POLB_22380_sm_suppinfo

advertisement

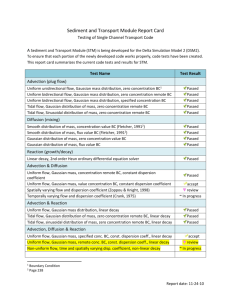

1 Supporting Information 2 S1 Analyzing the substrate systems 3 In order to model the pristine and blended films of different polymers and nanoparticles, at 4 first the optical constants of the substrates must be analyzed. We used a commercial ITO glass 5 substrate (Thin Film Devices) combined with a spin cast PEDOT:PSS (CLEVIOS HIL 1.3, 6 Heraeus Precious Materials). In a first step, the ITO was etched off and the blank glass 7 substrate was measured (SE, DP and T) and modeled. A generalized oscillator model was 8 applied, composed of three Gaussian oscillators to model the imaginary part of the dielectric 9 constant ( = 1 + i2). Each oscillator is defined by three fit parameters (amplitude, energetic 10 position and broadening). Absorption structures out of the measuring range were represented 11 by so-called Sellmeier-Poles. Absorptions with energy position out of the measuring range 12 but with tails in the investigated region typically show strong correlation of the energy 13 position parameter and the amplitude. In order to obtain unique results and to reduce the total 14 number of fit parameters the energy position was fixed for the out-of-range oscillators. Notice 15 that no reliable physical information can be extracted of the out-of-range values of amplitude, 16 energy position and broadening. The real part is obtained by Kramer-Kronig-consistency 17 (KK) [1]. For quantification of model quality the mean squared error (MSE) between 18 measured data (SE, DP and T) normalized on the total amount of free fit parameters was used 19 [1]. MSE weighting by factor 6:1 was adjusted to compensate the outnumbered T 20 measurements. The applied software WVASE32 uses the Levenberg-Marquardt algorithm to 21 find the minimal MSE in the multi-parameter space [1]. In addition the correlation between fit 22 parameters was investigated. Models with parameter correlation above ± 0.92 were discarded. 23 The parameters describing the glass oscillators are listed in Table S1. 24 The following equations describe the Gaussian and Lorentzian oscillators, and the Sellmeier 25 Poles [1]: 1 1 2 2 ln 2 E E 2 2 ln 2 Eph Ec ph c 2,Gauss Aexp exp B B 2 2,Lorentz 3 1,Pole E 2 AB 2 Eph 2 ph 2 2 Ec2 B 2 Eph A EC2 Eph2 4 In these equations A is the amplitude in arbitrary units, B is the broadening in eV, Eph is the 5 light energy and Ec is the energy position of the oscillator in eV. Poles in the UV and IR act as 6 additional offset and curvature terms for the calculation of ε1. For further details see [1]. 7 In the next step the ITO film was analyzed, using the film thickness of a mechanical 8 profilometer (Veeco Dektak 150) as a start and reference value. Again SE, DP and T Data 9 were modeled with a generalized oscillator model, using one Gaussian for the UV and one 10 Lorentzian for the NIR absorption. Both energy positions were out of the measuring range. 11 Thus both energy positions were fixed at 5.5 eV and 0.1 eV, respectively. We did not use a 12 Drude-oscillator for the free carrier absorption in the (N)IR, as it causes occasional software 13 errors during the fit procedure. A continuous layer could not sufficiently fit the measured data 14 in the NIR, which is often observed for sputtered ITO layers. Thus gradients of Lorentzian 15 amplitude were allowed in the optical model. A linear gradient allows for sufficient model 16 quality. The parameters of the oscillators are listed in Table S1. 