Study of mass transfer through different templated

advertisement

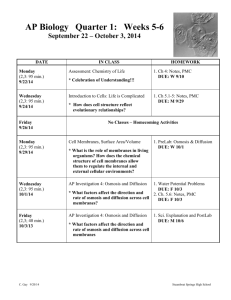

Gas Transport Mechanisms through New Templated Silica Membranes Prepared by Sol-Gel Method M. Pakizeh, M. R. Omidkhah*, A. Zarringhalam and M. Shariati Niasar Department of Chemical Engineering, Tarbiat Modares University, P.O.Box:14115-143, Tehran, Iran Abstract Different templated silica membranes were prepared by sol-gel polymerization route using cationic and non-ionic surfactants as template agent. -alumina support and prepared silica membranes were used in single-gas permeation and mixed-gas separation experiments. Gas transport mechanisms through porous membranes as well as influences of main parameters in each mechanism have been reviewed in details. The characteristics of gas transport through the support as macroporous membrane and templated silica membranes were investigated with several gas diffusion models in the range of 200-400oC and at pressure differences ranging from 0.2 to 1 bar. The experimental gas permeation data of alumina support were analyzed using the viscous flow model and results clearly showed good agreement between the model analysis and the experimental data. The prepared templated asymmetric silica membranes represented different behavior each other due to their different characteristics. The experimental data of silica membrane which templated by polyoxyethylene(4) lauryl ether (Brij30) showed that the permeation followed the Knudsen diffusion model in which the permeance decreased with increasing temperature. The experimental gas permeation data of cetylpyridinium bromide (CPB) templated silica membrane as well as non-templated silica membrane as microporous membranes revealed that they followed the configurational diffusion model in which the permeance increased with temperature. Separation factors obtained from mixed-gas separation experiments with 50/50 (vol%) gas mixtures were slightly lower than the permselectivities. 1. Introduction Supported inorganic membranes have attracted considerable attentions due to their outstanding thermal and chemical stability over the past half century [1]. Among the inorganic membranes, supported silica membranes have been frequently utilized in gas separation processes by many researchers due to their synthesis convenience and low cost [2]. By far, the sol-gel method due to introducing desirable characteristics such as: high surface area, high pore volume and bimodal pore size distribution has been reported as the best method for silica membrane synthesis [3,4]. Recently, the sol - gel method has been combined with template technology to improve the silica membranes performances. Template technology uses template agents which can be ionic or nonionic surfactants. Kresge et al. from Mobil Oil Corporation have used this technology and produced the class of mesoporous materials known as MCM – 41with hexagonal arrays structure for first time [5]. McCool et al. produced supported silica membranes which templated by cetyltrimethylammonium bromide (CTAB) in hydrothermal and dip-coating methods. They have reported that dip-coating membranes have a flux three times greater than * Omidkhah@modares.ac.ir hydrothermally prepared also the permeation characteristics of both membranes were governed by Knudsen diffusion model [6]. Zhong and coworkers have used dodcyltrimethylammonium chloride (DTAC) as template agent and have obtained mesoporous silica membrane. They have carried out the gas permeation experiments for C2H4, N2, C2H6 and CO2 gases which have been controlled by Knudsen diffusion model [7]. Doohwan and Oyama have prepared a novel silica membrane namely Nanosil which has been contained a deposited silica layer on Vycor glass as support. They have presented gas permeation experiments of He, Ne, H2, CO2, CO and CH4 both on Vycor glass and the Nanosil membranes and have found that the gas permeation mechanism on the Vycor glass has followed a combination of surface diffusion and Knudsen permeation models, while the permeation of the Nanosil has been controlled by a statistical solid state diffusion model. This