Assessment task plan:

advertisement

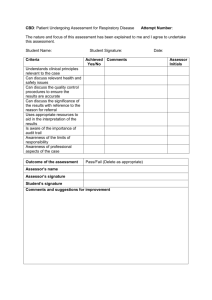

Student Name…………………………. Date……………… ASSESSMENT TASK PLAN Certificate III Plumbing BCP30103 Install roof components Competency No. BCPRF3004A BCP03 Plumbing and Services Training Package Assessment Record Assessment task plan: Install roof components BCPRF3004A Assessment task description: This assessment task, along with a number of other tasks and projects, will help you obtain BCP30103 Certificate III in Plumbing. To fulfil this assessment you are required to: Given the plans/specifications of an industrial roof, determine the material requirements, select and install the following components in a roof using approved flashing methods. an explosion vent and a skylight, a non-mechanised ventilator unit, a manual box-type louvre unit, and a continuous roof ventilator (ridge or slope mounted) This assessment is designed to assess the knowledge and skills you have gained from your training both on and off the job. You will be required to demonstrate your ability to perform tasks in a realistic work environment. In meeting the requirements of this task you may also have to demonstrate skills and knowledge gained in other units of competency. Before attempting this assessment task you should: complete the resource book BCPRF3004A install roof components submit resource book for assessment successfully complete the computer based assessment for BCP3004A have your assessor assign a workstation to you. This assessment will require the candidate to carry out three types of roof penetrations and flashings to accommodate the selected roofing components. Refer to the ‘Assessment task checklist’, to assist with the completion of this task. © Plumbing Training Moderation Group (Vic.) 2006 2 BCP03 Plumbing and Services Training Package Assessment Record Assessment method Please read the following instructions about your assessment. They will help you to achieve the level of performance required for a successful assessment. 1. You will need to read the assessment checklist and decide if you are ready to undertake the assessment. If you feel you cannot achieve the requirements of this assessment you should discuss further training with your assessor. 2. It is important that you clearly understand all the requirements of this assessment. If you are having difficulty with the terms or the steps to follow please speak to your assessor prior to commencing. 3. The assessment checklist is designed to help you progress in a logical manner through the tasks. If you follow this list and make sure you maintain the specified tolerances you will successfully achieve a satisfactory result. 4. There are quality checkpoints throughout the assessment which you need to observe. At these points have your assessor check your work prior to progressing. If you fail to observe these checkpoints and you have made a mistake or failed to maintain the specified tolerances you will have to rectify previous work. Depending on the nature of the mistake your assessor may stop the assessment and discuss further training and assessment arrangements. 5. A holistic approach to assessment means you will be assessed on a range of skills and knowledge and your ability to perform in a trade like manner. Not only will your skills and knowledge be assessed but also your ability to work safely. The way you work and your ability to work safely with tools and fellow workers will be observed and recorded by your assessor. Your ability to organise the task and work efficiently with regard to your time and materials will also be assessed by your assessor. 6. Your assessor is available throughout this assessment. If there is some aspect of this assessment that you have not previously considered you should seek clarification when it occurs. 7. Throughout the assessment you are encouraged to self assess your work. The self assess column can be initiated by you as you progress. Your assessor will assess you at certain checkpoints during your assessment and will initial the assessment checklist in the column provided. 8. During the assessment your assessor may ask you to explain various aspects of the job you are doing. Your assessor may also ask you specific questions about similar jobs or situations to determine your ability to problem solve and transfer knowledge to similar situations. 9. On completion of this assessment your assessor will discuss how you went and provide feedback. You should also take this opportunity to discuss any concerns you had with the assessment. Your assessor will take a copy of the assessment checklist to enter results on your student record. © Plumbing Training Moderation Group (Vic.) 2006 3 BCP03 Plumbing and Services Training Package Assessment Record Resources required to complete assessment: Texts AS3500.3.2 Stormwater Drainage – Acceptable Solutions 1998 Standards Australia. SAA HB 114: Guidelines for the design of eaves and box gutters. Manufacturers’ literature and specifications. State or Territories Regulations may override this Learning Guide. Web sites www.niceeasy.com.au www.wateronline.com www.hydroxyl.com www.masterplumbers.com Hand and power tools required to complete assessment: Hand tools Snips Tape measure Ruler Hammer Folding tools Pop rivet gun Square Hacksaw Hacking knife © Plumbing Training Moderation Group (Vic.) 2006 4 BCP03 Plumbing and Services Training Package Assessment Record Power Tools Power drill Tek drill Electric shears Electric nibbler © Plumbing Training Moderation Group (Vic.) 2006 5 BCP03 Plumbing and Services Training Package Assessment Record BCP03 competency standards credited on completion of this assessment task Code Title BCPRF3004A Install roof components Full or Partial Nominal Hours F 22 Assessment task checklist This assessment task incorporates the following requirements: Complete resource books relevant to task Complete theory (may be print based or computer) tests relevant to task *(AP) Obtain relevant standards, codes, regulations and instructions related to roofing installations Obtain plans/specifications for task Discuss the task requirements with your assessor Complete a job safety analysis (JSA) and list OH&S requirements *(AP) Plan the task Select appropriate tools and equipment Generate material list (if relevant) Plan sequence of work This assessment consists of three individual tasks competency will be achieved upon completion of all four tasks to the specified standard. Task number 1 In this task you will be required to fabricate and install a sheet-metal roof flashing for a ridge roof ventilation system. as per your assessment task drawing. Sheet-metal is to be .64mm zincalume or colorbond,. Task number 2 In this task you will be required to flash a rectangular or round roof component penetrating a corrugated