17 As the last step in substrate analysis, a thin (30 nm) PEDOT:PSS layer was spin cast on a 18 substrate. The ITO substrate was previous masked and etched, so that one part of the sample 19 was the blank glass, the other part glass+ITO. The uniaxial anisotropic PEDOT:PSS was 20 modeled according to Pettersson et al. [2], using two independent generalized oscillator 21 layers. The first layer represents the optical constants in the plane of the film (xy), the other 22 optical constants parallel to the surface normal (z). SE, DP and T were measured at the glass 23 and the glass+ITO position. Two models with the respective substrate were built and coupled, 2 1 which means the optical constants of the PEDOT:PSS were the same in both models. Again 2 we avoided the Drude-oscillator in order to improve the software stability during the fit 3 procedure. Finally the parameters of the oscillators were fit in order to match the measured 4 data of both measuring positions at the same time. As good agreement of modeled and 5 measured data was observed for both substrate configurations, the optical properties of 6 PEDOT:PSS seems to have no significant dependency on surface energy. The parameters of 7 the in-plane and out-of-plane oscillators are listed in Table S1. 8 3 1 S2 Modelling Ellipsometric data of pristine films 2 The strategy was to start with a GenOsc layer on top of the previously well characterized 3 glass/PEDOT:PSS and glass/ITO/PEDOT:PSS substrate, placed on the same sample. The 4 optical constants of the investigated film were coupled in both models in order to realize the 5 multi-sample-analysis for increased information and decreased parameter coupling. The fact, 6 that the normal transmission is only sensitive to the in-plane optical constants allows for a 7 separation of the xy- and z-oscillator model, at least to obtain good starting values. Thus we 8 started with fitting the xy- oscillators to the transmission data. Starting in the transparent 9 region, the range was increased step by step to the absorption region, subsequently adding 10 Gaussian oscillators if MSE starts to increase significantly. Afterwards a point-by-point (pbp) 11 fit over the full wavelength range was performed, using the KK-consitent GenOsc Model as 12 start values. The pbp result was used to readjusted and sort out the oscillators, followed by a 13 fit of that new GenOsc model on the measured data. These values were used as start values 14 for the z-direction, followed by fit procedures on the complete set of measured data (SE, T). 15 Again several loops of pbp-fits, readjustment of oscillators and oscillator-fits were performed 16 — in case of anisotropic material for both the in-plane and out-of-plane OC — until no 17 further improvement in MSE was found. 18 Finally MSE improvement of additional surface roughness and back side reflection were 19 tested, followed by readjustment of oscillators by the above mentioned routine. For most 20 films a thin surface roughness improved the fit quality, using a Bruggeman effective medium 21 approximation (EMA) with 50 : 50 volume ratio of film OC and void (n = 1, k = 0). The 22 surface roughness was rather small (< 3 nm) for all investigated pristine films. A final pbp fit 23 was performed with fixed layer thicknesses and the resulting OC were used for the EMA 24 models. 25 Figures S2 to S7 show the experimental data and the fit results of the pristine films on 26 glass/PEDOT:PSS substrate and for the 4 anisotropic polymer films also on 1 glass/ITO/PEDOT:PSS together with the modeled results of the oscillator models and the 2 final point-by-point fit results. The excellent agreement of the optical constants obtained from 3 the pbp- and the oscillator models ensure KK-consistent and thus physical results of the pbp 4 fit. The final oscillators used as star values for the pbp-fit procedure for the polymers are 5 listed in Table S2, those for the nanoparticle films in Table S3. Oscillators out of the 6 measuring range again use fixed energy position in order to avoid parameter correlation of 7 oscillator amplitude, energy position and broadening. Despite the high number of fit 8 parameters unique fit results could be obtained by the MSA of two different sample positions 9 with different substrate layer sequence and combined analysis of SE, DP and T 10 measurements. 