where (see Figure 2): Q= Volume flowrate [m3/s] Cd=Coefficient of discharge [Dimensionless] b= Breadth of weir [m] h= Head above crest of weir (upstream) [m] g=Gravitational constant [9.81m/s2] P=Height of weir crest above bed [m] When the rectangular weir extends across the whole width of the channel, the weir is referred to as a suppressed weir. For a suppressed weir, the Rehbock formula can be applied to determine Cd as follows: C d 0.602 0.083 h P (2) Procedure 1. Check that the flow control valve is completely CLOSED (clockwise). 2. Make sure that the drain from the Volumetric Tank to the sump tank is opened (lift black handle to lift ball out of drain hole and rest on “OPEN” ledge). Page 2 of 10 Updated: 09-16-08 3. Measure and record the width of the sharp crested overshot weir. 4. Slightly bend the rubber gasket upstream, Figure 3a, and insert weir into the channel above a hook with the sharp edge of the weir upstream. The weir must be secured to the bottom of the channel by attaching a hook through the hole in the bottom and hooking it to the retaining bar as shown in Figure 3b. Carefully pull the model down so that the rubber feet sit on the floor of the channel, as shown in Figure 3c. a) b) c) Figure 3. The rubber gasket of the weir should be bent upstream. 5. Make sure the flume is level by adjusting the channel slope, operated by a hand-wheel. Set the slope indicator to zero. 6. Straddle a hook and point gauge between the channel sides and above the weir. 7. The datum for all measurements will be the top edge of the weir plate. Carefully adjust the level gauge to coincide with the top of the weir, taking care not to damage the edge of the weir, and then record the datum reading. 8. Set the level gauge to zero at the height of the weir. This adjusts the level gauge to measure the height of the water with respect to the top of the weir, Figure 2. 9. Reposition the level gauge some way upstream from the weir. Page 3 of 10 Updated: 09-16-08 10. Plug the pump extension cord of the sump tank (hydraulics bench) into the outlet in the floor and turn the pump switch ON (the black button). 11. Slowly open the Flow Control Valve shown in Figure 1. Water will now begin flowing over the weir. 12. Assess whether the nappe is clinging to the back face of the weir. If so, then the ventilation tube is filled with water. Ventilate the nappe by inserting the end of a piece of hollow tube into the space behind the weir. The nappe should spring away from the weir. 13. Measure the flow rate (Q) and the head (h) for a span of head levels (h) having 10 mm increments. You should be able to collect measurements for at least four or five head levels. Note: You may wish to measure the flow rate and head MULTIPLE times for each head level for analyzing the uncertainty of the measurements. a. To measure the flow rate, use the sight tube and scale on the hydraulics bench (Figure 1) and a stopwatch to measure the volume change as a function of time. i. Only use the upper scale on the sight tube to measure in Liters. ii. Try to measure over at least 20 seconds (if possible) to obtain an accurate flow rate measurement. b. Measure the head with the level gauge. 14. Sketch the flow pattern as the water flows over the weir when the nappe is ventilated properly. 15. Reduce the flow rate until the water is no longer flowing over the weir. Then slowly increase the flow rate so you fill the ventilation tube with water and sketch the flow pattern with the nappe clinging to the weir. 16. Repeat step 13 to measure the flow rate (Q) and the head (h) while the nappe is clinging to the weir, incrementing the head in 10 mm steps. 17. After the experiment, turn the pump switch OFF, and close the Flow Control Valve. Questions 1. Plot Q against h, log Q against log h and Cd against h. 2. From the straight-line graph of log Q against log h find the intercept log k on the log Q axis and the gradient m. The relationship between Q and h is then Q=khm. 3. Calculate Cd for the condition when the nappe is not properly ventilated and for the condition in which the nappe is properly ventilated. 4. Is Cd constant for this weir? If not, under what conditions does it vary? 5. What average value of Cd would you use for this weir? Page 4 of 10 Updated: 09-16-08 6. Use Excel’s linear regression tool to find the uncertainty in Cd. 7. Does your value for Cd when the nappe is unventilated differ from your average value? If so, why? 8. Comment on the profile of the nappe when ventilated and unventilated. 9. How does the value for Cd predicted by the Rehbock formula compare with your average value? 