RRNAGEL.SW - Faculty of Medicine

OHS026

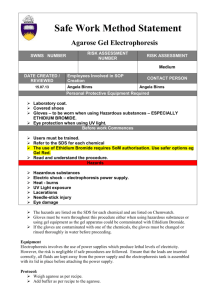

Safe Work Procedure

Faculty/Division

Medicine

Document number

RRNAGEL.SW

Initial Issue date

School/ Divisional Unit nephrology

Current version

1

Current Version

Issue date

29/05/2010

Next review date

01/5/2013

The Writing Safe Work Procedures Guideline (OHS027) should be consulted to assist in the completion of this form.

Safe Work Procedure Title and basic description

Title: Agarose gel electrophoresis for DNA and RNA

Description:

Associated risk assessment title and location:

Describe the activity or process

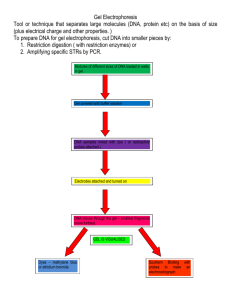

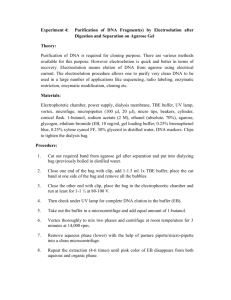

This SWP describes the making and running of agarose gels for the visualisation of DNA and RNA. This procedure involves the use of hazardous substances . The attached Risk Assessment, all associated

SWPs and all relevant MSDSs must be read before this method is undertaken.

This document cross-references other SWPs. Be aware that the hazards associated with the procedures described in those documents will not be detailed here . It is the individual’s responsibility to read the appropriate SWPs and their associated Risk assessments before beginning this work

.

Procedure:

A. Preparing the gel

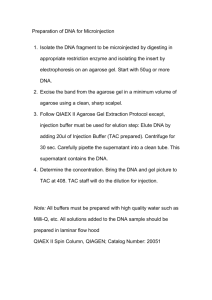

1. Weigh out the required amount of DNA or RNA grade agarose and place into an appropriately sized

Schott bottle or glass conical flask. Check that the bottle or flask you have chosen fits into the microwave before proceeding!

2. The amount of agarose needed depends on the desired percentage of the agarose gel and also on the size of the gel being run. For example, a 1% agarose gel would be made by adding 1 g of agarose to 100 mL of gel running buffer, a 2% agarose gel would be made by adding 2 g of agarose to 100 mL of buffer. A small gel tray takes ~50 mL of agarose gel, a medium sized gel tray takes

~100 mL of agarose gel, and a large gel tray takes ~200 mL of agarose gel.

3. To the Schott bottle or conical flask containing the agarose, add the required amount of 1 x TAE buffer. No more than ¼ full.

4. Gently mix the agarose and the TAE buffer by swirling the bottle or flask. Replace the lid of the bottle loosely . This stops the buffer from evaporating out of the bottle during heating.

___________________________________________________________________________________________________________

___________

Page 1 of 5

Safe Work Procedure

Uncontrolled document when printed

Date Effective: 15.5.2010

Current Version: 15.5.2010

Describe the activity or process

5. note; face protection, gloves, gown needed!! Place the bottle or flask into the microwave with loose lid. Heat on high until the first signs of boiling are seen. It can boil violently . Remove the gel from the microwave (NB: - this is a burn hazard ). The agarose should be fully dissolved and the gel should look clear. If it is not, swirl the flask gently and continue heating. Do not allow the gel to boil for an extended period of time. The bottle or flask can be removed from the microwave during the heating process and swirled gently before continuing to heat. This helps to break up agarose clumps and helps the agarose to dissolve faster.

6. Allow the agarose gel to cool until it can comfortably be held in the hand. Do this either by allowing the solution to cool. Do not place the bottle on ice or in ice cold water – this can cause it to shatter!

7. If allowing the agarose to cool on its own, this is a good time to set up the gel casting unit (see below). If you cool the agarose by running it under water, you should have the casting unit set up first.

8. Prior to pouring the gel, add 1 drop of 0.625 mg/mL ethidium bromide solution per 100 mL agarose and swirl the bottle or flask to mix.

: Tape is used to seal off the ends of the gel tray. Check occasionally for leaks if you choose this option.

1. Place the gel comb(s) into the comb slots on the gel tray. Combs of different thickness and with different numbers of teeth are available.

___________________________________________________________________________________________________________

___________

Page 2 of 5

Safe Work Procedure

Uncontrolled document when printed

Date Effective: 15.5.2010

Current Version: 15.5.2010

Describe the activity or process

2. Pour the agarose gel into the gel tray containing the gel comb(s) and allow it to sit at room temperature to set. If any air bubbles formed while the gel was being poured, they can be popped or moved to the edge of the gel using a 200 uL pipette tip. The gel turns opaque when it is set and is solid to the touch; this takes 30 – 60 min, depending on the size of the gel.

3. Once the gel has completely set, the comb can be removed by slowly lifting it straight up and out of the gel.

4. Place the gel tray containing the agarose gel into the gel tank, making sure that the wells are nearer the black or negative electrode. DNA and RNA are negatively charged and will therefore migrate towards the red or positive electrode when a current is applied. If the gel is placed into the tank the wrong way around, the DNA or RNA will run off the gel.