model could justify unexpected permeation of He, H2 and Ne gas (He>H2>Ne) through membrane whereas molecular size of H2 is greater than Ne molecule [8]. So et al. have prepared silica membrane in situ sol-gel and dip-coating methods with two step pore modification. With pore modification by Pd precursor, H2 selectivity was increased while Knudsen diffusion was replaced by surface diffusion model [9]. Thomas and coworkers have investigated the involving gas permeation mechanisms in multilayer membrane. They have proposed the configurational diffusion model and found good agreement between this model and experimental data for He and H2 gases [10]. 2. Mass transfer in inorganic porous membranes Mass transfer in porous media has been frequently studied by many researchers [11, 12]. Although, based on pore size and mean free path of gas molecules, several mechanisms have been presented, but in many cases these mechanisms due to existence of a large range of pore sizes cannot be used alone. Adsorptions and diffusion are two main phenomena that have important influences on overall gas transport in some cases. The interaction between gas molecules and membrane surface is considered by adsorption while diffusion describes the gas molecules transport through the membrane. Recently, the activated configurational diffusion model has been proposed as the most advanced model for the analyzing the permeance results of microporous membranes. 2.1. Viscous flow model When the number of intermolecular collisions is much greater than collisions between gas molecules and membrane surface which can be happened in the case of larger pores, the flow in a capillary can be expressed by Darcy's law [13]. The molar flux in narrow capillaries with laminar flow, can be described by a Hagen- Poiseuille type law: rp2 P dp Jv (1) 8 RT dz Eq. (1) is modified for real systems by introducing (porosity) and (tortuosity): Jv 2 rp P dp . 8 RT dz (2) By integration of Eq. (2) across the membrane thickness (L) gives the permeation: 2 Jv rp Pm Qv P 8 RTL where Pm ( P1 P2 ) / 2 (3) Thus, in this Flow, the permeation is proportional to the mean pressure and squared hydraulic radius (r2). Also the permeation decrease with temperature for gases because the viscosity of gases increases with temperature. 2.2 Knudsen diffusion model When the number of intermolecular collisions is much less than molecule-wall collisions, Knudsen diffusion occurs. In this regime, diffusion occurs in the result of consecutively collisions of gas molecule with pore wall. The Knudsen diffusivity is obtained from the geometric parameters related to the membrane and gas kinetic velocity: D= (geometric parameters).(gas kinetic velocity) 1/ 2 d p 8RT (4) Dkn 3 M Where dp is the pore diameter, R the gas constant and M is molecular weight of diffusing gas [8,13]. By substituting Eq. (4) in macroscopic description of transport process (Fick's first law; J= D(c)c), the expression for the Knudsen flow in a porous membrane is obtained: 0.5 2 rp 8 dp J kn . (5) 3 RTM dz After integration of Eq. (5) over the membrane thickness L the permeation is found to be: 1/ 2 J kn 2rp 8 Qkn P 3L RTM (6) As can be seen in Eq.(6), in this flow regime, the permeation of a single gas is proportional to the average pore radius (rp) and independent of mean pressure. Also, every diffusing gas should have the same value of Q (MT)1/2 = (dp/L) (8/9R)1/2 which is independent of temperature if gas transport through the membrane governed only by Knudsen diffusion. 2.3. Surface diffusion model In this model, gas molecules adsorb on the surface of membrane at first and in subsequence followed by diffusion to the other side of membrane where they desorbs to the gaseous bulk. Based on different assumption about the situation of adsorbed molecules, several adsorption models can be found in the literature [14]. Among them BET and Langmuir adsorptions models have been frequently used by researchers. In gas separation process using porous membranes, gas adsorption usually occurs in the state of monolayer. Monolayer adsorption has been well described by Langmuir adsorption model [15]. q bp