Develop - Liquid Crystal Institute

advertisement

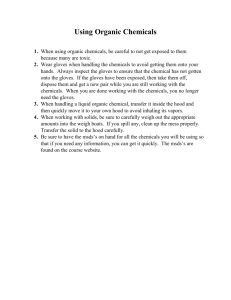

Process and Information Document #A-111 Cleanroom Facility, Liquid Crystal Institute, Kent State University, Kent, Ohio Photoresist Develop This procedure uses the photolithography wet bench. The photolithography wet bench is located in the Cleanroom Class 1000 South area. The bench requires house exhaust for operation. The wet bench/hood is our primary line of defense for removing volatile and hazardous chemicals/vapors from our cleanroom working environment. The hoods draw a large amount of air out of the facility. When the hoods are not is use, there is no reason to draw this treated air (thermal, humidity, particle; expensive) out of the facility to be wasted. So when not in use the hood faces should be closed. Also, the hoods will not remove volatiles fast enough if work is not performed in the hood. Therefore, chemical washing, acid etching, ect., should not be done anywhere but in the hood, i.e., not on table tops throughout the room. Not only is this hazardous to your well being, but it is hazardous to the equipment of the room. Acid vapors cause corrosion of steel tables and equipment and volatile organic solvents can cause the deterioration of susceptible materials used for air filtration, the flooring, etc. Gloves and safety glasses must always be worn while in the cleanroom. Safety glasses and gloves must also be worn by anyone standing around you, watching you or doing unrelated work. Regular gloves (latex, nitrile) are sufficient to protect your hands from the normal cleaning solvents (water, IPA), but have varying degrees of effectiveness for other solvents (acetone, NMP). Gloves offer adequate protection as long as they are intact. Pinholes develop in gloves in storage and therefore, the official facility policy is to wear two pair of gloves. If one pair has a hole it will be unlikely that the other one will as well. This is most important for acid etch procedures and not as much so for solvent washing procedures. Developer chemical is amine based. It must not be dumped down the drain. After use, developer chemical should be collected in waste developer containers and sealed. This chemical is also sensitive to air and will eventually become pH neutralized by CO2. Therefore, developer chemical must be sealed when not in use and its functionality will decrease over time upon continued exposure to air. The essence of using the developer chemical is as follows: 1. Pour an amount of developer chemical into a shallow glass tray, sufficient to hold and cover the substrate. 2. Submerge the substrate into the chemical and gently agitate. 3. 4. 5. 6. Remove the substrate after the appropriate time interval and rinse with water. Evaluate the substrate to make sure the desired outcome has been reached. Proceed directly to the etching process without further cleaning. Note: If there is not enough time to finish etching, substrates can be blown dry with compressed gas and stored. Do not attempt to clean them at this point or the remaining photoresist will be ruined by solvents. The above information is intended to give a general overview of the process and not enough information has been given for anyone to use the developer chemical without additional formal training and certification. Should you need to do pattern developing, please request formal training for the use of this machine from facility staff. Training sessions are scheduled as staff have time and you may have to wait a week or so until a time slot can be created and to allow for multiple users desiring the same training to be assembled into a group. Only Cleanroom Staff are allowed to train users on the use of cleanroom facility equipment and processes. Please do not ask others in the department, your company or in your research group to assist you to avoid formal training and certification. If training is given by unendorsed individuals, both the trainer and trainee will lose cleanroom use privileges for a period of time deemed appropriate by facility staff.