Surporting information-shorten

advertisement

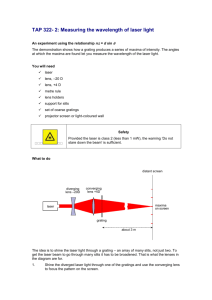

Surporting information Duty ratio-dependent fluorescence enhancement through surface plasmon resonance in Ag-coated gratings Xiaoqiang Cui a, Keiko Tawa*a, Hironobu Hori a, and Junji Nishiib Research Institute for Cell Engineering, National Institute of Advanced Industrial Science and Technology (AIST), Ikeda, Osaka 563-8577, Japan b Photonics Research Institute, National Institute of Advanced Industrial Science and Technology (AIST), Ikeda, Osaka 563-8577, Japan * E-mail address: tawa-keiko@aist.go.jp a Experimental Fabrication of grating SiO2 substrate Sub-wavelength grating structures on SiO2 substrates were constructed by previously reported two-laser-beam interference method followed by dry etching [1] . All substrates were cleaned by sonicating in a 1% Hellmanex (Hellma, Mullheim, Germany) solution for 20 min and thoroughly rinsed by fresh Milli-Q water and ethanol, finally dried completely under air flow. Cleaned SiO2 plates were first spin-coated with about 1 m thickness of positive photoresist (Tokyo Ohka Kogyo Co., Ltd., TDMR-AR80). The photoresist pattern was then formed by exposing to an interference beam of a He-Cd laser (Kimmon Electric, 1K3501R-G) with 325 nm wavelength and a power density of about 70 W/cm2 for 100 s. Duty ratio of the grating was controlled by irradiation time. The SiO2 surface was then etched by dry etching (ULVAC, NLD-500). Grating depth was controlled by changing etching time according to the relation of about 2 nm per second. The residual photoresist was then removed by acetone washing and then oxygen plasma treatment. (Yamato, RFG-500A). Coating with metal layers The SiO2 gratings were consequently coated with thin layers of Cr(1 nm)/Ag(200 1 nm)/Cr(1 nm)/SiO2(20 nm) by RF sputtering deposition (Rikensya, specially made). In order to improve the adhesion of Ag to SiO2, a Cr layer of less than 1-nm was deposited. After which, 200-nm silver layer was deposited followed by another layer of Cr, and then 20nm layer of SiO2. Therefore, the covered layer consists of Cr/Ag/Cr/SiO2 with the total thickness of about 222 nm. After deposition, the surface was immediately treated with 3-aminopropyltriethoxysilane (APTES, 1% vol) aqueous solution at 40C for 2 hours and then thoroughly rinsed by Milli-Q water and ethanol, with which the surface was modified with –NH2 groups for the further functionalization of biotin-poly(ethylene glycol)-Carbonate-NHS ester (NOF, SUNBRIGHT BI-050TS). Scheme SI. A schematic diagram of the angular scanning measurement setup for reflectivity (SPR) and fluorescence intensity (SPFS). SPR-SPFS measurement SPR-SPFS measurement was performed using originally constructed set up described previously with slightly modification (Scheme SI)[2]. A He-Ne laser beam (632.8 nm, 1 mm in diameter) serves as incident light on substrates for SPR-SPFS excitation. An optical chopper (used also as the reference for the lock-in amplifier) and two polarizers were used for intensity and polarization control respectively. During measurement, the reflected light was monitored by photo diode through a -2 goniometer controlling. The fluorescence emission was monitored by a photomultiplier (after passing through an appropriate lens, 1% and 10%-ND filter, and a narrow band interference filter, =6705 nm) mounted on the goniometer unit at a fixed angle of 55 degree. Therefore, the fluorescence enhanced by reverse coupling mode was not included in the detection. 