11 12 S3 EMA model for blend layers 13 EMA was used to fit the blend layer with the pbp-results of the pristine films. We used 14 Bruggeman EMA with variable screening factor (q), where q = 0 represents a side-by-side 15 configuration of P3HT and QD domains, q = 0,333 spherical domain shapes and q = 1 a 16 stacked configuration. For a review on EMA models see for example [3]. The EMA 17 composed of the OC of the pristine films was modeled on measured data, again using MSA of 18 two measuring position to increase information and thus to reduce parameter correlation. We 19 used coupled volume fractions and screening factor for the in-plane and out-of-plane OC and 20 tested single layers, gradients and surface roughness on fit quality. 21 Figure S8, S9 and S10 show the experimental results of Ψ, Δ and T of samples with 10 wt.% 22 polymer in QD with pyridine capping ligand on glass/PEDOT:PSS and on glass/ITO/PEDOT 23 substrates together with results of the EMA model using linear gradients of volume ratios. For 24 comparison in the lower part of the figures the optical constants of a free point-by-point fit are 25 shown together with the results of the graded EMA models. The pbp fit does not allow for 26 taking gradients into account. Thus the pbp-results are a kind of mean optical constants along 5 1 the blend layer thickness. In each case, the pbp-results are within the range spanned by the 2 gradient of the EMA-model. This agreement demonstrates the applicability of the EMA for 3 these blend films. 4 We found a linear gradient of the concentration combined with a surface roughness to fit most 5 of the blend films best. Other shapes of the gradient like exponential or Gaussian causes 6 partly improved MSE values, but increases also the parameter correlation and thus did not 7 allow unique fit results. The gradient was generated by a stepwise change of composition, 8 where the number of steps was increased until no further effect on MSE was accomplished. 9 Typically three to eight steps were required. The reported volume ratio was finally calculated 10 by the mean value over layer thickness, including the impact of surface roughness layers. 11 Details on the gradients and a comparison with high resolution TEM images will be reported 12 elsewhere. 13 It should be noted, that the EMA fails if the temperature during post-thermal annealing was 14 close to or above the polymers glass transition temperature. In this case the EMA can not fit 15 the experimental data sufficiently, and free pbp-fits show shifts in absorption structures that 16 can not be described by any EMA. 17 18 S4 Equation for ligand layer thickness 19 Assuming the QD to consist of a spherical CdSe core with radius rCdSe and volume 20 21 22 23 24 VCdSe 4 3 rCdSe 3 ; mCdSe CdSeVCdSe (SI 1) and a ligand layer shell of thickness dL and volume 4 3 3 VL d L rCdSe rCdSe 3 ; mL LVL . (SI 2) The mass ratio (m) is defined as m m Poly mQD m Poly mCdSe m L , (SI 3) 6 1 the volume ratio (v) as v 2 3 VPoly VQD VPoly VCdSe VL . (SI 4) Using Eqs. (SI 4) and (SI 3) a mass density ratio can be found A 4 v mCdSe mL VPoly . m VCdSe VL mPoly (SI 5) 5 Replacing the masses with their respective mass densities and volumes and using the volume 6 expressions of Eqs. (SI 1) and (SI 2) leads to A 7 3 3 rCdSe CdSe d L rCdSe rCdSe L 3 d L rCdSe 3 Poly . (SI 6) 8 Reorganizing Eq. (SI 6) finally leads to Eq. (3). 9 Assuming the CdSe-NR particles to consist of a cylinder capped with half spheres at the ends, 10 an analogue formulation can be found. Here the volume of the inorganic core is the sum of the 11 sphere volume with radius rCdSe and the cylinder volume of length lCdSe, the ligand volume is 12 the sum of the hollow cylinder and the sphere shell. 