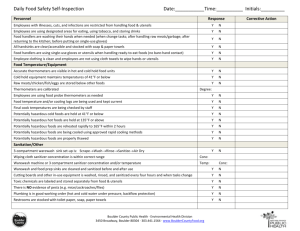

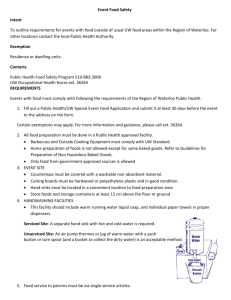

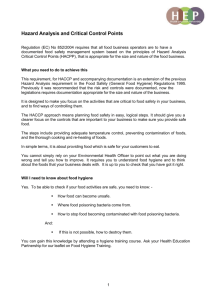

Food Safety Program - A template to assist SA aged

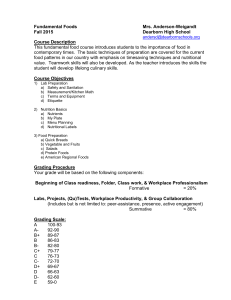

advertisement