5. Add 1 x TAE buffer to the gel tank until the agarose gel is submerged.

Option : Ethidium bromide may be added to the buffer in the gel tank at the same concentration as was added to the agarose gel, i.e. at 1 drop per 100 mL of buffer. This step stops an ethidium bromide (dark) front from appearing on the bottom of the gel.

C. Loading and running the gel

NB: - if working with both DNA and RNA, separate sets of reagents should be obtained/prepared and used.

1. Aliquot the DNA or RNA to be run into 1.5 mL tubes or onto parafilm. Make all samples up to the same volume with ddH

2

O water (DNA) or molecular biology grade water (RNA).

2. Also prepare a sample consisting of appropriately sized markers or ladders (this will be determined by your expected band size). Generally, 1 uL of this is used as “the sample” and diluted to the same sample volume as the DNA or RNA.

3. Add 6x loading dye to each sample of DNA or RNA (and the markers) for a final concentration of 1x loading dye (i.e. add 1 uL DNA or RNA sample), and mix well.

4. Using a pipette, load the samples into the wells of the agarose gel. It is important to load all of each sample. A good way to ensure that the entire sample has been taken up is, after loading the bulk of the sample, to pipette a small amount of tank buffer back onto the site from where the sample was taken up, take this up also, and add it into the same well.

NB: - incorrect or careless handling of the electrodes while using the power-pack constitutes an electrical hazard .

___________________________________________________________________________________________________________

___________

Page 3 of 5

Safe Work Procedure

Uncontrolled document when printed

Date Effective: 15.5.2010

Current Version: 15.5.2010

Describe the activity or process

5. Place the lid onto the gel tank, making sure to place black electrode to black electrode and red electrode to red electrode. Make sure that the power-pack is off before plugging in the cords, unless someone else is already running a gel. In this case, press the green “running man” button to pause the system before proceeding; the light will flash). Again, make sure that black is to black and red is to red.

6. If necessary, turn the power-pack on at the switch. Set it to the desired voltage (usually 70-100 V) and then press the green button. Run the gel until the dye front has nearly reached the bottom of the gel. (NB: - it is possible to set the gel to run for a specified time if desired. If more than one gel is run on the same power-pack it is not necessary to increase the voltage, as this brand of power-pack compensates.)

7. Once the gel has been run, press the green button to pause the system and then stop the powerpack by turning it off at the switch. (NB: - if someone else is running a gel, do not switch off the power-pack, and do not forget to “un-pause” the system!!)

8. Unplug the cords from the power-pack and remove the lid of the gel tank. Take the gel tray out of the tank and place it into a white plastic transport tray. These trays must be used when carrying the gels to the gel documentation system.

D. Discarding the agarose gel and TAE buffer

1. The agarose gel must be discarded into the contaminated waste bins.

2. The TAE buffer in the gel tank(s) can be reused several times before being discarded. To discard, follow the protocol described. Used TAE buffer must not be discarded before undergoing the correct decontamination procedure!!

List all resources required including plant, chemicals, personal protective clothing and equipment, etc

DNA grade agarose

RNA grade agarose (

TAE buffer (see)

Ethidium bromide, drop-bottle format, 0.625 mg/mL (NB: - this is a hazardous substance )

DNA/RNA markers (MBI Fermentas, various according to the DNA/RNA products)

6x loading dye (MBI Fermentas, Mass Ruler, cat. # R0621; or MBI Fermentas, 6x, cat. # R0611)

Molecular biology grade water

Gel casters, trays, combs (Bio-Rad, various model numbers)

Power-pack (Bio-Rad, model # Power Pac 300)

List potential hazards and risk controls including specific precautions required

Ethidium bromide is a potential carcinogen and hazardous, PPE must be worn at all times when using it and it can only be used within the electrophoresis areas

PowerPacs has potential electric shock hazards, ensure PPE is on and the pacs must not be wet.

When heating Agarose, the agarose may boil out of the container, make sure that thermal gloves are used when handling heated agarose.

List emergency shutdown instructions

If any problems arise with the powerpacs, turn them off at the power point.

___________________________________________________________________________________________________________

___________

Page 4 of 5

Safe Work Procedure

Uncontrolled document when printed

Date Effective: 15.5.2010

Current Version: 15.5.2010

List clean up and waste disposal requirements

Liquid ethidium bromide spills must be cleaned up immediately with paper towels and ethanol.

All agarose must be disposed of in the contaminated bins.

Running buffers may contain ethidium bromide and must be treated with Charcoal bags prior to disposal in the sink.

List legislation, standards and codes of practice used in the development of the SWP

MSDS for ethidium bromide

Supervisory approval, training, and review

Supervisor: Phil Peake Signature:

Plant custodian: Signature

List competency required – qualifications, certificates, licencing, training - eg course or instruction:

UNSW OHS training

Demonstration of correct procedures by qualified individual

SWP review date: Responsibility for SWP review:

___________________________________________________________________________________________________________

___________

Page 5 of 5

Safe Work Procedure

Uncontrolled document when printed

Date Effective: 15.5.2010

Current Version: 15.5.2010