q s 1 bP (7) where is the fractional occupancy of adsorption sites, q the amount of adsorbed gas molecules per unit mass of adsorbent (molg-1), qs the saturation amount of adsorbed molecules, P the pressure (pa) and b is an equilibrium adsorption constant (Pa-1). Equilibrium adsorption constant (b) has the following dependency on temperature: H a (8) b b0 exp( ) RT Where Ha is the heat of adsorption. At high temperature and low pressure (bp<<1) Eq. (7) is reduced to Henry's equation q q s bp KP K 0 exp( H a )P RT (9) where K is Henry's constant (mol-1g-1pa-1). In this regime, the amount of adsorbed molecules varies linearly with pressure. Concentration of gas molecules at membrane surface is product of membrane density () and the amount of adsorbed molecules: H a (10) c q K 0 exp( )P RT By introducing the Eq. (10) in Fick's first law: J s D0 (q) K 0 exp( H a E dp ) exp ( ) RT RT dz (11) By integration Eq. (11) across the membrane, permeation is obtained for surface diffusion model: D0 (q) K 0 H a E (12) Q s Q0 exp where Q0 RT L Qo (molm-2s-1pa-1) and Ha-E (KJmol-1) are the model parameters for surface diffusion mechanism. 2.4. Configurational diffusion model The configurational diffusion mechanism has been applied only for microporous materials. In this model is assumed that gas molecules can not escape completely from the potential field of the solid [17]. Several researchers have nominated this model as the gas translational (GT) diffusion model in literature [17,18]. Two main concepts are considered by this mechanism; the first is related to the Knudsen model and the later is related to the moving of gas molecules between sorption sites in a translational mode by overcoming the barriers formed by small channels which connect adjacent sorption sites: Ec 8RT (13) Dc g d p exp( ) M i RT With Jc 1 D CP RT (14) By integration of Eq (14) across membrane thickness L, Permeation is obtained: Qc JC g d p . P L Ec 8 exp( ) MRT RT (15) The temperature dependency of diffusivity of this model differs completely from that of the Knudsen model. The parameter g is the probability that a gas molecule can overcome the energy barrier Ec. Also the other models such as vibrational gas diffusion and statistical solid state diffusion model have been used by researchers [8]. 3. Experimental procedures 3.1 Membrane preparation In order to minimization of polycondensation rates of silica species, the standard sol was prepared in two acid-catalyzed reaction steps. With these procedures, the formation of highlybranched polymeric clusters was avoided. In the first step, 40 ml TEOS was added to a mixture of 38.7 ml EtOH , 4 ml DI-water, followed by the adding nitric acid (0.012 ml) while stirring the mixture (pH=4.6). The sol was refluxed for 1.5 h at 70 oC. In the second step, additional water and acid were added to the prepared sols so that the final molar ratios of sols were reached to the values of Table1 (pH=1.8). Table 1- Molar ratio of templates and precursors used in sols preparation Molar ratios Sample TEOS H2O ETOH HNO3 Template Si(TF) 1 6 3.8 0.086 0.0 Si(CPB) 1 6 3.8 0.086 0.14 Si (Brij) 1 6 3.8 0.086 0.14 The sol samples were then cooled to the room temperature, moreover the corresponding amount of surfactants powder were added and stirred at 250 rpm for 5 min. The obtained sols were referred as Si(CPB), Si(Brij) and Si(TF) considering their used template. As can be seen in Table 1, all the templates concentrations are above the Critical Micellar Concentration (CMC) [25]. The dipping solutions were aged for 3 days to allow the polymeric silica particles to organize and form around the template micelles. The home made polished alumina tube with the average pore size of 80nm and porosity of 30%, as measured by Pascal 440 series Hg porosimetry, was used as support. The inner and outer diameters of this support tube were: 10 and 12 mm and its length was 5cm. It was first cleaned in acetone by ultrasonic regenerator (Ultrawave) for 20 min and then dried in a laminar flow cabinet. The silica film on outer surface of the support may be damaged during the assembling to membrane holder, therefore, it