13 4 3 2 VCdSe rCdSe l CdSe rCdSe 3 4 2 3 VL rCdSe d L l CdSe rCdSe d L VCdSe 3 14 Substitution of Eq. (SI 8) in Eq. (SI 5) leads to an expression with dL and L. To bring it in the 15 form of a function dL(L) is not trivial, as in this model terms of lower order remain and the 16 3rd root. Using free available software for linear algebra [4] and excluding the imaginary 17 solutions the result is: 18 dL 19 with 1 123 2 z 2 3lCdSe l rCdSe CdSe 5/3 4 2 z (SI 8) (SI 9) 7 2 3 3 6 2 2916lCdSe z 1296 gl CdSe rCdSe 1728 grCdSe 54l CdSe 2 3 3 1296 gl CdSe rCdSe 1728 grCdSe 54l CdSe 1 g 1 3 (SI 10) L CdSe L A poly 2 3 S5 Thermogravimetric analysis of ligand layer 4 For several samples we studied the composition of the ligand layer by thermogravimetric 5 analysis (TGA) coupled with time-of-flight mass spectroscopy (MS). Heating films of the 6 nanoparticles causes partially evaporation of the ligands because the ligands, strongly bonded 7 on the nanoparticle surface, evaporate at an elevated temperature, higher than the annealing 8 temperature of the samples, due to the binding energy between ligands and nanoparticle 9 surfaces. The corresponding temperature level allows for an evaluation of binding energies of 10 the detected species within the film. Similar studies were already reported for example by 11 Kuno et al. [5] and Iqbal et al. [6]. This analysis allows to identify the ligand species and by 12 comparisons to evaluate the success of ligand exchange procedures. 13 Figure S11 shows a TGA-MS spectrum of the unwashed TOP/OA capped QD with a particle 14 diameter of approximately 5 nm. Three temperature regimes can be found, indicated green, 15 yellow and red. At temperatures between 100 and 200 °C (green regime) free or weakly 16 bound TOP/OA (original ligands from the CdSe QD synthesis) evaporates. This accounts for 17 15-20 wt.% of the film, and can be completely removed by MeOH-n-Hexane washing. In the 18 temperature regime between 200 and 350 °C (yellow regime) a medium bound TOP/OA-layer 19 evaporates. This layer accounts for 3-5 wt.% of the film, and can partially be removed by the 20 combination of pre-washing with MeOH-n-Hexane and pyridine refluxing procedure. For 21 temperatures above approximately 350 °C (red regime) a third ligand regime can be found. 22 Higher binding energies can be interpreted as a layer closer packed to the nanoparticle 8 1 surface. This inner layer of TOP/OA accounts for 12-18 wt.% and can partially be removed 2 during the washing and pyridine refluxing processes. 3 For the washed and pyridine capped particles some TOP/OA can still be found by TGA-MS. 4 We estimate the amount of extant TOP/OA to be in the order of 10 wt.% for particles with a 5 diameter of approximately 5 nm. 6 7 9 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 SI References [1] Johs, B.; Herzinger, C.; Guenther, B. WVASE for Windows, J.A.Woollam Co. Inc. Lincoln, NE, 2005 [2] Pettersson, L.A.A.; Gosh, S.; Inganäs, O. Org. Electron. 2002, 3, 143–148 [3] Fujiwara, H. In Spectroscopic Ellipsometry; John Wiley & Sons, Ltd 2007 Chapter 5, pp 177–181 [4] Wolframalpha computational knowledge engine (accessed April 23, 2011) http://www.wolframalpha.com [5] Kuno, J.; Lee, J. K.; Dabbousi, B. O.; Mikulec, F. V.; Bewendi, M. G. J. Chem. Phys. 1997, 106 (23), 9869-9882 [6] Iqbal, M.; McLachlan, J.; Jia, W.; Braidy, N.; Botton, G.; Eichhorn, S. H. J. Therm. Anal. Calorim. 2009, 96 (1), 15-20 10 1 Overview of figures 2 (all films on PEDOT:PSS) Figure Material Annealing Symmetry Thickness [nm] S1 Illustration of fit strategy -- -- -- S2 NR@pyridine 140 °C (15 min) isotropic 70.9 S3 QD@pyridine 140 °C (15 min) isotropic 74.5 S4 QD@HA treated HDA 140 °C (15 min) isotropic 42.4 S5 P3HT 140 °C (15 min) anisotropic 62.0 S6 PCPDTBDT 140 °C (15 min) anisotropic 61.7 S7 PCPDTBT 210 °C (20 min) anisotropic 67.4 S8 10wt.