Background:

advertisement

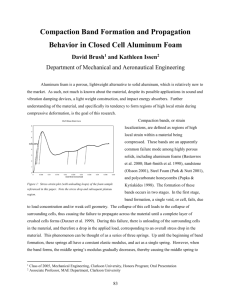

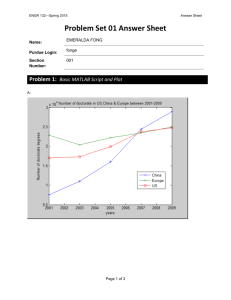

Compaction Band Formation and Propagation Behavior in Closed Cell Aluminum Foam David Brush ’05, Mechanical Engineering Department Faculty Advisor: Kathleen Issen, Mechanical Engineering Department Abstract: Aluminum foam is a porous, lightweight alternative to solid aluminum which is relatively new to the market. As such, not much is known about the material, despite its possible applications in sound and vibration damping devices, a lightweight constructions, and impact energy absorbers. Further understanding of the material, and specifically its tendency to form regions of high local strain during compressive deformation, is the goal of this research. Similar research performed by William A. Olsson on Sandstone will be used in part as a guideline, and an attempt to adapt his sandstone theory to aluminum foam will be made. Background: Compaction bands, or strain C5a15 Stress Strain Curve 8 localizations, are defined as regions 7 of high local strain within a bands are an apparently common 5 Stress (MPa) material being compressed. These 6 4 3 failure mode among highly porous solids, including aluminum foams (Bastawros et al. 2000; Bart-Smith 2 1 0 0 0.005 0.01 0.015 0.02 0.025 0.03 0.035 0.04 0.045 0.05 Axial Strain (Crosshead) et al. 1998), sandstone (Olsson 2001), Steel Foam (Park & Nutt Figure 1: Stress-strain plot (with unloading loops) of the foam sample referenced in this paper. Note the stress drop and subsequent plateau region. 2001), and polycarbonate honeycombs (Papka & Kyriakides 1998). The formation of these bands occurs in two stages. In the first stage, band formation, a single void, or cell, fails, due to load concentration and/or weak cell geometry. The collapse of this cell leads to the collapse of surrounding cells, thus causing the failure to propagate across the material until a complete layer of crushed cells forms (Daxner et al. 1999). During this failure, there is unloading of the surrounding cells in the material, and therefore a drop in the applied load, corresponding to an overall stress drop in the material. This phenomenon can be thought of as a series of three springs. Up until the beginning of band formation, these springs all have a constant elastic modulus, and act as a single spring. However, when the band forms, the middle spring’s modulus gradually decreases, thereby causing the middle spring to take up some of the displacement of the surrounding springs. The second, longer stage (band propagation) is when this original band propagates not across the material, but along it (parallel to the loading). Not all materials that form bands will exhibit propagation, however, many form multiple discrete bands instead. No matter whether a material propagates or forms multiple bands, this stage is characterized by a largely constant stress within the material, indicated by a “plateau region” on stress-strain plots. Similar research has been performed regarding the localization behavior of sandstone regarding propagation behavior (Olsson 2001). Linking of his results and those gathered from this research would make excellent progress toward a unified theory for compaction band formation in many, if not all porous solids. Of particular interest is the equation relating band propagation speed and overall deformation rate to change in porosity Where vr and vp are the rate of band thickening and overall specimen shortening, respectively, and P and Po are the band and original material porosities. The relation between relative propagation rate and energy absorption is also of interest, and is given by Where E – Eo is the change in strain energy, and σ is the plateau stress of the material. This second relation is of special interest due to the great potential aluminum foam has as an impact energy absorption material. Understanding this failure mechanism better is important for bringing porous materials into widespread use. Porous metals, such as aluminum foam, are already known to have many uses, including lightweight construction/filler material, sound damping, heat exchange, and impact energy absorbers (Sugimura et al. 1997; Bastawros et al. 1998; Daxner et al. 1999; Park & Nutt 2001). In construction materials, it is imperative that the material not be loaded past its peak stress, as doing this would lead to a massive compressive failure. Compression fractures in persons with osteoporosis may be looked at as such a failure. Also, as foam metals do not exhibit a fully elastic initial deformation, pre-loading of structural foam may be desired. Impact energy absorption applications, however, make full use of this same phenomenon, the plateau region of foam failure providing excellent energy absorption over a large strain at a nearly constant stress. Current/Planned Work: The focus of this research is on the band formation and propagation behavior in Aluminum foam, in particular Cymat. Samples of the material have already been compacted in a displacementcontrolled load frame, and images of one face of each specimen were taken throughout the process. Thus, the data for this research has already been gathered, although if the need arises, more samples can be tested. Figure 2: Full color strain map. The line down the center is the location of the vertical slice taken to and graphed in figure 3. Analysis starts in Vic2D. This program takes digital images and correlates them with a base image, finding displacements of the material imaged, then using those displacements to define local strains. Base images must be chosen based on what region of specimen deformation is to be analyzed, since too much difference between the two images analyzed will lead to a correlation breakdown and unusable results. Some preliminary analysis of the stress drop region has already been performed. 