was coated on inner surface of the support. The cleaned supports were dipped in the aged polymeric sols for 2 min. Dipping and withdrawal rates were approximately 2cms-1. The as-coated membranes tubes were then dried in a laminar flow cabinet for 2 h. Sol-gel transition was occurred immediately after withdrawal of the supports from the dipping sols, due to fast evaporation of solvent. The as-prepared Membranes were then calcined in air at 600oC for 4 h with the heating and cooling rates of 0.5◦Cmin-1. The dipping sols first were converted into wet gels after several weeks, then into clear films in laminar flow cabinet. Each clear film was ground and then calcined under the same conditions as membrane synthesis step. 3.2. Unsupported membrane characterization The surface area of the unsupported membranes was calculated by Brunaver-Emmett-Teller (BET) method using N2 adsorption-desorption isotherms at relative pressure( P/P0) of 0.01 to 0.995 at 77 K ( Micromeritics ASAP 2000). Pore volume was obtained considering the amount of N2 adsorbed. Average pore diameter of unsupported membranes were obtained using Barrett- Joyner- Halenda (BJH) method. 3.3. Gas permeation The as-prepared silica membranes were encapsulated in a custom-made stainless steel membrane holder by placing the two end sides of the tubular membranes into two aluminum annulars and sealed completely with high temperature resistant epoxy resin. A schematic representation of the membrane holder has been given in Figure 1. Sweep Gas Inlet Heater Stainless steel module Retentate Stream Feed Inlet Annular aluminium Membrane Heater Permeate Stream Figure 1: A schematic representation of the membrane holder The permeation properties of the tubular support and silica membranes were measured over the temperature range of 200-400 oC and pressure difference range of 0.2-1bar using the experimental set-up depicted in Figure2. Prior to the gas permeation experiments, ambient moisture was removed with dry argon flowing at 100°C for 4 h through the membranes. Single component permeation of a series of gases, considering the kinetic diameter, i.e. H2 (2.89Å), CO2 (3.3Å), CH4 (3.8Å) was measured by flowing a stream of each gas through the membrane. Vent T PG F F Membrane F Heater GC F T Needle valve Reducer 3-way valve F CO2 H2 CH4 Mass flow controller Ar DC 24 V Gas cylinder Pressure Gauge Temperature Indicator GC Gas Chromatography DC 24 V PC Power supply Figure2: Experimental set-up for single-gas and mixed-gas permeation. For mixed-gas permeation measurement, a per-mixed gas with known composition was used and the composition of both effluent streams were analyzed using an online Philips PU4410 Series Gas Chromatograph equipped with a stainless steel packed column (Hayesep N, 80/110, 2M) and thermal conductivity detector. The flow rate and the pressure of the tube side stream as well as the temperature of the membrane were varied. Pure argon with constant flow rate of 25cc/min was used as sweep gas, flowing in the shell side of the permeation cell at ambient pressure. Gas flow rate exiting from the shell side was measured by a calibrated soap-film flowmeter. The experiments were conducted under steady-state conditions (no change in compositions and flow rate with time). The gas flux was then calculated using the outlet gas flow rate and the concentration of the permeated gas outcoming from the shell side. The permeance, Q, is considered as ratio of gas flux, J (mol/m2 s), and the pressure difference (Q (mol/m2 s Pa) = -J/P). Permselectivity is defined as ratio of permeances of individual pure gases and the separation factor (i/j) is defined by following expression: retentate y ipermeate y j i / j permeate . retentate (i and j are the components of feed) (16) yj yi y AB is the mole fraction of component A in stream B. Infinity separation factor is obtained when y jpermeate 0.0 which can be obtained for dense membranes 4. Results and discussion Four types of membranes were studied in this work. One was a -alumina support, and the second was Si(TF), a supported type membrane consisting of a thin film of non-templated silica deposited