Silane CAS No.7803-62-5 - UCSF Environment Health & Safety

advertisement

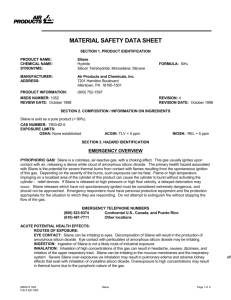

UCSF Lab Standard Operating Procedure Chemical Process, Name or Hazard Class: Silane Please fill out the form completely. Insure all users have access to this SOP. Refer to instructions for assistance. Enter text. Department: Date SOP was written: Enter date. This lab specific SOP has been reviewed and approved by: Principal Investigator Name: Enter text. Principal Investigator Signature Lab Manager/Supervisor: Type of SOP: ☐ Process ☒Hazardous Gas Enter text. ☒ Hazardous Class Purpose Silane is pyrophoric and a highly flammable gas. However, it does not always ignite when vented to the atmosphere. Lack of instantaneous ignition can lead to delayed ignition, resulting in fireballs or vapor cloud explosions, which can range in character from deflagration to detonation. It is important to understand the pyrophoric nature of silane and conditions surrounding ignition. There have been Silane explosions and accidents at various levels. If not stored and handled properly, Silane can pose a serious threat to the health and safety of laboratory personnel and emergency responders. Hence, it is important to thoroughly understand the properties of Silane and follow safety protocols to properly store and handle Silane. Several industrial and medical applications exist for silane and functionalized silanes. For instance, silanes are used as coupling agents to adhere glass fibers to a polymer matrix, stabilizing the composite material. In other words, silane coats the glass fibers to create better adhesion to the polymer chain. They can also be used to couple a bio-inert layer on a titanium implant. Other applications include water repellents, masonry protection, control of graffiti, applying polycrystalline silicon layers on silicon wafers when manufacturing semiconductors, and sealants. More recently, a growth in low-cost solar panel manufacturing has led to substantial consumption of silane for depositing amorphous silicon on glass and other surfaces. Silane is also used in supersonic combustion ramjets to initiate combustion in the compressed air stream. As it can burn using carbon dioxide as an oxidizer it is a candidate fuel for engines operating on Mars. Since this reaction has some byproducts which are solid (silicon dioxide and carbon) it is applicable only to liquid-fuel rockets (with liquid carbon dioxide), ramjets, or other reaction engines. Silane 1 Date: Click here to enter a date. Modified from SOP templates developed by UCLA EH&S (http://www.sop.ehs.ucla.edu/) Silane and similar compounds containing Si—H bonds are used as reducing agents in organic and organometallic chemistry. Physical & Chemical Properties/Definition of Chemical Group CAS#: 7803-62-5 Synonyms: Monosilane, silicon hydride, silicon tetrahydride, silicane Class: Pyrophoric and highly flammable gas Molecular Formula: SiH4 Form (physical state): Gas Flammable limits in air, % by volume: Lower: 1.4% Upper: 96.0% Potential Hazards/Toxicity Danger! Pyrophoric, flammable, high-pressure gas. Can ignite on contact with air. May form explosive mixtures with air. Does not need a source of ignition. Respiratory irritant. May cause respiratory system damage. Self-contained breathing apparatus and protective clothing may be required by rescue workers. Under ambient conditions, this colorless gas has a choking odor. Engineering Controls Always to be stored and used inside a gas cabinet. Personal Protective Equipment (PPE) Respiratory Protection If lab personnel would like to use respirator on a voluntary basis, they must be trained and fit-tested by EH&S. This is a regulatory requirement. (http://or.ucsf.edu/ehs/8193-DSY/version/default/part/4/data/) Hand & Body Protection Fire gloves Eye & Ear Protection Safety glasses, Face shield & Ear plugs Skin and Body Protection Nomex suit & Nomex hood First Aid Procedures Silane 2 Date: Click here to enter a date. Modified from SOP templates developed by UCLA EH&S (http://www.sop.ehs.ucla.edu/) If inhaled Immediately remove to fresh air. If not breathing, give artificial respiration. If breathing is difficult, qualified personnel may give oxygen. Call a physician. In case of skin contact Wash with soap and water. If irritation persists, seek medical attention. In case of eye contact Flush eyes with water. Hold the eyelids open and away from the eyeballs to ensure that all surfaces are flushed thoroughly. If irritation persists, seek medical attention. NOTES TO PHYSICIAN: There is no specific antidote. Treatment of overexposure should be directed at the control of symptoms and the clinical condition of the patient. Special Handling and Storage Requirements Basic Precautions Use only spark-proof tools and explosion-proof