% P3HT, QD 140 °C (15 min) anisotropic 63.3 S9 10wt.% PCPDTBDT, QD 140 °C (15 min) anisotropic 71.3 S10 10wt.% PCPDTBT, QD 210 °C (20 min) anisotropic 69.0 S11 TGA results -- -- -- 3 4 11 1 2 3 Figure S1. Schematic fit strategy. In (a) and (b) the measurement results of pristine films of 4 QD and the polymer P3HT were fitted with the parameter intensive KK-consistent 5 generalized oscillator model. The blend film in (c) was modeled using the constant OC 6 obtained by final pbp fit results of (a) and (b) in an EMA and thus strongly reduced number of 7 fit parameters. 8 12 1 2 3 4 5 6 7 8 9 10 Figure S2: Film of pyridine-capped NR on glass/PEDOT:PSS after post-thermal annealing for 15 minutes at 140 °C Experimental results (dashed black) of the ellipsometric angles Ψ, Δ under various angles of incidence and Transmission (T) at normal incidence together with the model results using an isotropic oscillator model (green), and results of a point-by-point fit procedure (red). The obtained isotropic optical constants (n, k) are shown in the lower graph in corresponding colors. 13 1 2 3 4 5 6 7 8 9 Figure S3: Film of pyridine-capped QD on glass/PEDOT:PSS after post-thermal annealing for 15 minutes at 140 °C Experimental results (dashed black) of the ellipsometric angles Ψ, Δ under various angles of incidence and Transmission (T) at normal incidence together with the model results using an isotropic oscillator model (green), and results of a point-by-point fit procedure (red). The obtained isotropic optical constants (n, k) are shown in the lower graph in corresponding colors. 14 1 2 3 4 5 6 7 8 Figure S4: Film of HAD-capped QDs after the HA treatment on glass/PEDOT:PSS after post-thermal annealing for 15 minutes at 140 °C Experimental results (dashed black) of the ellipsometric angles Ψ, Δ under various angles of incidence and Transmission (T) at normal incidence together with the model results using an isotropic oscillator model (green), and results of a point-by-point fit procedure (red). The obtained isotropic optical constants (n, k) are shown in the lower graph in corresponding colors. 15 1 2 3 4 5 6 7 8 9 10 11 12 Figure S5: P3HT (layer thickness 62.0 nm) on PEDOT:PSS after post-thermal annealing at 140 °C (15 minutes). top: Experimental results (dashed black) of the ellipsometric angles Ψ and under various angles of incidence, and the transmission T at normal incidence in comparison with generalized oscillator model results (solid red) using a linear gradient of the volume fraction. The plots on the left show the results of the blend film on glass (1 mm) / PEDOT:PSS (30 nm), the right side shows results of the film on glass (1 mm) / ITO (150 nm) / PEDOT:PSS (30 nm). bottom: Refractive index (n) and extinction coefficient (k) obtained by a point-by-point fit (green) and the oscillator model (red). The in-plane results are plotted as solid lines, out-ofplane results as dashed lines. 16 1 2 3 4 5 6 7 8 9 10 11 12 Figure S6: PCPDTBDT (layer thickness 61.7 nm) on PEDOT:PSS after post-thermal annealing at 140 °C (15 minutes). top: Experimental results (dashed black) of the ellipsometric angles Ψ and under various angles of incidence, and the transmission T at normal incidence in comparison with generalized oscillator model results (solid red) using a linear gradient of the volume fraction. The plots on the left show the results of the blend film on glass (1 mm) / PEDOT:PSS (30 nm), the right side shows results of the film on glass (1 mm) / ITO (150 nm) / PEDOT:PSS (30 nm). bottom: Refractive index (n) and extinction coefficient (k) obtained by a point-by-point fit (green) and the oscillator model (red). The in-plane results are plotted as solid lines, out-ofplane results as dashed lines. 