on support. The two later membranes were Si(CPB) and Si(Brij), supported silica membrane which were templated by CPB and Brij surfactants, respectively. The average pore size, pore volume and the surface area of unsupported membranes were calculated by BJH and BET methods using N2 adsorption/desorption data and the results have been illustrated in Table 2. Table 2- Textural characteristics of different samples of unsupported silica membranes Surface Average Pore area pore size volume (m2/g) (nm) (cm3/g) Si(TF) 121 0.987 0.0238 Si(CPB) 1160 1.51 0.426 Si(Brij) 482 2.86 0.372 Sample Permeance × 10-5 (mol/m2 s Pa) Such high surface areas of the Si(CPB), and Si(Brij) membranes compared to the Si(TF) membrane are due to the application of the templates. Average pore sizes of the Si(TF) and Si(CPB) samples categorize them in the microporous regime. In the Si(TF) sample, due to the absence of self assembled organic component, polycondensation of inorganic silicate or agglomeration of particles couldn’t occur around the specific structure of template. Formation of these particles without a tailoring template, accompanied with the removing of small ligand (ethyl group) which was covalently bound to silica network, lead to lower pore size, pore volume and surface area compared to other templated silica membranes. Average pore sizes of the Si(Brij) sample was in mesoporous regime. Differences between average pore sizes of these samples depend on the nature of the template and interaction between the silica particles and micelles. The adsorption of surfactants, e.g. CTAB and CPB, on silica surface at different micelle concentrations has been also studied by Atkin and coworkers [19,20]. Since the pore size of alumina support is much greater than the mean free paths of the diffusing gases (H2, CO2 and CH4), transport through the support membrane has generally been described by the viscous flow model. A property of gas transport by the viscous flow model is that the permeance increases linearly with increasing mean pressure at constant temperature . Also at constant pressure difference, the permeance decreases with increasing temperature. Gas permeance data on alumina support was studied and the results are shown in Figures 3 and 4. In spite of the molecular size of CH4 (3.8Å) being greater than CO2 (3.3Å), permeation of CH4 was greater than CO2 through the support. 1.5 H2 1.3 1.1 CH4 0.9 CO2 0.7 0.5 1 1.2 1.4 1.6 Mean pressure(bar) Figure 3: Gas permeation data through alumina support versus mean pressure at 400°C. Permeance × 10-5 (mol/m2 s Pa) 1.6 H2 1.2 CH4 0.8 CO2 0.4 170 220 270 320 370 420 Temperature(°C) Figure4: Temperature dependence of the permeance for the support at P=0.6 bar, Pm = 1.3. This implies that the support controls the permeation considering the viscosity and not the molecular size, again was in agreement with viscous flow model. The permeance data was fitted to the viscous flow model (Eq.(3)) by the least squares method and the best-fit parameters are shown in Table 3. Table 3- Determined the viscous flux parameter for support in different single gas permeations Regression Gas ε/τ H2 0.209 0.998 CH4 0.208 0.997 CO2 0.21 0.998 coefficient In the each case of next section, the membrane contains a silica thin layer deposited on alumina as support, therefore the overall resistance for gas permeation is a summation of resistance on the support and the silica layer: 1 1 1 (17) Qmembrane Qsup port Qsilica By subtracting the resistance of support from the measured resistance of supported silica membrane, the permeance of silica layer was calculated. Generally, mesoporous membranes with pore sizes of 2- 20nm exhibit Knudsen diffusion as dominating permeation mechanism. Since the ratio of the mean free path of diffusing gas molecules (H2, CH4 and CO2) to the pore size of Si(Brij) (2.86nm) are greater than 10, therefore gas transport through membrane can be governed by Knudsen diffusion mechanism. As described before, in this regime, permeance shows an inverse square root dependence on temperature and molecular weight of diffusing gas molecule. In the other words the value of Q(MT)1/2 which is equal to (dp/L)(8/9R)1/2 for each diffusing gas must be relatively constant and independent of temperature (Eq(6)). Using this approach, the gas permeance data were analyzed and the results are shown in Figures 5 and 6. Permeance × 10-6 (mol/m2 s Pa) 4.8 4.2 3.6 3 1 1.2 1.4 1.6 Mean pressure(bar) 2 Permeance × 10-6 (mol/m2 s Pa) Permeance × 10-6 (mol/m2 s Pa) Figure 5: Hydrogen permeance versus mean pressure for the Si(Brij) membrane (T = 400°C). 