equipment. Keep away from heat, sparks, and open flame. Protect cylinders from damage. Use a suitable dolly to move cylinders; do not drag, roll, slide, or drop. All piped silane systems and associated equipment must be grounded. Electrical equipment must be non-sparking or explosion-proof. Never attempt to lift a cylinder by its cap; the cap is intended solely to protect the valve. Never insert an object (e.g., wrench, screw driver and pry bar) into cap openings. Doing so may damage the valve and cause a leak. Use an adjustable strap wrench to remove over-tight or rusted caps. Open valve slowly. If valve is hard to open, discontinue use and contact your supplier. Use piping and equipment adequately designed to withstand pressures to be encountered. Use only in a closed system thoroughly purged with an inert gas prior to introduction of silane from cylinder. Close cylinder valve after each use; keep closed even when empty. Prevent reverse flow - Reverse flow into cylinder may cause rupture. Use a check valve or other protective device in any line or piping from the cylinder. Store and use with adequate ventilation. Follow safe practices when returning cylinder to supplier. Be sure valve is closed; then tightly install valve outlet cap or plug. Never work on a pressurized system. If there is a leak, close the cylinder valve. Never place a compressed gas cylinder where it may become part of an electrical circuit. Prior to using any plastics, confirm their compatibility with silane. Mixtures: When you mix two or more gases or liquefied gases, you can create additional, unexpected hazards. Obtain and evaluate the safety information for each component before you produce the mixture. Consult an industrial hygienist (IH division) or other trained person when you evaluate the end product. Remember, gases and liquids have properties that can cause serious injury or death. Tips for safe handling of silane Silane 3 Date: Click here to enter a date. Modified from SOP templates developed by UCLA EH&S (http://www.sop.ehs.ucla.edu/) 1. Follow the guidelines outlined in CGA G13. http://www.asiaiga.org/docs/AIGA%20052_08%20Storage%20_%20handling%20of%20silane%2 0_%20silane%20mixtures.pdf 2. Use and store silane in a well-ventilated area separated from other incompatible gases. 3. Monitor area for silane fire using an approved UVIR detector. 4. Monitor for gas leaks using silane specific gas detector. 5. Install a Restrictive Flow Orifice (RFO) on the cylinder outlet valve. 6. Place the pneumatic shutoff valve as close to the source as possible. The best practice is to use a pneumatic cylinder valve. 7. Use welded connections whenever possible. Where removable connections are used they should be a metal-gasket type like a VCR in a well-ventilated area. 8. Leak test the system at the silane cylinder pressure or higher. 9. Purge and evacuate the system prior to opening the cylinder valve or removing the silane cylinder. 10. When opening the system always anticipate a leak. 11. Wear appropriate PPE. 12. Participate in a silane safety training program. 13. Develop an emergency plan so that. procedures and equipment are in place in the event of an incident. The proper procedure to remove a vapor-tight outlet cap In addition to the tips listed above, it is important to be aware that the most likely point for a leak in preparing a silane cylinder for use is when the cylinder valve vapor-tight outlet cap is removed. With that in mind, to avoid operators becoming surprised or injured, they must be properly trained and fully clothed with the proper Personal Protection Equipment (PPE). The following minimum guidelines should be followed: 1. Operators should wear all appropriate PPE including fire gloves, Nomex suit or Firefighter turnout, face shield, earplugs, and safety glasses. 2. Operators should have a “buddy” equipped with the same PPE visually observing the operation and ready to assist if necessary. 3. Physically secure the cylinder away from other hazards as required by CGA P1. Silane 4 Date: Click here to enter a date. Modified from SOP templates developed by UCLA EH&S (http://www.sop.ehs.ucla.edu/) 4. Stand to the side of the cylinder valve outlet, then remove the plastic bag and the hold-down wire. 5. Confirm that the valve is closed tightly. 6. Position the cylinder to pull down with a wrench (a box wrench is preferred) when loosening the vapor-tight outlet cap. 7. Be aware that flames can come out of the leak-check hole in a Diameter Index Safety System (DISS) vapor-tight outlet cap. 8. Pull down slowly on the vapor-tight outlet cap and anticipate the possibility of a leak. Be ready to push up on the cap to reseal the system if a leak does occur. 