Supplementary information Local structure order in Pd78Cu6Si16

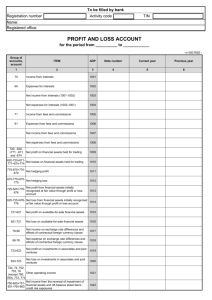

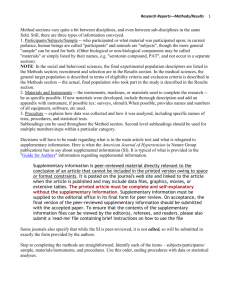

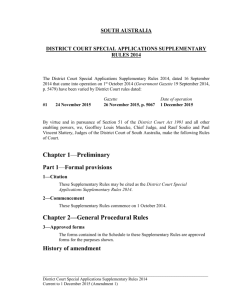

advertisement

Supplementary information Local structure order in Pd78Cu6Si16 liquid G. Q. Yue a,b, Y. Zhang b, Y. Sun b, B. Shen a, F. Dong a,Z. Y. Wang a, R. J. Zhang a, Y. X. Zheng a, M. J. Kramerb, S. Y. Wanga,b,c*, C. Z. Wangb,#, K. M, Hob, and L. Y. Chena a Shanghai Ultra-Precision Optical Manufacturing Engineering Center and Department of Optical Science and Engineering, Fudan University, Shanghai, 200433, China b Ames Laboratory, U. S. Department of Energy and Department of Physics and Astronomy, Iowa State University, Ames, Iowa 50011, USA c Key Laboratory for Information Science of Electromagnetic Waves (MoE), Shanghai 200433, China Corresponding author: songyouwang@fudan.edu.cn and wangcz@ameslab.gov Corresponding author: songyouwang@fudan.edu.cn and wangcz@ameslab.gov The undercooled liquid It is well known that a liquid can be undercooled (also known as supercooled) below its melting temperature. Undercooling is the process of lowering the temperature of a liquid below its melting point without it becoming a solid. A liquid crossing its melting (freezing) point will crystalize in the presence of a seed crystal or nucleus around which a crystal structure can form creating a solid. Lacking any such nuclei, the liquid phase can be maintained all the way down to the temperature at which crystal homogeneous nucleation occurs. Homogeneous nucleation can occur above the glass transition temperature, but if homogeneous nucleation has not occurred above that temperature an amorphous (non-crystalline) solid will form (see reference R1). The material is undercooled liquid in the temperature range of the melting temperature Tm ~ the glass transition temperature Tg.1 Undercooled liquids have been observed for many glass-forming metallic alloys. For Pd78Cu6Si16 alloy, the glass transition temperature Tg has been determined by experiment to be 630 K.2 The cooling rate in our molecular dynamics (MD) simulations is much faster than that of experiments, thus the Tg of simulations would be higher than that of experiments. In our manuscript, two temperatures, 962 K and 1009 K, are below the melting temperature. In order to verify the Pd78Cu6Si16 alloy at 962 K and 1009 K are in the undercooled liquid state, the diffusion coefficient D is calculated by taking the slope of the time dependent mean-square displacement (Eq. S1) through the Einstein relation (Eq. S2). The mean-square displacement as a function of time is given by (S1) where Nα is the number of α atoms, Riα are the coordinates of atom i, and τ is the arbitrary origin of time. Then D can be derived through the Einstein relation, (S2) The results were shown in Figure S1. It can be seen that the atomic diffusion at 962 and 1009 K is still very high with D=4.59×10-6 cm2/s at 962 K and D=5.52×10-6 cm2/s at 1009 K. It can also be seen that the turning point of the diffusion coefficient D(in natural logarithms scale)as the function of 1/T in Figure S1 is at 900 K. These results clearly indicate that the system at 962 K and 1009 K is in the liquid state. To further verify the system at temperatures of 962 and 1009 K is in the liquid state, we computed the self-part of the time-dependent van Hove correlation function (S3) where N is the number of atoms in the system, rj(t) is the time-dependent position coordinate of the jth atom. Here, 4πr2Gs(r, t)dr is the probability of finding at time t an atom in the vicinity dr of points at the distance r given that initially the particle was located at the origin. The comparison of the self-part of the time-dependent van Hove correlation function Gs(r,t) for Pd78Cu6Si16 alloy at 300, 962, 1009, and 1220 K are given in Figure S2. At 300 K, the system is solid and Gs(r,t) clearly shows that atoms vibrate around the equilibrium position with small displacements. The Gs(r,t) hardly changes with time at 300 K. By contrast, at 962 K and 1009 K, not only the displacements increase with time, but also Gs(r,t) has a much longer tail. The behavior of the Gs(r,t) at 962 and 1009 K is therefore very different from that of solid at 300K but similar to that of the liquid at 1220 K (which is above the melting temperature) as one can see from Figure S2. All of these results further verify the sample is undercooled liquid at 962 K and 1009 K. Supplementary Figure S1 0.13534 D (cm2/s) 1220 K 0.04979 1132 K 1009 K 962 K 900 K 0.01832 0.8 1.0 800 K 1.2 1000/T (K-1) 700 K 1.4 Supplementary Figure S1. The diffusion coefficient D (in natural logarithms scale) of Pd78Cu6Si16 alloy at different temperatures. Supplementary Figure S2 0.15 0.10 300 K 0.05 0.00 t=0.6ps t=1.2ps t=1.8ps t=3.0ps t=6.0ps 962 K 0.05 Gs(r,t ) 0.00 1009 K 0.05 0.00 1220 K 0.05 0.00 0.0 0.5 1.0 1.5 r (A) 2.0 2.5 Supplementary Figure S2. The self-part of the van Hove correlation function Gs(r,t) for Pd78Cu6Si16 alloy at 300 K at four different times and at 962, 1009, and 1220 K at five different times. Supplementary Figure S3 Pd2Si (189, hP9) Pd5Si (4, mP24) Pd9Si2 (62, oP44) Pd3Si (62, oP16) PdSi (62, oP8) Supplementary Figure S3. The crystal structures of Pd-Si binary compounds Pd2Si, Pd3Si, Pd5Si, Pd9Si2, and PdSi. The contents in parentheses are the space group number and Pearson symbol of the corresponding crystal in turn. References 1 Debenedetti, P. G. & Stillinger, F. H. Supercooled liquids and the glass transition. Nature 410, 259-267 (2001). 2 Wang, W. H. Elastic moduli and behaviors of metallic glasses. Journal of Non-Crystalline Solids 351, 1481-1485 (2005).