Standard Operating Procedures

advertisement

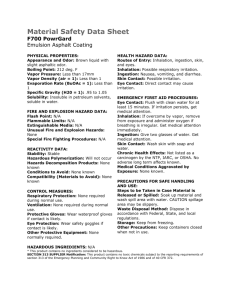

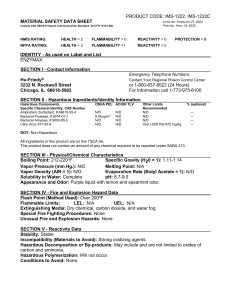

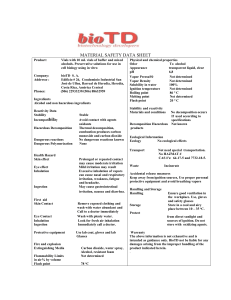

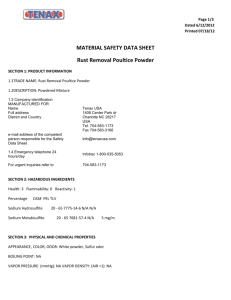

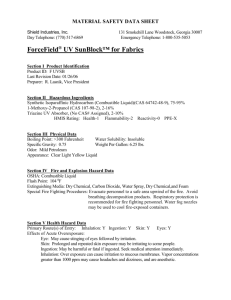

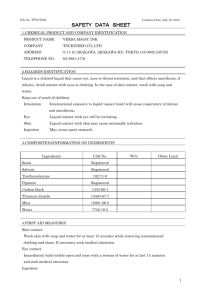

Standard Operating Procedure ________________________________________________________ Read the EH&S Standard Operating Procedures Fact Sheet before filling out this form. Print out the completed form and keep a readily accessible hard copy in the lab (also keeping an electronic copy is highly recommended). ______________________________________________________ Date: November 5, 2010 SOP Title: LECO High Pressure Operating Protocol Principal Investigator: Richmond Sarpong Room and Building: 926 Latimer Lab Phone Number: (510) 643-2485 Section 1 – Process Ultra-high pressure experiments. Section 2 – Hazardous Chemicals Chemicals involved include castor oil, hydraulic oil and copper paste. Section 3 – Potential Hazards For more information please see appropriate MSDS. Castor Oil Potential Acute Health Effects: Slightly hazardous in case of skin contact (irritant), eye contact (irritant), ingestion, and/or inhalation. Potential Chronic Health Effects: CARCINOGENIC EFFECTS: Not available. MUTAGENIC EFFECTS: Not available. TERATOGENIC EFFECTS: Not available. DEVELOPMENTAL TOXICITY: Not available. Repeated or prolonged exposure is not known to aggravate medical condition. Routes of Entry: Absorbed through skin. Eye contact. Toxicity to Animals: LD50: Not available. LC50: Not available. Chronic Effects on Humans: Not available. Other Toxic Effects on Humans: Slightly hazardous in case of skin contact (irritant), of ingestion, of inhalation. Special Remarks on Toxicity to Animals: Not available. Special Remarks on Chronic Effects on Humans: Not available. Special Remarks on other Toxic Effects on Humans: Acute Potential Health Effects: Skin: May cause skin irritation. Eyes: May cause eye irritation. Ingestion: May cause digestive tract irritation. It is considered a purgative and stimulates smooth muscle of the digestive tract. Inhalation: Mist may cause respiratory tract irritation. **EMERGENCY FIRST AID PROCEDURES** Eye Contact: Check for and remove any contact lenses. In case of contact, immediately flush eyes with plenty of water for at least 15 minutes using an eye wash. Get medical attention if irritation occurs. Skin Contact: Wash with soap and water. Cover the irritated skin with an emollient. Get medical attention if irritation develops. Serious Skin Contact: Not available. Inhalation: If inhaled, remove to fresh air. If not breathing, give artificial respiration. If breathing is difficult, give oxygen. Get medical attention. Serious Inhalation: Not available. Ingestion: Do NOT induce vomiting unless directed to do so by medical personnel. Never give anything by mouth to an unconscious person. If large quantities of this material are swallowed, call a physician immediately. Loosen tight clothing such as a collar, tie, belt or waistband. Serious Ingestion: Not available. Hydraulic Oil ORAL TOXICITY: Greater than 5000 mg/kg in rats. Based on data from components. EYE IRRITATION: Not expected to cause eye irritation. Based on data from components. SKIN IRRITATION: Not expected to cause skin irritation. Based on data from components. TLV: None established. Oil mist = 5 mg/cu meter. **EMERGENCY FIRST AID PROCEDURES** SKIN: Wash skin thoroughly with soap and water. Get medical attention if irritation develops. Launder contaminated clothing before reuse. If product is injected under pressure into or under the skin, or into any part of the body, a physician should immediately evaluate the individual regardless of the appearance of the wound or its size EYES: Flush eyes with plenty of water for 15 minutes using an eye wash. Get medical attention if eye irritation develops or persists. INHALATION: Remove to fresh air. Get medical attention if breathing difficulty persists. ORAL: Call a physician. Do NOT induce vomiting. Never give anything to an unconscious person by mouth. Section 4 – Approvals Required All experiments should be approved by PI prior to being carried out Section 5 – Designated Area The high pressure apparatus can be found in room 926 Latimer Hall. All experiments should be carried out in this area. Section 6 – Special Handling Procedures and Storage Requirements