9. Again, if silane is behind a vapor-tight outlet cap, one of the following will occur: Immediately ignite (a “flamer”), or Not ignite at all, or Ignite after a delay (a “popper”) 10. Once the cap has been removed, visually check the valve outlet surface for damage or debris. Never look directly into the outlet. Instead, use a dental mirror for visual inspection. Conditions for safe storage Store in a gas cabinet. Separate cylinders containing this product from oxygen, chlorine, and other oxidizers by at least 20 ft (6.1 m) or use a barricade of noncombustible material. This barricade should be at least 5 ft (1.53 m) high and have a fire resistance rating of at least ½ hour. Firmly secure cylinders upright to keep them from falling or being knocked over. Screw valve protection cap firmly in place by hand. Post “No Smoking or Open Flames” signs in storage and use areas. There must be no sources of ignition. All electrical equipment in storage areas must be explosion proof. Storage areas must meet national electric codes for Class 1 hazardous areas. Store only where temperature will not exceed 125°F (52°C). Store full and empty cylinders separately. Use a first-in, first-out inventory system to prevent storing full cylinders for long periods. Conditions to avoid: Temperatures in excess of 752°F (400°C) Incompatible materials: Air, water, solutions of bases, oxidizing agents, chlorine, and halogens will react violently with halocarbons. SALIENT POINTS TO REMEMBER 1. It can be dangerous to approach a Silane leak that is not burning, especially if there is a confinement (closed space). 2. Most Silane incidents occur either during cylinder change or immediately after cylinder change. Silane 5 Date: Click here to enter a date. Modified from SOP templates developed by UCLA EH&S (http://www.sop.ehs.ucla.edu/) 3. Common Problems/Incidents in Electronic Specialty Gases: Leaks from DISS and VCR connections, expansion cooling, elastomer gaskets, valve leakers, solids formation, product migration, gas liquefaction and gas backflow. 4. Silane leaks occur due to the following reasons: Improper torque, rapid cooling (rapid expansion of high pressure), impact (bumping of fittings with the tool), mechanical stress, vibration, twisting (pigtail movement to remove cylinder), use of elastomer gasket and high pressure cold flow and reuse of gasket. 5. Silane expansion cooling in the regulator can cause leak. 6. Physically secure the Silane cylinder away from other cylinders and hazards. 7. Position the cylinder to pull down with wrench (box wrench preferred) when loosening vapor tight outlet cap. 8. Be aware that flames can come out of the leak-check hole in the DISS vapor tight outlet cap. 9. Pull down slowly anticipating a leak, be ready to push up to reseal. If silane is behind vapor tight outlet cap, one of the following will occur - Ignite immediately (Flamer) or Explode (Popper) or release and not ignite. Prerequisites for Silane Use NOTE: Only experienced and well trained lab personnel must handle Silane gas cylinder. *There may be other requirements based on fire codes, depending on the quantity & concentration of Silane and other highly flammable gases used and/or stored in the lab. 1. Silane Gas Cabinet must be in place. 2. Auto purge system must be in place. 3. Gas cabinet exhaust with minimum face velocity of 200 cfm must be in place. 4. Excess flow valve and nitrogen aspirator must be in place (need nitrogen source and excess flow should be built into manifold). 5. Dedicated N2 cylinder for manifold purge must be in place. 6. Hands-on training for gas bottle change and manifold operation from vendor required. 7. All gas lines must be stainless steel, heliarc welded and helium leak-checked. 8. Burn box at the rear end of the tube furnace must be in place. 9. Silane sensor (Silane specific leak detector) must be in place. 10. If Silane is used with Hydrogen, then, Silane & H2 sensor must be in place. 11. Approved UVIR detector to detect Silane fire must be in place. 12. Use only DISS 632 connection with a Nickel gasket. 13. DISS 632 Connection: New uncoated nickel 200 gaskets must be used. 14. *Valve seats can leak. Hence, Silane cylinder valves must have a secondary seal on the outlet. 15. Appropriate PPE: Fire gloves, Nomex suit, face shield, ear plugs, safety glasses & Nomex hood Silane 6 Date: Click here to enter a date. Modified from SOP templates developed by UCLA EH&S (http://www.sop.ehs.ucla.edu/) 16. Pneumatic valve for Silane cylinder should be in place. The pneumatic valve must also have a manual operation valve in addition. 17. Restrictive Flow Orifice (RFO) must be in place. 18. Have Silane cylinder valve at a convenient/workable height. 19. Lab buddy system is a must to work with Silane (i.e., One must never work alone in the lab where Silane Gas is stored and/or used). 