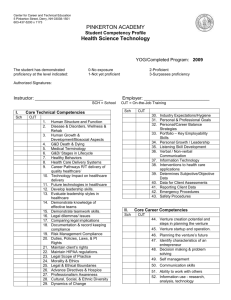

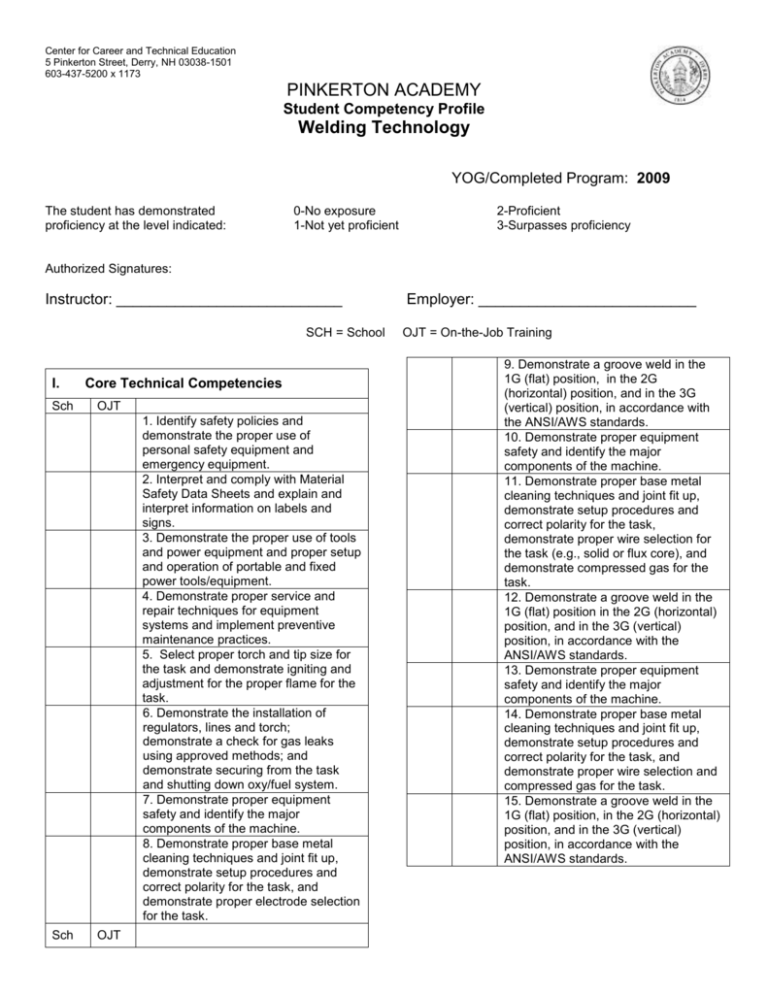

Program Competencies

advertisement

Center for Career and Technical Education 5 Pinkerton Street, Derry, NH 03038-1501 603-437-5200 x 1173 PINKERTON ACADEMY Student Competency Profile Welding Technology YOG/Completed Program: 2009 The student has demonstrated proficiency at the level indicated: 0-No exposure 1-Not yet proficient 2-Proficient 3-Surpasses proficiency Authorized Signatures: Instructor: ___________________________ SCH = School I. Sch Core Technical Competencies OJT 1. Identify safety policies and demonstrate the proper use of personal safety equipment and emergency equipment. 2. Interpret and comply with Material Safety Data Sheets and explain and interpret information on labels and signs. 3. Demonstrate the proper use of tools and power equipment and proper setup and operation of portable and fixed power tools/equipment. 4. Demonstrate proper service and repair techniques for equipment systems and implement preventive maintenance practices. 5. Select proper torch and tip size for the task and demonstrate igniting and adjustment for the proper flame for the task. 6. Demonstrate the installation of regulators, lines and torch; demonstrate a check for gas leaks using approved methods; and demonstrate securing from the task and shutting down oxy/fuel system. 7. Demonstrate proper equipment safety and identify the major components of the machine. 8. Demonstrate proper base metal cleaning techniques and joint fit up, demonstrate setup procedures and correct polarity for the task, and demonstrate proper electrode selection for the task. Sch OJT Employer: __________________________ OJT = On-the-Job Training 9. Demonstrate a groove weld in the 1G (flat) position, in the 2G (horizontal) position, and in the 3G (vertical) position, in accordance with the ANSI/AWS standards. 10. Demonstrate proper equipment safety and identify the major components of the machine. 11. Demonstrate proper base metal cleaning techniques and joint fit up, demonstrate setup procedures and correct polarity for the task, demonstrate proper wire selection for the task (e.g., solid or flux core), and demonstrate compressed gas for the task. 12. Demonstrate a groove weld in the 1G (flat) position in the 2G (horizontal) position, and in the 3G (vertical) position, in accordance with the ANSI/AWS standards. 13. Demonstrate proper equipment safety and identify the major components of the machine. 14. Demonstrate proper base metal cleaning techniques and joint fit up, demonstrate setup procedures and correct polarity for the task, and demonstrate proper wire selection and compressed gas for the task. 15. Demonstrate a groove weld in the 1G (flat) position, in the 2G (horizontal) position, and in the 3G (vertical) position, in accordance with the ANSI/AWS standards. Sch OJT 16. Demonstrate safety procedures for cutting, describe theory of plasma cutting, and set up and operate plasma cutting equipment. 17. Demonstrate layout and make straight line cuts. 18. Extrapolate information from multiple industry sources (e.g., reference books, blue prints and technical bulletins) 19. Explain and define (in written and spoken word) vocabulary to peers, instructors and employers in the fabrication field. 20. Recognize and discuss national standards and technical association. 21. Recognize and discuss the skills in quality assurance and quality control. 22. Demonstrate effective welding shop management skills. II. Sch Core Career Competencies OJT 23. Venture creation potential and steps in planning the venture 24. Venture startup and operation. 25. Planning the venture’s future 26. Identify characteristics of an entrepreneur 27. Community leadership, democratic principles, and social responsibility 28. Decision making & problem solving 29. Self management 30. Communication skills 31. Ability to work with others 32. Information use - research, analysis, technology 33. Mathematical concepts 34. Safety 35. Career development III. Work Experience Cooperative Education Employer #1 Hours Job Description Employer Comments Employer #2 Hours Job Description Employer Comments IV. Sch Other Technical Competencies OJT 1. 2. 3. 4. 5. Important Notice to the Student: If you wish to have a copy of this Competency Profile made available to a prospective employer the Center for Career and Technical Education office must have a “Consent for Release of Information” form on file.