2 Finite difference time domain (FDTD) simulation FDTD was used to simulate the electric field distribution around the grating surfaces. The cross-section profile for the simulation unit was drawn according to the SPM data. To explore the effect of different duty ratios, the pitch (400 nm), depth (20 nm), and trapezoidal slope angle (25 degrees) were all kept constant. The calculations were carried out for incident light with a wavelength of 632.8 nm. The periodic boundary was perpendicular to the grating surface, while a perfectly matched absorbing boundary was parallel to the grating surface. Fluorescence microscopy Fluorescence microscopy observation was taken on an upright microscope (BX51WI, Olympus, Tokyo, Japan) equipped with halogen (12 V 100WHAL-L, Olympus) and Hg lamp as well as an x10 objective lens (NA 0.30). The fluorescence images were observed by selecting a Cy5 filter with a CCD camera (Andor Technology, iXonEM+). During the series of measurements, illumination intensity (from Hg lamp), exposure time of 0.03 second, and CCD camera gain were all kept constant. We first patterned the grating surfaces with tape to make the comparison of fluorescence intensities easier. After coating, the tape was removed and the surfaces were modified with Cy5-labeled streptavidin, and then the samples were observed using a commercially available microscope. Fluorescence enhancement on gratings with different depth: Fig. S1. SPR curves in air measured using grating with depth of 10 nm, 20 nm and 30 nm, respectively. Duty ratio for each depth is the optimized condition. 3 Table S1. Enhancement factors from gratings with different depth under microscopic observation Grating depth 10 nm 20 nm 30 nm Enhancement factor 10 30 28 Highest enhancement is obtained in 20nm depth grating. All experimental conditions are same as that in Fig. 4. Dispersion relationship and resonance angle The angle-dependent effect of the enhanced fluorescence was explained by the dispersion relation. The wavenumber vectors of surface plasmon polaritons, incident light (of a propagated component), and a grating denoted as kspp, k0x, and kg, can be used to determine the dispersion relationship for Ag-coated gratings as: kspp = k0x + m kg. (m = 1 ,2, - - - ) (1) Here, Eq. (1) can be expressed by: /c ((Ag ∙PBS)/( Ag + PBS))1/2 = /c sin m2/ (2) in which , c, , , and are the angular frequency, speed of light, the complex dielectric constant for a material expressed by the subscript, the incident angle, and the pitch of the grating, respectively. Detailed discussion of the duty-ratio dependence of the fluorescence enhancement In general, the electric field intensity can be expressed as a function of both Fresnel’s transmission coefficient described by the dielectric constant and the reflectivity (R), i.e., 1–R, at a given resonance angle on the GC-SPR[3]. Therefore, the duty ratio dependence of the enhancement of the fluorescence can be interpreted by theoretically analyzing the relationship between the coupling efficiency, i.e., R, and the grating surface profile, including the duty ratio. Giannattasio et al.[4] reported the duty ratio dependence of the transmitted diffracted intensity (T–1) using a grating-assisted prism-coupled SPR. Taking into 4 account the fundamental difference between our work and this paper, including the optical geometry for the light–SPP coupling, the physical parameters to be detected, and the coupling modes (whether reverse coupling process was included or not), a duty ratio dependence of T–1 through the prism via SPP coupling can help us to theoretically interpret our results. In the work of Giannattasio et al., the profile of a periodic corrugation was expressed in terms of a Fourier expansion. The value of T–1 increased with the square of the grating amplitude and provided the largest value using a first-order approximation for a ratio of 0.50. SPR coupling is also known to be correlated with the effect of the duty ratio on the grating profile amplitude. For the largest amplitude, a duty ratio of 0.50 is considered to provide the smallest value of R, the strongest electric field, and consequently, the most enhanced fluorescence intensity in our study. Reference [1] K. Kintaka, J. Nishii, A. Mizutani, H. Kikuta, H. Nakano, Opt. Lett. 2001, 26, 1642-1644. J. Nishii, K. Kintaka, Y. Kawamoto, A. Mizutani, H. Kikuta, J. Ceram. Soc. Jpn. 2003, 111, 24-27. [2] K. Tawa, H. Hori, K. Kintaka, K. Kiyosue, Y. Tatsu, J. Nishii, Opt. Express 2008, 16, 9781-9790. [3] H. Raether, Surface plasmons on smooth and rough surfaces and on gratings. (Springer, Berlin, 1988). [4] A. Giannattasio, I. R. Hooper, W. L. Barnes, Opt. Commun. 2006, 261, 291-295. 5