1 dimensional “slices” of strain data were taken from a sample both halfway down the stress drop and at the base of the stress drop. Numerical integration reveals that at both points along the drop, 5% of the total displacement put into the band (defining the band region as everywhere compressive deformation occurred) came not from the moving load frame, but from the unloading of the surrounding material. Since the material exhibits linear elastic unloading, this seems to indicate that there is a linear correlation between the drop in stress during band formation and the displacement put into the band. One basic question that must be answered in the course of this research is how to define a strain to use as band strain. For the above calculations, all negative strains are considered to be in the band. That same preliminary data, however, shows that some material far outside of the band region also exhibits some negative strain. One possible answer is to look at either the maximum or average unloading strain, and use some percentage of that value as the boundary value for the band region. Another possibility is to use the overall specimen strain, either at every individual point, or perhaps at the onset of band formation. At first, a logical choice for this boundary would seem to be at 0 strain, however this approach would only yield reasonable results when unloading outside of the band occurs (I.E. during band formation). Analysis of the stress drop Strains down central pixels (x=493) will be done by correlating digital 0.01 0 0 100 200 300 400 500 600 700 800 900 1000 images taken of already-crushed specimens taken during the drop -0.02 in Vic2D. Initially, the 2- strain -0.01 -0.03 dimensional array of local strains -0.04 produced will be analyzed by -0.05 isolating “strips” of data going -0.06 Y-axis location Figure 3: Vertical strip plot of the region noted in Figure 2. The large dip is the strain localization region, and is negative (compressive). The region outside of this exhibits a slight positive strain (unloading). through the specimen, holding either the horizontal or vertical coordinate constant. These strips can then be used to create plots which correlate position and strain. Horizontal strips will be taken to look for edge effects, or more accurately corner effects, in the material, mainly to ensure that data is not taken too close to the sides of the specimen throughout the rest of the analysis. Vertical strips will be used to examine the relation between the unloading region and band region of the specimen during the stress drop, both to look for general trends and to obtain maximum and average unloading strains if one of these is chosen as a candidate for the definition of the boundary between band and non band strain. Also, band thickness at the bottom of the stress drop will be found, and compared with the size of the stress drop for many different samples in an attempt to correlate the two phenomena (It is expected that larger stress drops will correlate with thicker initial bands). In the plateau region, analysis will be done using complete strain maps. Data will first be loaded into TecPlot, where it can be more easily manipulated. Using the definition for band strain chosen from those discussed, the strain maps will be reduced to black and white maps, with all locations in the sample with local strain exceeding the definition of band strain will be black, and everything else white. By using a pixel counter (Photoshop), the area of this black region can be quickly determined, and by dividing this area by the image width, an average band thickness is determined. This band thickness, calculated at regular intervals within the plateau region of deformation, will be Figure 4: Two-tone strain map used to determine average band thickness. used to try to compare the behavior of the foam to current sandstone band propagation theory which has been formulated by Olsson. Schedule of work to be done: Summer 2004: Most of the outlined data processing, initial data analysis, possible compaction of more specimens Weeks 1-2: Stress Drop Correlations taken, horizontal cross sections taken and analyzed for corner effects. Weeks 3-4: Vertical cross sections taken, analyzed for trends. Weeks 5-6: Stress Plateau Correlations taken, comparison of different definitions of minimum band strain made to determine best definition. Weeks 7-9: Strain maps converted to black and white band/no band images, calculation of average band widths made. Week 10: Attempt to formulate equations governing band propagation, possibly by adjusting Olsson’s results. Fall 2004: September-October: Completion of data analysis, compaction of additional specimens (if needed) continued work on adapting Olsson results to foam, continued analysis of Stress Drop data. November-December: Writing of final paper. Possibilities for Future Research: As noted previously, not all materials which form compaction bands form only one band which then propagates. Many materials, such as sandstone and other brands of aluminum foam such as Alporas, form multiple discrete bands. The reason for this is yet to be determined however. Additionally, many materials, such as sandstone, have a much smaller stress drop at band formation, but again, the reason for this is unknown, and may even be related to the number of bands formed, since Alporas and sandstone have much smaller stress drops than Cymat, and both of them also exhibit much smaller stress drops. Also, it might be worthwhile to compare stress drop size and band width to the ratio of cell size to specimen height, as it seems logical that all of these would be somehow related to one another. Finally, porous materials other than aluminum foam and sandstone exhibit similar localization and propagation behavior, and would benefit from similar analysis to this research. References: Bart-Smith H, Bastawros AF, Mumm DR, Evans AG, Sypeck DJ, Wadley HNG, Compressive deformation and yielding mechanisms in cellular Al alloys determined using X-ray tomography and surface strain mapping, Acta Mater, 46 (10), 3583-3592, 1998. Bastawaros AF, Bart-Smith H, Evans AG, Experimental analysis of deformation Mechanisms in a closed-cell aluminum alloy foam, Journal of the Mechanics And Physics of Solids, 48, 301-322, 2000. Daxner T, Bőhm HJ, Rammerstorfer FG, Mesoscopic simulation of inhomogeneous metallic foams with respect to energy absorption, Computational Materials Science, 16, 61-69, 1999. Olsson WA, Quasistatic propagation of compaction fronts in porous rock, Mechanics of Materials, 33, 659-668, 2001. Papka SD, Kyriakides S, In-plane crushing of a Polycarbonate Honeycomb, Int. J. Solids Structures, 35 (3-4), 239-267, 1998. Park C, Nutt SR, Anisotropy and strain localization in steel foam, Materials Science and Engineering, A299, 68-74, 2001. Sugimura Y, Meyer J, He MY, Bart-Smith H, Grenstedt J, Evans AG, On the mechanical performance of closed cell Al alloy foams, Acta Mater, 45 (12), 5245-5259, 1997.