1.7 CH4 1.4 1.1 CO2 0.8 1 1.2 1.4 1.6 4.8 H2 3.8 2.8 CH4 1.8 CO2 0.8 150 250 Mean pressure(bar) Figure6: CO2 and CH4 permeances versus mean- 350 450 Temperature(°C) Figure7: Permeances of H2, CH4 and CO2 versus pressure for the Si(Brij) membrane (T = 400°C). temperature for the Si(Brij) membrane (P= 0.6 bar). Figure7 illustrates that permeance of gases decrease with increasing temperature similar to support. Generally, CO2 permeation through microporous or mesoporous membranes is governed by surface diffusion model at lower temperatures. However we conducted the gas permeation in both cases of single-gas and mixed-gas permeation at higher temperatures (473673K) and no contribution of surface diffusion mechanism was observed. Nearly constant values of Q(MT)1/2 for H2 and CH4 over the applied temperature range imply that the permeances of these gases through Si(Brij) membrane is controlled by Knudsen diffusion model(Figure 8). 1.5 1.2 0.9 0.6 H2 0.3 CH4 CO2 0 150 4.5 4.2 2.4 3.9 2.2 3.6 2 3.3 Si(TF) Si(CPB) 1.8 250 350 450 Permeance × 10 -6 (mol/m 2 s Pa) Permeance × 10 -6 (mol/m 2 s Pa) Q(MT)1/2× 10-4 (mol (g°C)1/2/m2 s Pa) 2.6 3 1 Temperature(°C) 1.2 1.4 1.6 Mean pressure(bar) Figure8. Q (MT)1/2 versus temperature for the Si(Brij) Figure9. Hydrogen permeance versus mean pressure membrane (P= 0.6 bar). for Si(TF) and Si(CPB) membranes at 400°C. In contrast to alumina support there is not an increase of gas permeances with increasing the pressure across the Si(TF) and Si(CPB) membranes as can be seen in Figures 9 and 10. The permeances through alumina support as macroporous membrane and Si(Brij) as mesoporous membrane decrease with increasing temperature over the entire range as expected from the viscous flow and Knudsen diffusion models while the permeance through the Si(TF) and Si(CPB) membranes shows an increase with temperature . 0.15 0.016 0.145 0.012 0.14 0.008 0.135 0.004 0 0.13 1 1.2 1.4 Mean Pressure(bar) 1.6 Permeance × 10 -6 (mol/m 2 s Pa) Permeance × 10 -6 (mol/m 2 s Pa) 0.02 Figure10. CO2 and CH4 permeances versus mean pressure at 400°C for Si(TF) and Si(CPB) membranes. The results imply that the gas diffusion mechanism for Si(TF) and Si(CPB) membranes follows an activated diffusion mechanism. Increasing of the gas permeances through both the Si(TF) and Si(CPB) microporous membranes with increasing temperatures have been presented by Figure 11 and 12. The permeation characteristics of the hydrogen molecules on the silica layer of both Si(TF) and Si(CPB) membranes were studied by comparing it with the gas permeability on the asymmetric silica membranes using Eq.(17) and the results have been shown in Figure 13. The calculations for H2 diffusion, revealed that the resistances of silica layers against the mass transfer were 88% and 74% of overall resistance for the Si(TF) and Si(CPB) membranes, respectively Temperature contributes in exponential terms as well as in gas kinetic velocity. Eq.(15) can be rewritten as: ln T Q ln LA c 8 E c 1 MR R T A g d p (18) A linearization was used by plotting the values of ln( T Qc ) versus 1/T and the best-fit parameters was calculated which have been indicated in Tables 4 and 5. Table 4-Values of configurational model parameters for Si(TF) membrane Gas A (m) Regression ΔEc (J/mol) coefficient H2 1.151×10-8 5403 0.9997 CO2 0.943×10-8 11051 0.9988 CH4 4.57×10-10 9833 0.9898 Moreover, the activation energies of CO2 are higher than those of CH4 and H2 in both Si(TF) and Si(CPB) membranes. The activation energy of CH4 is 9.833 kJ/mol and 6.076 kJ/mol for Si(TF) and Si(CPB) membranes respectively. de Vos et al.