17 1 2 3 4 5 6 7 8 9 10 11 12 13 Figure S7: PCPDTBT (layer thickness 67.4 nm) on PEDOT:PSS after post-thermal annealing at 210 °C (20 minutes). top: Experimental results (dashed black) of the ellipsometric angles Ψ and under various angles of incidence, and the transmission T at normal incidence in comparison with generalized oscillator model results (solid red) using a linear gradient of the volume fraction. The plots on the left show the results of the blend film on glass (1 mm) / PEDOT:PSS (30 nm), the right side shows results of the film on glass (1 mm) / ITO (150 nm) / PEDOT:PSS (30 nm). bottom: Refractive index (n) and extinction coefficient (k) obtained by a point-by-point fit (green) and the oscillator model (red). The in-plane results are plotted as solid lines, out-ofplane results as dashed lines. 18 1 2 3 4 5 6 7 8 9 10 11 12 13 Figure S8: P3HT blended with pyridine-capped QD using a mass ratio of 1:9 and postthermal annealing at 140 °C (15 minutes). top: Experimental results (dashed black) of the ellipsometric angles Ψ and under various angles of incidence, and the transmission T at normal incidence in comparison with EMA model results (solid red) using a linear gradient of the volume fraction. The plots on the left show the results of the blend film on glass (1 mm) / PEDOT:PSS (30 nm), the right side shows results of the film on glass (1 mm) / ITO (150 nm) / PEDOT:PSS (30 nm). bottom: Refractive index and extinction coefficient obtained by a point-by-point fit (solid red) and the EMA-model, respectively. The linear gradient of the volume ratio in the EMA model causes a change of optical constants along the layer thickness. The results at the substrate interface are shown (dashed red) as well as the results at the interface to the ambient (dashdotted red). 19 1 2 3 4 5 6 7 8 9 10 11 12 13 Figure S9: PCPDTBDT blended with pyridine-capped QD using a mass ratio of 1:9 and post-thermal annealing at 140 °C (15 minutes). top: Experimental results (dashed black) of the ellipsometric angles Ψ and under various angles of incidence, and the transmission T at normal incidence in comparison with EMA model results (solid red) using a linear gradient of the volume fraction. The plots on the left show the results of the blend film on glass (1 mm) / PEDOT:PSS (30 nm), the right side shows results of the film on glass (1 mm) / ITO (150 nm) / PEDOT:PSS (30 nm). bottom: Refractive index and extinction coefficient obtained by a point-by-point fit (solid red) and the EMA-model, respectively. The linear gradient of the volume ratio in the EMA model causes a change of optical constants along the layer thickness. The results at the substrate interface are shown (dashed red) as well as the results at the interface to the ambient (dashdotted red). 20 1 2 3 4 5 6 7 8 9 10 11 12 13 Figure S10: PCPDTBT blended with pyridine-capped QD using a mass ratio of 1:9 and post-thermal annealing at 210 °C (20 minutes). top: Experimental results (dashed black) of the ellipsometric angles Ψ and under various angles of incidence, and the transmission T at normal incidence in comparison with EMA model results (solid red) using a linear gradient of the volume fraction. The plots on the left show the results of the blend film on glass (1 mm) / PEDOT:PSS (30 nm), the right side shows results of the film on glass (1 mm) / ITO (150 nm) / PEDOT:PSS (30 nm). bottom: Refractive index and extinction coefficient obtained by a point-by-point fit (solid red) and the EMA-model, respectively. The linear gradient of the volume ratio in the EMA model causes a change of optical constants along the layer thickness. The results at the substrate interface are shown (dashed red) as well as the results at the interface to the ambient (dashdotted red). 