10. How do your values for k and m in the equation Q=khm agree with the theoretical equation for a sharp crested rectangular weir? “Sluice Gate” / Undershot Weir Equipment Set-Up Flume Adjustable undershot weir Hook and point gauge, 300mm scale- 2 required Stopwatch if measuring flow rate using the volumetric tank Summary of Theory/Background Page 5 of 10 Updated: 09-16-08 Figure 4: The upstream and downstream head are used to find the flow rate. For flow beneath a sharp edged undershot weir it can be shown that Q y1C D b 2 g y0 y1 1 y1 yo 2 ; (3) therefore, CD y1b Q 2 g yo y1 (4) 1 y1 yo 2 where (see Figure 4): Q= Volume flowrate [m3/s] CD=Coefficient of discharge [Dimensionless] b= Breadth of weir [m] yg= Height of weir opening above bed [m] y0=Upstream depth of flow [m] g=Gravitational constant [9.81m/s2]. Also, 2 V Q2 H 0 y0 0 y0 2 2g 2 g y0 b (5) Page 6 of 10 Updated: 09-16-08 2 H1 y1 V1 Q2 y1 2 2g 2 g y1b HL KL V12 2g H o H1 H L (6) (7) (8) where: H0= Total head upstream of weir[m] H1= Total head downstream of weir[m] HL = Head loss due to Sluice Gate [m] KL = Loss coefficient [dimensionless] = 0.5 y1= Downstream depth of flow [m] V0=Mean velocity upstream of weir [m/s] V1=Mean velocity downstream of weir [m/s]. Procedure 1. Check that the flow control valve is completely CLOSED (clockwise). 2. Make sure that the drain from the volumetric tank to the sump tank is opened (lift black handle to lift ball out of drain hole and rest on “OPEN” ledge). 3. Ensure the flume is level. 4. Measure and record the actual breadth (width), b, of the undershot (sluice gate) weir. 5. Apply a thin coat of bicycle lubricant to the rubber gasket material of the sluice gate on the side of the gasket that will be pressed against the sides of the channel. See Figure 5 for how the sluice gate will be installed; the rubber gasket should be bent upstream. Page 7 of 10 Updated: 09-16-08 Figure 5. The rubber gasket of the weir should be bent upstream with a thin coat of bicycle lubricant between the channel sides and the gasket. 6. Position the sluice gate assembly in the channel as shown in Figure 5, overlapping the measurement marker on the outside of the channel. Place the sharp edge of the sluice gate upstream. Be sure to tighten the set screws at the top of the assembly to fasten the sluice gate to the sides of the channel. 7. The weir should not bend/slip with the force of the upstream water, but if it does, apply plasticine (white putty) along the edges of the assembly on the downstream side. 8. Position two hook and point level gauges on the channel sides, one upstream of the weir and one downstream of the weir. 9. The datum for all measurements will be the bed of the flume. Carefully adjust the level gauges to coincide with the bed of the flume and record the datum readings. You may also wish to zero the level gauge at this height. 10. Adjust the knob on top of the weir to position the sharp edge to the weir 20 mm above the bed of the flume. 11. Turn the pump switch ON. Page 8 of 10 Updated: 09-16-08 12. Gradually open the flow control valve and admit water until y0=150 mm according to the measurement tape on the side of the flume. a. With y0 at this height, measure Q using the volumetric method as implemented for the rectangular weir. b. Also, measure y1 using the downstream level gauge. Note: You may wish to measure the flow rate and y1 multiple times to aid in analyzing uncertainty. 13. Raise the weir in increments of 5 mm maintaining y0 at the height of 150 mm by varying the flow of water. At each level of the weir record the values of Q and y1. 14. Repeat the procedure with a constant flow Q allowing y0 to vary. Record the values of y0 and y1 for different values of y0. Note: You may wish to measure the flow rate and y1 multiple times to aid in analyzing uncertainty. 15. After the experiment, turn the pump switch OFF, close the flow control valve, and unplug the pump of the hydraulic bench. Questions 1. Plot graphs of Q against yg for constant y0 and y0 against yg for constant Q to show the characteristics of flow beneath the weir. 2. Plot graphs of Cd against Q for constant y0 and Cd against yg for constant Q to show the changes in Cd of flow beneath the weir. 3. Comment on the effects of y0 and Q on the discharge coefficient Cd for flow underneath the gate. Which factor has the greatest effect? 4. Comment on any discrepancies between actual and expected results. 5. Compare the values obtained for H1, H0, and HL and comment on any differences. 6. Use Excel’s linear regression tool to find the uncertainty in Cd. 7. If the flow rate is not known, CD can be approximated as CC = y1/yg. How does CC compare to CD in predicting the actual fluid flow, Equation 3? Page 9 of 10 Updated: 09-16-08 Table 1: Additional Information on the Flume Length of working section: 2.5 m Width of working section: 76mm Depth of working section: 250mm Maximum positive bed slope: 1 in 25 Maximum negative bed slope: 1 in 100 Flow range: 50—125 liters/min Page 10 of 10