iron roof. Sheet-metal used for fabrication will be .64mm zincalume or colorbond. Task number 3 In this task you will be required to flash a rectangular Box Louvre through a metal deck roof using apron flashings on front and sides. Flashings will be fabricated from .64mm zincalume or colorbond sheet-metal. All work should be performed to industry standards and the finished job should be watertight and sealed with silicone sealant where appropriate. All work should meet the requirements of Australian Standards and manufacturers guidelines. *(AP) – Assessment Point © Plumbing Training Moderation Group (Vic.) 2006 6 BCP03 Plumbing and Services Training Package Assessment Record BCPRF3004A Install roof components Apprentice name: Group number: Student number: JOB 1 Ridge Vent Installation Ridge Capping Ridge Vent © Plumbing Training Moderation Group (Vic.) 2006 7 BCP03 Plumbing and Services Training Package Assessment Record JOB 2 Roof Vent Installation (round or rectangular) Corrugated iron roof sheeting This roof vent may be round or square depending on availability Roof Vent © Plumbing Training Moderation Group (Vic.) 2006 8 BCP03 Plumbing and Services Training Package Assessment Record JOB 3 Non Mechanical Rotary Louvre Installation © Plumbing Training Moderation Group (Vic.) 2006 9 Assessment task criteria Self assessment BCP03 Plumbing and Services Training Package Assessment Record Assessor use only NYC 1 BCPCM3001A – Flash Penetrations Through Roofs & Walls resource completed and checked – WN Locate, interpret and apply relevant information, standards and specifications to SA HB 39 WN Communicate and work effectively and safely with others PO Apply safety requirements throughout the work sequence, including the use of personal protective clothing and equipment PO Correct selection of tools and equipment PO Correct application to avoid electrolysis and dissimilar metals DM QN Silicon applied correctly, excess silicon removed,. DM QN Provision made for thermal expansion DM QN Minimum height of the up stand achieved as per HB39 Regulations Pop Rivets placed at a maximum of 40mm apart Compliance with regulations, standards and organisational quality procedures and processes Work area is cleared with correct disposal of waste and tools and equipment are cleaned, checked, maintained and stored according to workplace procedures and manufacturers’ instructions Documentation has been completed in accordance with workplace requirements 2 C 3 1 2 3 DM Possibility of capillary action avoided All joints water tight Sign and Date Ass PO PO PO DM PO WD © Plumbing Training Moderation Group (Vic.) 2006 10 BCP03 Plumbing and Services Training Package Assessment Record Assessment method legend Key Assessment method Description QS Questioning oral/written Assessor will ask a range of questions from the moderated bank of questions that supports the underpinning skills and knowledge required to achieve competency in this unit. Questions may be answered in written or oral form. WN Written notes Apprentice will complete written notes, activities or student resource materials to support the achievement of underpinning knowledge required to achieve competency in this unit. TB Test bank Apprentice will complete computer test bank assessment, which supports the underpinning skills and knowledge required to achieve competency in this unit. PO Practical observation Assessor will observe the apprentice complete practical task/s that meet the assessment criteria to the required specification in the workplace. DM Demonstration Assessor will observe the apprentice complete practical task/s that meet the assessment criteria to the required specification in a simulated work environment. CS Case study/project Apprentice will complete workplace-based projects or case study reports to support the underpinning skills and knowledge required to achieve competency in this unit. LB Logbook 3P Third party report Assessor will seek report from apprentice’s workplace employer, supervisor or other approved party on the performance of an apprentice in the workplace against assessment task criteria and requirements of the unit. WD Workplace documents Apprentice will provide copies of workplace documents to support the underpinning skills and knowledge required to achieve competency in this unit. Apprentice will provide evidence of practical work and/or assessment tasks completed at the workplace via personal logbook. © Plumbing Training Moderation Group (Vic.) 2006 11 BCP03 Plumbing and Services Training Package Assessment Record Agreement/Acknowledgement I accept the conditions of the assessment I am about to participate in. I understand that follow up assessments may be required if it is found I need further training in part or all of this competency. I shall undergo the necessary training if required by the teacher / assessor to successfully satisfy all standards as stated in the evidence guide of the relevant unit of competency found in the BCP03 Plumbing and Services Training Package. Unit title/s: Install roof components Unit code/s: BCPRF3004A Apprentice/Participant Name: Teacher/Assessor Name: Training recommendation notes: Student/Participant comments: I declare (apprentice name) has been assessed to be competent/not yet competent for the unit/s BCPCM3001A Flash penetrations through roofs and walls Teacher’s signature Date Student’s signature Date © Plumbing Training Moderation Group (Vic.) 2006 12 Underpinning theory questions 1. What is the correct procedure for applying silicone sealant? 2. What is the minimum up-stand for flashing penetrations? 3. What restrictions if any are placed on the following materials? 1 Lead 2 Zinc 3 Galvanised steel 4 Aluminium 5 Zincalume 4. State the minimum length of flashing material required to project under the top overlapping roof material? 5. How is capillary action prevented when making a penetration through a lap on corrugated iron? 6. What is the purpose of an anti capillary break? 7. What may be required in order to retain the integrity of a roof structure when making a penetration through it? 8. When working on steep roofs above a height of 2 metres what safety requirements must be adhered to? 9. How should the top ends of roof sheets be prepared prior to over flashings being installed? 10. For a roof ventilator to remove warm air from a building effectively what would be the most appropriate location for the vent? <Insert your institute logo here> BCP03 Plumbing and Services Training Package Assessment Record Job safety analysis Install roof components Signed off: Contractor: Date: Task: Accepted: Yes No Area: Procedure (in steps) Possible hazards Safety controls 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. Produced by Training Package Implementation Projects D:\116102629.doc 12-Feb-16 Sample Page 1