[22] have reported activation energy of CH4 around 10 kJ/mol for Si(400) that is vary close to that of the Si(TF) in present study also it is in agreement with Tsai et al.[21] findings on single-layer silica membrane (9.64kJ/mol). Table 5- Values of configurational model parameters for Si(CPB) membrane Gas A (m) ΔEc Regression (J/mol) coefficient H2 1.099 ×10-8 3753 0.9976 CO2 1.032 ×10-8 6076 0.9985 CH4 4.587×10-10 9605 0.9878 The activation energy of H2 was the lowest in both cases, indicating that hydrogen molecules overcome rapidly the barrier energy of the membranes and move easily between sorption sites in comparison with CH4 and CO2 molecules. The activation energy of H2 for both Si(TF) and Si(CPB) membranes are greater than the reported value (2968 J/mol) by Thomas et al. [10] for their composite membrane. While the A parameter of the Si(TF) and Si(CPB) are very close to that of their composite silica membrane for H2 (1.09×10-8 m). Table 6- Permselectivity (Pi/j) and separation factor (i/j) for Si(Brij), Si(TF) and Si(CPB)membranes at T = 400°C and Pm=1.3 bar Pi/j α i/j H2/CH4 H2/CO2 H2/CH4 H2/CO2 Si(Brij) 2.94 5 2.88 4.79 Si(TF) 149 15.5 131 12.9 Si(CPB) 135 35 123 28.4 Membrane References [1] Hsieh HP, Inorganic Membranes for Separation and Reaction, Elsevier, Amsterdam, 1996. [2] Uhlhorn RJR, Huis MHBJ, Keizer K, Burggraff AJ, Synthesis of ceramic membranes, part I, Synthesis of non-supported and supported γ-alumina membranes without defects, J. Mater. Sci.1992; 27: 527-537. [3] Brinker CJ, Sehgal R, Raman N, Schunk PR, Headly TJ, Polymer approach to supported silica membranes, J. Sol-Gel Sci. Technol. 1994; 2:469. [4] Brinker CJ, Sehgal R, Hietala SZ, Deshpande R, Smith DM, Loy D, Ashley CS, Solgel strategies for controlled porosity inorganic materials, Journal of Membrane Science 1994;94 :85. [5] Kresge CT, Leonowitz ME, Roth WJ, Vartuli JC , Beck JS, Ordered mesoporous molecular sieves synthesized by a liquid-crystal template mechanism Nature 1992;359 :710. [6] McCool BA, Hill N, Dicarlo J, DeSisto WJ, Synthesis and characterization of mesoporous silica membranes via dip-coating and hydrothermal deposition techniques, Journal of Membrane Science 2003;218 :55 . [7] Zhong SH, Li CF, Li Q, Supported mesoporous SiO2 membranes by sol-gel –template technology, Separation and Purification Technology 2003;32 : 17. [8] Doohwan Lee, Oyama ST, Gas permeation characteristics of a hydrogen selective supported silica membrane, Journal of Membrane Science 2002;210 :291 . [9] So JH, Yang SM, Preparation of silica-alumina composite membranes for hydrogen separation by multi-step pore modifications, Journal of Membrane Science 1998; 147:147. [10] Thomas S, Schafer R, Caro J, Morgenstern AS, Investigation of mass transfer through inorganic with several layers, Catalysis Today 2001; 67:205. [11] Karger J, Ruthven DM, Diffusion in Zeolites and other Microporous Solids, Wiley, New York, 1992. [12] Mason EA, Malinauskas AP, Gas transport in porous media: The Dusty-gas Model, Elsevier, Amsterdam, 1983. [13] Burggraaf AJ, Cot L, Fundamentals of Inorganic Membrane Science and Technology, Elsevier, Amsterdam, 1996. [14] Satterfield CN, Heterogeneous catalysis in practice, McGraw-Hill, New York, 1980. [15] Langmuir I, Chemical reactions at low pressures, J. Am. Chem. Soc 1915; 37:1139. [16] Reid RC, Prausnitz JM, Poling BE, The Properties of Gases and Liquids, McGrawHill, New York, 1987. [17] Xiao J, Wei J, Chem. Eng. Sci., 1992; 47:1123-1141. [18] Burggraaf AJ, Single gas permeation of thin zeolite (MFI) membranes: theory and analysis of experimental observations 1999; 155:45. [19] Atkin R, Craig VSJ, Biggs S, Adsorption Kinetics and Structural Arrangements of Cetylpyridinium Bromide at the Silica-Aqueous Interface, Langmuir2001; 17:6155. [20] Atkin R, Craig VSJ, Wanless EJ, Biggs S, Mechanism of cationic surfactant adsorption at the solid–aqueous interface, Advances in Colloid and Interface Science 2003; 103:219. [21] Tsai CY, Tam SU, Lu Y, Brinker CJ, Dual-layer asymmetric microporus silica membrane, J. Membrane Science 2000; 169: 255-268. [22] De Vos RM, Verweij H, Improved performance of silica membranes for gas separation, J. Membrane Science1998; 143: 37-51.