100.02 Appendix 4 - Plastic, Lead Acid Batteries, and Steel

advertisement

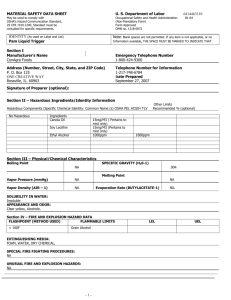

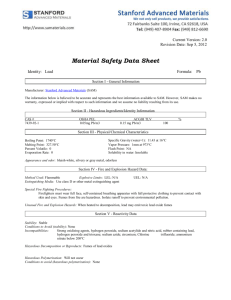

R E G U L A T O R Y A F F A I R S M A N U A L S E R I E S EPCRA Reporting Requirements P R O G R A M Appendix 3: Additional Reporting Guidance for SARA 312 Effective Date: February 2005 Rev. # 1 Mandatory Discretionary Page 1 1 0 0 1 0 2 . 0 1 R E G U L A T O R Y A F F A I R S M A N U A L S E R I E S EPCRA Reporting Requirements P R O G R A M 1 0 0 1 0 2 . 0 1 REGULATORY AFFAIRS DEPARTMENT ENVIRONMENTAL REGULATION OVERVIEW DISTRIBUTION: B. Knighton, K. Sitterle, J. Casey, L. Elder, G. Smith FROM: T. Tisa, D. Herbst, B. Hornyak, M. Nibert DATE: February 3, 2005 SUBJECT: Requirement for Reporting Sheet Metal, Lead Acid Batteries, and Plastics on SARA 312 OVERVIEW: This document serves as requirements on three areas where the above types of raw materials are reportable under EPCRA SARA 312. Each facility having these three items need to develop calculations based on the Q&A information given below to document that they do, or do not have to prepare a Tier II for these three items. Hazardous chemicals like paints, solvents, chemicals must be reported according to the regulations. INVENTORY REPORTING: “ Shall submit the Tier II form on or before March 1…. Covering all hazardous chemicals present at facility at any one time during the proceeding calendar year in amounts equal to or greater that thresholds. “ Hazardous chemical means any hazardous chemical as defined under 29 CFR § 1910.1200 (c) – any chemical which is a physical hazard or health hazard These are the physical and health hazards i. Immediate (acute) health hazard ii. Delayed (chronic) health hazard iii. Fire hazard iv. Sudden release of pressure hazard v. Reactive hazard Exemption – any substance present, as a sold in any manufactured item to the exempt exposure to the substance does not occur under normal conditions of use. Effective Date: February 2005 \ Rev. # 1 Mandatory Discretionary Page 2 R E G U L A T O R Y A F F A I R S M A N U A L S E R I E S EPCRA Reporting Requirements P R O G R A M 1 0 0 1 0 2 . 0 1 GUIDANCE MATERIAL: “Directive for Reporting Lead Acid Batteries under Sections 311/312” A directive published by OSHA sets forth the definition of an article and clearly identifies lead acid batteries as examples of products which would NOT be considered “articles” and would thus be exempted from the requirements. The directive states that the following is an example of a product which is not an article under the standard and thus is not exempted from the requirements: Lead acid batteries which have the potential to leak, spill or break during normal conditions of use, including foreseeable emergencies. In addition, lead acid batteries have the potential to emit hydrogen which may result in a fire or explosion upon ignition. OSHA further clarified this issue in another correspondence between OSHA and the Texas Department of Health: Therefore, all forms of lead-acid batteries are not considered articles because they have the potential to leak, spill, or break during normal conditions of use, including foreseeable emergencies. Consequently, an MSDS is required under OSHA. If none of EPCRA’s exemptions to the definition of hazardous chemical apply, and if the total amount of sulfuric acid present exceeds the sulfuric acid threshold level as defined under EPCRA, or the total amount of lead present exceeds the lead threshold level as defined under EPCRA, then the facility must report under EPCRA Sections 311 and 312. Example: Sulfuric acid in lead acid batteries need to be included if the site does battery charging and there is potential to expose employees. Calculation: 10 fork lift batteries (50 pounds of sulfuric acid) and 50 UPS batteries (1 pound of acid each) Total inventory is 550 pounds of sulfuric acid. "Sheet Metal Reporting and the Exemption for Manufactured Solids Under Sections 311/312" QUESTION: A facility stores and processes sheet metal that contains a hazardous chemical requiring a material safety data sheet (MSDS) under OSHA's Hazard Communication Standard (29 CFR Section 1910.1200(c)). The sheet metal, when in storage, is considered a manufactured solid and is therefore excluded from the definition of hazardous chemical under EPCRA Section 311(e)(2). Does this exclusion still apply when the sheet metal is cut, welded, or brazed? ANSWER: Effective Date: February 2005 Rev. # 1 Mandatory Discretionary Page 3 R E G U L A T O R Y A F F A I R S M A N U A L S E R I E S EPCRA Reporting Requirements P R O G R A M 1 0 0 1 0 2 . 