21 1 2 Figure S11: Thermogravimetric analysis with time-of-flight mass spectroscopy of a thin 3 film of quantum dots with a diameter of approximately 5 nm with the synthesis ligand 4 TOP/OA on glass. The highlighted temperature regimes indicate different binding energies of 5 the ligand that can be interpreted as different layers of the capping layer. 6 22 1 Table S1. Parameters for the poles and oscillators used for representation of the ε2 for glass, 2 ITO and the anisotropic PEDOT:PSS. Oscillator glass Gaussian 1 Gaussian 2 Gaussian 3 Gaussian 4 Pole Energy (eV) Broadening Amplitude (eV) (a.u.) 1.1021 3.2494 4.6378 5.1439 11 (fixed) 0.92089 0.09516 0.79971 0.68626 n.a. 1.27E-05 9.51E-07 9.15E-04 1.40E-03 149.48 0.1 (fixed) 5.5 (fixed) 11 (fixed) 0.001 (fixed) 0.2655 1.6080 n.a. n.a. 34.163…61.438* 3.9311 247.25 1.6983 0.5 (fixed) 1.1240 4.6837 5.5 (fixed) 11 (fixed) 0.7587 1.9073 5.0434 5.5 (fixed) 11 (fixed) 0.7776 1.6723 0.3523 0.5897 n.a. 0.5300 0.8707 0.3479 1.2665 n.a. 1.0517 0.1749 0.0358 1.5084 179.08 0.4952 0.0604 0.2420 1.6888 209.26 ITO Lorentzian 1 Gaussian 1 Pole 1 Pole 2 PEDOT:PSS Gaussian 1, xy Gaussian 2, xy Gaussian 3, xy Lorentzian 1, xy Pole 1, xy Gaussian 1, z Gaussian 2, z Gaussian 3, z Lorentzian 1, z Pole 1, z 3 4 * For ITO a linear gradient of the Amplitude was applied. The first value is the amplitude at 5 the glass interface, the second is the amplitude at the ambient interface. The linear gradient 6 was represented by stepwise changes of the amplitude value in 11 steps. 7 23 1 Table S2. Parameters for the poles and oscillators used for representation of the anisotropic ε2 2 for the in-plane (xy) and out-of-plane (z) orientation of the investigated neat polymer films. Oscillator P3HT Gaussian 1, xy Gaussian 2, xy Gaussian 3, xy Gaussian 4, xy Gaussian 5, xy Gaussian 6, xy Gaussian 7, xy Pole, xy Gaussian 1, z Gaussian 2, z Gaussian 3, z Gaussian 4, z Gaussian 5, z Pole, z Energy (eV) Broadening Amplitude (eV) (a.u.) 2.0484 2.1900 2.2755 2.5068 2.6911 3.1005 5.5 (fixed) 11 (fixed) 2.1033 2.4976 2.9556 4.9741 7.0 (fixed) 11 (fixed) 0.1288 0.1342 0.3492 0.3664 0.6765 1.3147 2.0228 n.a. 0.4527 0.4558 0.5450 0.4679 3.3710 n.a. 1.1767 0.7785 2.0233 0.7117 0.4326 0.2316 0.6243 146.1 0.3997 0.4314 0.1873 1.8210 0.6512 136.02 2.1441 2.2611 2.4151 2.7273 5.5 (fixed) 11 (fixed) 2.3011 3.0314 3.9029 4.4770 6 (fixed) 11 (fixed) 0.1485 0.2974 0.4198 0.8528 3.4935 n.a. 0.5458 0.4787 0.5510 0.4011 0.6718 n.a. 0.8339 1.6437 1.1890 0.6114 0.6115 139.2 0.3474 0.1592 0.2029 0.1971 2.1231 114.04 1.6712 1.7918 1.9973 2.9069 2.9917 4.8589 11 (fixed) 1.7764 2.1446 2.9288 3.9110 4.8177 11 (fixed) 0.1464 0.2587 0.4955 1.6455 0.3946 1.8283 n.a. 0.4760 0.3367 0.4777 3.7381 0.4707 n.a. 1.2077 1.5180 0.9251 0.2608 0.3940 0.4149 141.4 1.1588 0.3594 0.3267 0.2092 0.1793 117.47 PCPDTBDT Gaussian 1, xy Gaussian 2, xy Gaussian 3, xy Gaussian 4, xy Gaussian 5, xy Pole, xy Gaussian 1, z Gaussian 2, z Gaussian 3, z Gaussian 4, z Gaussian 5, z Pole, z PCPDTBT Gaussian 1, xy Gaussian 2, xy Gaussian 3, xy Gaussian 4, xy Gaussian 5, xy Gaussian 6, xy Pole, xy Gaussian 1, z Gaussian 2, z Gaussian 3, z Gaussian 4, z Gaussian 5, z Pole, z 3 4 24 1 Table S3. Parameters for the poles and oscillators used for representation of the isotropic ε2 2 for the neat nanoparticle films. Energy Oscillator (eV) QD@pyridine Broadening Amplitude (eV) (a.u.) Gaussian 1 Gaussian 2 Gaussian 3 Gaussian 4 Gaussian 5 Pole 0.1156 0.1425 0.3831 0.8583 2.6201 n.a. 0.2589 0.1290 0.2618 0.4810 3.4801 165.84 0.1218 0.4186 0.6833 2.1350 1.7274 n.a. 0.2441 0.2235 0.2368 1.3635 3.4640 196.81 0.1603 0.4984 0.9010 0.5637 2.7368 n.a. 0.1971 0.3325 0.6460 0.6038 4.1925 141.29 2.0450 2.1256 2.4117 2.8844 5.2433 11 (fixed) QD@HA treated HDA Gaussian 1 Gaussian 2 Gaussian 3 Gaussian 4 Gaussian 5 Pole 1.9861 2.2995 2.6981 3.6115 5.1094 11 (fixed) NR@pyridine Gaussian 1 Gaussian 2 Gaussian 3 Gaussian 4 Gaussian 5 Pole 1.9356 2.2627 2.8244 4.7773 5.3065 11 (fixed) 3 25