20. Have a lab-mate with the same level of training and PPE on, visually observing and ready to assist if necessary. You must have easy access to both landline/lab phone and cell phone at all times. Lab supervisor/lab PI must be aware of your plans to work with Silane on a given day. Must have a written Standard Operating Procedure (SOP) for Silane use/handling in place. Silane users must have thoroughly read & signed the SOP that is written approved by the lab PI/Supervisor. Your set-up must be in good working condition (with valves and supply lines working properly) You must have a ‘Lab Emergency Contact’ list readily available at all times. You must have access to a routinely inspected Safety Shower & Eyewash station accessible within 10 seconds. You must have access to ‘In case of serious injury at work – Steps 1 2 & 3 poster’. Must have NFPA fire diamond posted on the door with up-to-date/latest contact information. You must have easy access to the SDS (Hardcopy and Electronic copy/On-line) You must have access to UCPD in case of an emergency: Dial 911 only from a campus phone OR 310825-1491 from cell phone You must be aware of the emergency evacuations procedure. There must be exit signs in the lab. You must have access to a fully stocked first-aid kit. You must have access to a monthly inspected fire extinguisher. Spill and Accident Procedure Chemical Spill Dial 9-911 from campus phone or 415-476-1414 from cell phone or 415-2068522 (SFGH only) Spill – Assess the extent of danger. Assist contaminated or injured persons. Evacuate the spill area. Avoid breathing vapors. If possible, confine the spill to a small area using a spill kit or absorbent material. Keep others from entering contaminated area (e.g., use caution tape, barriers, etc.). Small (<1 L) – If you have training, you may assist in the clean-up effort. Use appropriate personal protective equipment and clean-up material for chemical spilled. Double bag spill waste in clear plastic bags, label and take to the next chemical waste pick-up. Silane 7 Date: Click here to enter a date. Modified from SOP templates developed by UCLA EH&S (http://www.sop.ehs.ucla.edu/) Large (>1 L) – Dial 9-911 from campus phone or 415-476-1414 from cell phone or 415-2068522 (SFGH only) for assistance. Chemical Spill on Body or Clothes – Remove clothing and rinse body thoroughly in emergency shower for at least 15 minutes. If discomfort persists, proceed to the Emergency Department. If no further discomfort is experienced, have the SDS ready and contact Poison Control Hotline at 1-800222-1222 for further exposure information. Notify your direct supervisor and EH&S at 415-4761300 during work hours, or 9-911 during non-working hours and weekends. Chemical Splash Into Eyes – Immediately rinse eyeball and inner surface of eyelid with water for 15 minutes by forcibly holding the eye open. If discomfort persists, proceed to the Emergency Department. If no further discomfort is experienced, have the SDS ready and contact Poison Control Hotline at 1-800-222-1222 for further exposure information. Notify your direct supervisor and EH&S at 415-476-1300 during work hours, or 9-911 during non-working hours and weekends. Medical Emergency Dial 9-911 (campus phone) or 476-6911 (cell phone) Note: All serious injuries must be reported to EH&S at 415-476-1300 within 8 hours. Non-Life Threatening Emergency– Go to Occupational Health Programs (OHP) Clinic, 415-8857580, 2330 Post Street, Suite 460 Hours of Operation for Appointments: Monday - Friday 7:30 a.m. - 4:00 p.m. (except Holidays). Note: All serious injuries must be reported to EH&S at 415-476-1300 within 8 hours. Needle stick/puncture exposure (as applicable to chemical handling procedure) – Wash the affected area with antiseptic soap and warm water for 15 minutes. For mucous membrane exposure, flush the affected area for 15 minutes using an eyewash station. Page the needle stick nurse by dialing 415-353-7842 (STIC). Decontamination/Waste Disposal Procedure Clean contaminated surfaces with soap and water and paper towels. Dispose of the paper towels as hazardous waste. Safety Data Sheet (SDS) Location Online SDS can be accessed at http://or.ucsf.edu/ehs/7241-DSY/msds.html Protocol/Procedure Quantities covered by this SOP: ______ (g , ml) to _______ (g, ml) Temperature range covered by this SOP: Silane 8 Date: Click here to enter a date. Modified from SOP templates developed by UCLA EH&S (http://www.sop.ehs.ucla.edu/) __ °C – __ °C General Overview and Purpose: Enter the experimental purpose Procedure: Enter experimental procedure. You can copy procedure from your lab notebook or from literature. NOTE Any deviation from this SOP requires approval from the Principal Investigator. Silane 9 Date: Click here to enter a date. Modified from SOP templates developed by UCLA EH&S (http://www.sop.ehs.ucla.edu/)