0 1 The exclusion for manufactured solids in EPCRA Section 311(e)(2) applies to "[a]ny substance present as a solid in any manufactured item to the extent exposure to that substance does not occur under normal conditions of use." Sheet metal is considered a "manufactured item" which is typically present as a solid. To determine whether or not the sheet metal falls under this exemption, the owner/operator of the facility must determine the extent of exposure to the substance under normal conditions of use at that facility. Storing, welding, and cutting can all be considered "normal conditions of use" at a facility. In this example, only the sheet metal in storage is exempt under Section 311(e)(2) because it does not create a potential for exposure to a hazardous chemical. Cutting, welding, brazing, or otherwise altering the form of the sheet metal does create a potential for exposure, negating the exclusion under Section 311(e)(2) and subjecting the weight of the maximum amount of sheet metal used in this fashion at any time to reporting requirements under 40 CFR Section 370.20(b). The regulations at 40 CFR Section 370.20(b) state that a facility must submit an MSDS and a Tier I form (or Tier II form) for any hazardous chemical present at a facility in an amount greater than 10,000 pounds and for any extremely hazardous substance present at the facility in an amount greater than or equal to 500 pounds or the threshold planning quantity, whichever is lower. The entire weight of the items to be altered (the non-exempt items) is counted toward the threshold, not just the weight of the hazardous chemical in the section of the item on which work is done. The weight of the entire piece of sheet metal is used because the sheet is the manufactured item; the exemption cannot apply to a portion of a manufactured item. (December 1993 Monthly Hotline Report) Sample Calculation: 1 sheet of cold roll steel goes through a laser cutter. Total weight of sheet is 100 pounds. Total inventory is 100 pounds (do need to add all of the steel undergoing welding, brazing at the same time). Mechanical cutting should not be included. “Polymer Pellet Reporting under Sections 311 and 312” Question: If polymers are in pellet form and require material safety data sheets, are they exempt from the definition of hazardous chemical under SARA Section 311(e)(2)? Answer: The Section 311(e)(2) exemption from the definition of hazardous chemical applies to "[a]ny substance present as a solid in any manufactured item to the extent exposure to the substance does not occur under normal conditions of use." Polymers in pellet form are manufactured items in a solid state and would not normally be a source of any hazardous chemical exposure; therefore the polymers in pellet form are normally exempt (52 FR 38344; October 15, 1987). Altering the solid state of the pellets (e.g., as part of a manufacturing process) creates a potential for exposure and would cause the polymers to become subject to the hazardous chemical threshold determinations (40 CFR Section 370.20(b)). When determining whether a threshold has been met, the weight of the polymer pellets "in Effective Date: February 2005 Rev. # 1 Mandatory Discretionary Page 4 R E G U L A T O R Y A F F A I R S M A N U A L S E R I E S EPCRA Reporting Requirements P R O G R A M 1 0 0 1 0 2 . 0 1 process" are no longer exempted as solid manufactured items and should be added to the weight of the polymers not in pellet form and not otherwise exempt. If at any one time the polymers not subject to an exemption exceed the thresholds, then hazardous chemical reporting is required (40 CFR Part370). (February 1993 Monthly Hotline Report) Sample calculation: 25 injection-molding machines. All use polypropylene (PP) pellets. 10 machines have been determined to have 25 pound of melted PP within them (barrel, nozzle and mold). 15 machines have 50 pounds of melted PP within them. The total inventory of PP that meets the definition of hazardous chemicals is 250 pounds + 750 pounds = 1000 pounds. This is less than 10,000 pounds therefore not required to report on 312. Effective Date: February 2005 Rev. # 1 Mandatory Discretionary Page 5