Castor Oil Precautions: Keep away from heat and sources of ignition. Empty containers pose a fire risk, evaporate the residue under a fume hood. Ground all equipment containing material. Do not breathe gas/fumes/vapor/spray. Storage: Keep container tightly closed and in a cool, well-ventilated area. Do not store above 24°C (75.2°F). Prevent from freezing. Hydraulic Oil Precautions: Keep containers closed when not in use. Do not handle or store near high heat or flames. Avoid breathing oil mists, wash skin thoroughly with soap and water after handling. Section 7 – Personal Protective Equipment Personal protective equipment required include safety glasses, lab coat, and gloves (latex or nitrile) Section 8 – Engineering/Ventilation Controls Castor Oil Provide exhaust ventilation or other engineering controls to keep the airborne concentrations of vapors below their respective threshold limit value. Ensure that eyewash stations and safety showers are proximal to the work-station location. 150 Hydraulic Oil Mechanical ventilation recommended. Section 9 – Spill and Accident Procedures 150 Hydraulic Oil Spill Procedures: Prevent entry into sewers and waterways. Pick up free liquid for recycle or disposal. Absorb small amounts with an inert material. Castor Oil Small Spill: Absorb with an inert material and put the spilled material in an appropriate waste disposal. Large Spill: Absorb with an inert material and put the spilled material in an appropriate waste disposal. Finish cleaning by spreading water on the contaminated surface and allow to evacuate through the sanitary system. Section 10 – Waste Disposal Castor Oil No special waste disposal is required. 150 Hydraulic Oil Disposal should be in compliance with current federal, state, and local laws. Materials may become hazardous waste through use. Consider recycling. Section 11 - Decontamination If contaminated wash with soap and water. Section 12 – Process Steps To Insert Sample: 1. Open chamber, add sample and push syringes to bottom. 2. Add castor oil until ~ 1 inch to top of pressure chamber. 3. Wipe thread and replace lid. 4. Secure center of lid with wrench and begin threading lid. 5. Catch excess castor oil with a pipette in the hold of the lid. 6. If no oil is seen coming out of lid, more must be added. 7. When the lid is all the way tightened, reverse one third turn. 8. Attach sensor (or plug) to hole in center of lid and tighten. 9. Open main valve (counter-clockwise). Motor lever to left. 10. Motor on until 6000 psi on the large gauge. Jog to 7000 psi. 11. Close main valve (clockwise). Wait 30-40 minutes for pressure to equilibrate. 12. Open main valve again and jog pressure to 7000 psi. 13. Close main valve. 14. Release pump pressure: Motor lever to right, jog to 500 psi on small gauge. Motor lever to left, jog once and small gauge should go to 0. 15. Allow reaction to proceed for desired time interval. To Remove Sample: 16. Bring back pump pressure: Motor lever to right, jog to 1000 psi -2500 psi on small gauge. 17. Open main valve slowly so large gauge goes to 0. 18. Turn pump on (piston will go down slowly). 19. When pressure returns to small gauge, turn motor off. 20. Motor lever to left, jog once and small gauge goes to 0. 21. Reverse loading instructions to remove sample. (Be careful not to scratch sides of chamber with tweezers) 22. Keep as clean as possible. 23. Remove all lab debris (paper towels contaminated with castor oil) from room. Heating Sample: Heat castor oil to desired temperature by selecting the desired temperature on heating unit (0-200oC) Allow temperature to equilibrate (approximately 30-60 minutes) Proceed as normal to insert sample (see above) Note: Care should be taken not to overfill the sample area when heating as the oil will expand when heated and flow into the threaded section. If the level of castor oil becomes too high a syringe can be used to remove excess oil. Alternatively the sample can be inserted, the lid closed, pump to desired pressure and then heat the unit to the desired temperature. As the temperature increases so does the pressure. Therefore, do not initially pressurize to final desired pressure as it will be overshot as temperature increases. After desired temperature has been reached the desired pressure can be obtained by jogging the system up. Maintenance: Charles Gates at Leco – (814) 355-7903 Training Documentation Name (Printed) Signature Date